The device and principle of operation of the hydraulic distributor

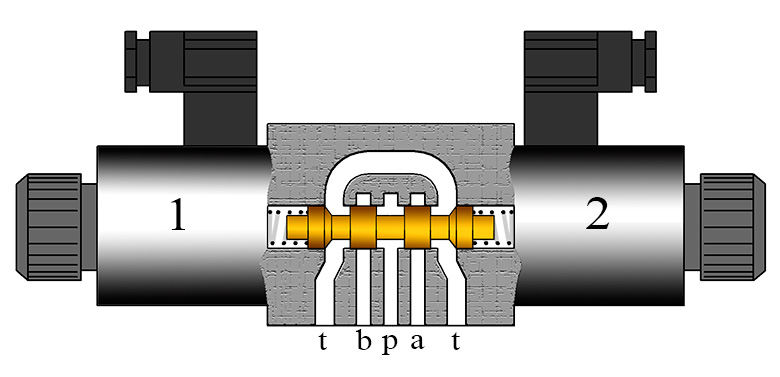

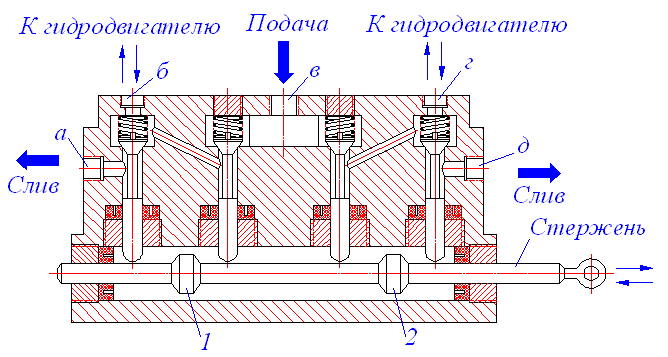

Consider the device of a four-line three-position distributor locked in the neutral position.

The principle of operation of the hydraulic distributor 44 of the scheme is shown in the video.

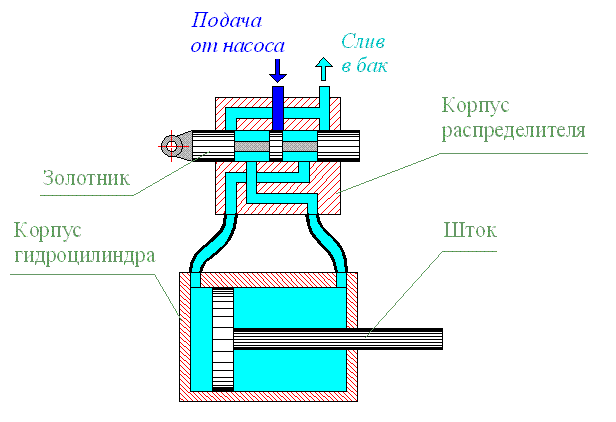

Channels for fluid supply are made in the distributor housing. The spool is installed in a hole bored in the body.

The distributor spool is a part, usually cylindrical, on which belts, grooves, grooves are made, necessary for separating or connecting various channels made in the distributor housing.

In the neutral position, the spool is held by means of springs, at which point it closes the P line. If a control signal is present, electromagnet 1 will move the spool to the right. In this position the spool will connect ports p and a, t and b. In the absence of a control signal, the springs will return the spool to the neutral position. If there is an electrical signal on electromagnet 2, the spool will move to the left, connecting channels p and b, t and a.

| Move spool to the left | Move spool to neutral position | Move spool to the right |

Classification of hydraulic engineering

These devices are divided based on the typology of locking structures. Hydraulic distributors, the types of devices of which differ in functionality, are divided into the following varieties:

- spools;

- crane distributors;

- with valve;

- jet;

- with a regulating element of the "nozzle-shutter" type.

Spool type distributors are very common. They are easy to manufacture, compact and reliable in operation. Withstand increased pressure up to 32 MPa and active flow, in contrast to the crane type.

The crane distributor is also quite widespread. Its valve design is based on the cylindrical shape of a rotary valve plug. But the faucet can also have a spherical, conical shape, and it can also be flat. A variety of types of locking elements makes this type of device very convenient and in demand.

Valve-based devices make it possible to avoid leakage of the working medium, which is often the case with spool valves. When the pressure exceeds 32 MPa, it is difficult to keep the hydraulic motor itself in a stationary position; position switching is required here. In this case, the valve distributor is relevant, which is characterized by increased weight and dimensions, completely seals the entire hydraulic line. This type of distributors is relevant where high tightness is needed. The locking structure, as a rule, is made in the form of a cone valve or a ball.

The “shutter-nozzle” device type works on the principles of a hydraulic pressure divider and qualitatively distributes the load during the flow of the working medium.

Inkjet options are characterized by reduced sensitivity to contamination, this is ensured by the complete absence of moving elements in the device.

Distributor breaker

How is the breaker-distributor arranged?

The breaker-distributor combines two devices: a breaker - interrupting (opening) the low voltage current circuit in the primary winding of the ignition coil in order to create an alternating magnetic field necessary to obtain a high voltage current in the secondary winding of the ignition coil, and a distributor - distributing the high voltage current by candles of engine cylinders in accordance with the order of its operation.The distributor-breaker (Fig. 1) consists of a housing 1, in which a shaft 2 is installed on a sliding bearing, which, with its lower spline 20, engages with the oil pump shaft and is driven from the camshaft gear. At the upper end of the shaft, a cam clutch 17 is freely installed, having the number of cams (faces) equal to the number of engine cylinders. The cam clutch is connected to the shaft through pins attached to the weights of the centrifugal ignition timing controller. A fixed disk 5 is fixed in the body of the interrupter, on which a movable disk 8 is mounted on a ball bearing. A fixed tungsten contact 4 is mounted on this disk, connected to the "mass" of the car. A movable tungsten contact is pressed against the fixed contact by a lamellar spring, fixed on a lever 18 isolated from the "mass". This lever has a textolite or plastic heel, with which it rests on the cam clutch. The leaf spring tends to keep the contacts closed, however, when the cam clutch rotates, its protrusion (face), running on the heel, removes the movable contact from the stationary one, thus opening the low voltage current circuit in the ignition coil. The movable contact, together with the lever, is isolated from the “ground” and is connected by wire 6 to the output terminal 7 and then by wire to the primary winding of the ignition coil. A current-carrying plate (rotor) 15 is installed on top of the cam clutch. An octane corrector 19 is installed in the lower part of the housing, the scale of which is graduated in degrees, and two nuts with a micrometric thread for fine tuning the octane corrector. A vacuum regulator 10 is attached to the breaker body on the side, the lever of which is connected to the movable disk of the breaker. A capacitor 9 is installed on the case or inside it. The breaker case is closed with a carbolite cover 11, in which contact plates are mounted connected to sockets 12 for installing high voltage wires in order to divert high voltage current to the spark plugs. The high voltage current from the ignition coil is fed by wire to the central terminal 13, in which the coal 14 is installed, loaded with a weak spring, due to which it is constantly pressed against the current-carrying plate 15. The distributor cover is pressed against the breaker body with spring latches 16.

Fig.1. Distributor breaker

How does a distributor breaker work?

When the shaft 2 rotates (Fig. 1), the cam clutch 17 rotates with it. When the face of the clutch runs on the heel of the movable contact lever, it moves away from the stationary one, breaking the low voltage current circuit. At the moment of greatest opening, the gap between the contacts should be within 0.35-0.45 mm. For its regulation, two screws are provided on the movable disk: adjusting eccentric and locking cylindrical. The gap is checked with a feeler gauge. With further rotation of the cam clutch, the face ceases to press on the heel of the lever and, under the influence of the leaf spring, the contacts close again, passing current into the primary winding of the ignition coil. With each opening, a high voltage current is induced in the secondary winding, which flows through the high voltage wire through the central terminal 13 of the distributor, coal 14, current-carrying plate 15, side electrode 12 of the distributor to the spark plug.

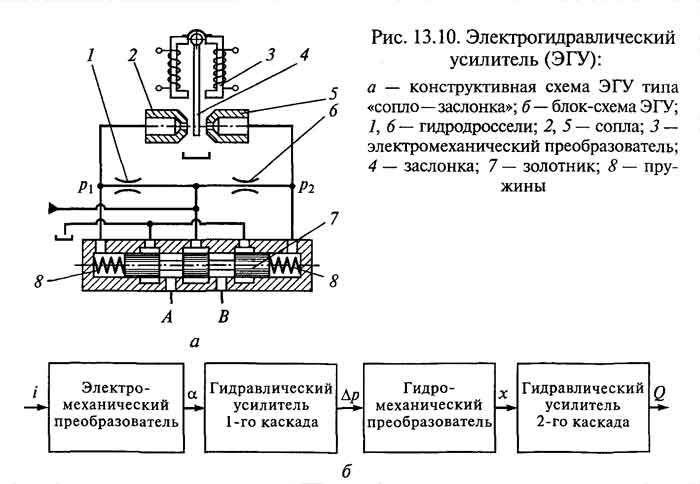

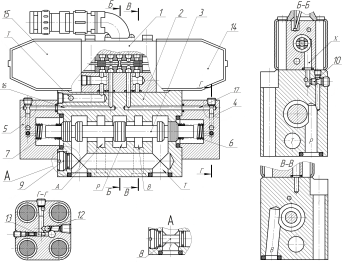

8.3. The device and principle of operation of the hydraulic distributor with electro-hydraulic control

Valve type

PG 73-2With

electro-hydraulic control

is a combination of control

distributor with electromagnetic

management

in the form of a pilot and the main

distributor with hydraulic

management,

which works in a similar way

distributor PG 72-3.

Three position

distributor

with electro-hydraulic control

(Fig. 3.12) consists of a body 2,

main spool 3,

lids 4

and 5,

springs 6

and 7,

ball valves 12,

chokes 13

and distributor pilot with electric

management 1.

Four way

performance

distributors (Fig. 3.13, a)

differ from five-way

(Fig. 3.13, b)

plug design 8

and 9,

(see Fig. 3.12) with which it is possible to

compound

drain channels T for four-way

or

disconnection for five-way

distributors.

supply

pressure to the ends of the main spool

channeled 16

and 17

from the control distributor 1.

As a control distributor

type hydraulic distributors are used

PG 73-1, and for distributors with

electro-hydraulic control

P and B types - P102 and BE type pilots

(PE) with electric control from

AC or DC.

Fig.3.12.

Three position hydraulic valve

with cylindrical spool

type

PG 73-2 with electrohydraulic control

Rice.

3.13. Graphic conventions

hydraulic distributor type PG 73-2

With

electro-hydraulic control

four-(a)

and five-way (b)

performance

hydraulic valve

works as follows. At

switched off electromagnets 14

and 15

pilot spool is in the middle

position and oil through the control channels

16

and 17

enters both end cavities

main spool 3,

and he springs 6

and 7

set to the middle position. At

turning on one of the electromagnets,

for example, the right one, one of the end

cavities (left) of the spool

3

connects to drain control line

T,

and the other (right) remains connected

with pressure control line

X (at

no traffic jam 10

pressure

control line

X

connects directly to the main

pressure line R).

As a result, the spool moves

to the extreme left position, compressing the spring

7

and displacing oil from the left cavity through

throttle 13

into the drain line.

At

spool switching 3

in the opposite position oil out

pressure line control line

enters under the end face of the main spool

through ball check valve 12.

Throttle control 13

you can set the speed of movement

spool, i.e. actuation time

separately in each direction. At

rotating it clockwise time

operation of the main spool

increases, and when rotating against

clockwise - decreases.

Prevention

To ensure the efficient operation of the tractor hydraulic system, it is necessary to follow the rules of operation and timely maintenance.

In the course of working with equipment equipped with hydraulics, its components should be regularly checked for malfunctions. The occurrence of a small-scale breakdown inevitably leads to the failure of other parts of the system. If this is found, it is immediately necessary to apply all available means to eliminate it:

do not exceed the prescribed load on the hydraulic pump, hydraulic cylinders, oil hoses and other components;

avoid indicators of excessively high pressure, if necessary, dump it in a timely manner or select a suitable control valve;

to maintain the stable operation of the hydraulic mechanism, it is important to change / add fluid to the system in a timely manner: an insufficient amount of it will lead to a decrease in work efficiency and a quick failure of the unit;

all work on maintenance and repair of the system should be carried out with the tractor engine turned off (on a "cold") after pressure relief.

Table of common faults in hydraulic systems and how to fix them:

|

Malfunctions and their causes |

Remedy |

|

Fault: low lifting-pushing force of hydraulic cylinders or its complete absence. Cause: The oil level in the system has dropped. |

Add oil. |

|

An oil with unsuitable specifications has been used. |

Change the oil to the correct one. |

|

Oil filter or hydraulic cylinder dirty. |

Replace or wash the filter element. |

|

The presence of air in the system. |

Blow out the system - remove air, identify the point of entry and eliminate it. |

|

The presence of fluid leakage through worn seals. |

Replace seals with new ones. |

|

The operation of the relief valve, pressure is disrupted - jamming occurs in the open position. |

Flush/purge valve. Replace if necessary. |

|

Malfunction in the valves of the hydraulic distributor. |

Replace valves or their parts, if necessary, replace the entire block. |

|

Leaks in the docking nodes of the system. |

Check for leaks, fix found by crimping, tightening, installing clamps, replacing. |

|

Malfunction of the piston or oil seals of hydraulic cylinders. |

Check hydraulic cylinder for pressure leakage. Replace seals, piston. If necessary, change the node as a whole. |

How to install hydraulics on a mini-tractor with your own hands, see the following video.

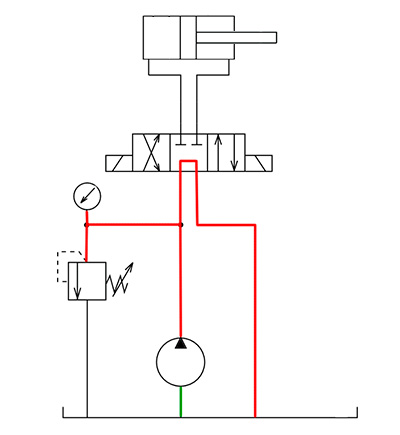

1. General information

During the operation of hydraulic systems,

the need to change direction

working fluid flow on individual

its sections in order to change direction

actuator movements

machines, it is required to provide the necessary

start-up sequence

these mechanisms, to unload

pump and hydraulic system against pressure and

etc.

These and some others

functions can be performed by special

hydraulic devices - guides

hydraulic distributors.

In the manufacture of hydraulic distributors

as building materials

apply steel casting, modified

cast iron, high and low carbon grades

steel, bronze. To protect individual

distributor elements from abrasive

wear, sliding surfaces

cementing, nitriding, etc.

Dimensions and weight of hydraulic valves

depend on the fluid flow through them,

with which they increase.

By connection method

to the hydraulic system hydraulic distributors

produced in three versions: threaded,

flanged

and butt

accessions. Choice of connection method

depends on the purpose of the hydraulic distributor

and flow through it of the working fluid.

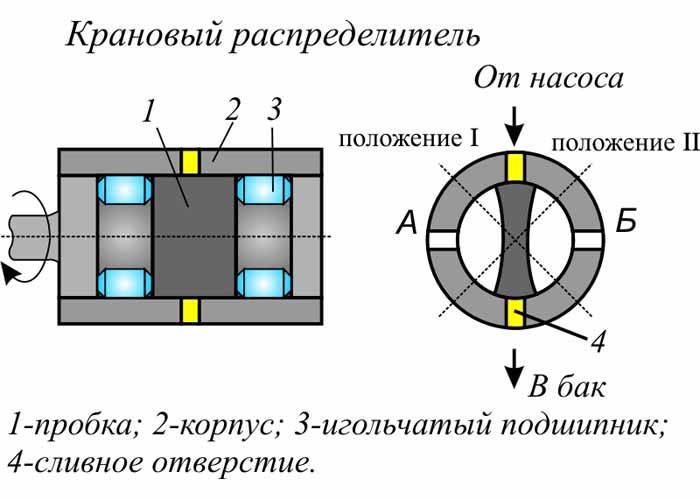

According to the design of the shut-off and control

element hydrodistributors

subdivided as follows:

Spool (shut-off and regulating

element is a cylindrical spool

or flat shape). In spool

control valves change

flow direction of the working fluid

carried out by axial displacement

locking and regulating element.

Crane (shut-off and regulating

the element is a crane). In these

control valves change

flow direction of the working fluid

achieved by turning the valve plug,

having a flat, cylindrical,

conical or spherical shape.

valve (shut-off and regulating

element is a valve). in valve

valves change direction

the flow of the working fluid is carried out

by sequential opening and

closing of working sections

valves (ball, poppet,

conical, etc.) of various designs.

By number of fixed positions

spool hydrodistributors

subdivided into two-position,

three-position and multi-position.

Management hydrodistributors

subdivided into hydraulic

manual, electromagnetic, hydraulic

or electro-hydraulic control.

Crane hydraulic distributors are used

most often as ancillary

in spool valves with

hydraulic control.