How to repair a drainage pump with your own hands

Of all the listed malfunctions of drainage pumps, only a few can be eliminated with your own hands. Really release the float (here the instructions are unlikely to be needed), remove the jammed impeller mechanical inclusions (you can not tighten the impeller, as in the video below), fix the shock absorber, repair the cable. To fix the shock absorber, you need to disassemble the body and simply tighten the nuts on the mounting bolts, locking the top one. This is the simplest of all. Repairing the cable will take time, but it's doable. In some models, it is easy to replace the capacitor.

Everything else cannot be done without craftsmen, and a torn stock is generally so difficult to fix that it is much more expedient to purchase new equipment. It will not be possible to replace the valve on your own (difficult, unprofitable) and repair the winding - you will need specialized tools. However, this does not apply to cheap Chinese pumps: either take them new or repair them yourself, since highly qualified repairs will cost more.

Video: do-it-yourself drain pump repair ↑

The citizen tells us how to fix the device, and what mistakes he made at the same time - he damaged the anchor, broke the impeller (oh, and Chinese impellers are strong). A person works cheerfully, together with a TV, so it is problematic to hear a lot, but everything is perfectly visible. With his own hands, he broke only at the beginning, and then he repaired it.

Repair of the drain pump power cord

If the power cord fails, the pump will not turn on (obviously), but sometimes it is impossible to visually detect a malfunction, that is, the wires are broken inside the insulating cable.

Before trying to repair the cable, you need to understand where it is broken. The two most likely are the connection to the pump, the section at the plug - that is, the most often bent sections. Here you need a medical method - palpation. That is, you will have to squeeze the cable with your fingers so that the broken wires are connected (they still can’t get away from the submarine) - this way you will find the place of the break (if you don’t forget to turn on the equipment).

To fix a cable that is broken where it enters the chassis, it must first be removed. Disassembly required. Surprises can await here: in some GNOMs, the bolts are not designed for tightening with normal screwdrivers - they are made for a 3-lobe bit (rare, now hexagonal holes are more common). The manufacturer's motivation is unknown.

There is a tensioner inside the case. It must be removed by unscrewing 3 bolts. Pull out the tension washer. Remove cable. Cut it off where the wires were broken and put it back in. Here another surprise may lie in wait - a swollen cable will not pass into the hole intended for it. You will have to lubricate it with machine oil (it is better not to consider the option of removing the clutch: you can disfigure the part).

After inserting the cable, put the tensioner in place, tighten the bolts, assemble the circuit, isolate the connections. When installing the cover, make sure that the spike fits into the groove. Don't push.

The composition of the pumping station

The complete set of the pumping station is as follows:

- Pump unit. The main parameters for selecting a separate pump or a finished pumping unit are the required water flow (in cubic meters / hour) and pressure (in meters).

- Pressure accumulator. It is a metal tank in which water pressure is constantly maintained. As soon as water is drawn, the pressure in the tank drops and the pumps turn on. When the pressure in the tank reaches the maximum setpoint (drawing stops and the pump continues to run), the pumps are switched off.

- Automation block.Without automation, it is difficult to imagine a modern pumping station. It was the pump automation system that made it possible to reach a new level of comfortable existence.

How a sump pump works

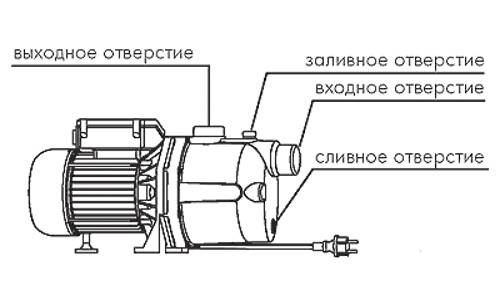

The drain pump works simply:

- the motor drives the impeller mounted on the shaft;

- impeller plates disperse the liquid inside the pump casing;

- under the action of centrifugal force, the liquid enters the outlet;

- the vacated space is immediately occupied by the liquid entering through the inlet.

The holes are located at different levels. It depends on the type of pump: submersible, surface. Submersibles take water from below, not from the side.

Video: Dzhileks drainage pumps ↑

Unplanned do-it-yourself repairs or in the workshop will not be needed if you follow the simple rules for operating the equipment, which are detailed in this video clip of the manufacturer. It also talks about the principle of operation of devices.

1 The main breakdowns of pumps and their diagnostics

The pump is a fairly simple mechanism. Its design is not particularly complex, but this is only a comparative judgment. After all, it has an engine, contacts, an impeller, a shaft, seals, a housing, etc.

All these parts interact with each other, which leads to their gradual wear. As a result, the pump will need to be repaired.

Plus, it is worth noting that the pump works in rather difficult conditions. This does not apply to Gileks surface pumps, which are assembled together with hydraulic accumulators and installed in separate rooms. However, even such equipment often needs repair.

What can we say about submersible pumps, for example, about the representatives of the Jilex Vodomet line. Find such equipment in a well or well all the time. As a rule, it is not taken out for the winter, which only complicates the situation.

It is worth noting that due to the relative simplicity of the design, it is quite possible to repair all equipment with your own hands. This, of course, is not the best option, since if you make a mistake, you will not only not repair the pump, but will only aggravate the situation.

However, in some situations, you can do it only with your own hands. The main thing is to understand the design features of submersible and surface pumps, as well as their connection types.

There are several of the most popular and well-known pump failures that should be highlighted separately. Diagnosing them is also quite easy. For example, if electricity is connected, but the pump simply does not respond, then something has happened to the contacts or the supply wire.

Disassembled submersible pump, the limiter is removed from the upper part of the housing

Checking this is easy enough if you have the opportunity to disassemble the device and diagnose the contacts with a tester. The absence of a signal on one of the contacts indicates its damage. It is possible that by this time it will be damp, will have an unnatural color, etc.

If all the mechanisms do not respond, then the cable is broken. This often happens with submersible water jet pumps, as their cable is suspended and poorly protected.

The rumble in the engine, uneven operation, clicks or “flooding” of the pump are all a consequence of problems with the engine or impeller. You can check the correctness of the theory if you disassemble the device and inspect it yourself. It is possible that the impeller is cracked or the bearings on the rotation shaft are out of order. These are the most common problems.

If the engine simply refuses to work, then the problem is already in it. Moreover, we already recommend not to mess with the engine. This is a rather delicate mechanism, especially for submersible models. For example, the water jet 50/25 pump engine cannot be disassembled at all, but this is typical only for some models.

Most often, the motor winding burns out, it can be replaced, but whether it will be profitable is an urgent question. It is possible that it will be easier to simply replace it with a new one. Moreover, the Gileks company supplies spare parts for its products to almost all stores in the country.

In surface pumps, for example, in Gilex Jumbo stations, the engine can generally burn out or wear out very much. All this is due to the dry running of the pump. Unlike submersible models, surface samples are very susceptible to this moment, and they suffer from dry running quite a bit.

If we are talking about Gilex Jumbo pumping stations, then it is worth noting one more widespread breakdown, which is very common. It is a problem with the pressure in the system.

There may be several reasons for this:

- Problems with the pressure switch;

- Problems with the accumulator;

- Pump problems.

Gileks Jumbo pumping station under renovation

In the first case, the relay itself goes astray. It is easiest to check it, since the relay is easy to configure and rather primitive. If problems appear during setup, then the relay is to blame.

In hydraulic accumulators, the membrane with air can burst or be damaged. This can only be checked by completely or partially disassembling the tank. The lack of sufficient air in the membrane leads to an imbalance of the entire system and, as a result, a pressure drop.

The pump can also react negatively, but this happens extremely rarely. As a rule, working elements fail, and the device simply cannot cope with swapping. But then you would notice the accompanying signs of breakdown. For example, a slight hum, low pressure, poor rotation of the impeller, etc. In all other cases, either the relay or the accumulator is to blame.

Principle of operation

Depending on the type of working part of the pump, the principle of raising water is also different.

Consider the types and brands of pumps:

- Water wheel. It works like a water mill, by scooping up water with blades.

- Archimedes screw. Water is lifted by a special screw lifting device - the impeller.

- Piston pump. Pumps of this type are used for pumping water from mines, country wells.

- Vane pump. This is one of the varieties of piston pump. Used for pumping water, oil and fuel.

- Bellows. The principle of operation is to press a special "accordion" that pumps liquid. Low price. Simple construction.

- Centrifugal pump. The most common type of pump. Works due to centrifugal force. Inside the pump there is an impeller with blades that rotate and eject water from the center to the periphery.

- Jet pump. Pumps water through compressed air or steam.

How to independently identify and eliminate malfunctions in pumping stations

Consider the common breakdowns and malfunctions in the operation of pumping units that occur during operation, the causes and methods for troubleshooting with your own hands.

The pumping device rotates, but water does not flow

Causes The operation of pumps "dry" occurs when an air lock forms in the pipeline. This occurs when the installation rules are not followed. The slope of the pipeline must be directed from the pump to the source of water supply.

In order for the pumping station to start pumping water again, you should check for leaks in the pipes, clean the suction line of the pump. Another reason for the lack of water in the pumping station is the depleted source of water supply (reservoir). In this case, turn off the pump until the source is replenished.

Cause:

- no water;

- suction height more than 7 meters;

- air has accumulated in the suction line of the pipeline;

- clogged valve.

Elimination method:

- fill the pump with water;

- reduce the suction lift of the pump;

- to remove air from the soaking-up pipeline;

- clean the valve.

The pump in the station turns on too often and delivers water in jerks

Most pumping stations have membrane tanks. Frequent switching on and off of the station is associated with damage to the membrane tank or insufficient pressure in the water supply network. For normal operation of the station, it is necessary to replace the membrane tank. Sufficient pressure in the network is checked by a manometer.

Cause of failure:

- the membrane in the expansion tank is damaged;

- foreign objects in the pump.

Elimination method:

- replace expansion tank membrane;

- remove foreign objects from the pump housing.

The pumping station is working, but the water comes in jerks, intermittently

Interruptions in work occur due to air leakage through leaks in pipelines and connections. Check for cracks and leaks and replace pipes or fittings if necessary.

The pump constantly pumps water without interruptions and shutdowns

The reason is a poor or inaccurate setting of the pressure switch, most likely it is set to too much pressure in the network. By adjusting the relay to a lower operating pressure, the problem will be solved.

The water supply or wastewater station does not turn on

The pumping station is usually powered by electricity, the lack of power to the station leads to the shutdown of the pumps, another reason is the pump impeller is stuck or the fuse is blown. You should inspect the pump, check whether the station is correctly connected to the electrical circuit.

A breakdown can occur when the motor winding breaks down, and the smell of burnt insulation appears. In this case, it is better to replace the engine completely.

Cause:

- no power supply;

- fuse failure;

- the impeller is broken.

Remedy:

- pump cleaning;

- turn the fan impeller;

- check the electrical circuit;

- check the pressure switch;

- check capacitor.

The pumping device (impeller) does not rotate and emits a hum

A long idle time of the pumping station leads to the hum of the motor. This happens either from the sticking of the motor rotor to the inner surface of the housing, or the capacitor in the terminal box has failed. You can correct the defect manually by disassembling the housing and advancing the rotor.

Malfunctions of pumping stations

These complex devices are quite reliable in operation. The first problems may arise 4-5 years after the start of work, provided that there were no emergency situations in which the pump had to rotate the impeller without water. And then these malfunctions rarely occur in the engine of the unit, but appear in other elements of the station:

- membrane hydraulic accumulator;

- pressure switch;

- check valve.

The most common problem leading to the complete failure of the pump motor is a check valve malfunction. It begins to let water through due to wear or clogging, the supply pipe is emptied, and the impeller rotates “dry”. Also, the rubber "pear" (membrane) installed in the reservoir of the accumulator may lose its tightness. There are also problems with the pressure switch, then the unit does not turn on when there is a drawdown in the house.

Types of water pumping stations

With built-in ejector

The principle of operation is based on the rise of water due to the created vacuum. The ascent is carried out from a depth of 20 - 45 meters. The pumping station has a large capacity. Due to the high noise level, such a station should be located in the basement.

With remote ejector

A pump with this type of ejector is immersed in water with two pipes at once. Water, entering the ejector, leads to the appearance of a suction jet. This type of pump is prone to sand blockage and corrosion.

Ejectorless designs

In these pumps, water is lifted using a multi-stage design. They operate silently and consume little electricity.

2 Repair of the pumping station Dzhileks

The pumping station is a self-priming surface centrifugal pressure apparatus with an ejector and a piping system. Models of this series are designed for horizontal installation and pump from 3 cubic meters of water per hour. The models differ in the level of engine noise and the presence of automation, which is needed to monitor the water level.

Partial dismantling of the pumping station Dzhleks

The Gileks automation unit must be configured in such a way as to turn off if the water level drops below the declared minimum according to the technical data sheet. If the setting and adjustment of the station is incorrect, it will not turn off in time, which will lead to breakdowns.

Let's consider an example of the repair of the Gileks Jumbo pumping station. They are equipped with a pressure switch RDM 5, a tank with membranes (hydraulic accumulator), an electric motor, a centrifugal pumping apparatus, a water intake with a filter and a piping system. You can monitor the pressure inside the installation using the arrow on the pressure gauge.

There are five main reasons why a station may fail or not work correctly:

- It hums but doesn't work. This happens if you left your device for a long time without water and movement. The impeller could just stick to the body. Twist it by hand and try to connect. If it still does not work, check the voltage level of the mains and the condition of the capacitor.

- Doesn't turn on at all. Ring the network, winding, cable with a tester. Perhaps somewhere the contacts just went away, and as soon as they are connected, everything will work again.

- Pumps water constantly and does not turn off. You need to set up the relay. You can adjust it with two mounting springs or screws (depending on which relay is installed in your station model).

- The flow of water is intermittent. The problem is the depressurization of the pipeline or joints. Also, check the water level.

- Too frequent switching on of the device with uneven water flow. It is necessary to check the relay setting and the integrity of the constituent parts of the accumulator tank. Either you have to change the unusable membrane, or the tank is cracked, or the relay itself is broken.

2 How to repair a Gilex pump

Now consider directly the repair of pumping equipment. It should be understood that the repair of a submersible sample will be different from the repair of a surface one.

To begin with, let's turn to models of the Water Cannon type. The Waterjet pump is a submersible pump that is available in various configurations. There are models of the 40/50, 55/35, 110/110 line, etc. However, they differ not so much in design as in the choice of specific components and dimensions. Otherwise, their design is extremely simple and repeats constantly.

Disconnected consumables, filters and water inlets of the Vodomet pump

Repair of the Water Jet pump always begins with its disassembly. To do this, it must be carefully removed from the well, disconnected from the system and dry the pump from the water.

Remove and dry the device.

Remove the top case or cover.

We remove the water intake mechanisms, you will have to use a vice

But remember that the case is hollow inside, and therefore it is important not to overdo it.

We disassemble the pumping part, if the breakdown lies there, then at this stage you will eliminate it. Otherwise, you will have to move to the engine.

We remove the corkscrew plastic ring and take out the engine.

Carefully pull out the wires and evaluate their condition.

After the repair is completed, fill the engine with non-toxic oil and assemble the pump in the reverse order.

It is important to note that the oil in the engine must be harmless. Glycerin is ideal, as it does not harm or pollute the surrounding fluid.

After disassembling the pump, fixing the problem will be quite easy. Problem contacts can be wiped with alcohol or soldered. Broken wires are replaced with new ones or fastened in an artisanal way.

Damaged consumables or rotating parts are only exchanged.They are cheaper to buy than repair. Well, it’s better to send the engine to a specialist who can disassemble, clean and repair it, and also guarantee you a positive result.

As you can see, disassembling and repairing the Water Cannon pump is quite easy. Moreover, it does not matter which Water Cannon you have chosen, since the design principle remains the same.

Water jet pump, ready for use in the well

They act a little differently when repairing surface pumps and Gilex Jumbo-type stations. Here you need to deal with a specific solution to the problem. If the pump is acting up, then you need to remove the housing and check all systems.

- We disconnect the equipment from electricity, the hydraulic accumulator and drain the liquid in the hose.

- Unscrew the back of the case.

- We remove the moving parts of the body.

- We disassemble the pump chamber.

- We remove the impeller seals.

- Carefully pull out the engine.

- We deal with wires.

- After the repair is completed, we assemble the pump back.

As in the previous case, you can solve the problem with a breakdown at any stage. The advantage of surface pumps is that their body is not one-piece, and it is easier to remove it. In this case, the parts can be inconsistently removed and turned off.

If there are problems with the impeller or consumables, then they are simply changed. You will have to get to the contacts through the engine camera - this is the main problem, but there should not be anything complicated here either.

Hydraulic accumulators are disassembled by disconnecting the hose and unscrewing the plate. Then the membrane is pulled out from there. It is advisable not to repair the relay yourself, as it is very easy to damage it.

The water supply pumping station provides the necessary pressure and water pressure in the pipes in front of the sanitary appliances. Properly selected and installed station will work for a long time, without breakdowns and replacement of expensive equipment. But sooner or later, the working parts of the pumps break down, corrode, and the timely identification of the cause of the breakdown will save time and money on replacing new equipment.

Many problems in the pumping station are fixed on their own, without contacting a service center. Before we learn about the causes of breakdown or incorrect operation of the pumping station and how to eliminate them, let's get acquainted with the very concept of "pumping station", the principle of its operation, types of pumps and its composition.

The purpose of the pumping station

What is the purpose of water supply systems? This is the pumping of water to the consumer from a water supply source (well, river, reservoir), and this requires a special pumping booster device.

It is the pumping unit that takes water through the suction pipelines and transfers it to a residential building or industrial building through pressure pipelines. No water supply system will work without pumping units.

Pumps are needed for supplying water for drinking needs, for extinguishing fires, pumping domestic and industrial wastewater, draining mines and basements, borehole and sand pumps. There are pumps for pumping solutions, feces, clean water, oil products. The selection of the type and brand of the pump is made for each specific case.

Popular models: al ko (alco), grundfos, gardena 3000 4, grundfos, gilex jumbo 60 35, marina, whirlwind, etc.

A few words about adjusting the pressure switch

A pressure switch is a device that automates a pumping station. The relay regulates the pressure in the water supply network, which is maintained by the accumulator. Therefore, the pressure switch and the accumulator always work in pairs.

The pressure switch unit responds when the tank is full or empty. The factory-manufacturer performs the “default” setting (minimum pressure 1.5 atmospheres and 2.5 atmospheres maximum pressure).

After connecting the relay to the pump, the relay is configured for a specific object (set water pressure in the system by technologists).

Setting up the relay for an individual project:

- The relay housing is opened, where the relay control units are located. The minimum pressure is adjusted by the tension of the large spring, and the maximum by the tension of the small spring.

- The adjustment of the "minimum" pressure is started on an empty drive. For what it is enough to turn off the pump and open the tap. Then loosen the big spring. Then turn on the pump and gradually tighten the spring. As soon as the pump begins to supply water, the large spring is no longer touched, the minimum pressure has become equal to the pressure of the air mass.

- Differential pressure adjustment is even easier. The pump is turned off and the pressure on the relay is measured. If the result is not satisfactory, the large or small spring is adjusted again. After that, the pump is turned on again and the value of the maximum pressure is measured.