Materials and methods of insulation of the foundation from the outside

In this case, foam, polystyrene foam and polyurethane foam can be used as heat-insulating materials. The latter is applied in the same way as when insulating the foundation from the inside, only before spraying polyurethane foam, it will be necessary to carry out some preparatory work to expose the lower part of the base of the house.

Operative method - insulation with polystyrene foam

For insulation with polystyrene foam or polystyrene foam, it will be necessary to free the entire foundation from the ground. To do this, a trench is dug around the perimeter of the house to the depth of the foundation, about 40-50 centimeters wide. Then the surface is carefully cleaned from the remnants of the earth and leveled (if necessary, of course). Waterproofing is applied to clean, dry walls, and then sheets of insulation are attached to a special adhesive or bituminous mastic. The joints between them are filled with mounting foam (this technique will protect the foundation from moisture penetration).

Important: the top sheets of insulation should rise about 40 cm above the ground level - this will protect both the foundation and the walls from a possible rise in groundwater. After all the work on gluing sheets of expanded polystyrene or polystyrene is completed, you can start backfilling the trench

A layer of sand (10 - 12 cm) is poured onto its bottom, then you can put insulation sheets (or you can not put it), after that - a layer of gravel (60 - 70 cm), and then you can fill it with concrete, you can fill it with the same sand, and you can roll up asphalt. If you are a creative person and love everything original and unusual, then you can decorate everything with stone or tiles.

After all the work on gluing sheets of expanded polystyrene or polystyrene is completed, you can start backfilling the trench. A layer of sand (10 - 12 cm) is poured onto its bottom, then you can put insulation sheets (or you can not put it), after that - a layer of gravel (60 - 70 cm), and then you can fill it with concrete, you can fill it with the same sand, and you can roll up asphalt. If you are a creative person and love everything original and unusual, then you can decorate everything with stone or tiles.

The technology for performing thermal insulation using insulation boards can be viewed on the video:

Ensuring thermal insulation with expanded clay

Another way to insulate the foundation from the outside is to use expanded clay. True, this method is already partially disappearing into oblivion, since it is quite costly and inefficient, although our parents used it when building houses.

The process of expanded clay insulation is in many ways similar to foam insulation. We dig a trench with a width of at least 1 meter to the entire depth of the foundation. A waterproofing material is laid at the bottom of the trench, and expanded clay granules are poured on top. The layer should be thick enough, because expanded clay has very weak thermal insulation properties. Roofing material is laid on top of expanded clay and sand or earth is poured.

If you decide to save on workers and carry out the insulation of the foundation with your own hands, then you can use for these purposes not only modern materials, but also those that were used by our ancestors. True, straw, peat, leaves or needles will be of little use, because if these affordable, natural “insulators” really helped in the fight against cold and frost, would a person begin to look for a replacement for them?

Insulation of the foundation, no matter what they tell you, is necessary in any case, because the weather conditions in Russia are so unpredictable that even the weather forecasters themselves are not able to answer the question of what awaits us tomorrow. Even if you live in Sochi or the Krasnodar Territory, where the temperature usually stays stable around zero, do not take risks, but take care of your home, otherwise it will be too late later.

Why you shouldn't insulate the foundation from the inside

Most experts argue that internal insulation is far from the best way to change the heat resistance of the basement of the foundation. And this is true, because the effectiveness of this technology is doubtful, and the consequences of such a rash decision are obvious.

In addition, such insulation will not shift the dew point into the body of the masonry (or monolith), but only close it, therefore, the effect of moisture condensation in the zone of contact between the warm air of the underground and the cold wall will not disappear anywhere.

In addition, the internal insulation will reduce the already small volume of the subfloor, which will complicate the revision of the basement floor, as well as repair work in the inner part of the basement area.

We warm the foundation with our own hands from the inside - when there are no other options

The process of insulating the base from the inside begins with a thorough preparation of the insulated surface (the inner side of the foundation walls).

To do this, do the following:

- Firstly, to eliminate all defects on the walls of the foundation (to repair cracks, crevices, holes).

- Secondly, apply a layer of frost-resistant waterproofing to the inside of the foundation wall.

- Thirdly, wrap the inner surface of the basement with a layer of vapor barrier, permeable only from the side of the house (top to bottom).

After that, you can proceed to the choice of insulating material and the technology for installing a thermal insulator. Moreover, in most cases, either expanded clay, or backfill soil, or foam panels are used as an insulator.

Accordingly, the soil and expanded clay simply fall asleep in the sinuses of the foundation - in this case, you should immediately forget about a possible revision of the subfloor and its repair. But this method is very cheap and this is its main advantage.

However, bulk thermal insulation can only be arranged in an open foundation, devoid of a basement. Installation of panel insulation can be arranged at any time.

And the operation looks like this:

- Foam panels are glued to the inner surface of the base or fixed with thermal dowels.

- The seams between the panels are filled with mounting foam.

- A reinforcing fiberglass mesh is stretched over the panels.

- A layer of facade plaster is applied along the grid, which increases the fire resistance of the finish.

This method is more expensive, but the effectiveness of this technique is comparable to progressive exterior trim.

At the end of the process of warming the base, care should be taken to ventilate the subfloor. To do this, it is necessary to leave vents in the body of the foundation wall - through holes located on the same axis. In the warm season, the vents are opened, and the natural flow of air removes condensate from the underground that has accumulated during the cold season. Well, in winter, the vents are carefully sealed, preventing heat leakage from the underground.

https://youtube.com/watch?v=VJ8qgpnbQio

About the site

zalman

Insulation of the foundation from the outside

When choosing a material, consider:

- price;

- resistance to deformation under soil pressure;

- lack of predisposition to moisture absorption.

The most popular today are:

- polyfoam, extruded polystyrene foam;

- polyurethane foam;

- expanded clay and gravel.

Let's take a closer look at each type of insulation.

Styrofoam

It is best to start such construction work immediately after the construction of the foundation. If the house has already been built, then in this case it is necessary to dig the base of the building about a meter wide around the entire perimeter, and dry the foundation walls and clean them of all contaminants.

If groundwater runs close enough, then it is necessary to build drainage:

- pour river sand at the bottom of the dug trench and lay geotextiles, and cover with a layer of gravel on top;

- a collector well should be arranged near the building;

- Lay perforated pipes 10 cm in diameter on top of the gravel;

- bring the pipes into the well;

- fill it with gravel, wrap it with geotextile and distribute river sand on top.

Then you can proceed to the insulation of the base of the building as follows:

- coat the basement walls with a latex primer, and then with self-adhesive waterproofing;

- glue the joints with sealant;

- fix the expanded polystyrene sheets on the waterproofing with special glue, applied pointwise in the center and, stepping back a couple of centimeters, along the edges of the sheet;

- press the slab against the waterproofing for a few minutes;

- overlap the next sheet, but a special groove must be applied to the joints;

- foam the resulting gaps, putty with glue and sealant;

- additionally, for fixing sheets above ground level, use plastic dowels with dish-shaped caps.

polyurethane foam

Polyurethane foam is a polymer heat-insulating material applied in liquid form by spraying onto a heat-insulated surface. Without a cylinder or a special machine, this procedure cannot be carried out. Such material combines three functions - heat, sound and waterproofing. Seams and gaps, which usually appear in the process of insulation in other ways, are completely absent in the presented method.

For insulation with polyurethane foam, it is recommended, together with the rented equipment, to invite a specialist who will quickly and professionally perform all the work.

But you can do it yourself. To do this, you need to take into account some features:

- the density of the material should be 0.60 q per 1 cubic meter;

- spraying manipulations should be carried out quickly and confidently, since polyurethane foam hardens in a matter of seconds, otherwise the work will have to be redone;

- it is necessary to apply two or three layers of 1.5 cm each;

- after applying the substance, waterproofing should be carried out.

Expanded clay

Before the advent of modern insulation materials, expanded clay was very popular. It is made from clay, by swelling and hardening. Its main advantage is low cost. However, the need to make significant efforts to lay it cancel this advantage.

A similar method of foundation insulation requires a lot of material, in addition, waterproofing, blind area and land work in large volumes will be required. Therefore, it is recommended to use expanded clay in combination with other methods of insulation.

When choosing this particular method, the technology will be as follows:

- make a trench about 150 cm wide;

- clean the external walls from pollution;

- apply bituminous mastic if there is no waterproofing;

- make drainage if groundwater is close;

- lay a plastic film on the bottom of the trench so that its outer edge is located at the level of the drainage, and the inner edge is at the wall of the base of the building;

- fall asleep on top with dry, cleaned expanded clay and make a blind area.

Insulation of the foundation and blind areas

- expanded polystyrene;

- polyurethane foam;

- Styrofoam.

For insulation with expanded polystyrene, it is better to use sheets of 100 mm in one layer or 50 mm in two layers. A waterproofing high-density polyethylene should be laid over the insulation layer to protect the joints of the expanded polystyrene sheets.

Polyurethane foam is sprayed onto any configuration of the blind area. After about 2-3 hours, the insulation is ready.

Styrofoam to carry out thermal insulation is also not difficult. First you need to level the surface, pour a 15-centimeter layer of sand, moisten and tamp. Then foam plates are laid, and the joints are filled with mounting foam. The foam must be firmly attached to the surface of the base with mounting foam.

How and how to insulate the foundation from the inside

So, you still decided to insulate the foundation from the inside, apparently you had good reasons for this. For thermal insulation of the inner surface of the foundation from the side of the basement or subfloor, it is best to use polyurethane foam, since it is much more convenient to work with it in a limited space, and it will take much less time for such work.

The thermal insulation process itself is very simple - you need to spray polyurethane foam over the entire inner surface of the foundation, while partially catching the basement walls. For greater confidence in your actions, you can insulate the floor and ceiling in the same way. Then you will definitely protect the basement from cold and moisture.That's just then you should carry out work on the decoration of walls, ceiling and floor.

Styrofoam and extruded polystyrene foam can also be used.

Opinion of experts on options for thermal insulation of the foundation

Most builders agree that it is best to insulate the foundation from the outside. In order not to be unfounded, they give quite strong arguments in favor of this method.

Regardless of the type of insulation used and the type of foundation, external thermal insulation helps protect the foundation from freezing, preventing the penetration of low temperatures into the building.

External insulation has a positive effect on the quality of concrete, and on the design of the foundation, after all, maintaining their strength for many years.

Also, the outer insulation is an additional barrier to groundwater, helping the waterproofing to protect the foundation from moisture.

In addition to the lower part of the foundation, the outer insulation resists temperature changes that occur in the upper, basement part of the house when the seasons change.

But there are cases when it is impossible to insulate the foundation from the outside, then, of course, there is no dilemma for the owner and there is only one thing left - to insulate from the inside. In fact, there are not so many advantages, but to be honest, there are only three:

Insulation of the foundation from the inside has a positive effect on the microclimate of the basement and the whole house as a whole.

Internal thermal insulation protects the foundation from groundwater.

Internal insulation does not allow condensate to accumulate in the basement.

In principle, there are positive points, but there are also negative ones:

Yet outside the foundation freezes through.

Due to temperature changes and heaving of the soil, deformations of the foundation occur and cracks appear along its entire perimeter.

What good is it that the foundation, so carefully built by you, in a few years will begin to crumble and collapse?

Why you shouldn't insulate the foundation from the inside

We list the main reasons why internal thermal insulation is not recommended for either load-bearing walls or foundations:

- freezing of reinforced concrete structures. The foundation in this case is not protected from temperature changes in any way, which negatively affects its service life;

- due to the displacement of the dew point to the area of the “insulation-foundation” boundary, it is required to create an additional vapor-tight layer from the side of the room;

- the latter event generally affects the microclimate in the basement, significantly increasing the humidity of the air. Hence - the need for an effective ventilation device and, accordingly, an increase in heating costs;

- reduction of useful internal basement space;

- in the end - an increase in the cost of work and materials compared to the device of external thermal insulation

From the foregoing, an obvious conclusion follows: warming the foundation from the inside is a forced measure, which is used only in cases where the installation of thermal insulation in accordance with the rules of building heat engineering is impossible for good reasons.

When there is no other choice: we insulate the foundation with our own hands from the inside

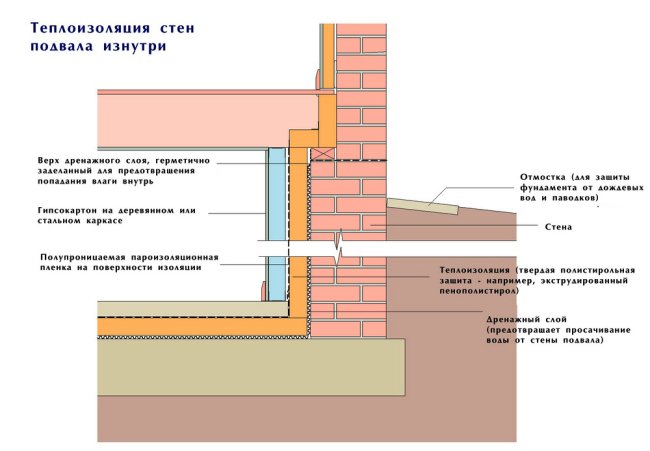

Obviously, such insulation makes sense for deep foundations, the underground part is the basement of the house. All work is carried out in several stages:

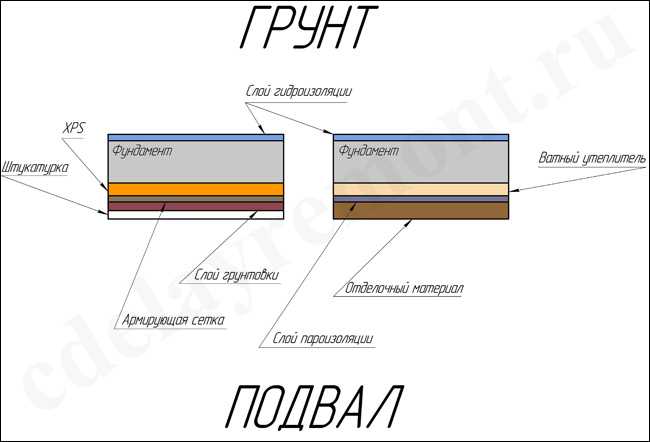

- preparation of the inner surface of the foundation, which consists in cleaning and leveling the base;

- selection of suitable thermal insulation material. It is possible to carry out insulation with polyurethane foam (spraying), extruded polystyrene foam boards or cotton wool insulation. At the same time, it must be taken into account that it will be necessary to create such conditions so that the vapor permeability of the created “pie” is minimal.If we use sprayed polymer compounds or XPS, which already have good performance, there is no need to create an additional vapor barrier layer. In the case of wadded materials, the insulation will have to be additionally isolated from the basement environment;

- calculation of the thickness of thermal insulation;

- fastening materials (or spraying - in the case of polyurethane foam) with bitumen-based adhesives, or dowels;

- further work is reduced to the interior decoration of the basement

Another nuance: all structures adjacent to the walls of the foundation require insulation. We are talking about basements with internal partition walls, which also need to be covered with heat-insulating materials. Otherwise, wet areas will form in the corners of the basement with all the ensuing consequences, and the walls themselves will be cold bridges.

What materials are best to use

When choosing thermal insulation for interior work, it is worth looking not only at their coefficient of thermal conductivity, but also at the behavior of the material under the intended operating conditions. It is believed that the insulation of the foundation with expanded polystyrene is the best option due to comparable high thermal insulation qualities. But at the same time, it must be taken into account that the foam at room temperatures gradually depolymerizes with the formation of styrene. Those. if you plan to use the basement as a full-fledged heated room, then you should think several times about using polystyrene foam insulation. In turn, finishing the premises with plaster materials can significantly reduce the emission of styrene. If you decide to rely on cotton wool insulation, then without fail the insulation must be protected from exposure to moist air by creating a vapor-tight barrier on its surface. The use of sprayed compositions is one of the best options, however, you are unlikely to succeed in carrying out your plan, which is called your own hands - you will have to call in specialists with the appropriate equipment.

Appointment of internal insulation

The main operation, which is carried out as part of the internal insulation of the foundation, is the lining of the basement walls using special sheathing components, which provides:

The scheme of insulation of the walls of the basement from the inside. Click on the photo to enlarge.

- effective reduction of heat loss;

- eliminates the ingress of cold inside the house;

- reducing the likelihood of condensation;

- increase the strength and durability of the foundation.

Depending on the type of heat-insulating material, a different technology of its fastening to the walls is also used. So, when using polyurethane foam, it is sprayed onto the surface, and the foam and other plate materials are mounted on the wall.

Internal thermal insulation has both advantages and disadvantages. The first include the reduction of heat loss and maintaining the optimum temperature in the basement. But if the insulation of the foundation is not done correctly, constant dampness will destroy the heat-insulating material, it will be cold in the basement, and the walls will be covered with mold and fungus.

To avoid the troubles described above, it is necessary not only to insulate the walls with high quality, but also to ensure reliable waterproofing and ventilation.

Why you need to insulate the foundation from the outside

The foundation of a wooden house is a supporting structure that is in direct contact with the natural foundation and the building itself. In addition to its supporting function, the foundation protects housing from the negative effects of the soil.

It is important that the base of the wooden house does not cause heat leakage from the dwelling.

The base of the house is constantly exposed to the penetration of moisture from the soil and changes in ambient temperature.In winter, the moisture that has entered the body of the base of the structure freezes and destroys the support array. Through the cracks, the cold begins to penetrate into the dwelling. As a result, the floors in the house will always be cold in winter. That is why it is necessary to arrange thermal insulation of the base of a wooden house.