What are asbestos cement pipes for?

Asbestos cement is a durable refractory material that combines the properties of asbestos and cement. Asbestos or, as it is also called, mountain flax, is a group of materials of the silicate class that look like thin, strong threads. These threads are used as a frame into which other building materials are poured or laid. In the case of asbestos cement, this building material is cement.

Asbestos gives strength to materials and protects them from fire. There are two types of asbestos: chrysotile and amphibole. The first is widespread in Russia, where there are deposits of asbestos. In construction, this material has been used for about five decades. Amphibole asbestos used to be common in Europe, but now it has been banned due to its negative impact on human health.

Asbestos-cement pipes are designed for those structures where there is water, steam or gas. They are able to withstand temperature fluctuations and, when properly installed, last for many years.

Option 1 car heater

Of course, in a serviceable car, a 12-volt electric heater is, to put it mildly, useless. But everything can happen: it happens that the stove refuses to work at the most “opportune” moment, and the car enthusiast sitting inside an uninsulated metal box is left face to face with severe frost. Also, a home-made 12 V heater may be needed if the rear window heating system breaks down.

- computer power supply;

- cooler (small fan): it can be removed from the same power supply;

- soldering iron with everything you need for soldering;

- the wire;

- a fragment of a tile;

- M5 bolts with nuts of the same diameter (8 pieces);

- nichrome wire.

If everything is ready, you can start creating a homemade heater.

Case manufacturing

First of all, the computer power supply must be disassembled into components. We carry out the disassembly in full: we remove the electronic board fixed with self-tapping screws, the cooler, as well as connectors and switches (during the operation of the heater, they can become a source of an unpleasant odor).

Did you know that a candle flame can be used to heat a room? Consider the principle of operation of a candle heater, and also talk about the nuances of its use.

Can infrared heaters be harmful to health? You will find the answer to this question below.

We asked ourselves which is better: a convector or an oil heater? Here https://microklimat.pro/otopitelnoe-oborudovanie/obogrevateli/chto-luchshe-konvektor-ili-maslyanyj-obogrevateli.html the comparative characteristics of these devices for various parameters are given.

Manufacturing of heating elements

To make a heating element, you do not need to "reinvent the wheel": in this capacity, we will use a nichrome spiral - the same as that installed in any heating element. Nichrome (an alloy of nickel and chromium) is a conductor, but at the same time it has significant electrical resistance, so when an electric current is passed through it, it gets very hot.

Spirals are made by winding nichrome wire on any cylindrical rod.

It is important to choose the resistance of the heating elements and the scheme of their connection (in parallel or in series) so that the heater does not overload the on-board electrical network. Otherwise, the operation of the device will be accompanied by all kinds of undesirable phenomena, for example, insufficient recharging of the battery

Otherwise, the operation of the device will be accompanied by all kinds of undesirable phenomena, for example, insufficient recharging of the battery.

As an example, consider a car brand Daewoo Sens.The electric generator installed in it is designed for a current of 70 A. Under such conditions, it is permissible to use an electric heater that consumes a current of 10 - 15 A - such a load for the on-board electrical network will be almost imperceptible.

Finished nichrome spirals must be screwed to the tile trim using M5 bolts and the same nuts. To do this, the tile will have to be drilled.

The tiles with heaters must be fixed in the case from the power supply in such a way that the cooler installed in its place blows it, expelling warm air into the car interior. As a result, we get a 12-volt fan heater.

To prevent the material from crumbling, tape or plaster must be glued to it at the drilling site, while the drill should rotate at a minimum speed.

Heater Assembly

After that, all wires are connected to the heater.

Their cross section must correspond to the calculated current strength.

In a copper wire for every 10 A there should be 1 sq. mm section, in aluminum - 1.25 sq. mm.

Do not confuse the diameter of the core with its cross-sectional area - for small diameter wires, these values \u200b\u200bare very similar.

Also, a fuse must be inserted into the circuit of the device, which, again, is selected depending on the calculated current strength.

Installation

Despite the modest voltage, a homemade heater consumes an impressive current and heats up quite strongly. In order to avoid emergency situations, it must be securely fastened so that the device does not accidentally fall while the car is moving.

What is more profitable to do it yourself or order

And here a dilemma creeps up: on the one hand, a solid fuel (TT) boiler is very similar to a conventional stove. And it will turn out to make a chimney for him. This is what many boiler owners think. However, it would be a mistake to assume that this business will be simple: competent calculations, thoughtful design and high-quality installation are important here, because the lives and health of all members of your family depend on this. Errors in the design, loose docking - all this can lead to the ingress of carbon monoxide into the room. And this is already very dangerous!

Therefore, if you do not have the professional skills of a stove-maker, then it is better not to take the job. And if you are confident in your abilities, or the design of the chimney is not very complicated, then feel free to get down to business.

It is better to order chimney calculations from a construction company, where they will do everything right for you!

Scope of application

Asbestos-cement pipes are used in various areas of construction. For example, they are used in the construction of sewerage, both pressure and non-pressure. Often they also serve to supply water, both drinking and technical. Such pipes can also be used in the construction of a hot water supply system.

In addition, asbestos-cement pipes are used in agriculture. There they are needed when installing a melioration system and drainage structures. In private houses, wells are built with their help, using them as casing pipes. In apartment buildings, there is another area of application for asbestos-cement pipes, in addition to supplying water and collecting sewage. These are garbage pipes. They are designed for both solid and liquid waste.

Due to the fire resistance of both the asbestos itself and the structures that include it, such pipes are used to build chimneys. However, there are several limitations in this area of application. In general, asbestos cement is used wherever there is a need for waterproofing, heat resistance, wear resistance and durability.

Specifications and production of products

In practice, asbestos cement is fiber-reinforced concrete. Its production includes the following steps:

- crushing asbestos raw materials obtained from mining enterprises; fluffing asbestos with further cutting of fibers; adding water to the ratio of cement to asbestos 85:15; withdrawing the resulting pulp onto a drum with a mesh structure; winding a film on a rolling pin to give the product the required wall thickness.

Production of products takes place only under strict control in accordance with GOST. The weight of an asbestos-cement pipe per 1 m is from 6 to 11 kg. For example, the weight of 300 mm products is less than 500 mm.

The pressure pipe is available in lengths of 3.95 or 5 meters.Its flow area has the following dimensions: 100, 150, 200, 250, 300, 400 and 500 mm. The weight of the product varies from 45 kg for a 100 mm product to 67 kg for a 150 mm product or 19 kg for a 300 mm product.

Products with a small diameter of 100 and 150 are more suitable for arranging wells or garbage chutes. Their light weight allows their installation in private households. Pipes with a diameter of 300 or more have significant weight, and they are used for laying industrial pipelines.

As well as other products, pressure pipe 300 is waterproof. The diameter of 300 mm allows fast and cheap installation of the system.

Non-pressure products are produced in lengths of 3.95 m, the diameter of which ranges from 100 to 200 mm.

BNT 100 has a weight of 24 kg. Articles 150 have a weight of 37 kg. The non-pressure asbestos-cement pipe 200, whose weight does not exceed 64 kg, provides a clean supply of water through the pipeline, so its installation is popular in the economic sphere.

About asbestos-cement pipes

Particular attention should be paid to the GOST standards for asbestos-cement pipes.

It is important to understand that GOST for asbestos-cement pipes regulates the following requirements:

It is important to understand that GOST for asbestos-cement pipes regulates the following requirements:

- Dimensions of products are defined in GOST 539–80; Methods for testing structures are described in GOST 11310–90.

If you study historical information, it turns out that in the days of the USSR, an asbestos-cement pipe was a strictly funded material. Most often, the use of these products was limited to reclamation facilities. At the same time, asbestos structures that would be used in construction did not exist.

Combining with a coupling, not amenable to pressure and pressure

The second type of connector is a non-pressure coupling. This type of connector is in most cases used for pipeline systems when installing a cable network, mainly in a moisture-intensive environment.

This can be achieved by drilling two holes in the coupling, the diameter of which is about 2 cm.

First of all, before the process of installing pipeline elements, at the ends of the parts to be connected, you need to make marks for the location of the coupling. This is necessary for centralization. In this case, the process of mounting the coupling does not differ; a coupling is put on a previously prepared pipe.

The pipe should already be in the ditch. Next, you need to provide clearance. The pipe to be connected advances precisely until it is formed with a size of about 5 mm.

After all, according to the requirements, the part is centralized.

To ensure the tightness of the joints, it is necessary to protect them with a special tape. The width of the tape is about 7 cm. Next, it is necessary to move the connecting part to the required joint location, tracking the holes according to the markings and ensuring that the coupling connects the elements of the two products to be joined.

To create a proportional gap for the rings, it is necessary to insert special wedges made of wood into the coupling. The mounting gap must be sealed with fiber obtained from the processing of flax. It is necessary to seal approximately one third of the gap between the end face of the product and one of the edges of the coupling.

A substance of organic origin in a molten state must be poured into one of the holes. This must be done until the substance is visible in the second of the holes.

This is how the connecting space is filled. It should be borne in mind that after pouring the substance, it is necessary to let the whole structure stand still, it is impossible to dry the substance with burners or dryers. It should harden on its own.

Alternatively, the joining process can be done using a solution of sand and cement. In this case, a distinctive feature of the installation is that it is not necessary to drill special holes in the connector.

Chrysotile cement and ceramic products

Chrysotile cement pipelines are a type of asbestos products. Their production has just begun. The difference between the two types of materials is that chrysotile is as safe as possible for health and the environment.

Asbestos-cement coupling is used to connect ceramic pipelines

It is assigned to the group of carcinogens, since after entering the body it remains in it for a long time, since it is excreted from it extremely slowly.

The installation of the pipeline between each other involves cutting the line. Sawing leads to the formation of a saw, which makes the products harmful. When working with the material, it is strongly recommended to use a respirator.

It is because of the pathogenic effect of amphibole on the body that chrysotope is used today. The way the pipe is marked indicates that chrysotile cement products have greater strength. For example, BNT-100 is suitable for systems with a small load, and BNT 150 is versatile and can be used in any system.

The use of asbestos couplings for connecting asbestos-cement pipes

To perform the process relating to the connection of asbestos-cement pipes, plastic couplings for asbestos pipes are used. This kind of connection acts as a common way of joining non-pressure asbestos-cement pipes to each other.

This is the case if a pipeline intended for communication cables is being laid. The method is used exclusively when working with tubular products, the diameter of which reaches 100mm - 300mm. If their installation is carried out in dry ground. Before the joints between the pipes are connected, the thermal heating of the coupling must be performed. To solve this problem, warming it up lasts 10 minutes at least. For this purpose, water is also used, which heats up in the tank and reaches a temperature of 100 ° C.

Dimensions of internal diameters are for reference only.

Further, one end of the coupling, which is in a hot state, must be put on the asbestos-cement pipe. However, it is worth clarifying that the product is laid a little earlier at the place of its future location than its connection is made. After the internal partition begins to interfere with the movement of the product, it is necessary to insert the asbestos-cement product with its second end from the opposite side until it stops, which creates the internal partition of the coupling.

Initially, asbestos-cement couplings for a pipe with a diameter of 500 mm are pushed onto the end of the pipe product. It, in turn, should already be in its location. The end of the coupling, equipped with a shoulder, which tends to protrude inwards, must be at a sufficiently close distance to the end of the product, which is intended for connection. The coupling must initially be pushed onto the tubular product more strongly and further than its length suggests. Next is the laying of the second pipe. In what working position the connecting element should be located is marked with a pencil using a template.

according to the outer diameter of the pipe

by wall thickness

The coupling must be in a symmetrical position relative to the position in which the end of the connected products is located. The installation of rubber rings is carried out precisely in the plane that is perpendicular to the placement of the longitudinal axis of the asbestos-cement tubular product. Their position cannot be skewed or twisted. The pipes are subjected to a centering process after the rubber track and fittings are placed on them. How easy it will be to pull the coupling depends on the competent implementation of the centering of the products. In order to pull the double-breasted clutch onto the joint, screw jacks are usually used.Centering the placement of pipes and checking the accuracy is carried out with a cord and a sight. They are fixed with the help of backfill, and compacted on both sides with soil. Connecting asbestos-cement products with a double-breasted coupling, we monitor the degree of dryness of the connecting ends of the pipes. This indicator is important in order to avoid sliding along them, which is inherent in sealing rubber rings during tightening of the connecting part.

Do-it-yourself brick chimney for a solid fuel boiler

In itself, the construction of the pipe is not difficult, especially for those who already had experience with similar material.

However, during construction, it is important to take into account some features that will allow you to create a reliable and durable structure. It will effectively cope with the effects of condensate and precipitation.

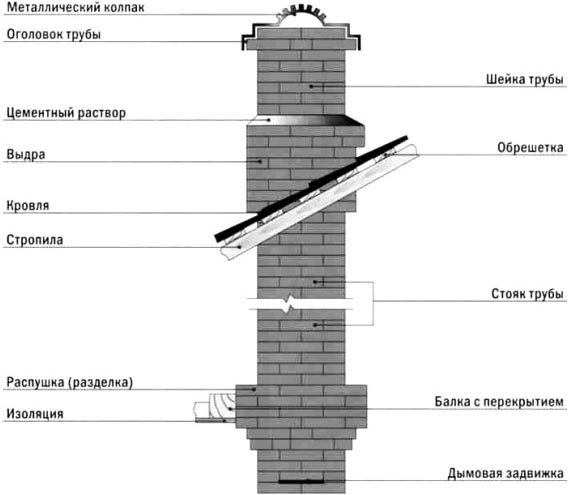

Brick chimney diagram: main components

Important: A brick chimney for a boiler can only be installed during the construction of a house, since such a pipe will have a considerable weight and will require a solid foundation at its core. The height of the foundation should be at least 30 cm, and the width should be selected based on the width of the structure itself: the foundation should exceed it by 15-50 cm on each side

The height of the foundation should be at least 30 cm, and the width should be selected based on the width of the structure itself: the foundation should exceed it by 15-50 cm on each side.

If the boiler chimney becomes part of an external wall, the foundation must also come out and be the lower level of the wall foundation.

- For laying out, it is necessary to use refractory bricks M75 or M50. To fix them, a cement mortar or a mixture of cement and lime is suitable. A high-quality chimney can be obtained by performing masonry with dressing: ensuring that the seams of the previous row are overlapped by the next.

- When erecting, it is necessary to process the inner surface and rid it of roughness.

- It is better to finish the upper part of the chimney for the boiler with a head protruding 10 cm beyond the brick base.

Under the head, you can add ventilation holes that will prevent air from blowing in. They must be placed on two opposite walls or on each side.

Compliance with these principles will allow you to create a chimney for a solid fuel boiler on your own, whether it is a straight pipe through the roof or going into the wall. Each design method has its own advantages:

- A chimney passing through an attic or roof will give off heat to all rooms through which it passes, therefore it is suitable for two or more storey buildings. In addition, it is easy to build.

- A chimney passing through a wall is compact and safer than a conventional chimney.

↓ Be sure to read the recommended material on the topic ↓

Blows the boiler through the chimney: what to do and how to prevent

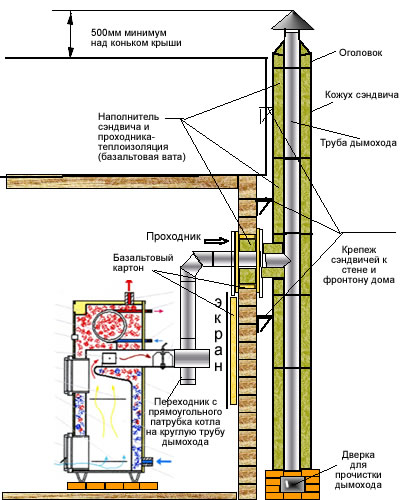

Scheme of installation of a metal smoke exhaust pipe

Tip: A metal pipe can be added to the inside of a brick chimney for a boiler, which will protect the walls from soot.

Video: tips for choosing and calculating a chimney for a solid fuel boiler

Thus, brick chimneys for boilers are the most optimal if the complexity, cost and reliability of construction are compared. Therefore, having studied all the necessary information, you can purchase materials and start building a chimney with your own hands.

Browse other related topics

Aerodynamic calculation of the chimney of boiler plants with natural draft

Do-it-yourself ceramic chimney installation, tips and tricks

Independent calculation of the section and height of the chimney

Chimney design for solid fuel boiler

It does not matter what material you prefer for arranging the smoke exhaust system. All chimneys for TT boilers have similar

A structure that includes the following parts:

- A pipe or a chimney is the fate of a round or rectangular shape, through which the combustion products move from the boiler to the external environment. The pipe material must be strong and heat resistant in order to withstand the high temperature of the flue gases.

- The condensate collection unit is a necessary element of the chimney. Everyone knows the law of physics: when hot air comes into contact with a cold object, small particles of moisture form - condensate. They settle on the walls of the surface. The condensate collector, as you understand, serves to remove excess moisture from the system. It is formed in the upper part of the smoke exhaust system and can drain down, risking getting inside the boiler. Therefore, the collector is mounted at the bottom of the chimney. Thus, the boiler and the chimney do not come into direct contact, but are connected to each other through a special tee.

- A damper is a special valve that can block the access of air from the boiler to the system. It closes when the boiler is not working so that the heat does not escape into the pipe.

- Revision hole - it is located immediately on top of the condensate collector. It is through it that moisture is removed from the system.

This is the general design of the chimney. Of course, it may vary depending on the material. For example, a steel chimney has a linear deformation compensator - this is a unit that maintains the strength of the structure and its tightness. The fact is that with regular heating / cooling, a steel chimney can “walk”, violating the docking density.

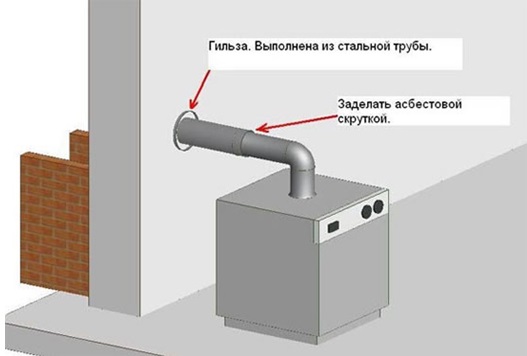

Installation of a chimney from asbestos pipes

To build a chimney from an asbestos pipe with your own hands, you must:

- at the first stage, prepare all the materials and tools necessary for installation;

- read the instructions for assembly and installation of the chimney.

Preparatory work

To independently assemble and install a chimney from an asbestos-cement pipe for a gas boiler, stove or fireplace, you must prepare:

- pipes of suitable diameter and length;

- couplings and asbestos-cement cord for insulation of pipe joints;

- reinforced concrete or brick base for the chimney;

- fastening clamps;

- insulation;

- adapter from the boiler pipe to the chimney pipe. As a rule, the heater is not immediately connected to asbestos-cement pipes, which increases the level of fire safety;

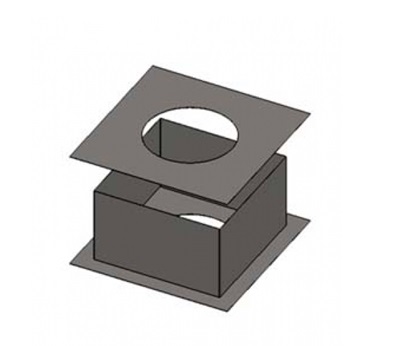

- cutting - a special device installed on the chimney when passing through the floors of the house;

Device for conducting a chimney through the ceiling

roof penetration for the safe removal of pipes to the roof of the house;

Device for bringing the chimney to the roof

a head, which is intended to protect the pipe from precipitation and is installed at the end of the chimney;

Device for protecting the chimney from precipitation

measuring tools, marking tools, drill, screwdriver, screwdriver.

If it is not possible to mount the chimney strictly vertically, then the channel bends are equipped with stainless steel pipes.

Assembly and installation

Main assembly steps:

- the base for the chimney is installed;

- along the entire length of the chimney, marking and installation of fastening couplings is carried out;

- an adapter is installed on the heater, to which the first asbestos-cement pipe for the chimney is fixed;

The correct way to connect the pipe to the heater

- with the help of couplings and an asbestos cord, a chimney is assembled;

- when the channel passes through the ceiling, a cutting is mounted, and when passing through the roof, a passage is installed. See the video for how to properly install the roof duct;

- the chimney ends with the installation of the head;

- along the entire length of the chimney is fixed to the walls with clamps;

Fixing the chimney with clamps

- the smoke exhaust system is insulated.

Chimney insulation with mineral wool

When building a chimney from asbestos-cement pipes, it is recommended to strictly follow all the rules that will increase the level of safe use of the system.

Preparing for pipeline assembly

The connection of asbestos-cement pipes in any way is carried out exclusively at the site of the pipeline, that is, directly in the prepared trench. Pre-assembly of the pipeline and its further laying is strictly prohibited, since there is a high probability of damage to the connections and depressurization of the system (leak formation).

The trench for the pipeline is made according to the following rules:

- the dimensions of the trench should be 25 - 30 cm larger than the diameter of the pipes being laid;

- in the proposed places of pipe joining, pits are equipped, the width of which is similar to the width of the trench, the length is 65–70 cm, and the depth is 10–20 cm more;

- the shape of the trench should be chosen so that the pipes to be laid are in contact with the ground for ¼ of the surface. This will increase the service life of asbestos pipes;

- the bottom of the trench and pit must be equipped with a sand cushion, 7–10 cm high. The density of sand laying should be more than 95%;

- cutting and laying of pipes along the entire length of the pipeline is carried out (in accordance with the system diagram).

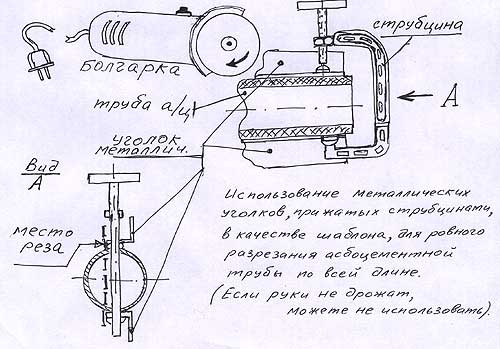

How to cut asbestos pipes correctly, see the video.

Chimney Requirements

We recommend that you carefully read the instruction manual for your boiler before proceeding with the construction of the chimney. It should indicate clear requirements for a chimney that is suitable for a particular model. If you did not find such information, then you can make a chimney from the material that you like best. But the following requirements must be met:

The structure must be vertical - this contributes to the effective removal of gas.

The cross-sectional area of the pipe must necessarily be greater than or equal to the cross-sectional area of the boiler outlet pipe. Less - no way!

Mounting the head (deflector) is required. If your roof is made of flammable material, then a spark arrestor is a must.

Carefully choose a place for mounting the headband. It is installed in the area of wind backwater. How to find it? Visually look for the point closest to the top of the chimney (roof ridge, tree, etc.). Mentally draw a line from this point to the horizon at an angle of 45º. The cap should be placed above this line.

The assembly of the chimney is quite simple: one element is simply inserted into another. However, there are 2 ways of such installation:

- by condensate - with this method, the parts are inserted into each other, based on the direction of condensate flow through the pipe. This option is used if there is no condensate collector in the chimney design. If it is, then part of the chimney from the boiler to the collector is constructed "by condensate", and the rest - "by smoke".

- along the smoke - as you probably already understood, with this option, the elements are mounted in the direction of movement of the combustion products.

It is no secret that the speed of removal and release of hot gases into the environment depends on the thrust force. The thrust force is a technical characteristic of the chimney itself, which shows the efficiency of its operation.

The draft force is influenced by such parameters of the chimney as its diameter, height, cross-sectional size.

- if the uppermost part of the chimney is already made, then the smoke will come out of the chimney faster, which is a plus.

- Maximum verticality, that is, a small number of branches and horizontal, inclined sections, this will increase traction.

How to determine the efficiency of the chimney?

Low efficiency - it is possible due to the illiterate design of the system, as well as due to loose joining of elements. Usually this is noticed already at the assembly stage, so everything can be fixed in time.Otherwise, you will have to disassemble the already assembled chimney and mount it again.

High efficiency - in this case, during the operation of the boiler, an audible buzz is observed in the pipes. You can use a gate valve that can partially block the pipe, thus adjusting the intensity of gas removal.