DEVICE AND PRINCIPLE OF WORK.

The device consists of the following components and parts: a tank-heat exchanger, a main burner, an ignition burner unit with a thermocouple and an ignition electrode installed in it, a combined gas valve (multifunctional regulator), a draft stabilizer, lining parts.

In the upper part of the tank - heat exchanger, a temperature controller sensor is installed, connected by a capillary tube to the thermostatic valve actuator ("bellows - thermoballoon" system), and a thermometer sensor

The design feature of the 630 EUROSIT combined valve is the presence of a device for stabilizing the outlet gas pressure, as well as the combination of valve control in one handle with the designation of the positions by the corresponding symbols and numbers on its end face and the pointer on the valve cover. The dependence of the temperature of the heated water on the position of the control knob scale is shown below:

The principle of operation of the temperature controller is based on the expansion of the liquid when heated. The working fluid, heated in the sensor (thermoballoon) from the water in the heat exchanger tank, heated by the combustion of natural gas, expands and flows through the capillary tube into the bellows, which converts the volume expansion into a linear movement of the mechanism that drives the system of two valves (instantaneous and dosing ). The design of the mechanism provides protection against thermal overload, which protects the system "bellows - bulb" from damage and depressurization.

- When setting the desired water temperature in the apparatus with the control knob to increase, the instantaneous (click) valve first opens, then the dosing valve.

- When the water temperature in the device reaches the set value, the dosing valve is smoothly closed, transferring the main burner to the "small gas" mode.

- When the temperature rises above the set value, an instantaneous (click) valve is activated, completely shutting off the gas to the main burner.

- In the absence of draft in the chimney, the exhaust gases from the furnace heat the draft sensor, the sensor is triggered by opening the normally closed contacts of the thermocouple circuit. The electromagnetic (inlet) valve closes and shuts off gas access to the main and pilot burners. The draft sensor is designed to operate during the absence of thrust for at least 10 seconds.

- When the gas supply from the network is interrupted, the pilot burner instantly goes out, the thermocouple cools down, the electromagnetic valve closes, blocking the gas access to the main and pilot burners. When the gas supply is resumed, the passage through the apparatus is completely blocked.

- When the gas pressure in the network drops below 0.65 kPa, the gas pressure on the pilot burner will also drop, the thermocouple EMF will drop to a value insufficient to hold the valve. The solenoid valve will close and cut off the gas supply to the burners.

SAFETY INSTRUCTIONS

Persons who have studied this passport are allowed to service the device.

The installation and operation of the apparatus must comply with the requirements of the Rules for the Design and Safety of Operation of Hot Water Boilers, Water Heaters and Steam Boilers with Overpressure, as well as the requirements of the Safety Rules for Gas Distribution and Gas Consumption Systems. PB 12 - 529", approved by the Gosgortekhnadzor of Russia.

The operation of the devices must be carried out in accordance with the "Fire Safety Rules for residential buildings, hotels, hostels, buildings of administrative institutions and individual garages PPB - 01 - 03".

The operation of the device is allowed only with serviceable automatic safety and thermal control.

Gas safety automatics should provide:

- Reducing the gas supply when the water temperature in the heating system reaches the set value.

- Shutdown of gas supply to the main burner when the set heating temperature is exceeded.

- Turn off the gas supply to the device in the following cases:

- when the gas supply to the apparatus is interrupted (for a time not exceeding 60 seconds);

- in the absence of draft depression or in the boiler furnace (for a time not less than 10 seconds and not more than 60 seconds);

- when the torch of the pilot burner goes out (for a time not exceeding 60 seconds).

During operation of the device, the temperature of hot water must not exceed 95 °C.

It is forbidden:

- operate the device with the heating system partially filled with water;

- use other liquids as a heat carrier instead of water**;

- install shut-off and control valves on the supply line and the pipeline connecting the heating system with the expansion tank;

- operate the device in case of gas leakage through the gas pipeline connections;

- use an open flame to detect gas leaks;

- operate the device in case of a malfunction of the gas network, chimney or automation;

- independently troubleshoot the device;

- make any structural changes to the apparatus, gas pipeline and heating system.

When the machine is not in operation, all gas valves: in front of the burner and on the gas pipeline in front of the machine, must be in the closed position (the handle of the valve is perpendicular to the gas pipeline).

All malfunctions during the operation of the apparatus on gas must be immediately reported to the emergency service of the operating enterprise of the gas economy.

If gas is found in a room, immediately stop its supply, ventilate all rooms and call an emergency or repair service. Until the malfunction is eliminated, it is forbidden to light matches in the room, smoke, use

** It is allowed to use household coolant "Olga" (manufacturer: CJSC "Plant of Organic Products") according to the instructions for use. After a period of operation, the coolant must be drained and disposed of.

The manufacturer reserves the right to make changes to the design and appearance of the product.

This technical documentation may differ from the description above, see the instruction manual enclosed with each boiler upon purchase.

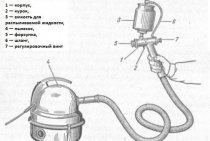

What does automation for gas heating boilers AOGV consist of?

A standard automatic system should have several basic elements.

Ignition elements. There is no burning torch in modern systems. The pilot burner is ignited by a piezoelectric element, which produces electrical energy as a result of mechanical pressure on the crystal. There are systems in which you need to open the gas supply valve with one hand, and press the piezo ignition button with the other. In the most modern boilers, one button is responsible for the operation of both processes. Further control of the gas valve is carried out in one of two ways:

- Due to the voltage that occurs when the thermocouple is heated.

- By heating an additional thermal generator (more often used in imported boilers).

Automation of gas boilers AOGV most often works due to the energy of a thermocouple.

In both cases, the generated energy creates a voltage that acts on the gas valve coil. It remains open, providing gas supply, as long as the gas burner is lit.

Thermoregulation system. These elements control the temperature of the water. They consist of a temperature sensor and a system of valves that shut off the flow of gas when the set temperature is reached. In the most modern models of boilers, a room thermostat has been added to the control circuit, which, depending on the temperature in the room, gives a signal and the need to close or open the gas supply valve.

Control elements for efficient and safe removal of combustion products. This is a draft sensor that is mounted in the chimney. Wires connect the draft sensor to the gas valve.In the absence of optimal traction, a signal is sent to the valve, it closes and stops the gas supply.

Automation for gas heating boilers does not allow you to turn on the gas supply, if the performance indicators of the equipment go astray, the slightest breakdown or depressurization of pipes occurs.

Additional elements and possibilities of automation

In some models, automation for gas boilers AOGV is equipped with a thermostat that provides regulation of gas flow. The reason for reducing the intensity of work may be an increase in the temperature outside or a thermostat signal in one of the rooms that the maximum allowable temperature has been exceeded.

Models that are mounted in the "Smart Home" system suggest the possibility of remote control of heating modes.

A modern, correctly installed and adjusted automatic system on heating equipment helps to reduce heating costs by 40%.

Distinctive characteristics of boilers

Among buyers, boilers of the Universal and Economy models are especially popular. There are significant differences in the technical characteristics of AOGV 116 of these series. The Economy version is manufactured using Russian automation; this unit can be controlled using a solenoid valve and a temperature control knob. They are connected to a thrust sensor and a thermocouple - one of the most important elements of the device.

Boiler AOGV 11.6 series The station wagon is produced on the basis of Italian automation

. The unit is distinguished by the presence of an automatic thermostat and piezo ignition. The device can be turned on by pressing just one button, while there is no attachment to electricity networks.

Features of AOGV

The abbreviation AOGV stands for simply - a gas water heating apparatus. The number after the letters indicates the power of the model, that is, the AOGV 116 boiler is a unit of 11.6 kW, respectively.

The technical characteristics of AOGV 11 6 3 indicate that the boiler is intended for heating a residential private house, a garage or a small utility room. The model is presented only in the floor version, household units have a power in the range of 11-29 kW. The fuel used to operate the device is natural gas.

At the bottom of the boiler is a heat exchanger, under it is a gas burner. It is she who heats the water. The unit can be converted

for the use of liquefied gas. High quality steel is used to manufacture the body of the device. The heat exchanger is made of tubes, which ensures a high efficiency of the device.

In this video you will learn how to light the boiler AOGV 11.5

On the back there are two fittings for inlet and outlet. The top one works with a straight line, the bottom one with a reverse one. The upper part of the body is attached to the chimney, its diameter must exceed 12 cm. Manufacturers produce two types of boilers - single and double-circuit boilers. The latter are intended not only for heating, but also for heating water.

Advantages and disadvantages

Among all the characteristics of the AOGV 11.6 boiler, its main advantages and disadvantages are distinguished. There are several main advantages:

- the possibility of using natural and liquefied gas as a fuel;

- energy independence;

- compatibility with any system material;

- uninterrupted operation with natural and forced circulation.

The unit can be connected to any heating system. It can be made of cast iron, metal-plastic, polypropylene or steel. That is why such boilers are considered universal. There are also some disadvantages of devices:

- the Economy series is made using obsolete parts;

- in the event of a breakdown, it is difficult for craftsmen to find suitable parts;

- compared to other units, this version has a rather high price.

Since Economy boilers are produced using elements made according to samples of Soviet engineers, it is very difficult to replace them during repairs. Better not to buy the cheapest options

, and opt for Universal. Although in the case of buying models with imported parts, difficulties also arise, since they are not available on the domestic market. You will have to order replacements for damaged items directly from the manufacturer. The average cost of boilers is 11-17 thousand rubles, which significantly exceeds the price of units from other manufacturers.

Gas boilers AKGV

The abbreviation of the Borinsky gas equipment of the AKGV series stands for combined gas apparatus with a water circuit. In fact, this is the same AOGV only with a built-in second coil for the DHW system. Line feature:

- leaky combustion chamber;

- two coils - heating + hot water supply;

- non-volatile automation.

This line is also equipped with sensors that prevent overheating of the coolant, turn off the boiler if the draft in the chimney disappears or the wick flame goes out. A gas pressure stabilizer and a mechanical filter are installed, which positively affects the operation of the heater. The burner is made of stainless steel, both coils are copper. The characteristics, the principle of operation of the boiler and protective mechanisms are the same as in the line of the Borinsky AOGV gas equipment. Fuel is natural gas only. All models are floor standing.

The DHW circuit requires special attention. The product passport states that it is not allowed to heat water for household needs directly from the water supply. That is, in transit, as, for example, in parapet boilers, water cannot be heated. Because of this, scale will form on the walls of the coil, as a result of which heat transfer will decrease, the conditional passage will decrease (up to the complete cessation of circulation), the coil will burn out. There is only one way out - the installation of an indirect heating boiler in the heating system.

AKGV series

Floor-standing boilers with a double-circuit heating system are also presented here. Boilers of this series require high-quality ventilation, which will remove combustion products, and a separate room. True, as the reviews of the models of this series show, you can also buy a gas boiler for installation in the kitchen.

- The burner power in these units varies from 11.5 to 29 kW. The most popular model has a power of 17 kW and heats a room of 150 square meters. meters

- The boiler is equipped with a bithermic heat exchanger - a coil is installed inside the tank, which is responsible for heating the water to the desired temperature

- The burner of the device has anti-corrosion properties

- Equipment for heating is equipped with a thermostat, a temperature control system and control of gas supply and draft in the system

Also, the AKGV series is distinguished by the fact that the outer walls do not heat up during operation, and with sudden gusts of wind, the thrust will not disappear due to a special stabilizing element.

You can buy a Borinsky heating boiler of the AKGV series for 250 USD, and you can buy Borinsky gas heating boilers with a higher power of 23 kW for $360. What do reviews say about the powerful model of the AKGV 23 heating boiler?

Anastasia, 32 years old:

I am glad that this model belongs to non-volatile, with constant power outages, parents always have a problem. It also heats the water well, but I won’t say that there is enough pressure for all needs - it’s enough to wash the dishes. ”

3. AOGV series - here are gas single-circuit boilers designed for space heating. The devices of this series are floor-standing units operating on natural gas.

AOGV models are made in a cylindrical body and are represented by several “sub-series” - an economy version with a Russian-made control unit, a universal device with a control unit from Italian brands and a comfortable unit, where the automation is presented by a German manufacturer.

- Floor-standing gas boilers Borinsky AOGV have a thermal power of 11.5 to 29 kW.

- Are intended for heating of rooms from 40 (at the minimum power) to 250 sq.m. meters (maximum boiler power).

- Gas boilers are equipped with an automatic system for stopping the gas supply in the absence of draft and fuse on the burner.

- Equipped with a thermostat with a temperature range up to +95 degrees.

You can buy a Borinsky boiler of the AOGV series for 220 USD. - such a model will have a minimum power, a unit for a large house with a maximum power will cost 450-490 dollars. Let's look at the reviews of the mid-range model with a power of 23 kW.

Alexander, 37 years old:

In general, I bought a model with Italian automatics for my 150 squares. I want to say that the efficiency is really about 90%, and the gas consumption is small - somewhere around 1.7 kg / hour (balloon). I am satisfied with the device and have not been overjoyed for half a year now.”

4. The KOV series are single-circuit floor-standing boilers, which are distinguished by high power and are designed for heating impressive rooms.

- Borinsky boilers KOV have a capacity of 30 to 63 kW;

- Equipped with automation from an Italian manufacturer;

- Are intended for heating of the area from 250 to 750 sq.m. meters;

- Gas boilers are equipped with a protection system in the absence of traction, gas supply interruption and the absence of a fuse on the burner.

You can buy a Borinsky boiler with a capacity of 30 kW for 600-660 USD, a boiler with a capacity of 50 kW for a room of 500 square meters will cost 820-860 dollars.

Choosing a boiler "Borino"

Before you buy a Borinsky gas boiler, decide what you need it for - will it only perform the function of heating, or do you need a double-circuit model.

- Look at the power - if your house is insulated, you can choose a boiler commensurate with the area of \u200b\u200bthe house. If your house is “cold”, take a model with a “power reserve”

- Look at the automation - all floor-standing boilers are equipped with a protection system, but the automation itself can be of domestic or foreign production

- Look at the combustion chamber and air outlet - the chamber can be closed and open, run on natural gas and from a cylinder. Some models may require replacement injectors for LPG operation.