Brief theoretical part

Hydrogen, also known as hydrogen, - the first element of the periodic table - is the lightest gaseous substance with high chemical activity. During oxidation (that is, combustion), it releases a huge amount of heat, forming ordinary water. We characterize the properties of the element, arranging them in the form of theses:

- The combustion of hydrogen is an environmentally friendly process, no harmful substances are emitted.

- Due to its chemical activity, gas is not found in free form on Earth. But in the composition of water, its reserves are inexhaustible.

- The element is extracted in industrial production by a chemical method, for example, in the process of gasification (pyrolysis) of coal. It is often a by-product.

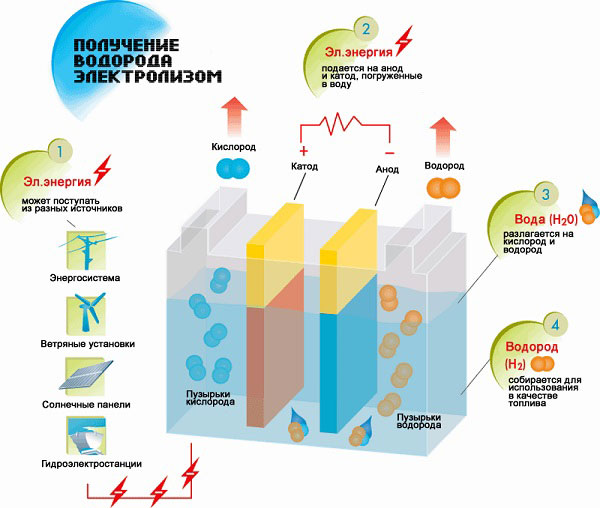

- Another way to produce hydrogen gas is the electrolysis of water in the presence of catalysts - platinum and other expensive alloys.

- A simple mixture of gases hydrogen + oxygen (oxygen) explodes at the slightest spark, instantly releasing a large amount of energy.

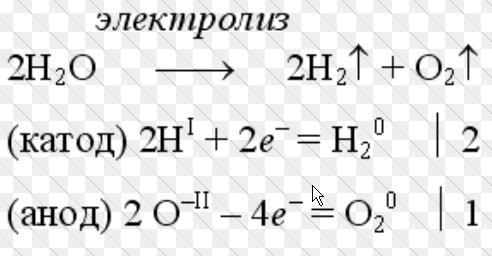

From the foregoing, the following conclusion suggests itself: 2 hydrogen atoms easily combine with 1 oxygen atom, but they part very reluctantly. The chemical oxidation reaction proceeds with the direct release of thermal energy in accordance with the formula:

2H2 + O2 → 2H2O + Q (energy)

Here lies an important point that will be useful to us in further debriefing: hydrogen reacts spontaneously from ignition, and heat is released directly. To separate a water molecule, energy will have to be expended:

2H2O → 2H2 + O2 - Q

This is a formula for an electrolytic reaction that characterizes the process of splitting water by supplying electricity. How to implement this in practice and make a hydrogen generator with your own hands, we will consider further.

Manufacturing instructions

First stage. First, take a sheet of steel and place it on a flat surface. From the sheet of the above dimensions (0.5x0.5 m), 16 rectangles should be obtained for the future hydrogen burner, we cut them out with a grinder.

Second phase. We drill holes for the bolt on the reverse side of the plates. If we planned to make a “dry” electrolyzer, then we drilled holes from the bottom as well, but in this case this is not necessary. The fact is that a “dry” design is much more complicated, and the useful area of \u200b\u200bthe plates in it would not be used 100%. We will make a “wet” electrolyzer - the plates will be completely immersed in the electrolyte, and their entire area will participate in the reaction.

water energy

The third stage. The principle of operation of the described burner is based on the following: the electric current, passing through the plates immersed in the electrolyte, will cause the water (it should be part of the electrolyte) to decompose into oxygen (O) and hydrogen (H). Therefore, we must have two plates at the same time - the cathode and the anode.

With an increase in the area of these plates, the volume of gas increases, therefore, in this case, we use eight pieces for the cathode and anode, respectively.

Each water molecule is made up of two hydrogen atoms and one atom

Fourth stage. Next, we have to install the plates in a plastic container so that they alternate: plus, minus, plus, minus, etc. To insulate the plates, we use pieces of a transparent tube (we bought it as much as 10 m, so there is a supply).

We cut small rings from the tube, cut them and get strips about 1 mm thick. This is the ideal distance for the hydrogen in the structure to be efficiently generated.

Fifth stage. We fasten the plates to each other with washers. We do it as follows: we put a washer on the bolt, then a plate, after it three washers, another plate, again three washers, etc. We hang eight pieces on the cathode, eight on the anode.

Next, tighten the nuts and isolate the plates with previously cut strips.

Sixth stage. We look at exactly where the bolts rest in the container, we drill holes in that place. If suddenly the bolts do not fit in the container, then we cut them to the required length. Then we insert the bolts into the holes, put washers on them and clamp them with nuts - for better tightness.

Next, we make a hole in the cover for the fitting, screw the fitting itself (preferably smearing the junction with silicone sealant). We blow into the fitting to check the tightness of the cap. If the air still comes out from under it, then we also coat this connection with a sealant.

Seventh stage. At the end of the assembly, we test the finished generator. To do this, connect any source to it, fill the container with water and close the lid. Next, we put a hose on the fitting, which we lower into a container of water (to see air bubbles). If the source is not powerful enough, then they will not be in the tank, but they will definitely appear in the electrolyzer.

Next, we need to increase the intensity of the gas output by increasing the voltage in the electrolyte. It is worth noting here that water in its pure form is not a conductor - the current passes through it due to the impurities and salt present in it. We will dilute a little alkali in water (for example, sodium hydroxide is great - it is sold in stores as a Mole cleaning agent).

How much is a kilogram of hydrogen

The average cost of 1 kg of hydrogen, depending on the technology of its production, according to the INEEL laboratory, is as follows:

- Chemical reaction - 700 rubles with the standard method of reducing the reagent and 320 - with the use of nuclear power.

- Electrolysis from an industrial network - 420 rubles. The data are valid for "proprietary", balanced electrolyzers. A handicraft product has obviously lower indicators.

- Production from biomass - 350 rubles.

- Conversion of hydrocarbons - 200 rubles.

- High-temperature electrolysis at nuclear power plants - 130 rubles.

From these figures, it can be seen that the cheapest way to produce hydrogen is at nuclear power plants, where an important resource is high temperature, which is a by-product of the main production. Hydrogen energy from renewable sources also does not pay for itself due to the high cost of equipment. But what about hydrogen heating at home based on a compact installation? You need to understand that the law of conservation of energy cannot be bypassed. In order to isolate H2 in the electrolyzer, a certain amount of electrical energy will have to be expended. To get it, fossil fuels were burned at the thermal power plant or the energy was generated by the hydroelectric power station. The electricity was then transferred through wires. At all stages of the process, inevitable losses occur and the amount of potential thermal energy received at the end will be a priori lower than at the beginning.

Factory and homemade installations

- profitable - the selection of materials is made at your choice;

- convenient - you can save on minor elements;

- simple - no need to resort to the help of specialists;

- reliable - you yourself are responsible for the quality, which gives you the right to choose materials that would satisfy all needs.

Some users complain that Chinese units, which are more affordable, break down after the heating season. Moreover, their repair in most cases requires large investments. While a home-made installation guarantees that its productivity will be at the highest level, and any breakdowns will be fixed as easily and quickly as the system itself was assembled.

The scheme of operation of a hydrogen boiler and the advantages of this heating method

The method of heating a home using a hydrogen boiler was invented relatively recently in Italy (and a hydrogen car engine, by the way, back in the 1960s).Previously, scientists also thought about using hydrogen as a “home” fuel, however, there was one problem: it was not possible to make a boiler from familiar materials due to the very high combustion temperature of this gas.

Now the situation has changed: hydrogen boilers are made from the same materials as everyone else. Reviews about them are mostly positive, they can be found by going to any thematic forum.

If someone hears the expression "Brown's gas", then there is no need to worry: we are not talking about mustard gas or a mixture to activate a nuclear charge. This is a mixture of hydrogen and oxygen, which must be activated by oxygen-hydrogen electrolysis (an electrolyzer is inserted in the device). Most installations run on this gas.

The process of obtaining hydrogen using electrolysis

The heating process is extremely simple: in a special installation (boiler) there is a tank with hydrogen. At a temperature of 300C °, the gas begins to interact with oxygen, forming water and steam, which are distributed through the piping system inside residential buildings.

Among the advantages of this type of heating are the following:

- hydrogen simply does not have combustion products with the exception of water (condensed water enters the heating pipeline - no chimneys will have to be kept);

- absolute environmental safety;

- hydrogen does not ignite, but gives off a large amount of thermal energy when interacting with oxygen (as a result of this catalytic reaction, water is formed);

- the actual temperature of the coolant is 40C ° (it may seem that it is not much, but this heating method cannot a priori have heat losses).

Home hydrogen generators

As can be seen from the previous section, most technological processes for the industrial production of hydrogen are associated with exposure to high temperatures, which is problematic at home. Consider hydrogen heating installations available in the private sector:

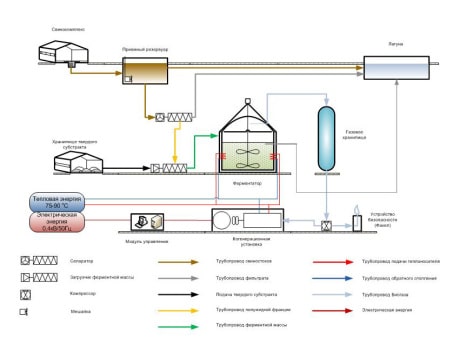

Hydrogen from manure

Biogas plants, of which there are many in Western Europe, are beginning to appear among domestic farmers. Handicraft biogas reactors, which are described on the Internet by "crazy hands" do not differ in either performance or generation stability. Only rather complex and expensive installations are effective, provided that raw materials are supplied to them steadily. This is unrealistic to implement on a small private farmstead, but it is possible in a strong farm. Hydrogen is only a by-product of biogas production and is usually not separated by burning with methane. But if necessary, H2 can be separated.

Schematic diagram of a biogas plant. In order for the process of generating combustible gases to be intensive, the raw materials are fermented and periodically mixed.

Hydrogen from water

An electrolysis hydrogen plant for home heating is the only solution currently available for a private home. The electrolyzer is compact, easy to maintain, it can be installed in a small room. The raw material for fuel production is tap water. There are a number of well-known manufacturers that offer similar home hydrogen generators for home heating and car refueling. For example, since 2003, Honda has been producing the Home Energy Station, today the third generation is already on sale. HES III is equipped with solar panels and can be installed in a garage or outdoors.

Home Energy Station is a very expensive plant capable of producing up to 2 m2 of hydrogen per hour from natural gas or water electrolysis. The station consists of a reformer, fuel cells, purification system, compressor and gas storage tank. Electricity can come from the grid or be generated by solar panels

In addition to the "branded" equipment, which, by the way, no one officially supplies to the CIS countries, today H2 generators manufactured by our friends in the Celestial Empire or Tajik colleagues in domestic garages are widely advertised. The level of quality and performance is different, from none to conditionally acceptable. The sellers of such equipment, unlike the more or less honest Japanese, who do not promise manna from heaven, use "dirty" advertising technologies, frankly deceiving potential buyers about the characteristics of their equipment, which is sold at inflated prices.

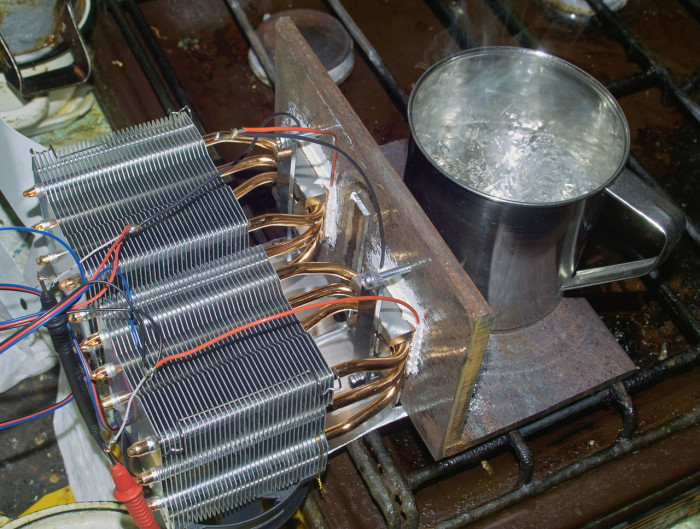

Semi-handicraft plant for the production of hydrogen

Do-it-yourself hydrogen heating, which provides for the independent manufacture of an electrolyzer, is widely discussed on near-construction Internet forums. This is possible and not even very difficult if the home master knows the basics of electrical engineering and his hands grow from where they should be. How effective and safe is a separate question.

The author of the video talks in detail about the design of a fuel cell for hydrogen production, mounted in the body of a conventional water filter. The installation is really working.

Another issue is that getting fuel is only part of the task. It is necessary to ensure its generation in the required volumes, to separate it from oxygen and water vapor, to create a reserve, to ensure a constant pressure when supplied to the heat generator.

Schematic diagram of a complete installation for hydrogen production. As you can see, one “cone with electrodes” is not enough here, we need reservoirs, a condenser, a compressor. If you calculate the cost of all equipment, it turns out to be expensive.

Pros and cons of heating

- Absolute environmental friendliness - the decomposition products of water (hydrogen, oxygen and steam) do not affect the state of health even during combustion.

- The maximum level of efficiency, reaching 96%, is much higher than the same coal, diesel or natural gas.

- The use of hydrogen as an alternative source of energy resources can significantly save the reserves of exhaustible natural resources, reducing their production by several times.

- Low cost - for heating residential buildings, the cost of the system is negligible, and the ease of operation, based on the primitive chemical reaction of electrolysis, allows you to assemble the system yourself.

Read also: We talk about the ethereal magnetoelectric generator

Of the shortcomings, only three indicators can be distinguished:

- The need to replace the metal plates every year is necessary in order for electrolysis to occur with the highest possible level of hydrogen production.

- Expensive equipment - the purchase of a factory installation will cost an average of about 35-40 thousand rubles.

A few good tips

Next, let's talk about other components of the hydrogen burner - the filter for the washing machine and the valve. Both are for protection. The valve will not allow the ignited hydrogen to penetrate back into the structure and explode the gas accumulated under the lid of the electrolyzer (even if there is a little of it). If we do not install the valve, the container will be damaged and the alkali will leak out.

The filter will be required to make a water seal, which will play the role of a barrier that prevents an explosion. Craftsmen, who are familiar with the design of a home-made hydrogen burner, call this shutter a “bulbulator”. Indeed, it essentially only creates air bubbles in the water. For the burner itself, we use the same transparent hose. Everything, the hydrogen burner is ready!

It remains only to connect it to the inlet of the "warm floor" system, seal the connection and begin direct operation.

Applicable materials

In the heating system, as a rule, distilled water is used, to which sodium hydroxide is added in a proportion of 10 liters of liquid per 1 tbsp. l substance.In the absence or difficulty of obtaining the required amount of distillate, it is also allowed to use ordinary tap water, but only if it does not contain heavy metals.

As metals from which hydrogen boilers are made, it is permissible to use any type of stainless steel - ferrimagnetic steel, to which excess particles are not attracted, will be an excellent option. Although the main criterion for choosing a material should still be resistance to corrosion and rust.

For assembly of the device, tubes with a diameter of 1 or 1.25 inches are usually used. And the burner is purchased in the appropriate store or online service.

If you choose the right materials and carefully study the heating scheme, the manufacture of the installation and its connection to the boiler is not difficult.

Advantages and disadvantages of hydrogen as a fuel

Actually, hydrogen has many advantages. As noted above, this is one of the most common gases on the planet (the most common in the Universe), an affordable and environmentally friendly type of fuel.

In general, the advantages include the following:

- ubiquitous (usually it is placed in cylinders - like liquefied gas);

- the hydrogen heating system, in fact, forms a closed cycle that does not require human intervention;

- relative cheapness of fuel;

- when using hydrogen, the average device releases 121 MJ / kg of energy, and the same indicator for the same popular propane is 40 MJ / kg.

Hydrogen fuel also has its drawbacks:

- the probability of a boiler explosion when the normalized pressure in the boiler is exceeded;

- if we take Russian conditions, it is not always possible to find hydrogen cylinders within walking distance (this is not propane natural gas after all);

- sometimes the temperature released during the catalytic reaction can be so high that a separate chimney must be made to exit steam and water (though this is true when it comes to old installations - in modern installations, steam and water immediately enter the pipeline, being a coolant);

- high noise level;

-

high water consumption.

Diagram of the device of the hydrogen boiler control unit

Where does pure hydrogen come from?

Note to the owner

“To draw attention to their products, some hydrogen boiler manufacturers make references to some kind of “secret catalyst” or to the use of “Brown's gas” in their devices. For example, you can extract hydrogen from methane gas, where there are as many as 4 hydrogen atoms! Only here, why? Methane itself is a combustible gas, why waste additional energy on the production of pure hydrogen? Where is the energy efficiency? Therefore, most often hydrogen is extracted from water, which, as everyone knows, cannot burn, using the electrolysis method for this. In its most general form, this method can be described as the splitting of water molecules into hydrogen and oxygen under the action of electricity.

For example, you can extract hydrogen from methane gas, where there are as many as 4 hydrogen atoms! Only here, why? Methane itself is a combustible gas, why waste additional energy on the production of pure hydrogen? Where is the energy efficiency? Therefore, most often hydrogen is extracted from water, which, as everyone knows, cannot burn, using the electrolysis method for this. In its most general form, this method can be described as the splitting of water molecules into hydrogen and oxygen under the action of electricity.

Electrolysis has long been known and widely used to produce pure hydrogen. In practice, not a single industrial hydrogen boiler, so far in any case, can do without an electrolysis plant or an electrolyzer. Everything would be fine, but this installation requires electricity. So, a hydrogen boiler must necessarily consume energy. The question is, what are these energy costs?

All the talk about the "calorific value" of hydrogen leads us a little away from this issue, but meanwhile, it is the most important. So, a hydrogen boiler can be profitable in the only case - the thermal energy produced by it must be higher than the energy consumed by the boiler.

Is it possible to independently create a hydrogen generator

It is better not to take risks, because such a process is associated not only with the need to know the intricacies of technology and chemistry, but also requires proper compliance with safety rules. But do-it-yourself installation of equipment is possible. To do this, it is enough to follow the instructions and not allow amateur performance.

The heating of any house should provide not only comfortable living for a person, but also the ecological cleanliness of the environment. This is achieved due to the fact that after the combustion of hydrogen, no harmful compounds are formed.

In Western countries, heating with hydrogen generators has gained wide acceptance and economic justification. If a similar method takes root in Russia, it will significantly increase the heating efficiency with minimal resource costs.

Features of Electrolytic Hydrogen Generator

A hydrogen generator based on the principle of electrolysis is most often produced in a container version. A prerequisite for the purchase of such a device for heating is the presence of the following documents: permission from Rostekhnadzor, certificates (compliance with GOSTR and hygienic).

The electrolytic generator consists of the following elements:

- a block that includes a transformer, a rectifier, junction boxes and devices, a block for replenishing and demineralizing water;

- devices for separate production of hydrogen and oxygen - an electrolyzer;

- gas analysis systems;

- liquid cooling systems;

- a system aimed at detecting a possible hydrogen leak;

- control panels and automatic control systems.

To achieve the most efficient process of electrical conductivity, lye drops are used. The tank with it is replenished as needed, but most often this happens about 1 time per year. Any electrolytic generators of industrial type are produced on the basis of European environmental and safety standards.

It has been experimentally proven that the purchase of a hydrogen electrolytic generator is much more profitable than the regular purchase of gas. So, for the production of 1 cubic meter of gas from hydrogen and oxygen, only about 3.5 kW of electrical energy is required, as well as half a liter of demineralized water.

Prospects for hydrogen in the heating industry

Many scientists call hydrogen the most promising fuel, and this is only confirmed by the following facts:

Hydrogen is the most abundant fuel element in the universe, and the tenth most abundant of all chemical elements on our planet. Simply put, there will definitely be no problems with hydrogen reserves;

- Despite the fact that it is a gas, it is absolutely harmless and non-toxic, so people, animals and even plants will not feel the harmful effects;

- In heating equipment that runs on hydrogen, the combustion product is ordinary water, so it’s not worth talking about harmful exhausts;

- The degree of combustion of hydrogen is 6000, which confirms the high heat capacity of this chemical element;

- By weight, this fuel is even lighter than air (14 times), so in the event of a leak, the fuel choice will evaporate on its own and very quickly;

- A kilogram of hydrogen today costs only 2-7 US dollars. But a kilogram is a lot, because the density of a substance is only 0.008987 kg/m3;

- The calorific value of 1 cubic meter of hydrogen is 13,000 kJ. Of course, this indicator is about three times lower than that of natural gas, but the price of hydrogen is ten times lower.

From this we can conclude that heating houses with hydrogen will cost no more than using conventional gas boilers. Also, the owner of such unique equipment will not pay crazy markups into the pockets of the owners of oil and gas companies, and there is no need to equip an expensive gas pipeline. At the same time, the owner will also save himself from going through tedious and long bureaucratic procedures to coordinate various projects.

In general, hydrogen can indeed be considered the most promising fuel. All the advantages of this element have already been experienced by employees of aerospace enterprises that use hydrogen as rocket fuel.

Negative sides of generators

True, there are certain disadvantages of using such generators. The technology for extracting heat from hydrogen is currently at the development stage, so some disadvantages cannot be avoided. First of all, it is inaccessibility, not every store has generators. Accordingly, in the event of a breakdown, a replacement part will have to be carefully looked for.

Cylinders with this substance are not very convenient to transport, it should also be noted that at room temperature hydrogen is a light volatile gas, and it is difficult to work with it. Buying such an alternative fuel in Russia today is not easy, and not everyone can handle the construction of electrolysis with their own hands. Also, when using home-made designs, it must be borne in mind that they can be unsafe, because it is impossible to guarantee complete control of the reaction.

But all these shortcomings will be only for a while, soon scientists will find a way to quickly obtain and conveniently transport hydrogen, and then it can be used to heat a house on an ongoing basis. The popularity of generators of this type is constantly growing, and they are moving from the category of exotic devices to "innovative".

Is it profitable to heat a house with hydrogen

Sellers of compact hydrogen generators convince buyers of the extraordinary cheapness of heating a house with hydrogen. Allegedly, it is even more profitable than heating with gas. They say that the water that is poured into the installation costs nothing, they are silent about the rest of the costs. Such promises have a magical effect on some of our fellow citizens who love freebies. But let's not be like Pinocchio and, before stepping into the Land of Fools, let's find out how much hydrogen heating at home actually costs.

The average selling price of natural gas for households for heating and electricity generation is 4.76 rubles/m3. 1 m3 contains 0.712 kg. Accordingly, 1 kg of natural gas costs 6.68 rubles. The average calorific value of natural gas is 50,000 kJ/kg. Hydrogen is much higher, 140,000 kJ/kg. That is, in order to obtain an amount of thermal energy equal to that generated by the combustion of 1 kg of hydrogen, 2.8 kg of natural gas will be required. Its cost is 13.32 rubles. Now let's compare the cost of thermal energy obtained from the combustion of 1 kg of hydrogen obtained in a good factory electrolyzer and from 2.8 kg of natural gas: 420 rubles against 13.32. The difference is truly monstrous, 31.5 times! Even compared to the most expensive of the traditional types of heating - electric, hydrogen cannot even compete close, it costs 4 times more! The electricity that will be spent on the operation of the electrolyzer is best used for the operation of heating electrical appliances, it will be more useless than an example.

It is these advertising technologies and methods of persuasion that are used by the sellers of installations for heating houses with hydrogen in order to sell their worthless goods at exorbitant prices.

As for the prospects for hydrogen energy, they are, but success is associated with promising industrial technologies that have not yet been invented. Household hydrogen generators and hydrogen cars are clearly unprofitable for at least the coming decades.Their very limited use in some countries is possible only thanks to serious government subsidies in the framework of experimental environmental programs.

Conclusion

So far, one can only speculate about what technologies humanity will use tomorrow. The prospects for hydrogen-based energy are skeptical by many scientists due to the small range of applications. But you can look at this situation from the other side. If a person tends to develop technologies for arranging his own life, interacting with the forces of nature, how can one discard the possibility of obtaining thermal energy as a result of the interaction of electricity and water?

It is foolish to pass up such an opportunity. If you can't find a way to apply this in today's world, maybe it's better to think about what kind of world we are trying to create? A hydrogen generator for heating a private house and other natural technologies must be developed and used.

9 Famous Women Who Have Fallen In Love With Women Showing interest in someone other than the opposite sex is not unusual. You can hardly surprise or shock someone if you admit it.

10 Adorable Celebrity Kids Who Look Very Different Today Time flies and one day little celebrities become unrecognizable adults Pretty boys and girls turn into s.

7 Body Parts You Shouldn't Touch Think of your body as a temple: you can use it, but there are some sacred places that you shouldn't touch. Display research.

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s don't worry about the shape and length of their hair. It seems that youth was created for experiments on appearance and bold curls. However, already

Unforgivable Movie Mistakes You Probably Never Noticed There are probably very few people who don't like watching movies. However, even in the best cinema there are errors that the viewer can notice.

10 Mysterious Photos That Will Shock Long before the advent of the Internet and the masters of Photoshop, the vast majority of photos taken were genuine. Sometimes the pictures got really unbelievable.