The principle of operation of furnaces with two hoods

The secret of the efficiency of this stove lies in its original design, which allows you to accumulate and save heat for a long time. To understand the principle of operation of a two-bell furnace, consider its design diagram.

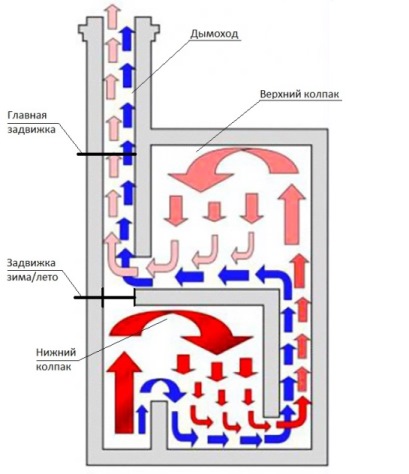

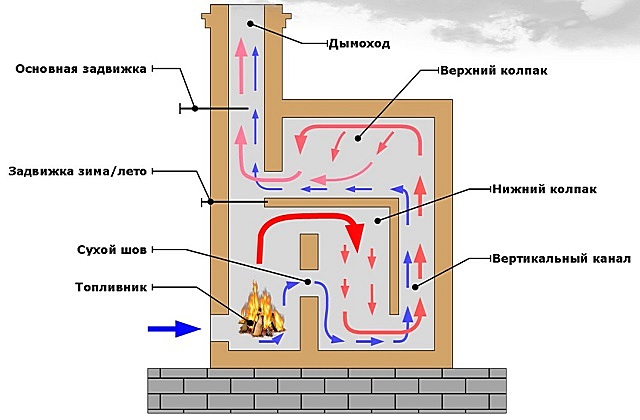

After kindling in winter, hot flue gases rise under the arch of the lower hood, transferring heat to the surrounding walls and the hob. But new air enters the combustion chamber, the combustion process continues and the release of hot combustion products continues, displacing the cooled gases under the top of the cap. Those, in turn, descend and fall into a vertical channel leading to the upper hood, where the two-bell design of the furnace provides for a repetition of the previous process with the release of gases to the outside through the chimney.

The temperature of the outgoing flue gases is lower than any other oven with a stove, as they intensively give off their heat to the walls of the stove. For this reason, the chimneys of heat sources of this design must be protected from the damaging effects of condensate. After the heating is completed, the heat remains at the top of both hoods for a long time even if the main valve remains open. Cold air entering through the blower cannot rise under the dome roof and passes into the chimney along the path indicated by the blue arrows in the diagram.

A double-bell cooking oven with a stove allows you to cook food in the summer thanks to an additional valve, the opening of which passes gases directly into the chimney. If the valve is not fully opened, then the flow of combustion products will be divided into two, going along different paths. In this way, in the autumn-spring period, it is possible to regulate the intensity of heating of the caps, that is, the thermal power of the stove.

Kuznetsov furnaces device and principles of operation, advantages, variations, drawings

Kuznetsov's stoves are well known not only to stove builders - they heat many houses in Russia and abroad. I. V. Kuznetsov has been working on improving furnaces since 1962 and has gathered around him a strong team of like-minded people. The team has more than one and a half developments, covering almost the entire range of household stoves, see fig.

Some of the furnaces of I. V. Kuznetsov

Many would like to fold one of the Kuznetsov furnaces with their own hands, and this article is to help them. But we are not going to reveal some hidden secrets of "blacksmiths" - they simply do not exist. On the website of Igor Viktorovich stove.ru, those who wish will find a huge array of stove information for free: from information on the design and construction of stoves to detailed drawings and recommendations for installing a stove in a house and arranging a blind area around a building with stove heating. We also do not intend to criticize or correct anything in this home-stove encyclopedia: we are far from I. V. Kuznetsov on the stove business, to put it mildly.

The purpose of this article is to provide a kind of introduction to Kuznetsov's collection of information, which makes it possible to navigate more freely in the source material. Let us explain with an example why this is necessary.

Let's say I'm a generalist auto mechanic with a lot of experience and I want to pass it on to others who are interested. A car is a complex thing. If I start to digress in the course of the presentation, explaining in detail that how running-in and caster (suppose, readers are not quite dummies, now everyone drives) affect the handling and directional stability of the car, and the gas distribution diagram affects fuel consumption depending on road conditions, and so on, I will eventually get confused to the point that I myself will no longer understand how the car I drive works.Willy-nilly, I will have to present the material, albeit “on my fingers”, but professionally fluently.

However, it will be hard to read it even for specialists like me, and for an amateur, in general, his head will spin. Therefore, I need someone to help me, who can be conditionally called a “recipient”. In fact, he is not a kettle at all, he can adjust the suspension himself and set the valve lifters. But in this case, his task is to describe how the entire stuffing of the car is assembled into one, controlled according to the principle: “Steering wheel, gasping, brake braking.”

In the automotive industry of the USSR, a similar situation arose in the late 50s - early 60s, when the industry began producing cars for general sale to the population. Then the superbestseller of that time was published - "How the car works." Under the editorship of none other than the most important designer of the legendary "Victory" A. A. Lipgart.

Information "from the receiver" will not yet allow you to start working: it does not provide deep knowledge that will allow you to at least intuitively estimate the necessary values of numerical parameters along the way. But it is essentially fundamental: having mastered it, a professional text is already read with understanding and faster. And, if something is still unclear somewhere in it, it no longer causes confusion and throwing, but just a mark in the mind: you need to find out more about this.

So far, the government has not adopted any landmark decisions on stoves and stove heating. But their role in household thermal power engineering in times of energy shortage is undeniable: already a heating stove with an efficiency of 70% in mass use will save fuel on a national scale, because. The projects of brand new heating plants include 35% heat losses in the mains, and there is no way to reduce them yet. So with the popularization of furnace knowledge, you have to get out yourself, without being either Lipgart or Kuznetsov. Well, let's try.

Design and principle of operation

The stove with a cap was developed by engineer Igor Kuznetsov in the early 60s of the last century. Subsequently, the Russian metallurgist Leonid Kotlyar improved the design so that it retained heat up to 19 hours. The peculiarity of "blacksmithing" is that the heated air does not leave the pipe, but is collected under the hood. Slowly, it cools down, and is forced out by rising hot streams. Saving heat is the advantageous difference between a bell-type furnace used for heating a house and a ducted one, where hot air, under the influence of draft, freely goes outside.

A two-meter-high structure with a base of 1m * 1m can reach a thermal power of 3.5–4.5 kW. Such a bell-type stove is enough to heat a house of 50 square meters in a temperate climate zone, if you heat it twice a day.

The inventor improved the design by adding another cap. In Kuznetsov's two-bell heating furnace, the first covering element is connected to the furnace compartment and separates the cold and heated flows. The second cap is located in the upper part of the furnace, retaining hot air, which, before entering the chimney, gives heat to the bricks for a long time.

A two-bell stove consumes fuel more economically and is usually equipped with a hob. This allows you to cook delicious meals without using electricity or gas. The design of the stove is already provided with an exhaust hood - there is no need to install an additional ventilation system.

More about round

Round stoves theoretically generally have a lot of advantages, only in the house they are not very convenient. However, there is a considerable demand for compact mobile furnaces, and here the extremely high efficiency of round multi-bells can be a decisive factor, because when the furnace size decreases, its efficiency drops sharply due to the square-cube law.

Such furnaces, of course, would have to be made of metal.This solves the problem of cleaning, the stove can be made collapsible. But the choice of metals suitable for the ratio of heat capacity and thermal conductivity is extremely limited. From inexpensive - only cast iron, but it is heavy and fragile.

However, there is a lighter and stronger metal material with similar properties. This is a product of powder metallurgy. With regard to scissor knives, “powder rubbish” is quite justified, but for an oven in which nothing works for shear, powder parts can be a godsend.

The second problem, which has already been mentioned, is the heat-resistant lining on the roof of the first cap. If it is possible to solve it, then, perhaps, the labors and efforts of Igor Viktorovich Kuznetsov will bear fruit more extensive and weighty than it seems now.

Third step right, step left

High loads on the material in Kuznetsov furnaces require not only careful design development, but also compliance with some fundamental design principles. The main one is a floating firebox made of fireclay bricks of the ShB-8 or Sh-5 brand. The body of the furnace is laid out of ceramic bricks of grade not lower than M150.

What does floating fire mean? Firstly, around it entirely, or in the places exactly calculated by the author, there must be a dry seam. It is not so easy to make it: after laying out the last row of fireclay (unless otherwise specified in the specification for the furnace), the clay mortar is picked out from the seams between the fireclay and ordinary bricks, and mineral cardboard pads are inserted instead of it - basalt, kaolin, etc. .

Unrelated and related building modules

Secondly, it is necessary to strictly observe the principle of incoherence of modules. What it is is shown in Fig. No protrusions of fireclay should enter the grooves of ordinary bricks, and vice versa, even with damping joints. TKR and heat capacity of fireclay differ significantly from "brick", and the firebox associated with the furnace body will tear the masonry during kindling. The blacksmith firebox should be a compact module installed in a nest made of ordinary bricks. How to arrange her exit into the chimney, the author explains in detail on the site.

It is also strictly necessary to follow his recommendations regarding the selection and preparation of materials. "Kuznetsovka" though brick, but high-tech, and endure replacement for ersatz and negligence no more than a rocket or a submarine - the replacement of titanium and composites with a tin can. The consequences, however, will not be so catastrophic, but they will also have to be seen at home, and not read in the news. And pay out of your own pocket.

In general, according to technology: a diligent, attentive and accurate beginner can build a Kuznetsov furnace. But a really experienced stove-maker, half-drunk, but thoughtlessly laying out a really very good stove or a Dutch stove, will definitely misfire on Kuznetsov's stove.

Second heat load

Nothing works on bare principles. In order for a theoretically absolutely correct stove to warm, dry and cook well, it must also be correctly executed in the material. For bell-type furnaces (and especially for double-bell furnaces), this means that the thermal load on the material must be high. To make a bell-type furnace massive, with thick walls is the same as burning a fire in a cave. To feel the heat, you need to sit by the fire itself, and there will be soot ...

Take a look at fig. On it are drawings and orders of some Kuznetsov furnaces: a bathhouse. heating and cooking. a double-circuit hot water boiler and an improved Russian one with a stove bench. Not being an experienced stove-maker, it is clear that the material per unit of power released (500 W * sq. M of the outer surface) in the Kuznetsov furnace is one and a half to two times less than in traditional ones. In general, any bell-type furnace is “emptier” inside a channel furnace of equal power.

Orders of some Kuznetsov furnaces

On the one hand, this is good, a brick with masonry mortar costs money.But on the other hand, it requires careful development and adherence to construction technology (see below). The heat load, from which a pile of cobblestone does not move, will destroy a thin brick wall even during an accelerating furnace.

Construction mechanics is also important for Kuznetsov's furnaces. The strength of the wall on clay mortar with a decrease in its thickness falls much faster than on cement-sand. Therefore, the foundation for these furnaces must be carried out especially carefully in strict accordance with the recommendations of the author. They also need to be strictly followed during construction.

Note: I. V. Kuznetsov allows you to freely copy his materials for himself, for construction, but objects to reprints. However, the pictures in Fig. small. An amateur will not build anything on them, and the master knows where you can get full-fledged drawings. Therefore, we hope that Igor Viktorovich will forgive us this small borrowing for the good of the cause.

Two-bell furnaces Kuznetsov order and its features

The principle of building furnaces, in which it is possible to implement the law of free movement of gases, has been known for a relatively long time. The most common and well-known option is a two-furnace furnace.

The principle of its operation is that air from the environment enters through the blower into the furnace. At the first stage of combustion, when the lightest fuel fractions are burned, the process is somewhat reminiscent of pyrolysis. This mode is the most efficient. But before Kuznetsov, few people enjoyed these advantages. But the orders have such a design that allows them to work in the pyrolysis mode. As a result, pyrolysis gases burn under the dome of the third hood. The process itself is interesting. Its features are that combustion is self-regulating. If the flame is too wide, then the draft deteriorates, and the combustion process slows down; if the heat is not enough, the draft increases, and the combustion process intensifies. Two-bell Kuznetsov furnaces (ordering) have a second dome so that the combustion process is not disturbed. The temperature in the second cap at an efficiency of about 80% reaches 300-400 degrees, and this is quite enough to transfer heat to the coolant.

The main stages of arranging a brick oven in order with your own hands

There are a number of key steps that need to be followed when using ordering for heating and cooking stoves. All of them have their own nuances of conduct and unique characteristics, knowing which you can ensure a high level of quality and minimize the cost of arranging a furnace with your own hands.

Next, an example of a furnace device based on the Swede order will be considered.

Work technology

In the design of such a heating installation. already in order, a blower is provided. This is especially necessary to remember when starting work on arranging the furnace with your own hands.

At the same time, it is important to take into account the peculiarities of laying the 1st row of bricks.

The fact is that here it is necessary to ensure compliance with the level and control of the angles, using a construction square for this purpose;

However, it is necessary to pay attention to all the characteristics of the first row. The fact is that this largely affects not only the service life and reliability of the heating installation, but also the efficiency of its operation;

The technology for using the ordering provides for, upon completion of the installation of the first oven row, the installation of the door and the blower, after which they proceed to the laying of the 2nd row;

When erecting the 3rd row of the cooking furnace, it is necessary to adhere to the exact ordering instructions

To create a blower, you should chop off a brick on each side

And here it is necessary to take into account that the arranged row must have the same height as the door;

For laying the 4th row of oven masonry, a place is chosen on the left side. This work begins with the installation of a door that provides ash removal.This will prevent normal operation of the machine. As for the masonry itself, when it is performed, they follow the same order as in the scheme itself. Moreover, it is imperative to take care of blocking the blower door. Above the ash pan it is necessary to make a hole in the form of a square. This idea is realized by laying bricks in a special way;

Starting to lay the 5th row, you need to follow that. so that the opening of the ash pan begins to narrow. In its appearance, this series is similar to the 4th. Therefore, the technology of its installation will be the same;

When starting the device of the 6th row, it is necessary to use a special brick with refractory properties as a material. Most often, the scheme developed by qualified stove-makers contains a note about this in the form of hatching. Such a hint allows you to simplify the masonry process and avoid possible difficulties in performing these works;

The brick that will be laid in front of the grate must be chipped. A detailed solution has a positive effect on the efficiency and quality of fuel placement on the grate during use of the stove. At the same time, the support of the grating will be directly provided by the 5th row of stove masonry;

The bricks of the 6th row and the grate of the grate should create between themselves a sufficient space 10–15 cm wide, where sand or ash must be placed, and the presence of such a gap is necessary to create the effect of expanding the metal of the grate when using the heater;

After creating the U-shaped channel at the previous stages, it must be blocked. Moreover, this is done with the expectation that as a result three new ones will arise. This stage involves the installation of the furnace door, the support for which will be directly provided by the 6th row of the furnace masonry;

The process of laying the 8th and 9th rows of laying the "Swede" oven is carried out according to the same scheme as in the case of the 7th. At the same time, it must be remembered that it must have the same placement height as the combustion chamber door. Here, it is mandatory to process bricks, with the help of which access to the partition of the combustion chamber and the left channel is blocked: they are trimmed on both sides, which ensures efficiency and a smooth transition of combustion products from the furnace to the channel;

Refractory bricks are used to create the 10th row of the furnace. The laying technology provides for ensuring the vertical placement, which should be supplemented by regular checks carried out through the building level. The need for this is due to the fact that for such furnaces, when ordering on these bricks, a special cooking floor should be placed;

Next, you can start gluing the furnace door. as a result, the final row will have two channels, characterized by the presence of a perfectly square section.

We put the bell oven

In double-bell furnaces, the thermal load on materials is extremely high. Therefore, it is easy to make a mistake and perform a similar design with massive walls. The fire will burn in it, but instead of the expected heat, you will get smoke and soot.

An analysis of the orders of Kuznetsov's furnaces for various purposes, which are based on a 2-bell variant, (heating and cooking, for a bath, with the installation of a double-circuit hot water boiler, etc.), makes it possible to identify a very characteristic feature. per unit Nvyd, equal to 500 W / m² of the outer surface of the material, almost 1.5 times less is consumed than in products of traditional designs.

This has both a plus (reducing the cost of construction due to the need for fewer bricks and masonry mortar) and a minus. Such products place high demands on the development and strict observance of all the technological nuances of masonry.Since the actual heat load, which is safe for a thick-walled furnace, is capable of destroying a thin wall already at the stage of an accelerating furnace.

Construction mechanics should also be close and understandable to a stove-maker who decides to lay out a bell-type furnace with his own hands. The simplest confirmation of this thesis is that the strength characteristics of a wall laid out using clay mortar, if its thickness decreases, fall much faster than that of cement masonry. This imposes increased requirements on the foundation of such a furnace. The stove-maker is obliged to strictly follow the recommendations of the author of the order with which he works. Moreover, not only during the arrangement of the foundation, but further, at all other stages of laying the furnace.

Their fundamental principle is a floating firebox. It is laid out from refractory bricks (chamotte). The most popular brands are Sh-5, as well as ShB-8. The rest of the body of the furnace is made of ordinary ceramic bricks, grades from M150 and above.

Recall floating, it is called because:

Around the firebox from all sides, or in places strictly established by orders, a dry seam is formed.

The technique for its implementation is as follows. After the laying of the last row of fireclay bricks is completed, the masonry mortar is removed from all seams between it and the ceramic bricks. Special spacers are inserted into the resulting voids, which are prepared from various types of mineral cardboard. The most commonly used are kaolin and basalt. It is possible to use other technologies, which must be specified in the specification available for a particular furnace.

Module inconsistency. This principle must be strictly observed. Fireclay bricks in any case should not be inserted into the grooves between ceramic bricks (the opposite is also true), even if there are damping joints.

The heat capacity of fireclay bricks and its TKR differ significantly from those of ordinary ceramic bricks. Therefore, the furnace, if there is a connection with the main body of the furnace, will simply tear the masonry already at the stage of kindling.

That is why it is required to make a firebox for such furnaces as a fairly compact module inserted into a nest prepared from ceramic bricks. At the same time, there are a number of technical nuances to ensure the removal of gases through the chimney.

It is very important to use in the work only the material named in the specification for the furnace, as well as indicated in the order. The designs of such furnaces are calculated and high-tech

Therefore, the replacement has a very negative effect on the performance of the finished product. At best, the furnace will have to be repaired. At worst, disassemble completely and lay out in a new way.

Advantages and disadvantages

Kuznetsov's designs have many advantages. One of them is increased efficiency - 93 percent. For comparison, in Russian furnaces it is about 80. At the same time, the blacksmiths have uniform heat transfer, less temperature fluctuations.

Other design benefits:

- Soot does not remain, and therefore the stove and smoke channel can not be cleaned for several years, which greatly simplifies maintenance.

- The device can be erected anywhere - in the corner zone, in the middle of the room, near the wall. Often, a two-bell stove heats several floors of a house on one tab.

- The stove chimney can be shortened to save bricks.

- "Kuznetsovka" is easily combined with a stove, fireplace, stove bench, differing in a variety of modifications.

- It is easy to connect a water circuit to the stove and pipe heated water for bathing or heating.

- Due to the increased level of pyrolysis, fuel is saved, which can be any.

- The masonry will last longer, less risk of cracks.

- With a short-open valve, it is almost impossible to cool the stove, because the hood is always filled with warm air, and the cold one is pressed down.

foundation of the foundations

Most of the advantages of Kuznetsov furnaces are provided by the principle of free passage of gases. Let's explain again with an example.

Let's imagine a stove with a complex system of flues: an undermark, a four or five turn Dutch. In this tight labyrinth, strong turbulences will inevitably arise. Have you heard how the oven hums? This is only an insignificant manifestation of the vortex energy raging in it. And there is nowhere to take it from, except from the fuel tab. If the channels are long and narrow enough, then at first glance there is nothing terrible here: the vortices, while they get to the pipe, will dissipate, cooling down, and still give their energy to the body of the furnace, and it to the room. But in fact, nuances appear, which will be discussed later in the text. Because of them, the efficiency of a channel furnace over 60% is an exceptional rarity.

In a channel stove, while it is heating, a huge flow of energy rushes about, and only a small part of it can be taken for heating or heating water without disturbing its operation. Such a furnace is somewhat similar to a nuclear reactor. Do not be afraid, only in terms of synergy, i.e. along the paths of energy circulation in it. In a nuclear reactor, it is necessary to put dozens of times more fuel than is necessary to ensure the design energy yield. Otherwise, neutrons will simply fly out without having time to meet uranium atoms ready to receive them. In a channel furnace, hot whirlwinds, not having time to cool down, will fly out into the chimney or, conversely, cool down immediately, giving off smoke and soot.

But the blacksmiths (details below) are already closer in terms of synergetics to the thermonuclear reactors of the future. "Thermonuclear" sounds scary, but this is only by association with the hydrogen bomb. In fact, fusion reactors are quite safe.

Why? Because they produce exactly as much energy as the consumer should consume, and the technological power reserve for rarefied plasma is scanty. If suddenly the chamber of a tokamak or stellarator is suddenly completely destroyed, the plasma will completely light up (there are no heavy atoms in it) and cool down before it reaches the walls of the room. The repairmen will swear - whether it's the duty to sharpen the laces - but after 5 minutes. will be able to blunt to elimination without protective equipment.

So what do Kuznetsov furnaces have in common with fusion reactors? The fact that the energy of flue gases, thanks to the principle of free passage, does not scroll many times in the stream until it is pushed into the body of the furnace, but immediately impregnates it. And now she has nowhere to go from there, except to the room and / or the hot water register.