Mineral wool

At the moment, this material is one of the most popular on the market. Its demand was largely due to high thermal insulation properties and a high coefficient of moisture protection. Note that the material is characterized by excellent thermal insulation properties, but in the case of mineral wool, they have dual characteristics.

Firstly, this insulation is used to protect against the penetration of cold into the room.

Secondly, it provides thermal protection, that is, when it becomes necessary to retain heat. For example, when performing work on the insulation of boilers, pipelines, where heat loss must be minimized, it is often used.

Such use of this material became possible due to the fact that it can withstand temperatures up to + 800 degrees Celsius. Mineral wool melts, but does not support the combustion process. This can also be considered another advantage of such a heat-insulating material. In order to ensure maximum thermal protection when using it, one condition must be met: during work, mineral wool with a foil layer must be used.

Scope of mineral wool

If we talk about the areas of application of mineral wool, then we note that there are quite a few of them. This material is used:

- for insulation of facades for plaster and siding;

- for thermal insulation of internal walls in rooms and partitions;

- for roof and floor insulation;

- for thermal insulation of frame-type buildings.

Note that at the moment this insulation is produced in two types: in mats and in rolls. The thickness and density of mineral wool can be different. Based on these parameters, this heat insulator is divided into grades.

Characteristics of materials for insulation

The main characteristics are:

- Efficiency - good thermal protection capability.

- Lightweight, especially when assembling insulation under drywall. It also reduces the cost of transportation and facilitates the process of working with it.

- Good vapor permeability. Required for good removal of water vapor to the outside of the building. You should equip a powerful hood in the room.

- Good adhesion to materials used for finishing walls inside the house after the installation of the insulation system.

- Environmental friendliness. It is desirable to use materials with the least strong fumes of ingredients of heat-insulating agents harmful to humans.

- Vitality. The wall insulation used must last at least 10 years without destruction.

Requirements for materials for wall insulation inside a country house

low thermal conductivity so that heat remains inside and cold does not penetrate from the outside;

durability, so that over time the wall insulation does not lose its qualities;

low flammability, so that in the event of a fire, such as electrical wiring, the material prevents the spread of flame;

low level of shrinkage, so that the material does not deform during operation, does not lose its thermal insulation properties and does not settle;

water resistance - resistance to moisture and the ability to repel it;

environmental friendliness - do not emit toxic substances that are harmful to health;

vapor permeability - the material must be "breathable"

This will contribute to a good microclimate in the house;

the ratio of rodents to the insulation should also be taken into account in order to provide for the fight against them.

compactness - if your house is small, it is important to choose a material that does not steal a lot of space.

Styrofoam or mineral wool

These two home wall insulation have common advantages, but there are also differences. We present a comparative analysis of them below.

Styrofoam

Many people who decide to use this material for insulation will naturally have a question of what this insulation for the walls of the house is made of. It is worth saying that polystyrene granules act as the main raw material for its production.

In the process of foam production, several stages are carried out:

- heat;

- thermal swelling;

- formation.

The last stage of production is the shaping of the final product. Also at this stage, the insulation acquires a final density, which will affect the thickness of the panels. Among all the characteristics of the material, it is the thickness that is the most important indicator. It affects:

- quality of thermal insulation works;

- the cost of insulation;

- dimensions of the house.

However, the main role belongs to air bubbles. Their formation occurs inside polystyrene granules during the production of insulation. They are important because:

- isolated from each other;

- air is the strongest heat insulator.

These two reasons led to the fact that the foam is currently a material with high rates of vapor permeability and moisture protection.

Thanks to these characteristics, such a wall insulation is popular among owners of apartments and houses. But it surpasses other heat-insulating materials not in this, but in a completely different way - in weight. He is small. You should know that foam is a material that is 98% pure air.

Extruded polystyrene foam

If we compare in terms of cost between foam and extruded polystyrene foam, then the latter turns out to be more expensive. However, using it for external insulation of the room, it is possible to provide high thermal insulation characteristics and reduce heating costs. Often this insulation for walls inside the house is used for floor insulation due to its strength characteristics. Note that for work on external wall insulation, this material is used extremely rarely.

Areas of application of foam

This material can be used for thermal insulation of a wide variety of surfaces. It is suitable for warming:

- gender;

- walls;

- roofs.

However, with external insulation of each surface, there are some nuances of work that you need to know about. For example, all experts say that foam plastic is an excellent choice for external insulation of buildings. Therefore, it is often used by owners of country houses. But it is also suitable for apartments. But if your dwelling is located on the top floor, and the insulation itself will be installed from the inside, then in this case it is possible to reduce the heat loss of the premises, but it is necessary to follow the installation technique of the material, using additional elements during operation. That's just the cost of warming urban dwellings will be quite serious.

There is one more point that the owners of apartments and houses should also pay attention to. Meaning the environmental friendliness of the material

Many people have great doubts about the fact that when this insulation is exposed to high temperature, it will not emit substances toxic to humans. In defense of the environmental friendliness of the material, the following arguments can be made:

- First of all, it must be said that scientists have proven that polystyrene foam is a material that does not pose any threat to human health. Therefore, in the manufacture of containers for food, this particular insulation is used.

- Styrofoam, when used for thermal insulation of walls, is separated from the space of the dwelling by a layer of vapor barrier and decoration. And this is a pretty good protection against possible negative effects of the material.

Classification of materials used to insulate walls from the inside

Stone mineral wool

Has received wide distribution. Benefits when using it:

- The lowest coefficient of thermal conductivity among all thermal insulation materials. Consequently, reducing heating costs in winter.

- Incombustibility and therefore good ability to resist the spread of fire indoors.

- Fairly good soundproofing. Wall insulation from the inside of the house using cotton wool drastically reduces the noise coming into the room, which is very important in multi-storey buildings.

- Low price.

- Vitality. Does not rot, resistant to chemical and mechanical influences. It is a barrier to fungi and mold.

glass wool

The material, created on the basis of fiberglass and a binder polymer, is quite static in interaction with other building materials used in the insulation and subsequent finishing of the room.

Benefits of using:

- Good elasticity. The material is compact when delivered in roll form. When used, quickly gains initial volume.

- Able to withstand heavy loads during operation without destruction. If the wall insulation from the inside is made of glass wool slabs, cracks on the wall are unlikely to appear.

- Vibration resistant.

- Sufficiently elastic, light, stable.

- Subsequent application of plaster is possible.

Liquid thermal insulation

A relatively new building material consisting of small empty ceramic granules of various inorganic components and a liquid polymer mixture. The possibility of applying it with a sprayer ensures good processing, even if we insulate in hard-to-reach places, and especially when the walls are insulated from the inside. In its composition, it resembles ordinary acrylic paint, but the layer of applied insulation sometimes even surpasses the layer made from traditional materials in its parameters.

Advantages:

- The minimum thickness of the insulation layer (a lot of usable space is saved).

- Warranty up to 15 years.

- It's easy to use.

- In some cases, it does not require a primer and finishing.

The disadvantages include its high cost in our building materials market and the need to purchase a special nozzle for spraying the composition.

Extruded polystyrene foam (EPS)

This is a completely synthetic material. Like polystyrene, it basically contains expanded polystyrene. The difference is only in the method of obtaining granules. If EPPS insulate the wall in the apartment from the inside, then it is even possible to glue the source material onto a previously cleaned surface without prior preparation.

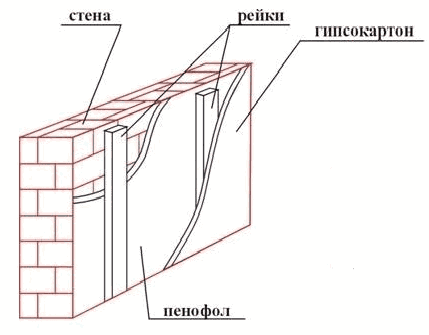

Foil insulation

A multilayer polymeric material consisting of a thin layer of foil reinforced on an insulating material - foamed polyethylene.Internal wall insulation, made using foil materials, is 50-70% more efficient than using conventional heat-saving materials with a slight increase in the cost of sources. One of the representatives of this class of insulators is penofol. When insulating the walls from the inside with penofol, it must be laid with a reflective film inside the room and fixed on the wall with ordinary construction nails.

The advantages of this material:

- Wide operating temperature range up to 150°C. It is possible to insulate the walls from the inside in steam rooms and baths.

- Good reflectivity.

- Absolutely static to moisture absorption.

- Sufficiently high steam-hydro- and heat-insulating parameters. When applied from inside the walls in industrial enterprises, it allows you to create a stable microclimate with significantly lower energy costs than without it.

- Quick and easy installation if the insulation is carried out indoors.

Penofol or penoplex

- waterproofing;

- heat-insulating;

- vapor barrier.

When installing penofol, they resort to the use of a special adhesive composition. But for the installation of penoplex on the surface, special fasteners are used - self-tapping fungi. You should know that penoplex is a panel with a smooth and even surface, which facilitates the process of laying a finishing material on top of it.

How to insulate a garden house for the winter

The most practical materials for thermal insulation of a summer house are basalt materials, expanded polystyrene or foam boards. Expanded polystyrene should be used for self-insulation of foundations and blind areas.

Penoplex plates are a dense and durable material that is not afraid of high humidity, however, these materials can emit harmful substances.

Insulation of a garden house for winter living

When using mineral wool, high-quality vapor barrier is required from the side of a warm room.

Mineral insulation when laying should be tightly packed into the frame. It is believed that mineral wool is not eaten by rodents and is environmentally friendly for humans. In order for the thermal insulation layer to be optimal, you must first calculate the thickness of the wall insulation on a heat engineering calculator.

Technical characteristics of heaters

All heaters have their own technical characteristics, which can affect the ease of installation and their heat-saving properties, for the right choice, you should familiarize yourself with them.

Varieties and properties of mineral wool

The class of mineral wool includes glass wool, stone, slag. All of them have one common characteristic - they are the finest fibers, which, thanks to their structure, can guarantee a high level of thermal insulation.

All mineral wools are highly hygroscopic, so it is important to use waterproofing during installation. When working with mineral wool, safety rules must be observed

Polyurethane foam properties

In a rigid (hardened) form, polyurethane foam has the lowest thermal conductivity of all heaters, and it does not need such a large layer as for mineral wool or foam plastic.

In addition, this type of insulation is very light, you do not need to use additional devices for its fastening, it is simply sprayed onto the surface. Such a monolithic coating guarantees the absence of cold bridges, the material is environmentally friendly and durable.

Related article:

Insulation of a country house which material is considered the best video

Recently, insulation has become a very topical issue due to constantly rising energy prices.

But this issue is especially acute for owners of country houses and summer cottages, who spend a lot of money during the heating season. Practical insulation is the choice of high-quality and reliable material. In addition, it is advisable to make all the necessary calculations in advance so as not to make a mistake when buying material.

Consider the thickness of the material

Among the most inexpensive are called expanded polystyrene plates and mineral wool. But whichever insulation you choose, you should keep in mind that:

- some of the heat loss passes through door and window structures - about 15%;

- approximately 7% of heat escapes through the ceiling and floor;

- the ventilation system is able to take more than 20% of the heat.

In many ways, the choice of insulation will depend on the climatic features of your region. Naturally, when choosing, you should take into account your financial capabilities and the result that you want to get.

What to use:

- So, for example, mineral wool can be used if the temperature outside the window in winter does not fall below -35 ° C. The highest quality material is produced using rocks, such as dolomite, which indicates durability and a high level of fire resistance.

- You can also use foam. It is distinguished by low weight, ease of use, high level of sound insulation.

- A cheaper material is also used - penoizol, which is supplied in liquid form. With its help, it is easy to fill the cracks and spaces inside the house, and penoizol will serve you for a long time, most importantly, follow the rules for its operation.

- Recently, ecowool has become increasingly popular, which is both inexpensive and reliable. It is distinguished by its environmental friendliness, thanks to which the material got its name. True, there are difficulties with installation - you will need a special tool for the home workshop, without which you are unlikely to do everything correctly. And this can lead to the formation of suspended dust in the room, which threatens with severe allergic reactions.

https://youtube.com/watch?v=mBbW3LfvgKo

As we have already said, in order to protect your home from heat loss by 90%, you will have to work on the insulation of the floor, ceiling, walls and windows. The work, of course, is not the easiest, but the result will pleasantly surprise you. Firstly, the house will become much warmer, and secondly, you will be able not to spend incredible amounts on heating.

Choice features:

We insulate the roof

The roof, if installed incorrectly, can absorb a large amount of heat, and therefore it is very important to protect your home from this trouble.

When choosing a material, pay attention to the service life, which will depend on the amount of precipitation, temperature fluctuations, wind strength. Naturally, it is also important here that the material does not let moisture through and is safe for health human

Beware of using polymer insulation, which quickly light up

The most important step is the insulation of the walls, since it is they that occupy most of any building, which means they also have the highest level of heat transfer. If we are dealing with wooden walls, then, first of all, they need to be cleaned of dirt and treated with special water-repellent and antifungal solutions. After that, all the gaps need to be caulked with dry tow. Many experts advise using jute fabric, which pleases with both price and ease of installation. After you work with the walls, you can move on to window openings, which also lead to heat loss. This is especially noticed by owners of houses with old frames.The procedure is as follows: we clean the frames, change the broken glass, seal the gaps between the frame and the wall with a sealant or mounting foam. The final stage is the use of a sealing tape that can close gaps up to 0.7 cm. The last step is floor insulation, for which various materials can be used. The main thing is that the heat does not leave the house, and the house is dry. In this case, expanded polystyrene is suitable, which is durable and strong.

It is up to you to decide with what material to insulate the country house, but you should do it as early as possible in order to be in time before the onset of cold weather. We can also share with you how to insulate your shed so you can take care of your pets too.

What to do with the roof

The question of the need to insulate the roof would be irrelevant. This isolation must be carried out without failure. Only in this case, the material characteristics and climatic conditions in the region should be taken into account.

When the leakage of thermal insulation of the roof of the house is reduced by 15%.

And if the attic space is used as an attic, it is simply impossible to do without reliable roof insulation. In the absence of a planned residential building in the attic, it is sufficient to insulate the ceiling of the house or attic.

Conclusion. From the foregoing, we can conclude that those people for whom convenience and comfort will not neglect the heating of the house.

The money saved on electricity, water and gas can be considered well-deserved, and the material will be paid in the first cold season.

Korovin Sergey Dmitrievich

Master of Architecture, graduated from the Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

A country house is a building that is initially calculated only for summer operation, therefore, during its construction, insufficient attention is paid to thermal insulation measures. If it is necessary to use it in the cold period, the question arises of how to insulate a country house intended for winter living.

Insulation of a garden house for living in winter

Floor insulation

To begin with, it is necessary to insulate the basement with foam plastic and the floor on the first floor.

Most often, in summer cottages, the floor is made of wood, so we will consider this particular design. If you want to save money, you can use traditional materials - sawdust or expanded clay. If you take work more seriously, then floor insulation can be carried out with mineral wool on wooden logs.

Wall insulation

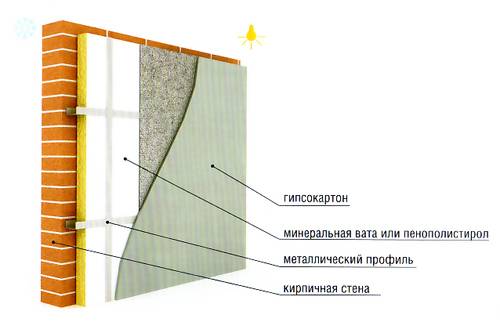

If the house in the garden is built of silicate brick or timber, then the insulation must be done from the outside.

In this case, you will save space in the living room, protect the walls of the building from freezing and possible mold. It is best to insulate the facade with mineral wool, followed by vinyl siding. How to choose mineral wool correctly read on our website here.

Insulation of the facade of the house without cold bridges

Attic insulation

Through the ceiling, a private house loses the most heat, since warm air always rises.

It is better to deal with warming from the side of a cold attic. On horizontal surfaces, you can use traditional and inexpensive bulk materials - sawdust mixed with earth or expanded clay. If mineral wool is used, then a rolled vapor barrier is first laid on the surface.

Let's sum up the comparison

When thermal insulation is performed using mineral wool, the creation of a frame is a must. On the wall, vertically mounted rails will act as fasteners. In terms of installation costs, the use of foam is beneficial. In terms of cost, this material is also beneficial. The price for it is three times lower than for mineral wool. However, having decided to stop the choice on polyfoam, it is necessary to keep in mind the following. If rodents appear in the dwelling, they will use foam sheets to build their house. They can destroy the insulation sheets, which will lead to an increase in heat loss.

When thinking about which thermal insulation material to choose, you should first consult with a specialist who, taking into account the room, will recommend you a suitable insulation.