Types and specifications

At the moment, Stropuva is produced in three varieties: wood, pellet and universal. Each of these three varieties is designed for a specific type of fuel, but can work on any other, albeit with less efficiency. In total, the line includes 4 sizes: 10, 15, 20, 40 kW and a Mini version with a power of 8 kW.

The Stropuva wood-fired boiler is equipped with a special air distributor that allows you to efficiently burn wood, has the following characteristics:

| Model | Mini S | S10 | S15 | S20 | S40 |

|---|---|---|---|---|---|

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m² | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency, % | 86,3 | ||||

| Firewood capacity, dm³ | 120 | 150 | 200 | 230 | 360 |

| Chimney diameter, mm | 160 | 180 | 200 | ||

| Burning time, h | 31,5 | ||||

| Price, rub | 65 000 | 87 150 | 92 348 | 97 545 | 107 730 |

The pellet version is equipped with a distributor for fuel pellets and an air supply manifold. Boilers working on pellets have the following data:

| Model | Mini SP | S10P | S15P | S20P | S40P |

|---|---|---|---|---|---|

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m² | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency, % | 86,3 | ||||

| Pellet capacity, kg | 50 | 70 | 110 | 120 | 200 |

| Chimney diameter, mm | 160 | 180 | |||

| Burning time, h | 72 | ||||

| Price, rub | 65 000 | 91 350 | 97 072 | 102 795 | 112 980 |

The last representative of solid fuel boilers is universal. These devices are able to work on coal, wood, fuel briquettes and pellets. The scope of delivery includes distributors for all types of fuel, as well as an air supply manifold. They have the following specifications:

| Model | Mini SP | S10P | S15P | S20P | S40P |

|---|---|---|---|---|---|

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m² | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency, % | 86,8 | ||||

| Pellet capacity, kg | 50 | 70 | 110 | 120 | 200 |

| Chimney diameter, mm | 160 | 180 | 200 | ||

| Coal burning duration, h | 130 | ||||

| Price, rub | 65 000 | 102 700 | 114 608 | 121 380 | 127 995 |

As you can see, from the presented model range, you can choose a solid fuel boiler for any room, type of fuel and available budget.

New piping units for Stropuva solid fuel boilers are already on sale

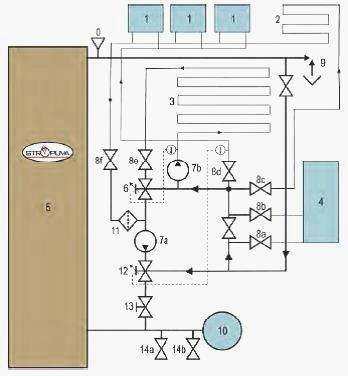

Recommended piping scheme for a long-burning boiler S40 / S40U Stropuva (option 2)

The operation of the scheme with the connection of a boiler, without a backup boiler and underfloor heating

The circulation pump (P) supplies the heating medium from the heating system, driving it through the boiler.

The heated heat carrier from the boiler Stropuva S 40 (1k) enters through the indirect heating boiler (B). With a sufficient diameter of the inlet pipes of the boiler, the valve (3) closes and the entire flow of the coolant goes through the boiler, which is connected in series, so the water in it heats up faster.

After heating domestic water (DHW), the coolant enters the radiator system.

(bk3 - 17) - a balancing valve designed to regulate the passing flow. With its help, the flow from the circulation pump is distributed so that it is enough to heat the radiators, and at the same time, so that it is sufficient for the boiler itself. The total flow depends on the power of the circulation pump and can be changed by switching the pump speed positions. A circulation pump with a power of 50–100 W is sufficient.

(bk1 – 3) – balance valve of a safety gravity radiator, with which the flow is adjusted so that the return pipe of the radiator is approximately 40°C colder than the supply pipe.

Recommended piping scheme for a solid fuel boiler of long burning S40/S40U Stropuva with connection of a boiler and underfloor heating, without a backup boiler

Fig.8. Elements of the prefabricated unit of the boiler room

1. Air vent, 2. Reducer ø 25 – 1, 3. Reducer ø 32 – 25, 4. Nipple ø 25, 5. Tee ø 25, 6. Connection ø 25, 7. Elbow ø 25 female, 8. Nipple ø 15, 9. Pressure relief valve 1.5 bar, 10. Ball valve with nut ø 25 int., 11. Ball valve with nut ø 25 int., 12. Circulation pump union ø 25, 13. Circulation pump, 14. Ball valve ø 15 in., 15. Three-way control valve ø 25, 16. Valve nut ø 25, 17. Elbow ø 15 in./out., 18. Elbow ø 25 in./out., 19. Filter ø 25 , 20. Balancing valve ø 25, 21. Reduction ø 25–20, 22. Expansion tank, 23. Plug ø 25 male, 24. Cross ø 25, 25. Tee ø 25 – 15, 26. Three-way mixing valve ø 25 , 27. Balance cock ø 15, R – to/from radiators/s, B – to/from boiler/s, F – to/from floor heating/s, H – to/from dryer/s with thermostatic valves

The three-way control valve ø 25 (15) can be installed manually.

Fig.9.Recommended piping scheme for a long-burning boiler Stropuva S 40 (option 3)

Operation of the scheme with the connection of a boiler and underfloor heating, without a backup boiler

The heat carrier heated in the Stropuva S40/S40U boiler passes through steel pipes ø 25. Air is removed from the apparatus through an automatic air vent (0). A safety valve (9) is installed on the outer circuit.

The heat carrier is directed along the outer contour to the three-way mixing unit (12). The mixing unit (12) at the bottom of the circuit is required for mixing the return heat carrier after the circulation pump.

The temperature difference between the supply and return coolant must be within 15-20°C. Accordingly, at a flow temperature of 75°C, the return temperature should be 55-60°C.

The boiler (4) is connected in a small circuit through a valve (8a, 8b). After the boiler is heated, water enters the nearest radiator (2) through the balance valve (8c).

Additional radiator (2) must be connected separately. The radiator is necessary to prevent the boiler from overheating when the circulation pump (7a) is turned off.

The radiator system is connected at the top of the small circuit through a valve (8d). The return line from the radiators is led to the circulation pump (7a) through the valve (8f). On the small circuit, after the coolant is taken to the radiators, the underfloor heating is connected through the circulation pump (7b).

The heating medium of the underfloor heating return line is supplied to the three-way distribution valve (6) through the valve (8e).

The three-way mixing valve (6) is required to mix the flow and return lines and bring the temperature of the underfloor heating flow line to 25-35°C.

The three-way dividing valve (12) is connected to the circulation pump (7a) in a common return line. In the lower part of the circuit, after the mixing unit (12), a balancing valve (13) with a flow meter is installed to regulate the flow of water into the boiler.

Drain valves (14a, 14b) are installed in the return line after the balancing valve (13) for replenishing and draining the coolant from the system, as well as an expansion tank (10). The pressure in the expansion tank should be 0.5-0.8 atmospheres.

Advantages and disadvantages

Sectional diagram of the Stropuva boiler

It is worth briefly listing the main advantages of Stropuva boilers:

- Profitability and convenience - their installation does not require expensive gas supply, and the long duration of work on a single fuel filling saves money and time.

- Energy independence - there is no electronics in the design, so wood-burning boilers, when used in a gravity heating system, do not need electricity.

- Safety and reliability - one of the advantages is the control with a bimetallic valve - a simple and trouble-free draft regulator.

- Aesthetics along with simplicity - STROPUVA boilers differ from similar types of devices in their elegant appearance and compact placement. The clear device of the unit eliminates any difficulties during operation.

Among the shortcomings, the following can be noted: their performance is strongly affected by the humidity of the loaded fuel. But this is rather a minus of all solid fuel boilers, and not of a specific brand in particular. The solution here is simple - keep firewood or coal in a dry place.

Checking the health of the sling boiler

Before regular use of the boiler, it is imperative to test its serviceability. This is necessary so that in the future the operation of the boiler takes place in a safe mode.

So, it will take up to a third to fill the barrel of the apparatus with firewood. From above, it is covered with a lid, and before that, a match must be thrown into the barrel so that the fire begins to flare up. For better ignition, be sure to add kerosene there.

Ideally, the firewood should ignite immediately.In this case, no draft, no smoke, no smell should be observed. If any of the above is observed, then you should not use such a boiler. With a high probability, he will harm the owners of the house. However, if everything was done correctly, then there should not be such problems.

The specified amount of firewood is enough to heat a small room during the day.

Basic Models

You can buy the Stropuva boiler in specialized stores that are dealers of the manufacturer, as well as in online stores. The minimum price is 60 thousand rubles for the minimum power model. We continue the review with a description of the models produced.

Stropuva Mini S8

Before us is the smallest wood-burning boiler with a capacity of 8 kW, designed to heat rooms up to 80 square meters. m. It works on wood briquettes and firewood, equipped with a safety valve and a thermometer. The heating temperature of the coolant is from +60 to +95 degrees. The maximum pressure in the circuit is up to 1.5 bar. The efficiency of the model is 85% - a pretty good result for solid fuel equipment. The estimated cost of this boiler is 61 thousand rubles.

Stropuva Mini SP8

This boiler differs from the previous model by supporting pellet operation. In this mode, it needs to be connected to a 220 volt power supply - electricity is used to operate the fan used in the fuel ignition system. When working on firewood and briquettes, the boiler operates offline. The rest of the parameters are almost 100% similar.

Stropuva S20

One of the most popular models. It allows you to heat residential buildings up to 200 square meters. m. The boiler is built according to a non-volatile scheme, briquettes and ordinary firewood are used as fuel. The burning time is up to 31 hours. If you want to forget about laying fuel for a few days, we recommend purchasing the Stropuva S20U modification - it can run on coal, providing up to 120 hours of continuous burning. The Stropuva S20P model can work on pellets for up to three hours.

Stropuva S40

Before us is the most powerful boiler in the entire line. Its thermal power is 40 kW, the burning time is up to 31 hours, the heated area is up to 400 square meters. m. The device is equipped with a rather impressive heat exchanger jacket that can hold 58 liters of water. The maximum pressure in the system is up to 2 atmospheres at an average temperature of up to +75 degrees. More than 90 kg of firewood is placed in the combustion chamber of the device. Modifications for work on pellets and coal are also produced.

Other models and manufactured modifications

Also on sale are solid fuel boilers from the Stropuva company with a capacity of 15 and 30 kW. They are designed for areas up to 150 and 300 square meters. m. All the models considered in the review are available in three versions:

- The main one is that the equipment works only on firewood and fuel briquettes (euro firewood).

- With index P - it is possible to work on pellets, burning up to 72 hours.

- With index U - units with the ability to work on coal, burning time up to 120 hours.

Naturally, the actual burning time may be shorter - it depends on the characteristics of the fuel (type of wood, degree of dryness).

Some people have design requirements for heating equipment

If you really care so much about how the boiler looks, then we have good news - Stropuva produces its equipment in several colors. The main color (and the most common) is yellow.

It is possible to purchase boilers of brown, blue, red, green and black colors. Spotted coloration (yellow and dirty green colors) is also provided.

Installation and installation of the boiler Stropuva S20

Stropuva S20/S20U/S10 boiler is installed in rooms that meet state requirements for boiler rooms. The height of the room in which the device will be installed must be at least 215cm.

The floor must be concrete (at least in the place where the boiler will stand). The room must necessarily be insulated from heated living quarters, and it must have a vertical ventilation duct and a window or opening in the outer wall so that outside air can easily enter the boiler and ventilation duct.

Using a mirror through the hole for cleaning the chimney, the inside of the chimney is inspected.

The chimney must be clean. It should be free of rebar or bird nests and uncovered openings into hollow floors and adjacent shafts.

It is checked that there are no holes in the chimney from the outside through which parasitic air can enter, cooling the chimney and reducing draft in it. All openings and connections in the chimney must be sealed.

If there are internal holes in the chimney to ceilings or adjacent shafts and it is impossible to close them, an oval or cylindrical stainless steel insert must be inserted (rectangular inserts are unreliable due to holes formed at the joints due to temperature changes).

The installation of the boiler Stropuva S 20 is carried out directly on the concrete floor, and the gaps formed between the floor and the boiler are closed with heat-resistant material (silicone (180 ° C) or a solution of lime and cement with sand or other materials).

The boiler can be placed on a concrete bottom for installation with a sealing rope.

When carrying the unit, its parts are sometimes deformed, therefore, after installing it in the chimney and closing all the doors, as well as the hole for cleaning the chimney, check the operation of the upper damper, whether it is adjacent to the surface of the air supply hole, as well as the tightness of the doors using a candle flame or matches.

Norms and requirements for the installation of the boiler S20/S20U Stropuva

Chimney Requirements

The diagonal of the chimney opening can be 10% less than indicated in the main technical data, but not more than twice.

How to start the Stropuva boiler

First you need to purchase a piping kit for tying equipment with a heating system. We recommend buying a kit with the ability to connect an indirect heating boiler. It includes a set of pipes, a safety group, an expansion tank and a circulation pump. Also on sale are kits for connecting underfloor heating.

It is not recommended to use raw firewood - this will become an obstacle to the normal operation of the boiler.

Ignition is carried out in the following way - here is a brief instruction for use:

- We load a full firewood combustion chamber with the air distributor raised.

- We fill the finished masonry with sawdust.

- We open the damper for switching to firewood.

- We open the air damper by 3-5 cm.

- We kindle the top layer, cover the loading door, leaving a gap 3-5 cm wide.

- We are waiting for confident combustion, close the loading door and immediately lower the air distributor.

Please note that the cleaning door must be closed. A new portion of firewood can be thrown into Stropuva's boiler at any time, but it is dangerous to do this with coal

In any case, the manufacturer recommends that you always wait for the fuel to burn out completely before adding a new batch.

A new portion of firewood can be thrown into Stropuva's boiler at any time, but it is dangerous to do this with coal. In any case, the manufacturer recommends always waiting for the fuel to burn out completely before adding a new batch.

About firewood

As mentioned above, the quality of the fuel is of great importance. And for the efficiency of the heating equipment, and to increase its service life. This is especially true for firewood - a very unstable type of fuel. The efficiency of the boiler depends on the uniform supply of fuel, moreover, aligned according to its calorific value.

This is most important for modern technological heating devices burdened with automation.

Firewood, on the other hand, differs in its technical qualities - humidity, specific heat of combustion. That is why manufacturers of boiler equipment insist on choosing high-quality fuel.

Pellets and fuel briquettes - more efficient fuel for a wood-burning boiler

The easiest way to achieve this requirement will be the choice of artificial "logs" - pellets, fuel briquettes.

You can read more about the differences in firewood and their varieties in the article Pros and cons of various types of solid fuel for boilers: wood and its derivatives.

The manufacturer's recommendations, as a rule, have an indication of what length of logs are suitable for a particular model of firebox. There are options for boilers that fit meter-long logs into the combustion chamber.

Log log strife

The wood of different tree species has a different density, which means the ability to release heat. But besides it, other features of firewood that affect the operation of the boiler are also important: the amount of non-combustible (ballast) substances and the presence of resins that pollute the chimney and the internal structure of the device during combustion.

birch firewood

Birch has dense wood, so it burns hot and gives off a lot of heat - 3750 kcal, even if the firewood is damp. It is highly flammable. But when burning such firewood, especially raw, tar is released - a substance that is useful in medicine, cosmetology or for protecting surfaces from decay, but extremely harmful to the insides of the boiler.

Soot on the boiler heat exchanger

Alder firewood

Burning alder firewood practically does not emit soot. Moreover, burning alder wood helps to clean the chimney. Alder is flammable, burns well and gives off a sufficient amount of heat - 2100 kcal.

Aspen firewood

Burning aspen, like alder, cleans the chimney. But by themselves, such firewood emits a little heat during combustion - up to 1650 kcal.

Pine firewood

They burn well and rather hotly (3800 kcal), but pine wood is resinous, a lot of soot is formed during combustion.

Firewood in the warehouse

Spruce firewood

Spruce firewood is comparable in quality to pine, but has a slightly higher specific heat of combustion - 3900 kcal, besides, they are less resinous.

Poplar firewood

Poplar burns hot, but quickly burns out.

Firewood from apple and pear

Firewood from fruit trees - apple trees or pears - have dense wood, which means they emit a lot of heat, burn and smolder for a long time. But these species are usually grown for their fruits, so such firewood is not common. Another feature: the trunks of pears and apple trees are clumsy, the chocks do not prick well, and the logs turn out to be knotty, it is difficult to stack them tightly in the firebox.

Oak, beech, ash firewood

Oak, beech, ash have dense wood; when burning these species, a lot of heat is released - up to 3600 kcal. Of the minuses of oak or beech firewood, one can name their rarity on sale and the difficulty in splitting and melting the boiler with them.

Considering the described qualities of wood as a fuel, a good owner stocks up different types of firewood: some - so that they flare up easily, the second - so that they burn for a long time and hot, and the third - to periodically clean the chimney from soot.

Work reservation

The Stropuva boiler will delight you with long-term fuel burning. But even in this case, you can miss the moment of the next bookmark. As a result, the temperature of the coolant in the heating circuit will begin to fall. To prevent this from happening, we recommend installing a backup electric boiler in the circuit. Having detected a temperature drop below the set limit, it will turn on and maintain the set temperature.

Electricity consumption will be small, if you do not forget about laying firewood for 2-3 days. The vast majority of the time the boiler will burn, giving heat to consumers. Therefore, huge expenses should not be expected.In addition, the auxiliary boiler does not have to be as powerful as the main one - a model with a power 2-3 times lower is quite enough so as not to chatter with your teeth in the morning. We also recommend that you work on the insulation of your home so that it retains the accumulated heat longer.

How to fire up a cauldron

In cycling, the most difficult thing is not to ride, but to start the movement and finish it. So it is in the operation of the boiler - it is most difficult to melt it. Do not expect that lighting the boiler will take you a little time: you will have to allocate about an hour for this procedure.

The firebox of a wood-burning boiler is a responsible occupation

The beginning of the furnace - cleaning the ash and preparing the boiler for work. After the ash pan and the combustion chamber are cleaned, you can proceed to kindling.

Warming up the boiler furnace and chimney

For your own comfort and proper start-up of the boiler, you need to warm up its furnace and chimney. If the heater is not equipped with a forced smoke exhaust system, in order for the fuel to start burning, it is necessary to create draft. The formation of thrust is based on the law of Archimedes: heated gases become lighter and tend to "float". For their movement and removal, fuel-burning heating appliances are equipped with a chimney.

Boiler diagram. Photo site www.viessmann.ru/

The design of the boiler is such that the path for smoke is difficult: on its path there is a heat exchanger and a convective surface of a complex shape, which reduces the speed of movement of combustion products. And the chimney pipe is usually located horizontally, which also makes it difficult to move smoke. Therefore, if the boiler is not warmed up, the combustion products look for the easiest way. And most often the smoke begins to seep into the room.

In some cases, the vertical part of the chimney is equipped with a chimney (a small firebox used to warm the chimney) with a door that can be opened to burn a small amount of combustible fuel (for example, paper) directly in the chimney itself. When using a firebox, the inside of the chimney channel warms up.

If this possibility is not provided, then kindling is laid in the furnace - crumpled paper, birch bark - something flammable. On top of the kindling - chips and splinter, then logs of small thickness. The combustion chamber must be filled with firewood no more than half of the calculated volume.

At the moment of kindling, it is necessary to open the chimney damper and the blower valve, ensuring the flow of air for combustion.

There are tips before starting the firebox to open a window in the boiler room, if any: do not forget that oxygen is needed for the physical and chemical combustion process.

How to heat a boiler with wood

It takes about 5 cubic meters of air to burn a kilogram of firewood. If air is supplied to the boiler furnace from the boiler room, then it is imperative to arrange forced ventilation - especially if there are no windows in the boiler room or they are sealed (with double-glazed windows).

After laying the logs, kindling is ignited. When a steady burning appears, the firebox door must be covered and the bookmark should be allowed to burn out.

Rated output

As soon as the combustion chamber and the chimney have warmed up sufficiently, you can proceed to the main stage of the boiler operation. To do this, repeat the kindling process using well-burning materials. Now the main laying of firewood is already complete, in order, according to the instructions for the device, to fill the combustion chamber.

After the fuel has ignited, the boiler will reach its design power after a while. Now the combustion process will occur for some time on its own. How long depends on the volume of the combustion chamber and the principle of operation of the boiler. After the firewood bookmark burns out, you will need to make a new one.

A properly functioning boiler is a source of heat and comfort in a country house

Important! When kindling, do not use lighter fluids or flammable gasoline, diesel fuel, etc.

Solid fuel boiler Stropuva design and principle of operation

Introduction

Stropuva solid fuel boilers differ markedly from other solid fuel heating appliances and not only in their original color. Their device is also very unusual. Today we will try to figure out what advantages their design has and what disadvantages it has. And the real owners of Stropuva heating boilers will share their experience of using them with the readers of kotlydlyadoma.ru.

The history of the Stropuva boiler began in 2000 in Lithuania, when it was invented and patented. Since then, thanks to its original technology, burning time, high efficiency and non-volatility, these devices have taken their rightful place in the heating equipment market.