Processing Options

In the field of maintenance and restoration of chimney ducts, traditional materials have long ceased to be relevant. They are being replaced by polymer-based products. With their help, the sealing of the stainless steel chimney becomes as reliable as possible, retains the result obtained over a long period of operation.

Chimney treatment can be carried out in two ways.

The first method involves the application of PEK-1 paste, made on the basis of dianic epoxy resin, capable of turning into a polymer having a spatial, network structure, on the inner walls of metal pipes. The paste turns into a solid if a special hardener made with aromatic polyamine is used during the work.

On the surface of the chimneys, the application occurs as follows.

- Experts prepare the surface.

- A special primer is prepared and applied to the surface.

- A polymer paste is applied to the surface of the applied primer brought to working condition.

- Masters check the quality of the work performed.

However, the protective coating should only be applied by the worker. Accordingly, the use of this technology becomes possible in the presence of pipes with a diameter of at least 150 centimeters.

The second method is intended for those who use a chimney, the diameter of which is not more than 120 centimeters, where, accordingly, the worker cannot climb inside. Here we are talking about a pre-prepared composite sleeve.

The presented sleeve is a prepreg, the structure of which includes fiberglass for additional reinforcement. The prepreg is impregnated with a paste based on furan resin. Being rolled up, the sleeve is lowered into the chimney, which needs to be completely sealed.

Next, experts begin to use steam, with which the sleeve is inflated. Then the sleeve completely takes the form of the old channel. Under the influence of elevated temperature, hardening occurs, as a result of which a new surface appears. In other words, here we are talking about chimney sleeves using composite-based materials.

The procedure is performed in the following sequence.

- The chimney is inspected.

- The material is drawn along the entire length of the channel.

- The roll is inflated with steam to reach the desired size. There is a tight fit to the inner walls of the channel.

- The material is brought to a state of complete readiness for 2-4 hours.

- The correctness of the work is being checked.

Due to the unique installation technology, the material is optimally suited for both small and large diameter pipes. Due to the special properties of this product, an excellent installation possibility is provided, regardless of the slope, the number of irregularities inside the channel.

Watch related videos:

Why is chimney sealing necessary?

The chimney is designed to remove hot combustion products from the combustion chamber of the heating unit - boiler, stove, fireplace. Any fuel during combustion produces a lot of carbon dioxide (CO2), a small amount of carbon monoxide (CO), sulfur oxide (SO2), a small amount of oxides of some other elements, water, unburned fuel particles (soot). All of them are harmful to humans.

The temperature of flue gases from solid fuel boilers can reach 600 ° C and above, gas boilers - 200 ° C, when cleaning the flue by igniting soot, it reaches 1000 ° C. A small trickle of hot gas from a chimney is a common cause of fire.Even 200 ° C for a long time is enough to start smoldering wallpaper.

Therefore, the tightness of the chimney is a prerequisite for its operation. Modern heat-resistant sealants are used to seal the joints of individual elements of prefabricated chimneys. In addition, they are used for emergency sealing of leaks that occurred during the heating season, when it is not possible to turn off the heater and disassemble and replace part of the chimney.

Heat-resistant sealants are even used to seal holes and crevices in traditional brick chimneys. Traditionally, clay was used for this, but as a sealant it is unreliable. In addition, heat-resistant sealants waterproof the exit of chimneys to the roof - this protects the rafters and under-roof structures from getting wet and rotting.

Selection principles

Sandwich pipe and accessories for it should be selected according to the following criteria:

- The type and number of modules.

- Thickness, brand of insulation.

- The wall thickness of the pipes, the material from which the protective casing is made.

- The material from which the inner pipe is made, the wall thickness.

Smoke sandwich pipes are made from different grades of alloy steels, which determines their technical characteristics.

Dimensions

Particular attention must be paid to the size of the sandwich pipes for the chimney. It should be selected depending on the power of the heating equipment.

The classic cross-sectional size of the tubes is 120 mm. The optimal power in this case is up to 3.5 kW. If more powerful furnace equipment is used, the pipe diameter must be increased. The diameter of the sandwich chimneys for boilers or furnaces with a power of 5 kW is 180 mm, 7 kW is 220 mm.

Life time

The service life of a sandwich chimney depends on several factors:

- exploitation activity;

- type of fuel burned;

- grade of steel from which the inner part of the part is made.

For example, a product made of AISI 316L steel with a thickness of not more than 0.5 mm can withstand about 10 years of active operation. If the part is made of AISI 310 steel, the thickness of which is 0.8 mm, the service life will be doubled.

Stacked firewood for the stove

Chimneys made of stainless steel

This type of chimney is assembled in modules of sandwich pipes and other elements made of stainless or galvanized steel.

The chimney sandwich pipe is the main element of the chimney system, which consists of an internal contour, a heat insulator layer and an outer casing

You need to pay special attention to them, because their number in the estimate will be larger, and the main load will fall on the inner contour of such a pipe

If the boiler room runs on solid fuel (pellets, firewood, lignite) or gas, the inner contour of the chimney is made of AISI 321 heat-resistant steel.

A feature of AISI 321 is the increased content of titanium in the alloy. If the boiler room runs on diesel fuel, the inner contour of the chimney is made of AISI 316 acid-resistant steel. AISI 316 is stainless steel with a high content of molybdenum in the alloy.

The heat insulator layer is stone wool on a basalt basis. The heat insulator reduces the amount of condensate in the chimney and the transfer of heat to the outer casing.

The outer casing is made of AISI 430 stainless steel or galvanized steel.

Manufacture of chimneys by the Chimneys of Petersburg plant

The Chimneys of Petersburg plant manufactures chimneys under the Eco-Steel trademark with diameters from 80 mm to 1500 mm.

In the manufacture of chimneys, we use special grades of stainless steel: AISI 321 for solid fuel and gas boilers, AISI 316 for diesel boilers. Stainless steel thickness from 0.5 mm to 2 mm.

As a heat insulator, we use a combination of two stone wools - Rockwool and Paroc. The thickness of the heat insulator is from 30 mm to 100 mm.

The outer contour is made of AISI 430 stainless steel or galvanized steel.

In addition to the manufacture of chimneys, we provide services for the design, dismantling, installation and delivery of structures and elements to the site.

Chimney design

The initial stage of manufacturing a chimney is the development of a project, according to which in the future it will be possible to determine the amount of materials required to assemble the structure.

When designing a structure, the following are determined:

- type of pipes to be used for construction;

- chimney dimensions;

- the amount of materials.

From what pipes can a chimney be made

The following stainless steel chimney pipes are used for construction:

standard or monotubes. A single-wall chimney can withstand temperatures up to 450ºС and is mainly used for buildings located in warm regions;

Standard stainless pipes

sandwich pipes. They are made of several layers of metal, between which a layer of insulation is laid. Sandwich pipes can be used in various regions, including the Far North.

Pipes with additional insulation

There is no fundamental difference between the pipes. Standard pipes can be insulated independently with any material.

Chimney sizing

After choosing the type of pipes, the dimensions of the chimney are determined. At this stage, you need to calculate:

- the length of the pipeline for removing smoke;

- flue diameter.

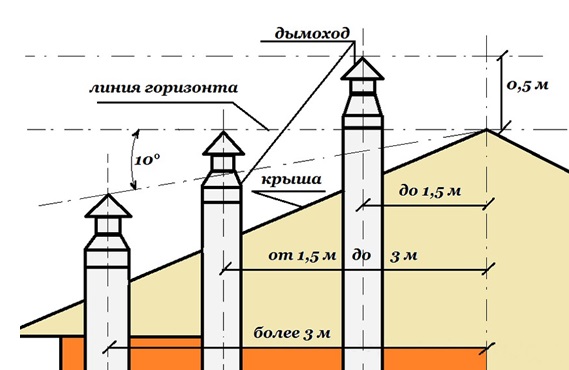

When calculating the length of the structure, the following rules must be followed:

- for normal draft and complete removal of harmful substances from the living quarters, the total length of the chimney should not be less than 5 m;

- the minimum height to which it is necessary to bring the chimney on the roof of the house is 0.5 m;

- when removing the pipe at a distance from the ridge of the roof, it is necessary to take into account the permissible norms of deviation from the horizon.

Permissible deflection angles of the chimney

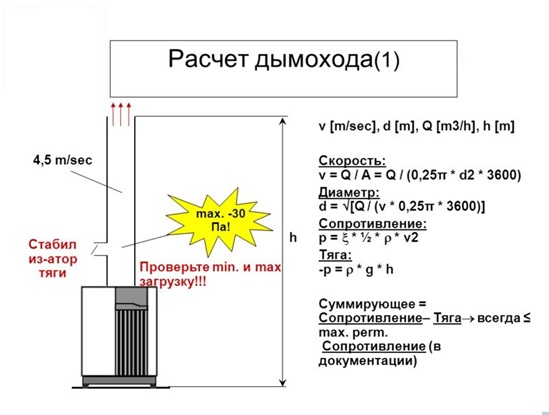

To independently determine the diameter of the chimney pipes for a boiler, fireplace, stove or other heating equipment, you need to know the power of the heating device.

To calculate the cross section, you can use:

formulas. Such a calculation is considered the most difficult, since the formulas take into account the indicators of the amount of fuel burned, the rate of passage of gases in the pipe, the thrust indicator, and so on;

Independent calculation of the section

- special programs. On the Internet you can find many programs developed by specialists that simplify the calculation process as much as possible;

- normative parameters calculated by experts earlier.

The following standards have been developed for the cross section of the smoke channel:

- for a device with a power of less than 3.5 kW, pipes with a size of 0.14x0.14 m are suitable;

- if the power of the heating equipment for a bath or house is more than 3.5 kW, but less than 5.2 kW, then pipes with dimensions of 0.14x0.20 m must be used;

- if a gas boiler or other equipment with a capacity of more than 5.2 kW is installed, then pipes of 0.14x0.27 m are optimally suited.

If larger pipes are used for the chimney, then the increased draft will burn more fuel to achieve the optimum room temperature. When using pipes of a smaller cross section, combustion products will not be completely removed.

Preparation of materials and tools for assembly

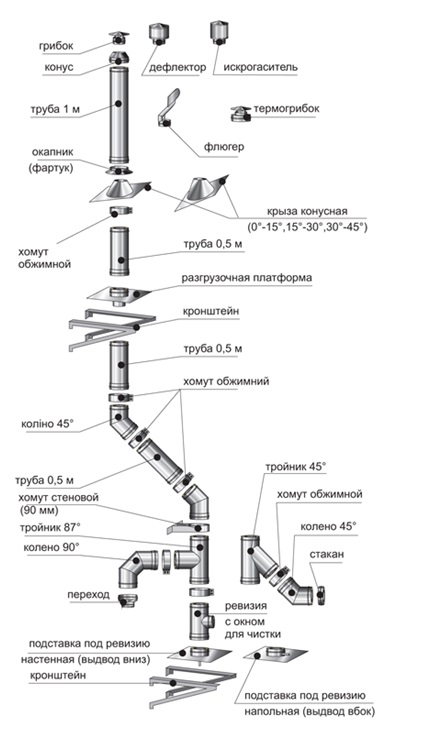

To assemble the chimney, you will need to purchase:

- pipes of a certain diameter and length;

- brackets for attaching the pipeline to the roof and ceiling to give the system additional strength;

- crimping clamps that allow you to connect the individual elements of the stainless steel chimney into a one-piece structure;

- revision. A special element is installed for the convenience of monitoring the state of the chimney system and timely cleaning;

- unloading platform for the correct passage of the chimney through the ceiling;

- a node for bringing the system to the roof, which includes such components as an apron and a roof;

- cone and cap (fungus). Additionally, you can install a deflector or spark arrester.

The main elements of the design of the chimney channel

To carry out work on assembling the chimney, you will additionally need a heat-resistant sealant that gives the system strength and rigidity, and a heater for arranging passages through the ceiling and roof.

What are stainless steels for chimneys

By itself, steel, as you know, is not the best material for making pipes. Especially designed for such a serious operation as removing smoke from a heating system. Ordinary (or black) steel is a durable material, but highly susceptible to corrosion.

The problem of rust on steel products was solved when stainless steel was used in production. The resistance of this material to corrosion is due to the fact that chromium was added to the alloy of ordinary steel. When interacting with oxygen, a special film is formed on the surface containing chromium, which has an anti-corrosion property.

There is a classification of stainless steel used in the creation of various products:

Steel class AISI 430 (as well as AISI 409, AISI 410) will have a mass content of chromium equal to 11%. This class is not suitable for the production of pipelines, since its use is possible only in low-aggressive environments.

The use of steels of such classes is advisable in the manufacture of dishes and interior elements. AISI 304 or AISI 321 steels have a chromium content of about 17%. Also, the composition of the alloy will include nickel, which provides the steel with ductility. The alloy is widely used in the production of pipes.

Such products not only do not become covered with a layer of rust over time, but can also function perfectly at temperatures up to 450 degrees. The use of chimneys from the presented steel classes is possible only under temperature conditions not exceeding this limit. AISI 309 class steel. This variety is considered a heat-resistant material, the alloy contains at least 25% chromium, and nickel - at least 20%.

Chimneys made of this alloy can be used in higher temperature conditions, as well as in fireplace systems, solid fuel boilers and gas turbine installations. AISI 316 grade steel. In addition to chromium, stainless steel contains titanium and molybdenum. Chimneys made of this class of material are optimal for use in any conditions.

The maximum temperature for the AISI 316 class is 800 degrees, which fully satisfies the requirements of modern heating systems. AISI 310S class steel. The most expensive and heat-resistant material. It differs from other species not only in absolute resistance to chemical (acidic) effects, but also in the ability to withstand temperatures reaching 1000 degrees.

Chimney systems are made only from those types of steel that are heat resistant

The main requirement for smoke exhaust hoses is their wall thickness. This is especially true for gas-fired boilers. The thickness of chimneys for such equipment should be more than 1 mm.

Is sealing required

Without good sealing, no chimney can function safely and reliably. Therefore, sealing is mandatory. In the case of using a steel chimney, sealants may be different, depending on:

- temperature parameters (heat-resistant);

- composition (two- or one-component);

- bases (silicone or silicate).

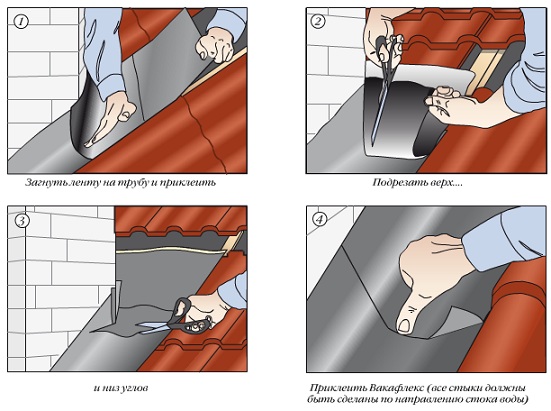

Stages of waterproofing the top of the chimney pipe

Other sealing methods may also be used. The main condition in this case is to ensure the required level of safety and reliability in operation.

How to accurately and correctly apply sealant

When working with both types of polymers, it is necessary to prepare the surface of the chimney: clean, remove dust and dirt, and degrease. It is desirable to sand the steel with fine sandpaper to improve the adhesion of the polymer.

The surface under the heat-resistant sealant must be completely dry.The tube is filled into the gun and a small amount of silicone is squeezed onto the sealed joint. Allow to harden (approximate time is indicated on the package).

The base for the heat-resistant silicate polymer is prepared and lightly moistened. Apply sealant and let dry. Excess heat-resistant mass is removed until the sealant has hardened. You can pre-glue the masking tape along the joint, and remove it after application.

It is desirable to perform work in warm weather.

Features of sealing sandwich chimneys

Sandwich pipes have a metal surface. Both silicate and silicone polymers are used for their sealing.

A characteristic feature of sealing sandwich pipes is the need to seal both the inner and outer pipes. In addition to the general safety considerations that were given at the beginning of the article, it is very dangerous for a sandwich to get atmospheric moisture from the outside or condensate from the inside into the insulation.

The outer layer should be coated with silicone - it has excellent hydrophobic properties. For an internal joint, a heat-resistant sealant is selected depending on the type of heater and smoke temperature.

The sealing process itself is not particularly difficult - a bead of sealant is applied to the joined surfaces of the outer and inner layers and gently smeared with a layer of 1-2 mm using a spatula or a flat steel plate, then the chimney modules are joined together.

Tips on how to choose

Heating equipment and chimneys are a very important and unsafe part of home engineering. The life and health of residents depends on their serviceability. Therefore, saving on heat-resistant sealants is not worth it. It is best to buy materials from well-known brands and in large stores with a receipt.

Silicone is expensive and sometimes counterfeited. If several bottles are purchased, then you can squeeze a little polymer out of one, wait for curing and set it on fire. Silicone ignites heavily, will emit a mixture of black and white soot (hydrocarbons and silicon oxide). Fake (most commonly used acrylic polymers and PVC) will burn with the release of black soot.

It is also worth mentioning that heat-resistant sealants for stoves and chimneys are sold in tubes for a construction gun. If sellers advise polymer in ordinary tubes, be aware that most often it is a sealant for cars, it contains acid and is completely unsuitable for heating equipment and chimneys, so carefully read the labels on the package before buying.

When choosing, be sure to read the label. The operating temperature must correspond to the operating conditions, this is the most important criterion for choosing a heat-resistant sealant for the chimney. The sealant should be neutral, not acidic.

approximate price

Below is information on how much the most common brands of heat-resistant polymers cost. Silicone polymers are much cheaper than silicate ones.

Varieties of sealants for chimneys

Heating communications in a residential building are often subjected to all kinds of temperature, mechanical and other damage. In particular, this applies to brick structures, to a lesser extent - steel, polymer and other communications. The use of sealants gives chimney structures not only tightness, but also significantly strengthens them in relation to mechanical and other loads.

Sealing materials have different properties depending on the places of use. In the case of chimneys, sealants that are resistant to thermal stress are required for operation at high temperatures.

The basis of most sealing compounds and products are polymeric materials. In most cases, sealants for chimney pipes are one-component, in more rare cases - two-component.Two-component pipe sealants require high-precision mixing before use, where overdosing by even a few grams can lead to loss of important properties. Therefore, one-component sealing materials, which usually have a paste-like consistency, are mainly popular. It is better to use quality materials so that you don't have to think about it later than to seal the pipe on the roof from leaking, which will inevitably happen when using low-quality sealant.

High temperature sealants fall into two main categories:

- Heat-resistant, resistant to temperatures up to 350 °C. Such materials are used for the construction of the outer surfaces of stoves or fireplaces, especially brick ones. In addition, they are suitable sealants for chimneys on roofs, with the exception of metal ones.

- Heat-resistant pipe sealants withstanding temperatures up to approx. 1500 °C. They are used for metal chimneys, as well as for joining metal and brick parts. In particular, the use of such sealants for chimneys made of stainless steel or other types of steel is acceptable.

In general, the choice between heat-resistant and heat-resistant sealants depends on the location of the mounted area and the temperature in it.

You should also pay attention to sealing materials based on polymer SMX

They are not classified as high-temperature sealants, but are specifically distinguished as a sealing adhesive suitable for operation at temperatures up to 200 ° C. One of its advantages is that installation work with it can be carried out even at sub-zero temperatures in winter.

Some features of heat-resistant and heat-resistant sealants should be discussed in more detail.

What parts are needed for a stainless steel chimney pipe

The choice of accessories for the chimney channel will depend on the initial drawing. You can choose everything you need from the existing range:

Straight sections of chimneys. The length of the straight sections, which are the basic part of any smoke channel, can vary from 330 mm to 500 mm and 1000 mm. The straight sections of the system are fastened with a simple socket method, they do not need any connecting elements. Elbows (outflow) with an angle of 45 degrees.

Designed to change the angle of inclination of a straight pipe. The scope of the outlet elbows is vertical and inclined (horizontal) sections. Bends from 90 degree angles. Versatile: Due to the four-piece design of the right-angled elbow, the angle of inclination can be changed from 0 to 90 degrees.

They are used mainly when connecting a short horizontal part extending from the boiler (pipe) with the main smoke sleeve. Tees. Available in various configurations: 87 and 45 degrees. They play an important role in the maintenance of the chimney.

With the help of tees, it is possible to clean the system and fix the main channel with a condensate collector. They are also used as splitters when connecting two heating sources (the procedure requires the agreement of the relevant authorities). Audits. Also, like tees, they make it easier to clean the chimney from internal contaminants.

Usually installed under the base of a vertical flue duct under a tee. Condensate collectors. Necessary for the release of excess moisture from the vertical flue. Collection watering cans are also installed under the tee. Protective elements for the upper part.

Fungi deflectors, weather vanes, waterproofing skirts are used as protection against atmospheric precipitation. Spark arresters also protect non-heat resistant roofs from fire. Other details. Also, during installation, heat-resistant penetrations through the roof, penetrations for walls and interfloor ceilings are used.

Installing modular ducts and sandwich chimneys is a fairly unproblematic undertaking.It is possible to achieve efficient operation of the system, even without special knowledge in this area. The selection of a chimney and fittings made of a suitable steel grade and compliance with technical standards will make it possible to install a safe and hermetic system.

https://youtube.com/watch?v=—n3cFRbKRkrel%3D0%26controls%3D0%26showinfo%3D0

- www.eco-steel.ru

- moluch.ru

- trubamaster.ru

Types and differences

All types of sealants for use at high temperatures are divided into two large groups - heat-resistant (silicone) and heat-resistant (silicate). They differ in chemical composition and permissible operating parameters.

heat resistant

Heat-resistant sealants are made on the basis of silicones - organosilicon oxygen-containing compounds. They withstand temperatures up to 300°C, at 100°C and above, heat-resistant silicones outperform all traditional elastic materials.

Silicones are durable, elastic, chemically inert, waterproof, resistant to biological influences, UV radiation. Can work with rapid temperature changes, non-toxic, environmentally friendly.

Heat-resistant silicones are available in the form of a reddish-brown paste. The color of the sealant is given by iron oxides. Operating temperatures can range from 170 to 300 ° C, this information is indicated on the packaging.

Scope of silicone: sealing the outer surfaces of the chimney, the junction of the pipe and the roof, sealing non-through cracks on the brick surfaces of fireplaces and stoves, sealing pipes of gas boilers with high efficiency and low heating of flue gases.

Silicone seals

For the convenience of consumers, the industry produces a huge range of silicone seals - gaskets, membranes, cords, tubes, seals of various configurations. They are used to seal windows and doors, in household appliances, in cars, electrical engineering.

A master flash is made from silicone - an elastic sealant for the passage of a pipe through the roof. They produce special heat-shrink tapes - they are wrapped around the joints of the chimney modules, when heated, they melt and tightly fill the sealed joint.

Heat resistant

To seal and repair the internal surfaces of chimneys, combustion chambers, solid holes in brick pipes, joints of cast-iron and steel elements with stove masonry, assembling sandwich chimneys, refractory silicate polymers are used that can withstand temperatures up to 1200 ° C (for a short time - even up to 1500 ° C ).

Silicate sealants are black or black-gray in color and have a viscous consistency that cures within 15 minutes of application. The thickness of the seam can reach 15 mm. Heat-resistant silicates form an inelastic seam. Works are carried out at temperatures from 1 to 40 °C.

Adhesive facing compositions

The industry produces special heat-resistant compounds for lining stoves, fireplaces and chimneys with tiles (plain, fireclay, clinker, porcelain stoneware), natural or artificial stone. Usually they are made on the basis of silicates, contain liquid glass, kaolin, cement, plasticizers, polymers.

Such mixtures withstand temperatures from -30 to +170 ° C and even higher. In industry, other high-temperature adhesives are also used, which require strong heating for drying, but they have not received distribution in everyday life.

Which view is better

Each type of sealant is designed for certain operating conditions and performance of certain functions. Silicones are used on the outer surfaces of chimneys, stoves and fireplaces, sealing elements of gas boiler pipes. Heat-resistant silicate polymers are used in any case, if the place of application of the sealant is heated to more than 300 °C. They can also be used to seal leaks in heating units, even for metal.