cluster drilling

The method bears this name for the reason that the finished scheme of mouths and faces resembles a kind of bush. Wells from several faces, grouped on one site, converge to one mouth. In the case of this method, installation and preparatory work is significantly reduced, the number of working transport links, power lines and water supply is reduced.

The method bears this name for the reason that the finished scheme of mouths and faces resembles a kind of bush. Wells from several faces, grouped on one site, converge to one mouth. In the case of this method, installation and preparatory work is significantly reduced, the number of working transport links, power lines and water supply is reduced.

A feature of the cluster method is a certain condition for the construction of a well. In particular, the most important condition is the absence of intersection of trunks with each other.

The disadvantages of the method:

- It is required to stop the operation of wells until the construction of a certain structure is completed for fire safety purposes.

- High risk of crossing completed cups.

- The overhaul of such a structure is quite complicated.

- When drilling underwater, it is difficult to eliminate gryphons.

Pad drilling is used when an increase in oil and gas recovery is required in a productive area, or when an idle well is resumed. The construction of a well with a cluster method can be three-lateral, double-lateral parallel, double-lateral sequential.

The design of the bush has a conical shape with a top in the form of a bush platform. The volume of installation and preparatory work depends on the placement of the mouth of the bush, and the area of \u200b\u200bthe territory for future alienation from the bush also depends on this. The maximum efficiency of this drilling method is achieved in swampy areas.

Industrial drilling methods

The auger method is used when working in areas with sand and gravel soil. Aquifers can be located at a depth of several tens of meters. With this method, the soil is pushed outward by the blades of the rotating device. This method of production is considered to be quite fast. But it is more often used in the construction of structures of small sizes.

With the shock-rope method, a powerful pointed chisel is used to develop soil rocks. It produces forward-return movements, carrying out the destruction of the soil. For more efficient production, a special weighting rod is used. It is attached to the drilling structure.

The most productive method of excavation in the construction of water intake devices is considered to be the rotary method. Its efficiency is several times higher than the rope-impact method. This is achieved due to certain design features of the installation:

- during work, a cone bit is used as part of the drill string;

- its rotation is carried out using a rotor;

- drill collar is used to increase productivity;

- well walls are treated with a special flushing solution;

- for the final arrangement of the well, casing pipes, filtration devices and pumping units are used.

Equipment

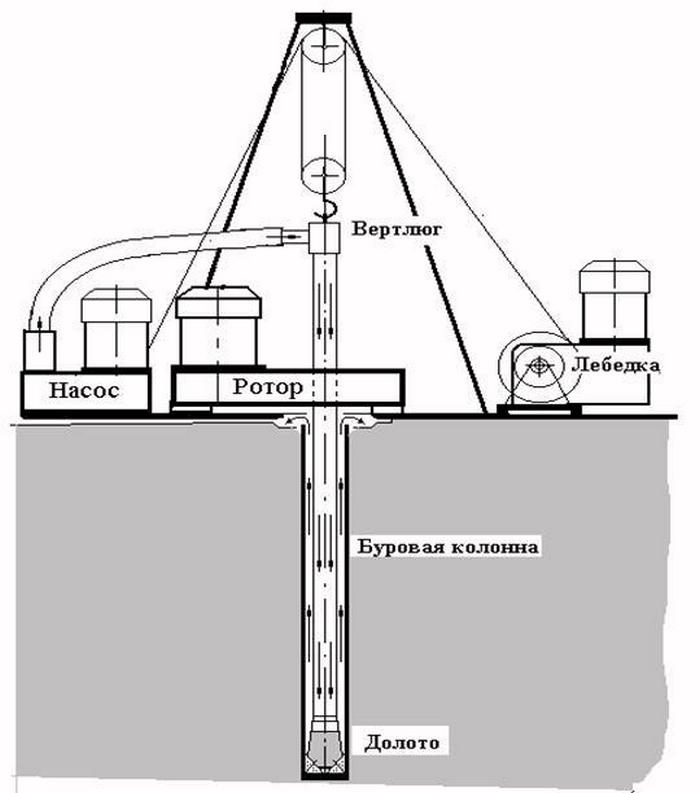

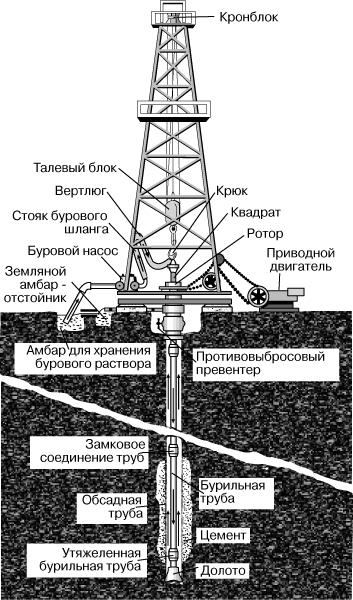

Rotary drilling cannot be carried out without special equipment, which includes the following devices and mechanisms:

- tower;

- rotor;

- driven drilling rig;

- piston type pumping equipment;

- drilling swivel;

- mechanisms and equipment for cleaning with a washing solution;

- traveling system, consisting of a crown block;

- gutter;

- vibrating sieve;

- hydrocyclones (usually used in oil drilling).

The mobile version of the rotary drilling rig has all of the above components, except for the cleaning system with a flushing solution.

oblique way

To perform an inclined drilling technique, the following tools and materials are required:

Earth drilling tool:

- Cleaver;

- Beam;

- Twine;

- Long drill guide pin;

- Cable;

- Casing;

- Metal cable.

This method is most often used in the repair of communications, especially in cases where a residential building has already been built, but it is necessary to conduct sewage or water supply through the foundation. To avoid digging deep trenches, inclined drilling is used. To begin with, the angle of inclination is calculated so that the lower part of the pit coincides with the end of the embedded pipe.

An earthen drill is installed in a pre-selected place and immediately given the desired angle of inclination with the help of a transverse beam laid on the trench. A guide pin is installed on the drill, which allows you to maintain the direction set before starting work, and drilling of the hole begins. Here, continuous monitoring of the process is required, since when deepening or deviating from the desired trajectory, the walls of the pit should be hemmed.

When the hole is ready, a casing pipe is lowered into it, repeating the diameter of the well.

A cable and a metal cable are passed into the pipe, then the necessary cable or hose is pulled into the pipe with the help of a cable. A string is tied to the cable, with the help of which, if necessary, the cable is pulled back.

If a power cable is placed in the pipe, the hose or cable can be easily replaced. In this case, it is possible to cope only with the help of only one inclined drilling, while digging a deep trench and violating the integrity of the foundation will not be necessary.

Areas of use of such technology

Among the points of application of core drilling of wells, it is worth highlighting a few basic ones.

Mining industry - development of mountain deposits of solid minerals.

The result of the passage is a core with a solid structure, which is used to analyze the rocks in this area. It is periodically extracted to find out the picture of the occurrence of rocks in this area.

Autonomous water supply - the organization of the process needs to study the bowels of private land holdings in order to have access to underground water sources. Hydrogeological drilling is necessary to select the location of a water well.

Construction - for drilling a dictating well for driving piles - equipping pile foundations. Builders need to know at what depth there will be a sand layer or large stones begin. The stability of the building depends on this. This technology is ideal for drilling large diameter holes in reinforced concrete structures.

A similar method is suitable for vertical passage of wells, horizontal and at the desired angle.

Method of artificial curvature

Artificial curvature of the axis of the drill glass is applicable when it is necessary to drill oil or gas wells. Artificial deviation is divided into cluster and multilateral. This method has been successfully applied in the following cases:

- For working with deep layers under slopes;

- In case of deviation of the completed trunk;

- When oil occurs under a layer of salt deposits;

- If necessary, bypass crumbling places;

- To open the layers under the bottom of the reservoir;

- During the construction of the face into layers under residential buildings;

- If it is impossible to eliminate the backfilled well;

- To get away with a new direction;

- To save drilling time;

- When drilling with a cluster method in a flat area;

- When passing a coal seam for degasification.

The forced warping process requires special motors, including electric drill, turbo drill and screw motor.

https://youtube.com/watch?v=f74Rdq0gXeQ

Multilateral method

This method consists in conducting two shafts from the main bottomhole glass, while the main shaft is used more than once.

This method consists in conducting two shafts from the main bottomhole glass, while the main shaft is used more than once.

In this case, the working area and the filtration surface increase, but the volume of drilling work in the surface formation decreases.

Depending on the auxiliary shafts, the following types of multilateral design are possible:

- Radial - horizontal main shaft and radial - auxiliary.

- Branched - consists of two inclined shafts and an inclined main.

- Horizontally branched - similar to the previous type, but the angle of the auxiliary trunks is ninety degrees.

The choice of the type of multilateral design is determined by the shape of the auxiliary wellbores and their placement in space.

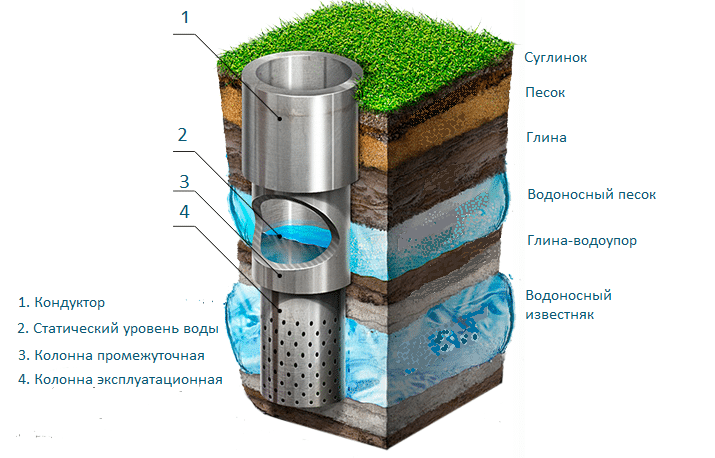

Types of wells

Wells are of 3 main types:

- filter;

- artesian;

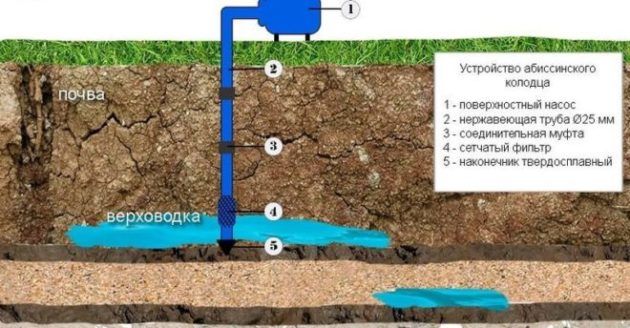

- Abyssinian.

The filter well is dug to a depth of 40-50 meters. The limit for it is the sandy layer. Deeper than this, drilling of wells of this type is not carried out.

Artesian are considered the deepest types. The depth of their drilling ranges from 50 to 400 meters. The main purpose of such holes is to obtain clean artesian water of high quality.

Abyssinian - the most shallow. The depth of their drilling does not exceed 30 meters. When creating holes of this type, a submersible pump is not used due to the small diameter of the pipe.

For private houses, organizations that drill wells dig a filter-type well to a depth of 40 to 50 meters. Such water wells are often called artesian, which leads to a substitution of concepts. Their difference from filter wells is not only in depth, but also in the quality of the water received. A big difference in the price of work and the complexity of the implementation.

Technology features

First, let's define what a rotary drilling method is. This is a special technology for drilling wells, which is used if it is necessary for a hydraulic structure to provide large volumes of environmentally friendly drinking water. At the same time, the well will be distinguished by stable and durable operation. In this case, this method is better suited than any other drilling technology.

The rotary drilling rig and the technology itself have the following advantages over other drilling designs and techniques:

- A well drilled in this way will have high productivity, that is, it will produce water in large volumes.

- Durability of a hydraulic structure.

- Water supply from the well is carried out stably (without a decrease in the level and interruptions).

- The quality of the extracted liquid will be on top. It can be safely used for drinking purposes.

This method of drilling wells allows you to get a hydraulic structure that will have such a high debit that the water from the source will be enough not only to supply water to a residential building, but also to irrigate the garden, fill pools and other reservoirs, as well as to meet various technical needs.

A rotary drilling rig is used when it is necessary to drill a deep well for water. The essence of the method is as follows: a shaft with a tip in the form of a chisel is lowered into the drill pipe. During the rotation of the shaft, the bit destroys the rock. Rotation is carried out due to the functioning of the hydraulic installation.

To clean the well from the rock in it, a special flushing solution is used. It is fed into the tunnel through pipes. There are two delivery methods that can be used:

- The drilling fluid is pumped into the drill pipe using special pumping equipment. After that, it is squeezed out through the annulus. This method is called direct flushing. It is shown in the video at the end of the article.

- The second way is done differently. The solution is fed into the annulus, and then, using pumping equipment, it is pumped out of the drill pipe along with the crushed rock. This method is called backwash.

The backwash method has one indisputable advantage - using this technique, you can get a hydraulic structure with a large debit, since the opening of the aquifer is of the highest quality. Among the disadvantages is the need to involve complex high-tech equipment, so this technique is more expensive.

The advantage of rotary drilling with direct flushing is its relative cheapness in comparison with the second method. That is why this method is most often used when drilling water wells on private property.

The main methods of drilling wells

Depending on the type and condition of rocks in the near-surface layer, the diameter and type of the rock cutting tool, the drilling method, the type of cleaning agent and the drill string, the following main methods of well drilling are used.

- 1. Installation of a pipe-direction of the well into a hole previously dug by hand. After installation in the pit, the pipe-direction is either cemented or buried. This method is used when drilling large-diameter wells with roller bits with mud flushing (mainly oil and gas wells) and when drilling geological exploration wells using the shock-cable method.

- 2. Drilling the well "dry", i.e. without flushing or blowing. This option is used when drilling from the surface of the earth in cases where the upper interval of the geological section is represented by sedimentary rocks using conventional projectiles (without a removable core receiver). For drilling, the core set is equipped with a SM or SA type carbide bit, and drilling is carried out with slow rotation of the column and increased loads to a depth of 2-3 m to bedrock. If the bedrock lies deeper, then “dry” drilling is carried out to the maximum possible depth, and then a directional pipe is installed and drilling is carried out to the bedrock already with flushing with a smaller tool.

It is possible to dry-drill by landing a casing string equipped with a bit or shoe into loose loose rocks with rotation and under the action of increased axial load to the maximum possible depth. After that, the casing string is not extracted, and the rock inside the string is drilled out already with flushing with a smaller core barrel set.

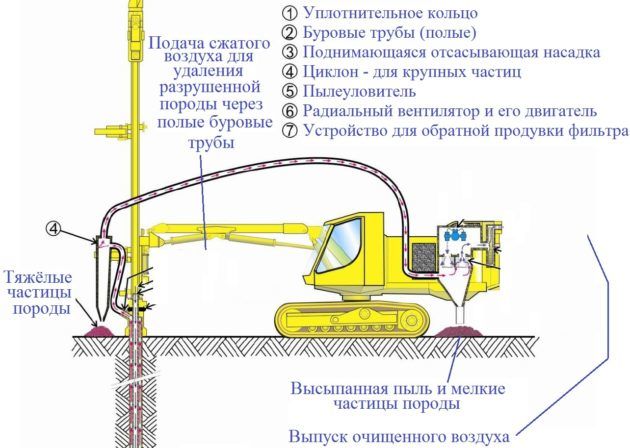

3. Drilling with purge air hammer or cone bit can be used on any, including hard, weathered rocks, rocks saturated with large debris and at considerable depths. This method is recommended for various drilling conditions, but only if no core is required in the drilling interval. For drilling, for example, a P-105 pneumatic hammer (bit diameter 105 mm) and a compressor providing an air pressure of 0.2-0.5 MPa can be used. For operational drilling, it is advisable to have a mobile compressor in the organization with a set of drilling tools specifically for drilling operations.

When drilling in unstable, alluvial, loose rocks, drilling with an air hammer can be carried out from the surface with advanced fastening of the wellbore, when the destruction of the rock at the bottom is accompanied by clogging of the casing string equipped with a shoe or a special bit. According to this scheme, drilling is carried out in accordance with Atlas Copco's OD, ODEX and DEPS methods.

4. Drilling with flushing with diamond or carbide tools is carried out when drilling from underground mine workings without installing casing pipes, if the rocks are stable and not prone to swelling and collapse.

In this case, technical water is removed from the well by a spout and enters the sump along the groove.

The wellhead when drilling horizontal or rising wells, drilled from underground mine workings, is necessarily equipped with a special sealing wellhead nozzle when using the SSK projectile for drilling. Then the delivery and extraction of the core receiver and overshot is carried out due to the adjustable hydraulic head in the sealed space of the wellbore.

The option of drilling with flushing is also practiced when drilling wells from the surface of the SSC. In this case, drilling is carried out with flushing with water using an SSC core set with a hard-alloy or diamond crown to the maximum depth and a core receiver with a core is removed to the surface. Technical water, at the initial stage, pours out of the well and is removed outside the drilling rig along the groove. Next, the casing pipe of a larger size left in the well and emerging on the surface of the core pipe is drilled, equipped with a reinforced shoe. After drilling with the casing pipe, drilling with the SSK projectile continues, and drilling with the casing string is carried out until the casing string enters the dense bedrock.

Drilling with flushing is also carried out when drilling with a double column of KGK (hydrotransport of the core). In this case, water circulates through the gaps in the string and enters the sump without pouring out and without contacting the well walls.

Preliminary work

After the drilling machine is installed, a special commission arrives to check the equipment, machinery and quality of work.

When the drilling rig is ready, preparations for drilling begin. As soon as the drilling machine is installed and the construction of the structures is completed, the drilling machine is checked by a special commission. The foreman of the drilling team, accepting the commission, together with it monitors the quality of work, checks the equipment and the implementation of labor protection.

For example, according to the method of execution, luminaires must be in an explosion-proof casing, emergency lighting for 12 V must be distributed throughout the mine. All comments made by the commission must be taken into account before drilling begins.

Before starting drilling, the equipment is equipped with the appropriate equipment: a square hole, drill pipes, a chisel, small-scale mechanization devices, casing pipes for a conductor, instrumentation, water, etc.

The drilling rig should have houses for housing, a gazebo, a canteen, a bathhouse for drying things, a laboratory for analyzing solutions, equipment for extinguishing fires, auxiliary and working tools, safety posters, first aid kits and medicines, a warehouse for drilling equipment, water.

Scheme of installation of a tower for drilling.

After the drilling tower has been installed, a series of works on re-equipment of the traveling system begins, during which equipment is installed and small-scale mechanization is tested. Drilling technology begins with the installation of the mast. Its direction must be set exactly in the center of the axis of the tower.

After centering the tower, drilling is carried out under the direction. This is the lowering of the pipe to strengthen the wells and the filling of its upper end, which should coincide in direction with the gutter, cement. After the direction in the process of drilling wells has been established, the alignment between the axes of the rotor and the derrick is checked again.

In the center of the well, drilling is carried out under the hole for the square and in the process they are cased with a pipe. The drilling of the well hole is performed by a turbodrill, which is held by a hemp rope to prevent too fast rotation. At one end it is attached to the leg of the tower, and the other is held in the hands through a block.

Process steps

The technology is implemented in the following sequence:

- The surface is cleaned of debris and foreign objects.

- Not far from the future hole, they dig a hole two meters deep to drain the flushing fluid.

- A hole is punched in the ground to accommodate the drill, the crown is connected to the core pipe, it grows as it is driven.

- After with drill pipes - the top one is fixed in a drilling rig powered by an engine - in this way the sinking begins.

- When the pipe is completely filled, it is raised to the surface, extracting rock from it with a hammer, the blows are not applied too hard.

- The drill is again immersed in the well and drilled until the required depth is reached.

Drilling takes place with flushing, but if there is not enough water for this, the workflow is carried out dry. If specialists use diamond tools in their work, they use a special emulsion for regular washing.

In the case of sandy soil, liquid glass, clay mass are added to the solution, strengthening the walls of the hole.

For soils with an unstable structure, the well, in the process of deepening, is reinforced with casing pipes. Often, instead of flushing with water, a cheaper blow with compressed air is used.

Sand well drilling

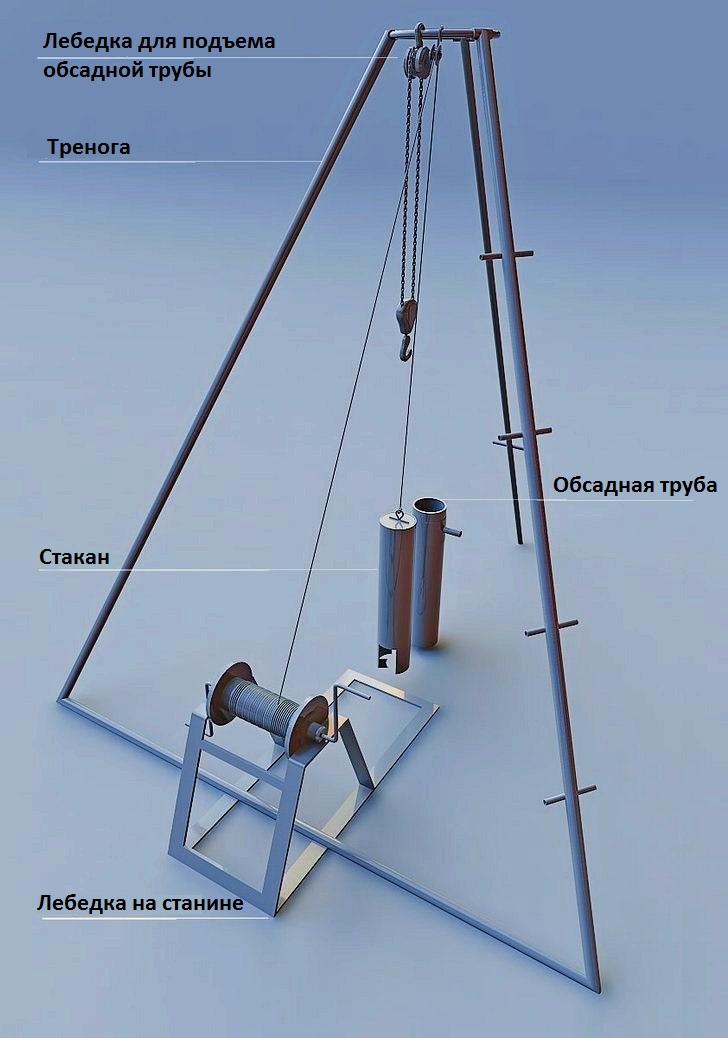

To drill a well with your own hands, you can use the shock method. On the selected area, prepare a site for mounting the tripod.

The type of projectile depends on the type of soil - dense clay soil is pierced with a glass, and loose clay soil is pierced with a bailer. The glass can be turned into a bailer by welding a cone with a metal ball on the inside of the pipe.

The tower is assembled in the form of a tripod from metal pipes, a pulley for a movable rope is attached at the top. At the base, a lifting mechanism and a shaft are attached, on which the rope is wound.

In the place where the well is planned, a recess is made for the casing by half a meter. A projectile must fall into this hole. The projectile rises and falls sharply into the recess. Through each meter, the drilling tool is lifted and cleaned from adhering earth.

Features of drilling in different soils

When carrying out cable-percussion drilling with your own hands, depending on the types of soils found, a number of recommendations should be followed.

Soft, non-friable soil

The easiest way to work is with a driving glass. A winch lowers it to the surface of the soil. When a sufficient amount of rock is collected inside the glass, it is removed outside.

loose soil

A bailer with a valve is used. It prevents the spillage of rock, which is extracted only on the surface. In this case, it is mandatory to strengthen the walls of the face. For this purpose casing pipes are used. They go deep into the soil under the influence of their own weight, which allows you to extend the life of the well.

The diameter of the casing pipes should be slightly larger than the drill string, which ensures its passage to the desired depth.

rocky rock

A chisel is used to crush the soil, and a bailer is used to extract it out. To expand the diameter of the well, the use of a casing string is not enough. To do this, use a special expander with moving cutters. It is lowered through the casing pipe. When it reaches the desired depth of the face, the cutters unfold. They cut the soil, which facilitates the movement of the casing string.

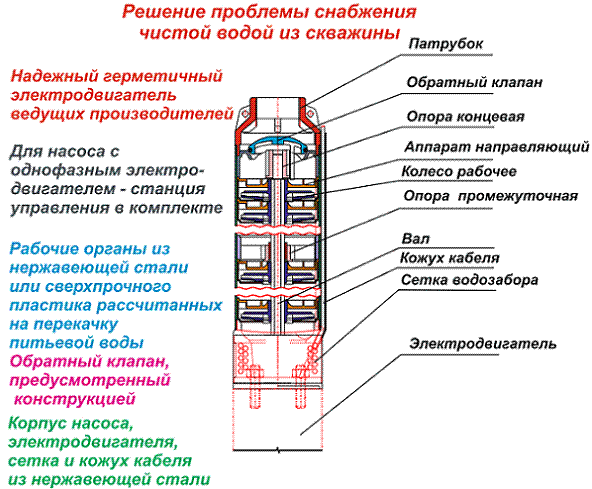

The choice of pumping units for industrial wells

The withdrawal of water from the intake structure is carried out using special pumps. When choosing them, the following factors must be taken into account:

- the power of the drive used;

- Type of equipment;

- operating pressure level;

- performance of the pumping unit.

Pumping units are used for pumping clean water, which may contain a small amount of impurities. Corrosion-resistant metal alloys are used to manufacture the pump housing. The electric motor is reliably protected by a hermetic shell.

Submersible type pumping units are used to draw water from an industrial well. Their working blades are immersed in water. The pump is secured with a stainless steel cable.

At the final arrangement of the structure, water intake structures are mounted in it. With the help of them, water is delivered to the consumer.

The essence of technology

The soil-destroying device is a core drill (drill bit) - a special tool that has hard-alloy cutting parts or diamond inserts.

With its help, professional drillers quickly create holes in the soil of the desired depth and diameter.

Core drilling of wells is carried out by craftsmen at high speeds of the main part, so the installation is subject to a powerful load. For the device of the crown - a durable and convenient ring made of steel billet - a hollow cylindrical piece with sharp cutters - hard alloys are used: tungsten, steel or diamonds will win.

The crown moves strictly along the edge, and the rock from the inside remains intact. After the working shaft is filled with soil, samples are periodically removed for examination from the core receiver and determination of the geological section of the site.

The small diameter of the drill, up to 160 mm, allows you to overcome up to several hundred meters in a shift, it all depends on the hardness of the rock.

After core drilling has been completed and the results have been examined, it is easy to start auger drilling with full recovery of the contents of the well.

Classification and general characteristics of drilling methods

The drilling process consists of the destruction of the rock at the bottom of the hole (well) with a drilling tool and the removal of destruction products (drilling fines) from it.

With all drilling methods, the following main operations are performed: preparation and installation of the drilling machine to start work, drilling (destruction of rock) with cleaning the bottom of the well from destruction products, building up the drilling string to achieve the required drilling depth and disassembling it after completion of work, changing worn out drilling tools and moving the machine to a new hole or well drilling site.

At present, rotational, shock-rotary, shock-rotational and rotational-impact methods of drilling boreholes and wells (mechanical drilling methods), as well as fire and combined drilling are used. The effectiveness of the use of explosive energy in explosive drilling of wells, as well as high-voltage electrical discharges in electric pulse drilling, is investigated.

During rotary drilling, the tool rotates around an axis coinciding with the axis of the hole or well and simultaneously with a certain force is fed to the bottom. The magnitude of the force is set from the condition of exceeding the ultimate strength of the rock for indentation on the area of contact between the cutting blades of the tool and the rock. In this case, successive destruction from indentation and chipping of rock particles from the bottom occurs. Destruction products are removed using twisted rods (when drilling holes), augers (when drilling wells), flushing the bottom with water or blowing with air.

At mining enterprises, they use: rotary drilling of holes with cutters using hand and core drills; rotary (auger) drilling of wells with cutters and diamond tools using drilling rigs.

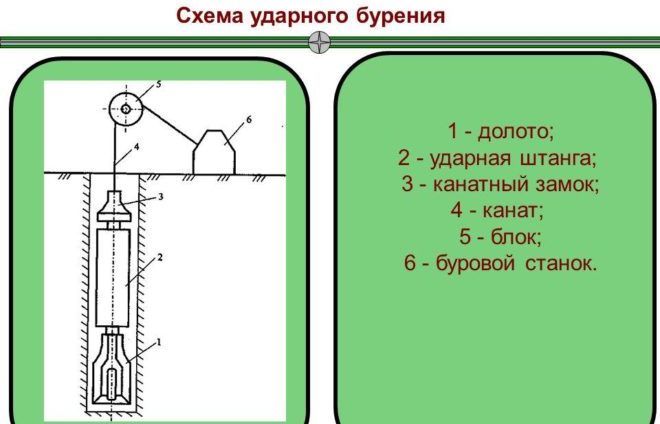

In the percussion method of drilling, the tool (chisel or crown) strikes the bottom and destroys the rock under the blade. After each impact, the tool rotates through a certain angle, which ensures the consistent destruction of the entire bottomhole area and obtaining a round section of the hole or well.

During rotary percussion drilling with conventional and submersible drill hammers (perforators), the tool rotates intermittently only in the intervals between blows by a rotary device mounted in the hammer.In some designs of hammer drills, the rotation of the tool occurs during the period when the piston strikes the tool.

In percussion-rotary drilling with down-the-hole hammers and drill hammers with independent rotation, impacts are applied to a continuously rotating tool. The destruction of the rock with these drilling methods occurs only as a result of the introduction of the drill bit during impacts.

In rotary percussion drilling, impacts are applied to a tool that is continuously rotating under a large axial force. Destruction occurs both as a result of the introduction of the tool during impacts, and as a result of rock chipping during the rotation of the tool.

Drilling with cone bits is performed both in the percussion method with pure rolling bits and in the rotational percussion method with sliding bits, in which the teeth, along with rolling along the bottom, cut the rock with a sliding motion along the surface of the bottom.

During fire drilling, the destruction of rock at the bottom of wells occurs due to thermal stresses that occur when the rock surface is rapidly heated by hot gas flows (2000 ° C) emitted from the burner nozzles at supersonic speed (2000 m/s or more).

During explosive drilling, the destruction of rock at the bottom of wells occurs by successive explosions of small explosive charges. Two methods of explosive drilling are known: cartridge drilling, using cartridges of liquid or solid explosives that explode at the bottom from a blow or detonator, and jet drilling, in which liquid explosive components (fuel and oxidizer) are fed through the drill to the bottom and a liquid flat charge is formed. The explosion of this charge is caused by injecting a drop of an initiating compound (a eutectic alloy of potassium and sodium).

During electric pulse drilling, the destruction of rocks at the bottom of the well occurs due to electrical breakdown of its section by a high-voltage (up to 200 kV) discharge. Instantaneously released energy in the breakdown channel destroys the rock, which is removed from the bottomhole by a dielectric flow circulating in the well (solar oil, water, etc.).

Combined drilling methods are being developed, in which there is a joint effect on the bottomhole of a percussion tool and a cutter (percussion-cone method), cutters and cones (cutting-cone method), cutters and a fire burner (thermo-cone method), a fire burner and a percussion tool ( thermal shock method).

Drilling methods

The process of making wells, like any other technology, has several types:

- shock-rope;

- rotary;

- downhole motor drilling;

- turbine;

- with screw engine;

- electric drill.

Scheme of installation for shock-rope drilling of wells.

The percussion-rope method of drilling wells is considered the most tested. With it, the well shaft is formed due to periodic blows of the bit on the bottomhole. This process occurs under the influence of the weight of the bit itself and the heavy rod. The raising of the bit together with the rod, which are fixed on the rope, occurs due to the balancer of the drilling mechanism.

With the rotary method, the rotation of the tool is transmitted through the rotor. In this type of well drilling, the rotor is installed on the wellhead through a string of drill pipes, which play the role of a full shaft. When drilling small wells (with a small diameter of the trunk), the process occurs due to spindle motors.

The rotor drive is carried out from the cardan shaft connected to the winch. Or it can be a chain drive from one engine. The advantage of the drive is that it can adjust the speed of rotation over a wide range, reduce the load on the winch and reduce its wear.

The rotor for drilling is selected according to the degree of load, power, as well as the diameter of the shaft. Rotary drilling has 2 channels of energy transmission for bottom hole:

- mechanical from the drive;

- hydraulic from pumps.

Installation for well drilling rotary and turbine methods and with the help of an electric drill.

When drilling with a turbine method, the drill string does not rotate during operation, but takes over the torque from the downhole motor. This method also transfers hydraulic energy.

Turbine method - transmission of rotation to the bit from the turbine shaft, which is driven by the movement of the mud flow. It turns out that with the turbine method, only 1 channel of energy transfer to the bottomhole is involved in the process.

The turbodrill standing above the tool is a machine that leads the process of converting the hydraulic energy of the pressure of the flow of the fluid used into mechanical energy, aimed at rotating the tool.

The drilling process is the lowering, lifting of the drill string into the well and maintaining it on weight. The drill string is an assembly of pipes lowered into the shaft, fastened together with drill locks. Its task is to supply hydraulic and mechanical energy to the bit.