Methods for flushing heating systems

Currently, one of three technologies is used to clean water heating systems:

- chemical washing;

- hydrodynamic washing;

- pneumohydropulse washing.

Chemical washing technology.

Hydrochemical flushing of water heating systems is much more effective than other methods of removing mud and salt deposits, and therefore is the most popular today. It allows you to quickly and fully restore the throughput and operating parameters of the heating circuit of any size. To remove unwanted formations by chemical cleaning, the following compositions are used:

- alkalis;

- solvents;

- complexones;

- dilute mineral acids;

- dilute organic acids;

- composite solutions.

Various chemical compositions can be supplied both in the form of liquids and in the form of powders.

Results of hydrochemical cleaning of the heat exchanger.

Before choosing the composition with which hydrochemical washing will be carried out, a diagnostic procedure should be carried out. It will allow you to determine the composition of scale and other contaminants formed inside the heating circuit. Based on the data obtained and taking into account the material of pipes and devices, not only the reagent is selected, but also the equipment through which the flushing will be carried out, as well as the technological schedule. For chemical flushing, special pumps are used that are connected to the heating system using hoses. Before starting the operation, the chemical solution is poured into a container, the volume of which corresponds to the scale of the heating system.

The use of chemicals is the only way by which boilers of autonomous heating systems can be flushed, the heat exchangers of which consist of small diameter tubes. If in a single-circuit boiler the appearance of scale can be prevented by using prepared water in the heating system, then for double-circuit units that heat running water, this problem never loses its relevance.

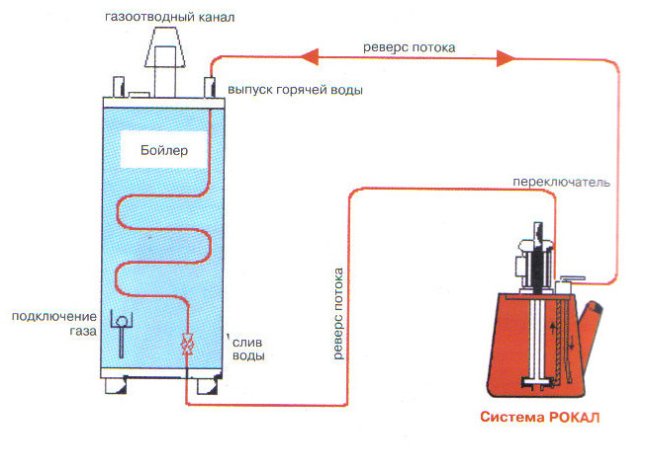

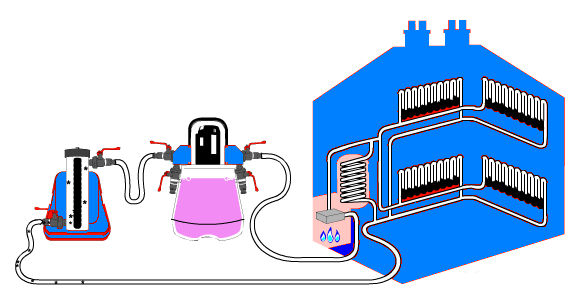

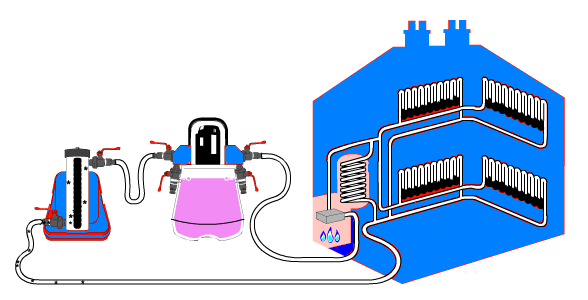

Flushing the boiler - scheme.

A significant disadvantage of the hydrochemical method for cleaning pipes and radiators is its toxicity. Therefore, when carrying out work, the safety instructions must be observed with particular care. It is better for owners of private housing to contact a specialized organization, flushing the heating system on their own can end in an emergency. The invited experts will not only correctly select the optimal composition, but also perform preventive treatment of the elements of the heating system, which will extend its service life and prevent the formation of deposits from scale and dirt for a long time.

https://youtube.com/watch?v=aIj4td-6xN8

Flushing the heating system of a private or apartment building by a chemical method can only be carried out after checking all elements and connections for leaks. If any parts of the circuit are made of aluminum, hydrochemical flushing cannot be performed.

Experience shows that regular washing of boilers, pipes and heating radiators with the help of chemicals extends the service life of these elements up to 20 years.

Hydrochemical flushing is carried out for several days, while the heating system is operating normally.

Instructions for flushing the heating system

There are 2 main methods for flushing the heating system, namely:

- using special hydropneumatic equipment;

- using chemicals.

Washing by hydropneumatic method

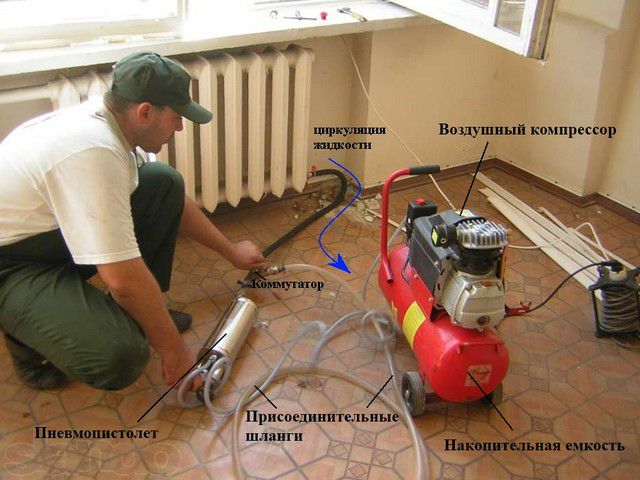

Hydropneumatic flushing of heating systems - instructions

This method is actively used by domestic ZhEKs and is quite effective. You just need to do everything in accordance with technology.

The principle is extremely simple: first, water is discharged from the system, then it is fed back. To "adjust" the water flow, a special pneumatic pump is used. As a result, under the influence of a rather powerful pressure, scale and other deposits peel off, and when the water is drained, they are removed from the system.

To independently carry out such a procedure, you will need a pneumatic pump capable of pumping pressure over 6 kg / cm 2.

The sequence of actions is as follows.

First step.

Close the return valve.

Second step.

We connect the pneumatic pump to the valve installed after the valve.

Third step.

Let's drop the return.

Fourth step.

Let the pneumatic pump build up pressure above 6 kg / cm 2, and then open the valve to which it is connected.

Fifth step.

We cover all the risers one by one. We do this so that at one moment no more than 10 risers are blocked. Following this rule will make the flushing procedure as efficient as possible.

Sixth step.

We transfer the system to reset in the opposite direction. To do this, we do the following:

- close the discharge and close the valve connected to the pump and turn off the device;

- close the open valve, and then open a similar one on the "return";

- reset the heating system. To do this, we connect the pneumatic pump to the valve in the opposite direction, after which we open the valve and turn on the pump. The fluid will move in the other direction.

You can determine the required duration of flushing "by eye". Is a clear clear fluid coming out of the system? You can finish! Return the valves and valves to their original position and turn off the pump.

Prepare a suitable container to collect dirty water. If desired, you can connect a hose to the battery and ensure that the dirty coolant is discharged into the sewer.

Chemical flush

The use of this method can be resorted to only in two cases, namely:

- if necessary, cleaning the heating system with natural circulation, built using steel pipes. It is advisable to use chemicals in situations where, for any reason, there is no desire to flush the entire system. Most often, blockages are deposited in heat exchangers. The system can silt along the entire perimeter. In the second case, there will be little sense from chemical washing;

- if it is necessary to restore the old heating system. Over decades of operation, pipes can become clogged and overgrown so much that the power of the pneumatic pump will not be enough for effective cleaning. Of course, it would be possible to take a more powerful pump, but no one will give guarantees that the pipes will not burst under such pressure.

The principle of flushing is simple: instead of a coolant, a special solution containing acid and alkali is poured into the system. Then the mixture is circulated for 2-3 hours (if it is not a line with natural circulation that is being cleaned, for this it will be necessary to connect a pneumatic pump), after which it is drained and the pipes are filled with a standard coolant.

Never use such chemical mixtures to clean aluminum pipes. If the products remain intact after such washing, they will serve much less.

Is it possible to flush a separate battery

Now you know how to flush the heating system. However, sometimes it becomes necessary to clean a separate battery. There is a solution for this situation as well.

Purchase a flush faucet from a plumbing store. In addition, you need to purchase a rubber hose and a fitting with a thread that matches the diameter of the purchased flushing valve. Fit the fitting to the hose.

Direct flushing is carried out in the following sequence.

First step.

We connect a flush valve to the heating radiator.

Second step.

We connect the fitting with a hose to the flushing tap.

Third step.

We direct the other end of the rubber hose into the toilet.

Fourth step.

Open the flush valve and leave for 20-30 minutes. In the process of waiting, we hold the hose so that it does not jump out of the toilet.

Hydropneumatic flushing and hydraulic flushing of heating systems

Flushing of heat supply systems is necessary for efficient space heating. This procedure is recommended to be carried out once a year, before hydraulic tests. In extreme cases, you need to flush the heating system at least once every few years - this will help increase the heating efficiency. Owners of private houses will also be able to reduce the cost of heating resources and extend the life of pipelines.

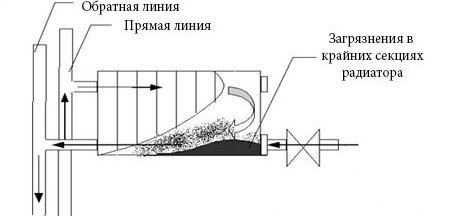

As a result of hydraulic flushing, various deposits are removed from pipes and radiators: scale, rust, scale, etc. Sometimes they occupy more than 2/3 of the pipeline diameter. The thicker the layer of deposits, the more the amount of thermal energy transmitted to the room decreases. You can see what pipes with deposits look like in the photo.

Employees of the housing office should flush the heating systems, and every year. But in practice this is not always done. As a result, hydro-pneumatic flushing of heating systems is carried out by specialized companies that residents of houses apply to.

Chemical flush type

At the moment, such flushing is positioned as the most popular and effective. Its main advantage is that it quickly and without a trace relieves pipes of harmful deposits.

In the process of such washing, various solvents, alkaline-based liquids, complex solutions, as well as compositions made from organic or mineral types of acids are used to achieve the desired effect.

The disadvantage of this type of flushing is that the chemical fluids used are extremely toxic and dangerous. Therefore, when working, it is necessary to be extremely careful and make sure that the solution does not get on the skin or in the eyes.

It is strictly forbidden to use liquids based on alkali or acid if your batteries or radiators are made of aluminum. Also, chemical flushing is not possible if the tightness in any part of the heating system is damaged.

Scheme of chemical flushing of heating. Click to enlarge.

After all, if you show negligence and allow a solution that is actually poison to enter the sewer, this will inevitably lead to such catastrophic consequences as mass poisoning.

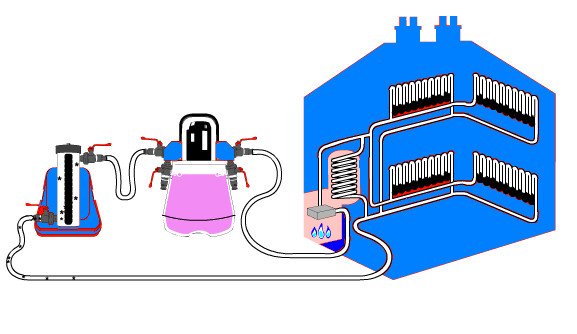

The chemical type of flushing occurs with the help of special tools. The whole structure consists of several hoses, a pump and a container with a solution.

As you know, pipes can be made from a variety of materials - cast iron, alloys, aluminum, steel, brass, copper, etc. Depending on this, the master selects the appropriate pipe cleaners from scale, which will not damage the metal of the system itself.

To make it more convenient for the owners, such cleaning can be carried out gradually, over several days.

If everything is done correctly and all foreign deposits are removed from the walls of pipes and radiators, then the consequence of such work may be an increase in the life of the heating system.

It will be able to work up to 20 years without requiring major repairs. The capacity of the batteries is also improved, heat ceases to disappear.

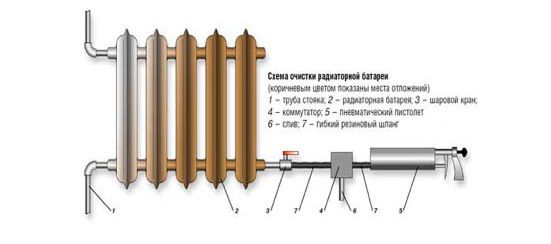

Hydrodynamic flush type

The scheme for flushing heating in a similar way involves the active effect of water on scale and deposits. This happens thanks to a stream of water, which, under the strongest pressure, is directed to the desired area.

Water is supplied through special nozzles of the required size and diameter. This type of washing is more expensive than chemical washing, but the result is much more satisfactory.

Scheme of using the hydrodynamic method of cleaning the heating system. Click to enlarge.

This type of flushing is best suited for batteries made of cast iron. Descaling cast iron with chemicals is very problematic due to the properties of the material itself, and sometimes even impossible.

However, the hydrodynamic system does an excellent job in such cases.

Another undoubted plus is the environmental friendliness of such washing, since no acids and solvents are used. But only water.

To achieve the desired effect, specialists must have a special mechanism that will create a pressure of two hundred or more atmospheres.

Naturally, all scale is removed solely by the action of water. No additional fluids or reagents are needed.

But even here everything is not as simple as it seems. Before flushing with this method, it is necessary to take the radiator to the service. There it will have to be treated with a special liquid so that the layer to be removed becomes softer and more pliable.

Only then can the walls be treated with a jet of water operating under pressure. Using this method, you can remove almost everything: grease, scale, rust, dyes, soot, etc.

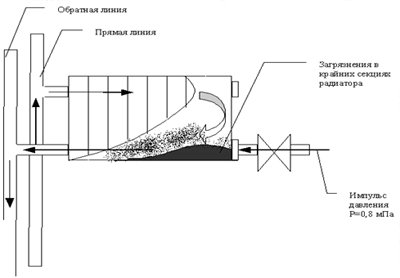

Preparation for hydropneumatic flushing of the heating system

For the process to be successful, it is necessary to take into account the features of the heating system.

Before cleaning, do the following:

- examine communications;

- identify sections of the pipeline that need to be flushed separately, and break the procedures into stages;

- if necessary, install shut-off valves to block pipe sections and remove washed-out deposits;

- make the required calculations to obtain a good washing result;

- determine whether it is necessary to carry out a hydraulic test of the heating structure.

act of hydraulic heating system testing and pipelines

"). The quality of flushing is assessed by the degree of reduction in the hydraulic resistance of pipelines - this indicator is determined before and after the procedure.

Why flush the heating system hydropneumatically

During operation, scale settles on the inner surface of the pipes. It causes malfunctions in the heating circuit. Plaque on the pipe walls shortens the service life of the pipeline. The sediment adversely affects the thermal conductivity of pipes, reducing the level of heat transfer. Since the thermal conductivity of scale is significantly lower than that of the pipe material, heated rooms receive less heat, although fuel consumption remains the same.

Scale damages the metal, leading to the formation of fistulas. This leads to a rupture of the pipe, which has to be repaired at the most inopportune moment.

Flushing of heating pipes from deposits is done once a year. Before proceeding with cleaning, a system diagnosis is carried out. With its help, they determine what kind of deposits have accumulated inside the pipes in order to choose the right equipment for flushing and subsequent anti-corrosion treatment of the pipeline. Processing delays the next processing, keeping pipes clean longer.

The photo clearly shows why you need to clean the communications of the heating system

Scale occurs in the same way as in a kettle: the same heated water circulates through the pipes. Due to thermal effects, substances that are present in abundance in water precipitate, settling on the walls. A millimeter thick layer reduces the heat transfer of the circuit by 15%.