Why does a gas boiler need a filter

- small debris, earth, sand;

- lime and metal salts;

- dissolved gases.

The cleanest is the liquid from the water supply, since it must first be cleaned of harmful impurities. However, when passing a long way through the pipes to the consumer, even the purified liquid becomes contaminated, because it gets litter accumulated in the water supply. If this has already happened, read the article “Do-it-yourself flushing of the heating system and radiators in a private house, the frequency of cleaning the heating”.

Why is it necessary to soften the liquid before supplying it to the heating system? The fact is that the impurities contained in it settle on the walls of the device and the inner surface of the pipes. Over time, they accumulate and lead to a decrease in throughput. The liquid does not pass well through the pipes, and the scale formed as a result of exposure to hot temperatures and lime salts reduces heat transfer. When using hard water, the following can happen:

- pipes do not pass liquid;

- the room does not warm up;

- the gas appliance burns out or explodes;

- pipes crack and leak;

- valves are failing.

Types of filters that soften water for gas boilers

To clean the device from plaque and scale, many consumers carry out regular mechanical cleaning of the equipment. However, this measure often leads to accelerated breakdowns. The safest method of protecting a heating installation is to soften the liquid entering it. For this, experts recommend using filters and softeners. Consider the main features of popular cleaners.

Salt (polyphosphate) filter

The polyphosphate device is an effective and inexpensive softener and cleaner. Its work is based on the ability of the filler included in it - crystals of sodium salts - to neutralize lime impurities. In addition, it traps coarse debris and contributes to the formation of a protective film on the inner surface of the equipment, which prevents the appearance of sediment and inhibits corrosion processes. Main advantages:

- affordable price;

- ease of use;

- high level of protection;

- operational safety.

However, this salt purifier needs to be replaced frequently. The approximate period of its use is 12-18 months. Other negatives:

- the need to change the reagent about 1 time per quarter;

- liquid cannot be used for domestic needs, since purification and softening occurs using aggressive substances.

Magnetic cleaner

The action of magnetic installations is based on the ability of magnets to create a field that promotes the disintegration of large salt particles into small ones. The cleaner also prevents impurities from settling on the walls of the equipment. Some of them remain on the cleaning device, and some continue to circulate in the system, but do not settle in the pipes. Due to the influence of the magnetic field, the sharp edges of the salts circulating in the pipes contribute to the elimination of previously formed plaque.

However, experts consider this cleaner ineffective. High temperatures and fluid flow rates reduce the effectiveness of the magnetic field. To enhance the work of the magnet, the force of electricity is used by placing an electric winding on it.

Coarse filter

Coarse filters are designed to eliminate impurities larger than 1 micron. These cleaners remove small particles of earth, sand, rust and other constituents. However, the installations do not eliminate lime salts. Their work is provided by elements in the form of a fine mesh, on which debris settles. The disadvantages of such devices:

- during their operation, it is necessary to constantly clean the filter surface;

- liquid does not soften.

Coarse cleaners are recommended to be installed as the primary cleaning element. However, in order to protect the heater from damage, it is necessary to additionally install an electromagnetic or polyphosphate cleaner.

How to choose and install a filter

When choosing a cleaning plant, you should focus on the frequency of use of the heater and the quality of the fluid supplied. General recommendations:

- for private use, cleaners and softeners are suitable that do not require constant replacement and cleaning of the constituent elements;

- if the water is dirty and hard, you should use the double method of cleaning and softening;

- when choosing a device, it is necessary to take into account its size, since some devices require a lot of space;

- it is necessary to purchase cleaners and softeners in specialized outlets that provide repair or replacement during the warranty period;

- you should choose cleaners from well-known manufacturers;

- when buying a filter, you need to take into account the diameter of the junction with the pipe and the pipe itself.

To install the cleaning device, you need to prepare the following tools: a brush for cleaning pipes connected to the boiler, sealing tape, a device for cutting and soldering pipes (if the pipeline is plastic), threading (if the pipes are metal), pliers, tow. Install the cleaner in front of the pump. Before installation, it is necessary to clean the pipes from scale and plaque. Installation steps:

- make a cut in the pipe;

- the first shut-off valve with a tap is soldered to it;

- install the cleaning device, additionally fixing it on the bracket;

- attach the second shut-off valve and fix it.

Dear reader! Your comments, suggestions or feedback will serve as a reward to the author of the material. The following video is carefully selected and will certainly help the perception of the foregoing.

How to clean a gas boiler procedure for each node and do-it-yourself cleaning video

The modern market for heating equipment is saturated with a very wide range of boilers of various types. But a special place in this range is occupied by gas boilers. which are gaining more and more popularity every day.

This trend is due to the fact that units of this type are very efficient and economical devices for heating a country house and even an apartment. In order for the gas boiler to function smoothly and stably, it is necessary to properly care for it.

One of the types of such maintenance is cleaning the gas boiler from soot and other contaminants. Let's talk in more detail about why to clean the gas unit, as well as in what ways this can be done.

Mechanical flushing of the gas boiler

The algorithm of actions should be as follows.

Step one. The upper body is removed. To do this, it is necessary to turn off the electrical power and gas supply (if all this is provided for by the boiler design).

Step two. The exchanger is disconnected from the heating main.

Step three. The fixtures are removed.

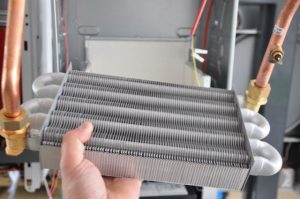

After that, you can remove the heat exchanger from the heat generator and proceed directly to the flushing procedure. And what can be seen after dismantling? As a rule, all internal cavities are clogged with scale - metal, calcium or sodium salts, as well as trivalent ferum.

For cleaning, you will have to use metal tools - pins, scrapers, and so on.

In the course of work, special care should be taken so as not to damage the surface of the structure.

In some cases, the device is wetted in a container filled with a weak solution of hydrochloric acid. And as soon as the scale softens, you can begin to remove it. At the end of the procedure, all internal voids are washed with water under slight pressure.For this purpose, you can attach a hose connected to the water supply system.

You can see for yourself how much dirt will pour out. You need to wait until clean water starts to flow. Additionally, you can tap the surface of the device with a mallet (this is a special hammer made of wood or rubber).

Burner cleaning

During the operation of gas burners, carbon deposits gradually form, which accumulates and can interfere with the correct operation of the unit. Cleaning the element consists in the mechanical removal of contaminants. This can be done in various ways - remove carbon deposits with special brushes or use chemical solvents. Here everything will depend on the degree of pollution.

Cleaning the heat exchanger

As for cleaning the heat exchanger, the situation here will be somewhat more complicated. The fact is that the element is not only exposed to external influences, but also contaminated from the inside, and therefore the issue of cleaning it requires more detailed consideration.

Cleaning outside

Externally, the heat exchanger has some similarities with the car radiator of the cooling system. This is a tube bent into a coil, which is surrounded by transverse plates that serve to increase the heating efficiency. Plates are usually made of metals with high thermal conductivity. Over time, the heat exchanger plates become covered with soot from the gas flame, which accumulates and interferes with the normal functioning of the device. The cleaning of the element is carried out in the same way as cleaning gas burners - with the help of brushes or chemicals and a sponge, the outer surface of the heat exchanger is cleaned of contaminants.

https://youtube.com/watch?v=ccEAX_yoExc

For the information that helped in the creation of the article, we thank the sites: infoaqua.ru, kottedj.jofo.me, v-teplo.ru, kotlydlyadoma.ru.

Heat Exchanger Flushing Methods

The heat exchanger for a gas boiler is one of the main parts of the unit. The quality and temperature of the coolant, the efficiency of the device depends on it. When using hard water on the walls of the element, salt and lime deposits are deposited. From here, the equipment overheats, fuel consumption increases, and the load on the circulation pump increases.

Do-it-yourself flushing of the heat exchanger is done in three ways.

For free access to all parts, it is necessary to dismantle the element, then carefully remove the scale with a scraper, vacuum cleaner or a metal brush

Here it is important to be careful and careful not to damage the parts and sealing materials of the boiler system, which will lead to depressurization and breakdown of the unit.

Do-it-yourself cleaning of the heat exchanger of a double-circuit boiler is carried out by soaking parts in solutions that soften deposits (for example, a 30% solution of citric acid). Then, with improvised means, all mechanical impurities are removed from the channels.

Types of softeners

Today there are the following types of softeners:

- Polyphosphate.

- Magnetic.

- Electromagnetic.

The first is also called saline. It is simple and cheap, and at the same time effective.

His device includes:

- Transparent flask.

- Plastic cover.

- Drain mechanism.

- Salt crystals.

The principle of operation is as follows: water follows through salt crystals. It is filled with sodium polyphosphates. The result is a film that captures and neutralizes hard salts. And the system receives protection from the accumulation of harmful elements and scale.

Such models have some types of format:

- a flask where crystal powder is poured,

- models with cartridges

The disadvantages of these filters are:

- Water after this treatment becomes unsuitable for food purposes, because polyphosphate is a toxic component.

- The modest operational life of the indicated crystals.

Pros:

- Filler consumption is 3-5 grams per 1000 liters.

- A complete replacement of the contents of the flask or device assembly is required when the crystal volumes are reduced by at least a factor of two.This is usually done every 6-8 months.

- The price tag of the filters themselves is in the range of 300 - 1200 rubles. Crystals cost about 150-400 rubles.

The magnetic device costs more, but is also characterized by better efficiency and safety.

In addition, it has compact dimensions. Experts recommend using it to protect gas boilers from salt formations.

The basis of his work is the radiation of the magnetic field. It changes the composition of water. The action algorithm is as follows:

- Water passes through the filter, after which it changes its physical structure for a certain period of time. And then crystallization is realized when heated much faster, and occurs in the volume of water, and not in the heating circuit itself.

- After magnetic exposure, the salts that covered the walls fall off, transforming into very small crystals.

- This sediment, without causing damage to the system, follows through the heating section. It is completely stopped or removed by a coarse purification device.

What a magnetic device looks like and how it works is shown in detail in this diagram:

The specificity of the magnetic technique lies in its short-term effect. For this reason, the question arises - how should such a filter stand in relation to the boiler heat exchanger. Everything is quite simple - the distance between them should be the smallest. After all, the heat exchanger in the boiler is a site of heating and intensive formation of salts.

Advantages of the magnetic filter:

- Bypassing it, the water becomes suitable for food purposes and retains its taste and composition of useful salts.

- Unlimited period of service.

- The average price tag is in the range of 1200 - 3000 rubles.

Electromagnetic analogue.

If the heat carrier has a high temperature and moves at high speed, then it is difficult to completely separate the salts in it with conventional magnetic devices. In this situation, the voltage of electricity helps. For this, the magnet is equipped with a special winding.

This is the best option for apartment buildings. For private buildings, as a rule, a magnetic device is enough. Some owners combine different types of filters, organizing a whole system of them to guarantee a highly effective water purification result.

The price of electromagnetic devices ranges from 5,000 to 20,000 rubles.

Fluid for flushing heat exchangers of gas boilers

Hydrochloric acid:

To clean heat exchangers made of copper or stainless steel, an aqueous solution of hydrochloric acid with a concentration of 2-5% is successfully used. Special additives, inhibitors, help protect the metal without preventing the dissolution of oxides and carbonates. Washing with hydrochloric acid is the lot of professionals who are aware of their actions when working with this aggressive reagent. Independently, at home, it is highly not recommended to clean the gas boiler heat exchanger with this tool without a clear understanding of the ongoing processes.

Liquid Detex:

Detex flushing agent is used to remove scale, oxides, salts and various biological deposits from the walls of cast iron, steel and copper heat exchangers. Due to the content of surfactants and corrosion inhibitor additives, it protects the metal, thereby increasing the service life of heating equipment. Depending on the degree of contamination, the Detex concentrate is diluted with water in a ratio of 1/6 - 1/10 and poured into the washing machine.

The process of circulation of the flushing liquid through the heat exchanger of the gas boiler is accompanied by gas evolution, the stop of which indicates the end of the action of the reagent. If the required flushing quality is not achieved, increase the Detex concentration until the gas formation process resumes and continue the cleaning procedure. At the final stage, it is necessary to flush the heat exchanger with a neutralizing liquid, and then with water.

Orthophosphoric acid:

Flushing with phosphoric acid is effective for heat exchangers of gas boilers of all types.This cleaning agent not only perfectly removes scale and dirt, but also does not cause any harm to the metal and even creates a protective film. To obtain an effective regent, it is necessary to dilute phosphoric acid in water to obtain a 13% solution.

Scheme for connecting gas double-circuit boilers in any private house and its main nuances

If the house is not equipped with a centralized hot water and heating system, then the owner must take care of this on his own. Double-circuit gas boilers are very convenient in everyday life, because they can quickly heat water. At a flow rate of 6 liters per minute, they are able to heat water up to 37 degrees. However, to get the maximum heating effect, you need to properly connect it and adjust the power.

The principle of operation of such a boiler is based on the fact that the system has two circuits that do not depend on each other in any way. The first one supplies the heating system with hot water, and the second one supplies water directly to the plumbing system.

Disadvantages and advantages of magnetic filters

To date, scientists cannot confirm the effectiveness of magnetic cleaning devices. Some even believe that they are completely useless. Despite this, such devices are ubiquitous. The advantages of magnetic filters include the following properties: they do not need to be cut into pipes; the water supply is not dismantled due to the fact that the device is installed directly on it; the filter is small and easy to operate; after installation, the device immediately starts working; it does not need to be adjusted, maintained, flushed and replaced; term of application - up to twenty-five years; there are practically no accidents; corrosion reduced by half; safety; lack of power supply. As a result, it can be seen that the magnetic filter for water purification is completely safe for human health.

Criterias of choice

All softening devices have a similar principle of operation. The differences are only in the quality of the results, in rare cases, minor design specifics.

Therefore, there are no strict criteria for their selection.

But if you need to buy such devices, you should take into account them:

- Productivity - throughput potential. Its unit of measurement: cube. m per hour. The second option is l / hour.

- Parameters. In terms of diameter, magnetic devices are not significantly inferior to pipes, and polyphosphate analogues need a solid space around their circumference.

- Thread diameter. It must be identical to the diameter of the pipes used at the installation site.

- Brand. It is better to take products from reliable and famous manufacturers, for example, Geyser, Aquaphor, and in specialized stores that provide repairs or change devices when their warranty period is valid.

The simplest connection schemes

The simplest scheme for connecting a gas boiler provides for direct connection of the boiler to the heating system. That is, the supply and return lines of the heating system are immediately connected to the boiler nozzles. Of course, at the same time, the above nuances are observed.

According to the requirements, such a scheme is appropriate for simple heating systems. As a rule, they are in apartments and small houses. In addition, it is possible only when a boiler is used, equipped with an expansion tank, a safety group and a circulation pump.

If the heating system in the house is complex, that is, it includes high- and low-temperature elements (the first are radiators, the second are represented by underfloor heating, a heated towel rail), then for the "consistency" of the movement of the coolant in the house, the circuit must be supplemented with a hydraulic separator. It will smooth out the influence of some contours on others.

One of the requirements for creating such a scheme in the house is the installation of a separate circulation pump for each circuit of the heating system. That is, they include their own pump in the warm floor, and their own in the wiring of pipes and radiators.

Meaning of appliances

Due to very hard water, the walls of heat exchangers and highways are covered with precipitation.As a result, the pipes narrow, and the heat carrier cannot circulate fully, and the gas boiler begins to consume too much fuel, and its service life is significantly reduced.

In order to develop the service life of the device and the entire heating network, it is necessary to ensure normal working conditions and soften the incoming water. For this, a special filter is mounted. He treats the water with special methods, and it becomes completely harmless to the heating circuit of the boiler.

If you do not take such measures, the pipes will look like this:

To test even clean well water, testing can be done using special strips. They are usually purchased at retail outlets where coffee machines and household appliances are sold. Also in this regard, pet stores are suitable.

These are strips of paper coated with a layer of reagent. They fall into the water for a few minutes. After that, their color is compared with the spectrum of results.

Here you should focus on the current GOST 31865-2012. The hardness of water is measured in degrees - ° F.

Soft water is considered to be less than 2°F.

It has an average hardness at rates of 2-10 ° F.

Extremely hard is considered at a value of more than 10 ° F

In practice, even with water parameters of 4-5°F, salts settle on the pipe walls and scale is formed. The gas boiler ceases to function normally, and it is urgently necessary to install a high-quality water softener. Which of its varieties to choose is decided by the situation and the type of boiler.