Calculation of the ventilation system

Normative supply air volume

Typically, natural ventilation systems are used in residential buildings. In this case, outside air enters the premises through transoms, vents and special valves, and its removal occurs through ventilation ducts. They can be attached or located in the internal walls. The construction of ventilation ducts in the external enclosing structures is not allowed due to the possible formation of condensate on the surface and subsequent damage to the structures. In addition, cooling can reduce the rate of air exchange.

Ensuring natural air flow through ventilation

The determination of the parameters of ventilation pipes for residential buildings is carried out on the basis of the requirements regulated by SNiP and other regulatory documents. In addition, the indicator of the multiplicity of exchange is also important, which reflects the efficiency of the ventilation system. According to him, the volume of air flow into the room depends on its purpose and is:

- For residential buildings - 3 m3/hour per 1 m2 of area, regardless of the number of people staying on the territory. According to sanitary standards, 20 m3/hour is sufficient for temporary residents, and 60 m3/hour for permanent residents.

- For auxiliary buildings (garage, etc.) - at least 180 m3 / hour.

To calculate the diameter of pipes for ventilation, a system with natural air flow is taken as the basis, without installing special devices. The easiest option is to use the ratio of the area of \u200b\u200bthe room and the cross section of the ventilation hole.

In residential buildings, 5.4 m2 of air duct cross section is required per 1 m2, and about 17.6 m2 in utility buildings. However, its diameter cannot be less than 15 m2, otherwise air circulation is not provided. More accurate data are obtained using complex calculations.

Algorithm for determining the diameter of the ventilation pipe

Based on the table given in the SNiP, the parameters of the ventilation pipe are determined based on the air exchange rate. It is a value that shows how many times during an hour the air in the room is replaced, and depends on its volume. Before determining the diameter of the pipe for ventilation, do the following:

- Calculate the volume of each room by multiplying its three dimensions.

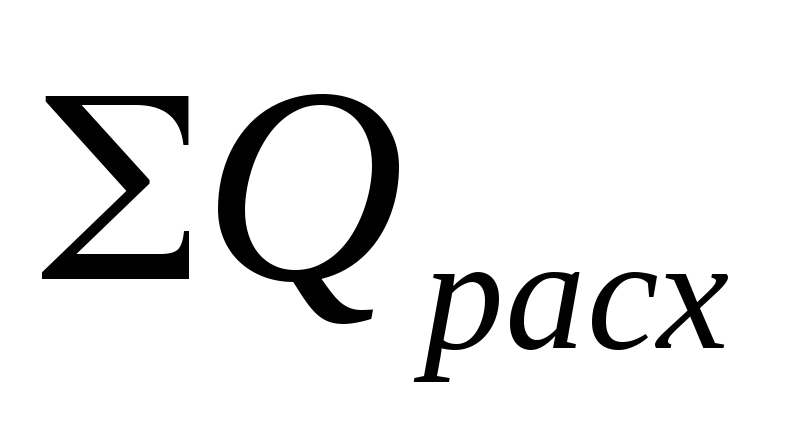

- Determine the required volume of air according to the formula (separately for each room)

- Usually, for most rooms, either an exhaust or an inflow is normalized. In some rooms, it is necessary to ensure both the supply of air and its timely removal.

- All L values must be rounded up so as to obtain a multiple of 5.

- For those rooms where only supply or exhaust is needed, the calculated air volume is summarized separately.

- Make up a balance in which the total volume of inflow and exhaust must match.

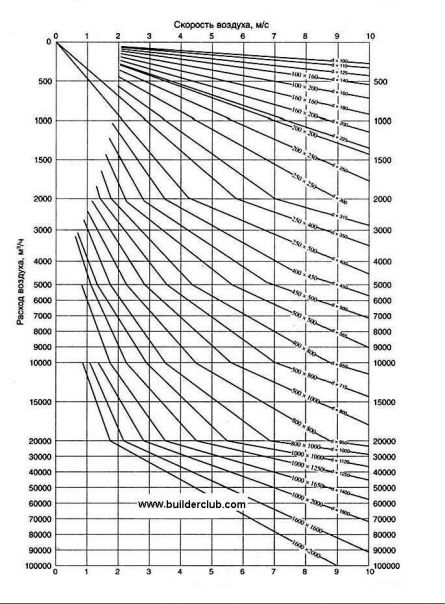

- Having determined the required volume of air for the entire housing, the diameter of the exhaust pipe is found from the diagram. In this case, it should be taken into account that the speed in the central duct should not exceed 5 m/s, and in its branches - 3 m/s.

Diagram for determining the diameter of the ventilation pipe

Method of calculation

For general ventilation, the required

air exchange is determined from the condition

removal of excess heat and dilution

harmful emissions from fresh air

allowable concentrations. Ultimately

permissible concentrations of harmful substances

in the air of the working area set

according to GOST 12.1.005-88.

2.1.Estimated temperature value

supply air depends on

geographical location of the enterprise

take equal to 22.3 °C.

Air temperature in the working area

take 3 ... 5 ° C higher than the calculated

outside air temperature. Density

air, kg/m3, entering the

room,

.(1)

.(1)

The excess amount of heat to be

removal from the production area,

determined by heat balance:

,(2)

,(2)

where

various sources, kJ/h;

consumed (lost) by the walls of the building

and leaving with heated materials,

kJ/h

To the main heat sources

in industrial premises

relate:

-

hot surface equipment

(furnaces, drying chambers, pipelines

and etc.); -

equipment driven by electric motors;

-

solar radiation;

-

staff working on the premises;

-

various cooling masses (metal,

water, etc.).

Because the air temperature difference

inside and outside the building in a warm

period of the year is insignificant (3 ... 5 ° С), then

when calculating air exchange by excess

heat release heat loss through

building structures can be ignored.

At the same time, some increase in air exchange

positive effect on working conditions

working on the hottest days of the warm

period of the year.

With considering

formula (2) takes

the following view:

.(3)

.(3)

In this design task, the excess

the amount of heat is determined

only taking into account heat dissipation

electrical equipment and operating

personnel:

,(4)

,(4)

where

-heat generated during operation

equipment electric motors, kJ/h;

- the heat given off by the worker

personnel, kJ/h.

Heat generated by electric motors

equipment,

,(5)

,(5)

where

β is a coefficient that takes into account the load

equipment, its simultaneity

work, mode

work; β = 0.25…0.35; N—total

installed power of electric motors,

kW.

The heat generated by the working staff

(6)

(6)

where n is the number of employees, people; TOR- heat released by one person, KJ / h (taken

equal to 300 kJ/h in light work; at

moderate work 400 kJ/h;

during hard work 500 kJ/h).

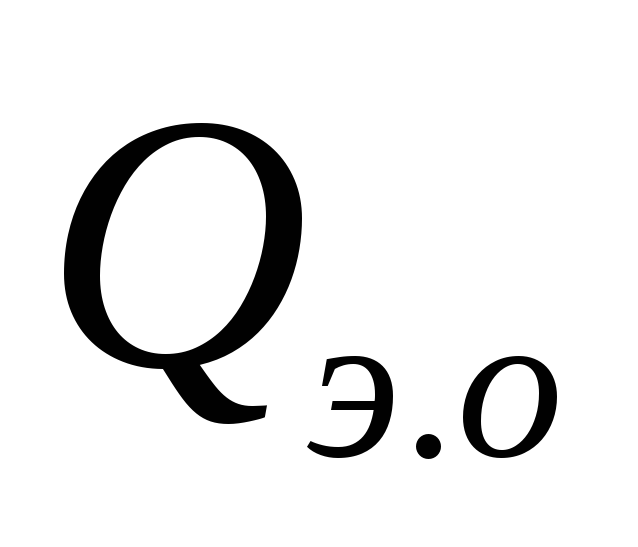

2.2.Consumption

supply air, m3/h, required

to remove excess heat

(7)

(7)

where

Qout of 6

— excess amount of heat, kJ/h;

With —

heat capacity of air, J / (kg-K);c=

1.2 kJ/(kg K); ρ is the air density,

kg/m3;toudis the temperature of the air being removed

from the premises, is taken equal to

air temperature in working

zone, °С; tetc

— supply air temperature, °C.

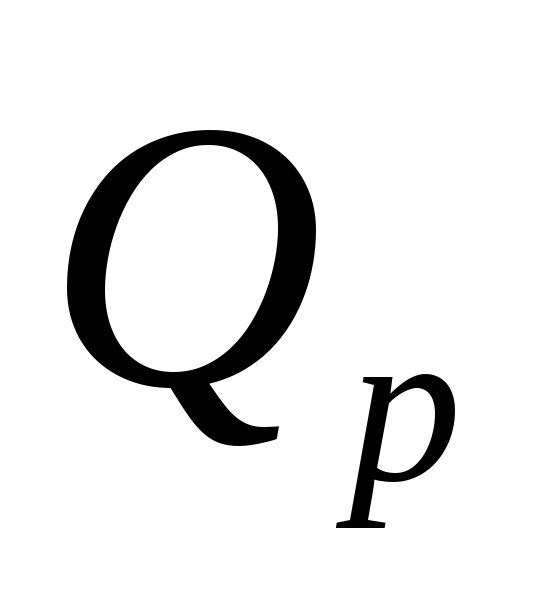

Supply air consumption, m3/h,

necessary to maintain

concentration of harmful substances in given

within,

,(8)

,(8)

where

G—

the amount of harmful substances emitted,

mg/h (see table); qoud

—concentration

harmful substances in the exhaust air,

which must not exceed the maximum

permissible, mg / m3, i.e.qoud

qMPC;qetc-concentration

harmful substances in the supply air,

mg/m3.

(9)

(9)

2.3.Definition

required air exchange.

To determine the required air exchange

Lnecessary

compare valuesL1and L2calculated

according to formulas (1) and (8), and choose the largest

of them.

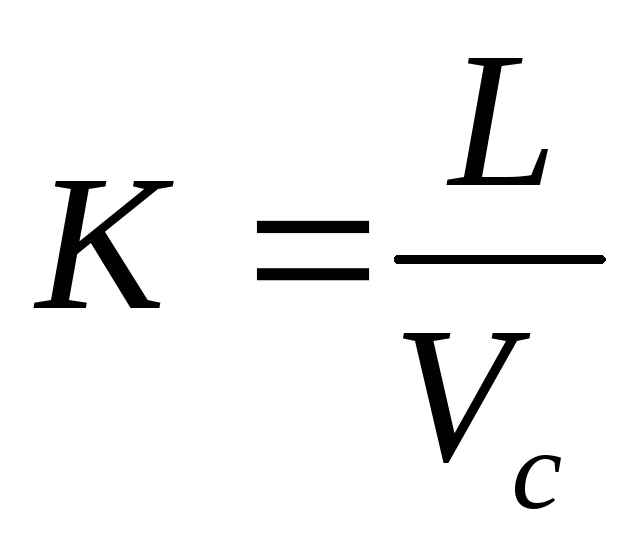

2.4. By

nomogram (Fig. 1) choose a fan

TsAGI series Ts4-70 No. 6 and identify it

main features: district

wheel speed ω,

m/s,

speed n,

rpm, efficiency η,

total pressure H

kgf/m2 (

mm water st)

2.5.Air exchange rate, 1/h,

where L—required air exchange, m3/h; Vc-interior

free volume of the room, m3.

Room air exchange rate

usually ranges from 1 to 10 (large

values for rooms with significant

emissions of heat, harmful substances

or small in size).

For machine and instrument-making shops

recommended air exchange rate

is 1 ... 3, for foundries,

forging and pressing, thermal shops,

chemical industries - 3 ... 10.

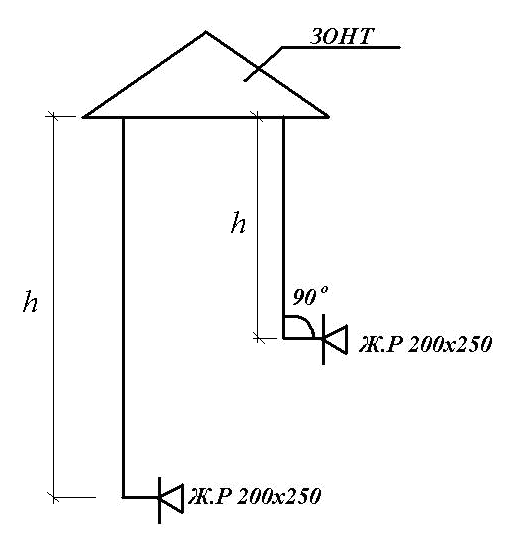

2 Calculation of natural ventilation channels

Design

exhaust, natural ventilation

kitchens, sanitary facilities and bathrooms.

Natural exhaust solution scheme

ventilation of kitchens and sanitary facilities

separate isolated ventilation

channels. Exhaust openings are closed

louvered grilles, which have

on high

0.5÷0.7 m from the ceiling. Featured

louvre dimensions:

—

for kitchen 200250

mm;

—

for latrines and bathrooms 150150

mm;

—

for combined sanitary units 150200

mm.

V

brick buildings exhaust ducts

laid in

thicker walls. The size

channels is a multiple of brick size min

the size

140140

mm. Having arranged the channels in terms of a typical

floors, transfer them to the attic plan. By

each room is sized

the amount of air to be removed (table

11).

Table 11

Air exchange rates

and recommended sizes of ventilation ducts

|

A type |

Air exchange |

Featured |

Square |

deq, |

|

Kitchen with stove: two-burner three-burner four-burner |

60 75 90 |

140140 140270 140270 |

0,020 0,038 0,038 |

140 180 180 |

|

Toilet |

25 |

140140 |

0,020 |

140 |

|

Bathroom |

25 |

140140 |

0,020 |

140 |

|

Combined bathroom |

50 |

140270 |

0,038 |

180 |

gravitational

natural pressure is determined

at outdoor temperature

equal to +5 ºС. At higher temperatures

room can be ventilated

using transoms or vents.

Calculation procedure:

1.

We determine the natural gravitational

pressure for channel natural

ventilation, kitchens with a three-burner

slab on the second floor. Aerodynamic

calculation starts with the most unfavorable

located channel - channel of the second

floors, output the channels as independent

korinnikov

,

,

kg/m3,

where

m - distance from the center of the exhaust

holes to mouth

exhaust shaft

(Fig. 14);

Fig.14.

kg/m3;

kg/m3;

Pa.

Pa.

2.

Recommended air speed

in the channels of the upper floors = 0.5÷1.0 m/s.

Recommended

channel size is 140270

mm.

Square

channel 0.038 m2.

Diameter

equivalent deq=180

mm.

3.

Determine the air velocity in the channel

m/s.

m/s.

4.

Determine the equivalent channel diameter

mm.

mm.

5.

Determine friction pressure loss

per linear meter of air duct

adj. F

R=

0.035 Pa/m,

m/s

m/s

at mm.

mm.

6.

Determine friction pressure loss

along the entire length of the brick channel, taking into account

channel roughness coefficient

determined by air speed m/s

m/s

(app.3)

0,035·3,4·1,30=0,155

0,035·3,4·1,30=0,155

pa,

where

channel.

7. Define losses

pressure on local resistances (30)

,

,

where

local resistance on the site (w / r

=1.2; elbow 90º = 1.2; probe over the shaft =1,3)

(Appendix I).

By

adj. We define

m/s

m/s

Pa.

Pa.

8. Define

total pressure loss due to friction and

local resistance

0,155

0,155

+0.677 = 0.832 Pa

,

,

2,0

> 0.832 Pa

General information

Ventilation - Organized and Regulated

air exchange to remove

from indoor air polluted

harmful impurities (gases, vapours,

dust), and the supply of fresh air into it.

According to the method of supplying fresh

air and removal of contaminated system

ventilation is divided into natural,

mechanical and mixed. By appointment

ventilation can be general and

local.

General ventilation is a system

ventilation designed for

supply of clean air to the room,

removal of excess heat, moisture and

harmful substances from the premises. In the last

case, it is applied if harmful

selections go directly to

room air, and workplaces are not

fixed and located throughout

room.

Usually air volume Letcsupplied to the premises during general exchange

ventilation, equal to the volume of airLv,

removed from the premises. However, in

clean shops of electrovacuum

production for which a large

the absence of dust matters, volume

more air flow

hoods, due to which some

excess pressure in the production

indoors to avoid dust

from adjacent rooms. In general

the difference between the volumes of inflow and

extract air must not exceed

10…15%.

In systems with mechanical drive

air movement through ducts

carried out by fans

create much more pressure

compared to the natural impulse.

This makes it possible to increase the speed

air movement, supply air to

greater distance and provide

smaller ducts.

Fan selection is carried out according to

aerodynamic characteristics,

which are compiled for each number

and fan type and express the dependence

between its performance

air, pressure and speed

working wheel. However, from various

types and numbers of fans are selected

the one whose efficiency is greater for the same

performance and pressure. Should

remember that the efficiency of the selected fan

must be at least 0.85 ήMax(ήMax—

maximum efficiency of the fan according to its

aerodynamic characteristics).

Peripheral speed of the impeller

centrifugal fan according to the condition

noiselessness should be no more than 25 m / s

for residential buildings and 17 m/s for clubs and

cinemas; circumferential speed of the worker

wheels of axial fans - no more

35 m/s for residential buildings and 25 m/s for clubs

and cinemas.

Consequences of poor ventilation

If the fresh air supply system is not properly organized in the premises, there will be a lack of oxygen and increased humidity. Mistakes in the design of the hood are fraught with the appearance of soot on the walls of the kitchen, fogging of windows and the appearance of fungus on the surface of the walls.

Fogging windows due to insufficient ventilation

It should be borne in mind that pipes of round or square section can be used for the installation of the ventilation system. When removing air without the use of special devices, it is advisable to install round air ducts, as they are stronger, tighter and have good aerodynamic characteristics. Square pipes are best used for forced ventilation.