The pressure in the boiler rises

When the pressure in a double-circuit gas boiler drops, this is somehow understandable, but when the pressure itself grows! What could it be? However, this is exactly what I had to face once. This was discovered thanks to a safety, relief valve. He began depressurizing by spitting water from the boiler. The manometer showed a pressure exceeding 3 bar.

First of all, I relieved the pressure in the heating system through the Mayevsky tap, and began to observe the readings of the pressure gauge, the pressure slowly but surely grew. The first thought was to skip the make-up tap, pulled it up, nothing has changed. Then I took out a boiler maintenance manual (the manual can be downloaded here) began to consider the hydraulics diagram, and pretty quickly realized that the reason was in the secondary heat exchanger.

So, there are two reasons why the pressure in the boiler can gradually, but constantly increase: 1) The feed valve does not hold. 2) Faulty secondary heat exchanger

Features of Ariston gas boilers

The popularity of Hotpoint / Ariston branded equipment is associated not only with the low price of all products. The functionality of this technique is often close in its characteristics to the flagship models of well-known manufacturers.

So, for gas appliances of this developer, the presence of such functions is considered the norm:

- Automatic maintenance of the outlet water temperature regardless of any changes in the environment, as well as fluctuations in the temperature of the water itself and a change in its pressure. The intensity of the flame is regulated without user intervention;

- Automatic pumping of air from the heating system, which creates safe conditions for the operation of the device;

- In the event of emergency situations, the operation of the circulation pumps is blocked.

Rice. one

All protective systems, as well as the flame maintenance and regulation unit, work through an electronic board. This allows you to organize not only a convenient panel with control buttons, but also an indication of the current mode of operation, and, if necessary, error codes indicating the alleged cause of the problem.

The decoding of these codes is usually presented in the instruction manual. The owner of the equipment can independently understand the situation and, as far as the skills are available, also eliminate the cause. But in most cases, such information is useful only in order to determine whether it will be enough to simply restart the boiler or whether it is time to call the master to the house.

How to work with the menu

By pressing the “OK” button once, the number 2 will flash on the digital indicator - this will be the first digit of the future three-digit code (Menu group number)

With the plus and minus buttons, you can change this value from group number 2 to any other group. To fix the selected group for further entering the code number, you need to press “OK” again - after that the second digit of the future three-digit code starts flashing (Submenu)

Having selected the submenu, we fix it by pressing the “OK” button again and in a similar way select and fix the third digit (Parameter)

Everything! Now the screen will no longer display the three-digit code itself, but the set value of this parameter, which can be changed by pressing "plus" "minus". After making the necessary changes, do not forget to fix them by clicking "OK".

Please note that after selecting the desired menu, after a few seconds of inactivity, the three-digit code (to remind you where you are) and the parameter corresponding to this menu will be displayed in turn.

The ESC button is used to exit the settings menu and return to the previous step. The exit is carried out step by step, one press is equal to one step back.

Practicing

Now, if you want to practice, to better understand the switching order.For example, enter the menu code 701, this will turn on the forced air removal mode, in fact, turn on the pump in the boiler for 6 minutes.

When this mode is enabled, the symbol “P I -” will light up on the display. You can exit the “Anti-air” mode without waiting 6 minutes if you press ESC.

Then, using ESC, try to go back and switch to mode 300, which means (Set water temperature in the boiler) in the values \u200b\u200byou can see the temperature that you currently have on the DHW regulator.

Design features of the gas boiler Baksi baxi, Navien, Ariston

In any case, familiarization with the technique of this class and the features of modern models is useful. This knowledge will help to choose the right equipment, not to make mistakes during operation.

In domestic boilers Baksi (baxi), Navien and Ariston, gas, diesel and solid fuels are burned to heat water, electric heating elements are used. For a more complete use of the potential of energy resources, heat exchangers are being improved. They make long ducts of complex shape to ensure that the liquid remains in the working area for a long time.

Compactness is the current trend. Manufacturers offer gas boilers with square bodies of relatively small thickness. Some models, due to their aesthetic characteristics, deserve to be placed in a conspicuous place.

The next feature is the introduction of automated control systems. They control the combustion process, change the operating modes, taking into account the readings of temperature sensors on the street and in separate rooms. When overheating, the equipment turns off without user intervention.

It is necessary to carefully consider situations when the Baksi gas boiler does not heat water. This happens, for example, when the supply of energy resources is interrupted. It is not difficult to make an appropriate check even without special professional training.

Circulation pumps, valves, other typical components and assemblies rarely fail. Their designs are designed for many years of operation without mandatory maintenance. There are no moving parts in electronic circuits. Their breakdowns are due to marriage. Subject to the rules established by the manufacturer, the resource of modern gas heating boilers is more than 10 years.

Voltage surges in the power supply network can damage the electrical part of the equipment. To exclude such influences, an external stabilizer is installed. Checking the grounding system will come in handy. This completes the set of preventive measures for this group of problems.

It is much more difficult to provide protection against the most common cause of breakdowns in gas boilers - scale.

It is she who will be studied in detail in this article. When heated, calcium and magnesium salts are converted to a solid state. It is these impurities that clog narrow technological holes in heat exchangers. They also form a porous structure on the surface of electric heating elements. With a significant violation of the normal heat dissipation, their cases are damaged.

To prevent the formation of scale and lime inside the boiler, it is advisable to install non-chemical filters (water converters), magnetic and electromagnetic, which will ensure a long “life” for your boiler and an uninterrupted supply of hot water, as well as protect the heating circuit.

Removal of air locks in the system

Better to start with batteries. To remove air jams, a Mayevsky crane is usually installed on them. We open it and wait for the water to run. Did you run? We close. Such manipulations must be done with each heater separately.

How to start the boiler with your own hands photo

After the air is removed from the batteries, the pressure in the system will decrease and the pressure gauge needle will drop.At this stage of work, the solution to the question of how to start the boiler involves re-feeding the system with liquid.

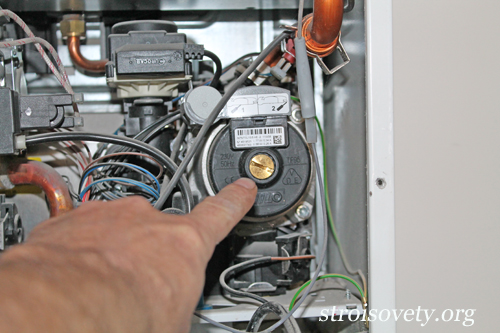

Now, the most difficult thing is that starting gas boilers requires venting air from the circulation pump. To do this, the boiler needs to be disassembled a little. We remove the front cover and look for a cylindrical object with a shiny cap in the middle, which has a slot for a screwdriver. After we have found it, we put the boiler into operation - we supply it with electric power and set the water heating regulators to the working position.

Releasing air from the circulation pump when starting the boiler photo

The circulation pump will immediately turn on - you will hear a faint hum and a loud gurgling and many incomprehensible sounds. This is fine. As long as the pump is airy, it will be so. We take a screwdriver and slowly unscrew the cover in the middle of the pump - as soon as water begins to seep out from under it, we twist it back. After two or three such manipulations, the air will come out completely, incomprehensible sounds will subside, the electric ignition will work and start working. We check the pressure again and, if necessary, add water to the system.

Basically, everything. While the system is warming up, you can do a detailed study of the instructions (if, of course, you have not already done so) and debug the system, which involves starting the boiler. Everything is simple here - the batteries closest to the boiler must be screwed on, and the distant ones should be run to the fullest. Such debugging is carried out by means of control valves installed on the pipe connecting the supply to the heating radiator.

Service menu of the boiler

For all manipulations with switching modes, only 4 buttons are involved - Plus, Minus, Ok / Menu, ESC.

It is important to understand that not all menu items of the boiler will be available to you, some of them will become available only when additional devices are connected to the boiler, such as external sensors or a solar collector. And most of the menu items are available only by the service code, I'll tell you about it below, but for now, "let's practice on cats"

And most of the menu items are available only by the service code, I'll tell you about it below, but for now, "let's practice on cats"

Our kitties will be values that are open to free access. But first, read how to work with the menu.

Distinctive abilities

According to reviews of Ariston gas wall-mounted double-circuit boilers, they have 4 distinctive features that are useful for their owners:

- All models of this company are equipped with automatic protection systems.

- The presence of a water pump, which is necessary for the constant circulation of water through the pipes.

- Possibility to choose a model with an expansion tank. With its help, automatic pressure control will occur inside the heating system.

- Ariston equips its equipment with various types of ignition. It can be automatic, which will greatly facilitate the life of the owner of a particular boiler. Otherwise, each time the unit is started, a person will need to press a special button.

Secondary heat exchanger for gas boiler

The fact is that the water that is used for DHW (hot water supply) is heated by the water that is used for the CO heating system. For these purposes, the secondary heat exchanger serves. It is designed in such a way that two channels isolated from each other for the flow of water pass inside the sealed container. One channel with heated water, and the other with the one that needs to be heated.

At the same time, a large area of contact between the heated water and the heated one is provided through the metal plates. When a partition is broken inside the heat exchanger (a small fistula appears), then an exchange of liquids begins to occur, the water from the water supply, the one that needs to be heated, has a stronger pressure and begins to be forced into the heated water channel. That is, it enters the circuit of the heating system, thereby causing an increase in pressure in the system.

Error codes of other boiler units

The list of all possible errors, their digital designation, decoding can take a long time. In order to more fully understand the significance of various codes, it is worth giving a description of the most important, most frequently occurring problems with gas boilers.

- 501 - Ariston boiler error 501 indicates problems with ignition, the boiler must be reset with the RESET button. If there is no flame, the gas supply must also be checked.

- 6p1 - if an error 6p1 of the Ariston boiler occurs, it is necessary to check the exhaust system, it means that the contacts of the relay responsible for the operation of the fan have not closed in the normal way. Sometimes resetting with the Reset button helps.

- 5p3 - with an error 5p3 in the Ariston boiler, a flame separation from the burner was detected.

- 117 - if error 117 occurs, the Ariston boiler must be reset using the Reset button, and it should work.

- sp3 - no burner ignition. It is found in models with the EGIS Plus index and the like. Sometimes it is interpreted as a flame detachment, which makes it possible to attribute the sp3 code to the most critical errors.

Particular attention should be paid to problems such as flame separation. It occurs due to too powerful gas flow and can lead to gas contamination inside the boiler.

The same error of the Ariston 501 or 6p1 boiler does not cause any special problems, except for the inability to turn on the water heating. Mistake - the separation of the flame in the Ariston boiler may indicate serious problems in the supply system, they cannot be solved on their own, you just need to call the master, having previously turned off the gas supply.

When the flame breaks off, a fire hazardous situation arises, so if it occurs frequently or at least systematically, it is necessary to be puzzled by checking the gas supply line. In the boiler, the accumulated gas can flare up and cause mechanical damage to it or even endanger the health of people living in the apartment.

In addition, the heating efficiency is significantly reduced, the gas consumption for the same volume of water increases. The power of the flame must be regulated smoothly, without pops inside the boiler and other abnormal phenomena and sound effects. Only then can you expect economical operation from the heater.

Sensor Diagnostics

If the flow sensor is a microswitch, then for diagnostics it is enough to check the contact closure with a tester. To do this, disconnect the contacts from the sensor, connect the tester in the “ringing” mode, turn on the water tap. If the circuit does not occur, then the sensor is faulty and requires inspection and, if necessary, replacement. It happens that the accumulated dirt interferes with the circuit and it is enough to clean it. Poor quality of tap water and lack of pre-filters is the most common problem. Reed sensors contain a magnet, so they attract rust microparticles and quickly fail.

Sensors with a flow meter register the amount of water flow, which can usually be displayed on the boiler display. For BAXI boilers you need:

hold the “i” button to access the information menu for 5 seconds

use the DHW temperature adjustment buttons to scroll to parameter A08 (actual water flow through the sensor, liters per minute * 10)

Now it remains to compare the actual flow of water from the tap with the flow of the sensor. If the actual flow does not match the value of the sensor, then most likely it needs to be replaced.

Since the mechanical part of the flow sensor is a turbine, in case of contamination, it can wedge and the signal from the sensor disappears. No signal from the flow sensor - the boiler stops heating water.

Relay for boiler Ariston

Then, much later, analogues of the necessary relays were found on Aliexpress. This is an OMRON relay G5NB-1A-E, or Panasonic ALD124 24 B. They are also 24 volts, but as it turned out, this is not a problem. The relays are made and look great, probably the original. So now I have some stock.

I already had to repair the boiler with friends and use one of the Omron relays that I received: It got up like a native, it works fine. By the way, sellers mainly offer these relays in batches of 10 or 50 pieces. So I ordered a batch. Later I found a seller from whom you can order them individually at a good price, the reviews are good. Link to this seller By the way, there is an opportunity to use Cashback.

P.S I want to add about cashback, for a few small purchases I received $ 2.32. So it really works. Sign up and get a refund on every purchase. About

For those who are interested in why the gas boiler does not light up when the fan is running, read on.

Why does the gas boiler go out, or rather, the boiler does not ignite

The gas wall-mounted boiler has several degrees of protection, for your own safety, and to protect the boiler from more serious damage. One of the elements of the safety group is a pressure switch or, as it is called in the manual for the boiler, “air pressure switch” (Instructions for operating and repairing the boiler)

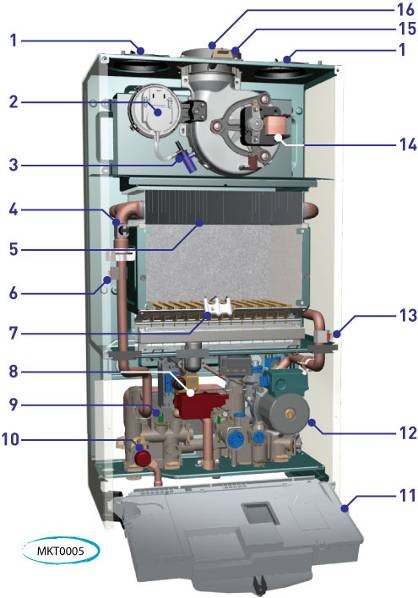

In the above drawing, the air pressure switch (Pressostat) is under No. 2,

No. 14 Fan motor for exhaust gases (combustion products)

No. 3 Air pressure tap with steam trap.

By the way, in my boiler, this node No. 3 was performed differently. I had the so-called venturi tube, which also has a certain protection function, but more on that in the next post.

Back to our problem: So, as it should be. In short, after the start command is received from the control unit, the fan control relay is turned on.

In the chamber with the turbine (Snail), a thrust is created which, through the venturi tube, transmits a vacuum to the pressure switch in which the membrane is retracted with the contacts closed, which in turn informs the control unit that everything is in order - there is thrust, you can work, give a spark!

Thus, in a working boiler, the order is as follows:

START COMMAND —> FAN —> PRESSOSTAT —> GAS VALVE and SPARK.

But what happens when the fan control relay sticks? The fan receives power as soon as the boiler is plugged into the socket. It starts to rotate, creates a vacuum and the contacts of the pressure switch close even before

how the command to launch was received. The control unit does not leave this unnoticed and cancels the ignition command, displays error 607 on the display - which means: The air pressure switch worked before the start of ignition.

So with a stuck relay, the following is obtained:

FAN —> PRESSOSTAT —> START COMMAND —> ERROR 607

Here are the pies! That's all.

What are the types of wall-mounted boilers Ariston

All Ariston boilers are divided into 3 series. They have different technical indicators and functions, namely:

- Clas - this series refers to more bulky and powerful devices for heating residential premises. They are equipped exclusively with special regulators that automatically regulate the gas supply. This is necessary to save fuel, which is very convenient in terms of utility costs and frequent business trips for the home owner.

- Genus. These are the most innovative and multifunctional models of Ariston gas units. They have more features than other boilers from this manufacturer. Along with the equipment itself, the buyer will receive additional accessories such as a fan required for smooth speed control, as well as heat exchangers, primary and secondary. All devices from the Genus line are distinguished by the presence of a large liquid crystal display. It will display all the characteristics that correspond to the operation of the boiler at the moment.

- Egis. The units from this series are small in size and attractive in appearance, which have earned them great popularity among owners of small apartments. The device will fit well into any interior.An important feature of these boilers is that, for their size, they have a fairly high level of efficiency and low fuel consumption, which is controlled by an intelligent control system.

Descriptions of the double-circuit boiler Ariston

One of the most important components in all gas boilers is the burner, in this case it can be modulating or conventional. The first option is more popular than the second. When using it, the entire system will be regulated automatically, without human intervention. In this case, the power of the installed heating equipment depends on the temperature indicators.

The burner is also divided into 2 types:

open;

It is the safest, since it does not involve the entry of combustion products into the room in case of emergency. Also in this case, the owner may not worry about building a chimney. It is necessary to bring a special coaxial pipe to the closed burner; it can always be brought out in any accessible place.

An open-type Ariston boiler, in any case, requires a chimney to bring combustion products outside. Also, do not forget about natural traction. Air will enter the system from the living quarters, so it will have to be constantly ventilated.

The coaxial pipe used in the closed combustion system has the advantage of being made of 2 layers. One is necessary for the removal of combustion products, and the other will ensure that fresh air enters the boiler. Thus, the owner of the equipment does not have to constantly ventilate the room and worry about natural draft. The room will always have enough oxygen.

Specifications

Almost all gas boilers from the Ariston brand have a capacity of 15 to 30 kW. Thus, each client will be able to choose the necessary indicators for the size of his apartment or house. It is also worth noting other distinctive characteristics of such gas equipment:

with maximum efficiency, boilers have a high level of efficiency;

all wall-mounted boilers have Russian instructions and designations on the equipment itself, so citizens do not have problems with controlling the unit;

most models from this manufacturer are able to perfectly cope with water in the system and low pressure;

special attention to this equipment should be given to those people in whose houses power surges often occur. Ariston boilers can easily cope with such jumps in the network;

all models are very easy to operate

To start using the boiler, you do not need to study the instructions for a long time, all the features of operation are intuitive and accessible even for those who install such a unit for the first time.

In some cases, the boiler cannot simultaneously heat water and provide sufficient space heating, this applies to budget models. In this case, a person needs to think about installing an additional boiler.

Clogged heat exchanger reduced capacity

Often scale or dirt build-up on the inside walls of the heat exchanger is the cause of problems with hot water. If tap water does not undergo preliminary filtration (coarse cleaning) and the temperature of hot water is too high, the heat exchanger walls become overgrown with scale and dirt over time, their thermal conductivity and flow area decrease. Each time the user increases the DHW temperature on the boiler more and more to get the desired result on the mixer. With an increase in temperature, scale forms even faster and, as a result, the DHW temperature of the boiler is at its maximum, and the water is not heated enough. This process has a particularly negative effect on a boiler with a bithermic heat exchanger. Plate heat exchangers lend themselves well to flushing.

Malfunctions of heating boilers

Basically, major malfunctions begin to appear during the heating season, when two boiler circuits are operating - heating and water heating. It may happen that it does not start at all, or it does not heat well enough. With the launch, the issue will have to be resolved separately, but if it does not heat the water enough, then the reason may be the clogging of the heat exchanger. As you know, the quality of water in our systems is far from ideal, and besides, few users install it in front of the boiler. So the heat exchanger becomes clogged, resulting in poor boiler operation.

Here are the most common malfunctions of gas boilers in the event of which it weakly heats water:

- randomly shuts off periodically

- smokes heavily,

- does not develop enough power,

- making noise

- clogged

- the pump is broken.

If it so happened that the gas boiler does not heat the water, then often the reason is the formation of limescale on the walls of the heat exchanger, which, as it accumulates, becomes very durable and not only reduces the temperature of the water, but also reduces the throughput of the boiler. The thermal conductivity of scale is ten times less than metal, so it is not surprising that the boiler does not heat water. If no preventive measures are taken, then very soon the boiler will have to be completely disassembled and deposits removed mechanically.

Only a timely one can help this trouble, and it should be done regularly, especially if cleaning and softening filters are not installed in front of the boiler.

Special chemicals are used for flushing, but they must be used with great care, since they are equally destructive to lime deposits and to the material from which the heat exchanger is made. It is best to invite a specialist for this purpose.

For the safe and efficient operation of the gas boiler, preventive maintenance is recommended. It is advisable to do this regularly before the start of the heating season; you should not wait for the situation when the boiler does not heat water. This approach will ensure its long service life and economical operation. Major repairs are carried out as necessary by an employee of the service center - it is strictly forbidden to do this on your own.

Vaillant boilers are particularly reliable and safe. Breakdowns of such complex equipment must be eliminated by the master. But, minor malfunctions can be removed on your own if you have a basic level of knowledge about the design of heating and heating boilers.

Most faults are indicated on the boiler display. Having a decoding of errors, you can figure out what is the reason for the boiler's failure to heat water. Where to start the search if the heating of water in the Vailant boiler does not work, and the indicator does not show an error, or can it be interpreted in different ways?

Burner modulation errors

To heat running water, in most cases, a boiler power close to maximum is required. In modern boilers, the burner power is regulated over a wide range. Adjustment occurs by changing the amount of gas supply by the gas valve. The amount of adjustment is determined by the control board, depending on the logic of operation and settings. The process can be observed visually by the height of the flames on the burner.

If the boiler settings are set to 100% boiler power in the DHW mode, but visually the flames on the burner are weak, or obvious interruptions are visible, then you should check:

gas valve setting (static and dynamic gas pressure)

Such checks may only be carried out by a qualified technician.

Three-way valve

The three-way valve is installed in boilers with two heat exchangers.When a signal is received from the flow sensor, the electronics give a signal to the valve and the heated water from the first heat exchanger is sent to the second heat exchanger, where heat is transferred to the passing tap water. If, for example, actual switching does not take place (valve defective), then the heating medium will continue to circulate in the heating circuit and there will be no heat transfer to the hot water circuit.

If, for example, a valve closes the heating circuit only partially due to a malfunction, then there will be problems with insufficient heating of hot water, since part of the heat will go to the heating system.

If the boiler does not turn on as needed

You open the mixer valve, but the boiler does not react and does not try to ignite the burner, and no errors occur. Regardless of the scheme of operation of the DHW circuit of the boiler, a sensor is installed on the outlet pipeline, which determines that the water has begun to be parsed. It is also called a DHW flow sensor. There are different types of sensors: some simply detect the presence of water movement in the pipeline, others can quantitatively measure the flow. The latter are used to provide greater comfort due to precise control of the burner power depending on the flow rate.

In both cases, at the beginning of the water flow from this sensor, a signal must be sent to the control board. If for some reason this does not happen, the boiler will be idle.

The sensor type is easiest to determine by the number of contacts. Two means it is a closing microswitch. Three - a sensor with a flow meter.

Features of some models on the example of Ariston EGIS Plus 24

The gas boiler of the EGIS Plus 24 brand is equipped with a double-circuit heating system, a closed combustion chamber and a wall-mounted casing. They can heat an area up to 250 sq. m. In addition to automatic protection against major misfortunes (overheating, freezing or jamming of the pump), there are two important features. This is the ability to easily endure all power surges and stable operation under conditions of reduced gas pressure.

But, despite such a well-thought-out design, this model also has weaknesses. So, the sp3 error in it appears much more often than others. In different situations, the flame does not burn, even under externally favorable conditions, to the point that the masters shrug. And they adjust the valves, check the access and removal of air / exhaust gases, clean the scale and still the mistake can happen again at the most unexpected moment.

The alleged causes of the sp3 error according to the reviews of the owners look different. It seems that connecting to the water supply through a hose interferes, then an error is generated after switching to the heating system after using hot water. In general, EGIS Plus is considered a reliable model, but the appearance of defects, such as the floating error described, reduces its popularity.

Small boilers for heating using gas are now often used in houses and apartments, and many of the best such devices are produced under the Italian brand Ariston. We will consider some models of this brand and give relatively to these models instructions for the Ariston gas boiler.

This brand is known all over the world. Its roots, like many other great brands, date back to the early 20th century, when enterprising Italians set up a family business. Now Ariston household appliances do not need any recommendations.

Gas boilers Ariston, if you do a brief review, reveal themselves as very reliable and popular. The company mainly specializes in wall-mounted household boilers with two heated circuits - for heating and for hot water supply. They are presented in several series:

- Genus;

- Clas;

- Egis;

The first family has rich functionality. The second family is famous for practicality. The third series is distinguished by the compactness of the boilers, coupled with their excellent design.We will talk about the models of the last two series below. Every type of Ariston gas boiler has good reviews from consumers everywhere.

Conclusion

When buying one of the Ariston wall-mounted gas boilers from the seller, you need to check the availability of all the necessary documentation, which

confirm that the equipment corresponds to the manufacturer. Only in this case, problems with the device will arise very soon.

Some failures in the operation of the boiler may be due to incorrect parameters in the service menu settings. This can happen, for example, after unskilled intervention or ... as it once happened in my practice, after filling the boiler board with water.

Of course, first of all, the service menu serves to configure, adjust and diagnose the operation of the boiler. In this article I will share how to enter the service menu of the Ariston Class 24 FF boiler and how to change the parameters, as well as give the values \u200b\u200bthat were set in my boiler from the factory.

Before proceeding with any settings, it is important to carefully consider the menu structure, as well as to understand whether you need to intervene and change any parameters. Incorrect intervention can lead to serious malfunctions

For example, there is a parameter that is set depending on the version of the boiler and is used by specialists when replacing the board.

Given all of the above, you must understand that some of the parameters I have given as "Factory Settings" may differ from those you need specifically, and therefore you carry out all these gestures and settings at your own peril and risk.

Quick article navigation