PVC pipes are now increasingly used in the installation of various systems: water supply, gas pipeline, sewerage. The combination of their advantages, such as lightness, durability, resistance to various influences and corrosion, leaves no chance for metal counterparts. Another significant advantage of PVC pipes is the extreme ease of installation, which does not require any specific skills or professional equipment.

PVC pipes can be connected in several ways:

- socket connection;

- flanged;

- by cold welding or adhesive bonding.

All these methods are available to a non-professional at home. All you need to do is just follow the instructions exactly.

Connection of plastic pipes in a socket way

This connection method is used in two cases:

- when assembling a pipeline;

- when creating a connection of several pipelines.

In the first option, only pipes with a socket at one end will be needed. In the second case, care must be taken to select suitable fittings – special connecting elements for PVC pipes.

To connect pipes in this way, you need to do the following:

- Thoroughly clean the outer surface of the plastic pipe at the place of the future connection, and the inside of the socket.

- Inspect the rubber ring, which is located in the groove of the bell, for bulges, deflections, displacement.

- Chamfer the end of the PVC pipe at an angle of 15 degrees and mark on it the depth to which the product should enter the socket. The distance from the edge of the pipe to the mark should be 10 mm less than the depth of the socket.

- Lubricate the joints and the O-ring with glycerin or silicone compound. Make sure that no foreign particles get on the surface after lubrication.

- Align the parts so that their axes match.

- Make the connection, taking into account the previously noted depth. No need to push the pipe deeper than the mark. In case of difficulties, you can use the lever in the form of a crowbar. In this case, do not forget to make a wooden spacer, placing it between the crowbar and the end of the product.

We connect PVC pipes with flanges

Another connection method involves the use of a cast iron flange with a rubber gasket. The work is carried out in the following sequence:

- PVC pipes are cut to the desired length, the cut is made strictly perpendicular to the axis. The cut surface must be very smooth and free of burrs and cracks. It is not necessary to remove the chamfer with such a connection.

- A flange is put on the end. The rubber gasket is placed so that its edge recedes from the end of the PVC pipe by at least 1 cm.

- The flange is pushed onto the gasket, the second corresponding flange is connected to the first bolt, securing the ends of the pipes. Tighten the bolts evenly and alternately, avoiding excessive tightening.

Connection of pipes made of polyvinyl chloride by the method of "cold welding"

Cold welding does not require special equipment and is a bonding process using a special class of aggressive adhesives. Instead of high-temperature exposure, which is used in conventional welding, a chemical is used here. Under the influence of glue, the top layer of the connected objects dissolves, and the structural elements are connected to each other into a single whole at the molecular level. Pipes are glued using fittings made of the same material.

The procedure for gluing pipeline elements is as follows:

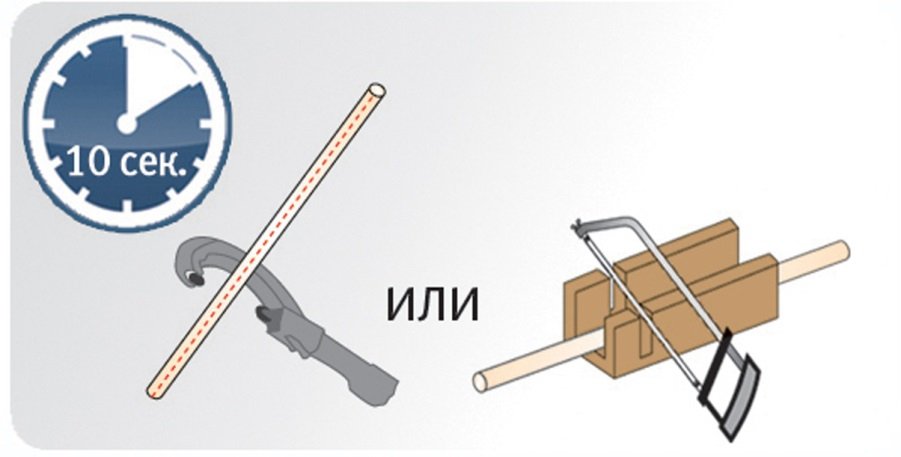

- Cut a piece of PVC pipe to size if necessary. Use special scissors or cutter. In the absence of these tools, take a hacksaw for metal.

Important! It is necessary to cut the pipe so that the angle relative to the axis remains straight.

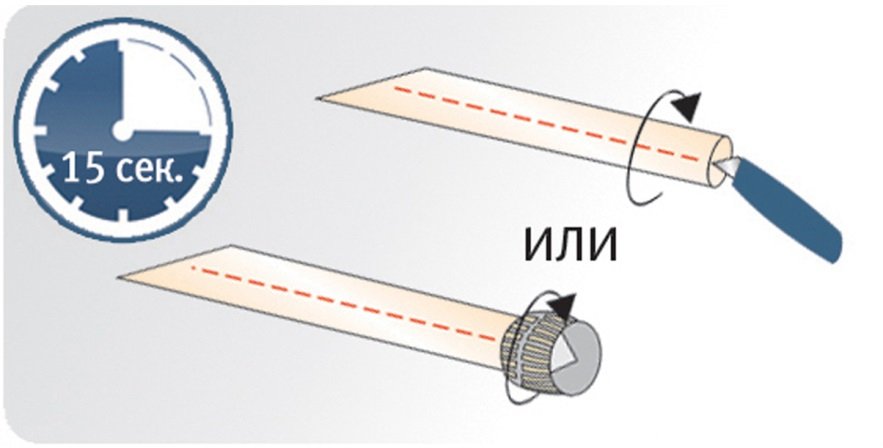

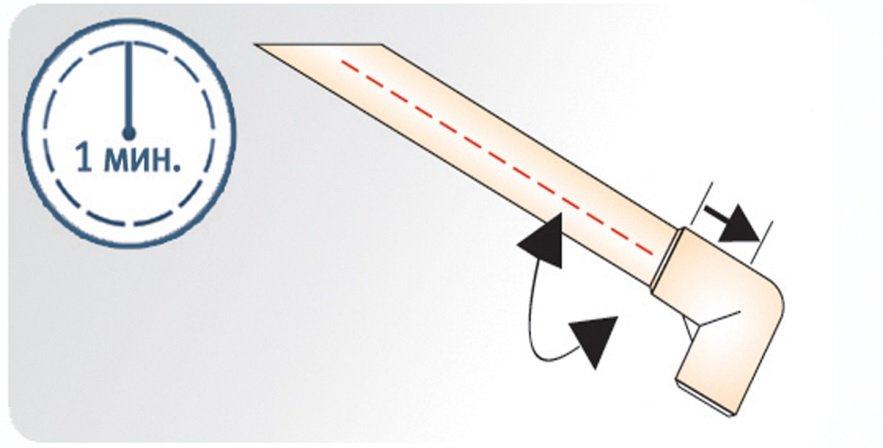

- Sand the ends of the pipes with sandpaper or a file, removing sawdust and burrs. Using a knife or special tool, chamfer the outside of the edge. Blow out the product.

- Treat the parts that you need to connect with a primer - a special cleaner. It will help to degrease and soften the plastic and thus provide a better adhesive effect.

- Before starting the connection, make sure that the dimensions of the parts are compatible by inserting the pipe into the fitting socket. It should enter without effort, but not too freely. Make a mark in the form of a single line, so that after applying the glue, immediately connect the parts correctly.

- Apply the adhesive evenly on the PVC pipe and on the inside of the fitting in a moderate layer.

Important! Use only special glue recommended by the manufacturer for gluing PVC products.

- Immediately insert the pipe into the fitting socket until it stops and turn it a quarter of a turn. This is to ensure that the adhesive is distributed as evenly as possible. After joining the elements, they must be held in this state for 20-30 seconds until the glue sets. At the junction of the parts, a uniform layer of glue should appear, which must be removed with a clean cloth.

It is necessary to wait 24 hours until the glue has completely dried, after which the operation of the pipeline can be started.