CONNECT HEATED FLOOR

Underfloor heating is a system of low-temperature infrared heating. It works exactly as it is called - the heated floor heats the air. The system is trendy, modern, and every homeowner considers it his duty to shove it where he can or cannot. Concerning a heat-insulated floor it is necessary to understand the following: the floor has to be warm, instead of hot. Comfortable temperature is 22-24 degrees. A hot floor of 26 degrees or more is appropriate in the bathroom and hallway - so that the shoes dry. In other places, the hot floor causes discomfort.

Not the fact that the comfortable temperature of the warm floor in your conditions is enough to heat your room. Therefore, together with a warm floor, it is recommended to provide heating radiators in the places where they should be, i.e. under the windows, at least a few. Otherwise, it may turn out that for half a winter you will have to walk not on a warm, but on a hot floor.

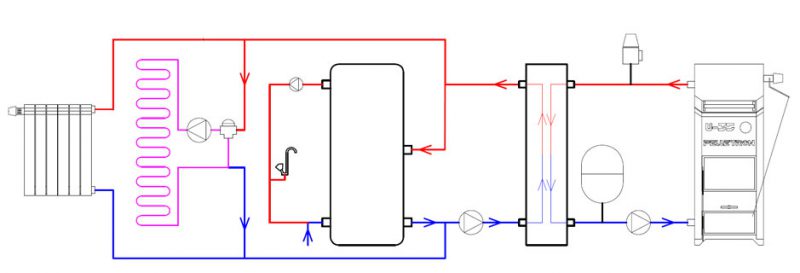

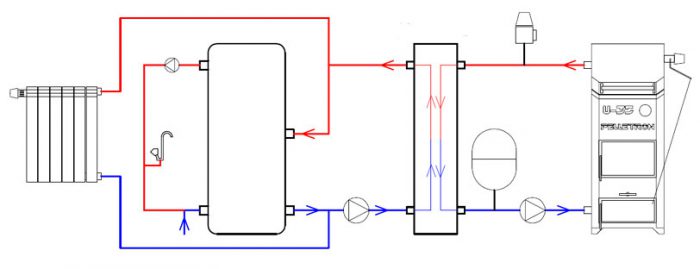

Here's how underfloor heating works.

The "warm floor" system has a coil laid in the floor (pink). The coil has its own circulation pump, which provides continuous circulation of water through the coil. The mixing valve controls the temperature of the water in the coil.

How it works? Assume the mixing valve is set to 26 degrees. On the one hand, water with a temperature of 70 degrees (red arrow) from the heating system is supplied to the valve inlet. On the other hand, water at a temperature of 20 degrees (pink arrow) from the coil is supplied to the mixing valve. The valve will mix the water so that it is exactly 26 degrees at the inlet to the coil. Excess water taken from the heating system, when mixed, is drained back into the system (blue arrow).

Such a scheme for assembling a warm floor is very viable and inexpensive. So before purchasing an expensive mixing unit for underfloor heating, think about it, is it really necessary?

Now let's connect the underfloor heating to the heating system.

By the way, the proposed floor heating scheme has manual control (i.e. it is not thermostated). The underfloor heating temperature is controlled by turning the mixing valve knob and, as a rule, this is absolutely sufficient.

Is it possible to control underfloor heating automatically according to the air temperature? Of course, it is possible, but the significant financial costs of such management should be well justified.

Now everything really works as it should!

As you can see, from one heat source (boiler with or without a hydraulic arrow) with a temperature of 70 degrees, we immediately powered all the thermal equipment: radiators and underfloor heating and a hot water boiler.

The proposed schematic diagrams, i.e. they show the principle of building a heating system based on solid fuel boilers, omitting the actual technical implementation of the solutions.

And why, in fact, 70 degrees in the boiler? The temperature should be above 60, but below 80. Above 60, in order to avoid condensation in the boiler, and below 80, so that there is a margin for overshooting the temperature to the normal limit of plastic pipes - 92 degrees. The proposed 70 degrees is usually enough for all occasions in winter and summer.

But the fashionable “weather regulation”, available in some boilers, is just a temperature change in the boiler by a few degrees when the intake temperature changes. And, as you now understand, it does not play any role.

And one more important point. The boiler has a minimum output. The minimum power of the Pelletron boilers: U25, 35, 25 is 3 kW, and U60 is 5 kW. If you stop the heat consumption of the heating system at all, then the boiler will not immediately, but still boil.

To prevent this from happening, ensure that the guaranteed heat consumption is higher than the specified one.To do this: put 1-2 radiators at full flow (without heads or unscrewing the heads to the maximum), install heated towel rails in bathrooms and toilets, do not be zealous about insulating pipelines, collectors and other elements of the heating system.

Usually, these measures are sufficient to ensure that the heat consumption is above the minimum.

To create comfortable conditions, more and more often, the owners of mansions and apartments are striving to equip innovative underfloor heating, one of the varieties of which functions by supplying water heated to a certain temperature into pipes laid in a certain way.

In this case, it is important to correctly select a boiler for a water-heated floor that meets all the requirements and is suitable for specific conditions.

Connection to the heating system

The comfort of underfloor heating, which creates a uniform thermal background throughout the volume, is difficult to overestimate. They are of particular relevance in autonomous residential buildings, they are used even in apartments where it is possible to equip local heating equipment, since connecting a water heated floor to a heating system coming from a central boiler room is prohibited for several reasons:

- low quality of the heat carrier;

- exposure of pipes to significant hydraulic resistance;

- the risk of damage to the elements of the system from hydraulic shocks.

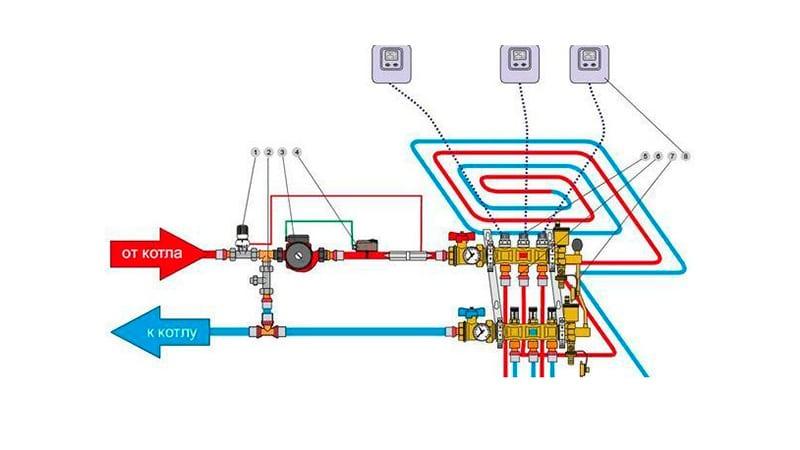

Using your own heating system requires the presence of a mixing unit that lowers the temperature of the coolant, since when heating the house, the liquid heats up to 75 ÷ 90 ° C, and ≤ 50 ° C is allowed for the floor.

Collector - connecting the underfloor heating to the heating system

The sequence of work includes several stages:

- Simultaneously with the sensor, the circulation pump is securely fixed on the inlet pipe.

- A mixing valve (preferably a three-way valve) is connected to the warm pipe of the heating system.

- The outlet of the non-return valve installed on the outlet pipe is connected respectively to the heating return pipe with a branch leading to the mixing valve.

Functioning of floors heated by a heating system

The liquid from the hot pipe of the heating system is mixed with cold water to the desired temperature in a three-way mixing valve. Then, with the help of a pump, it is fed into the heating, placed in the desired sequence, floor circuit. Having passed the entire area and given off heat, one part of the liquid enters the cold pipe of the heating system, and the other is sucked in for subsequent use in the mixing unit.

The temperature sensor regulates the parameters of the coolant, controlling the functioning of the three-way valve and the pump. Having made a test run after complete installation, the degree of comfort of the achieved floor surface temperature is assessed. If there are problems, then the sensor is adjusted in the direction of decreasing or increasing the initial values. You can adjust the three-way valve to the desired amount of coolant supply.

Connecting a warm floor to a central heating system

You can use a two-way valve or a supply valve with a thermal head equipped with a sensor that controls the opening or closing intervals of the pipe supplying the coolant to the floor circuit. Hot water mixing in such a device is not constant, as in the previous case, but is carried out only in the interval when the tap is open. A bypass must be provided, which is equipped with a safety valve that operates if the pressure becomes critical at the manifold inlet. Part of the water is discharged into the return line, which prevents overheating of the floor.

Heated floors from an electric boiler are the main nuances of such a system

Heating private spaces with underfloor heating is becoming quite popular among homeowners.One of the types is the organization of a system based on water pipes. In this option, the question of the correct selection of a source of warm water becomes urgent. And one of the types is the use of an electric water heater.

Water heating system

Water heater application

During the installation of a hydraulic underfloor heating, the apartment owner needs to solve two problems:

- get a working design that heats the air in the room to the optimum temperature,

- choose a cost-effective option at the manufacturing stage and in the course of work.

For heated floors, electric or gas water heaters are used, which provide local heating in the apartment. However, in the case when the apartment is connected to the main heating, this will not work. It is not allowed to connect other consumers to the system, except for the installed radiators.

In this situation, it is necessary to look for alternative sources, and one of which is electric storage electric water heater. Of course, this device is not designed for such an application, and the TP circuit will become an additional load on it. And this can lead to failure of the drive. And yet the creation of such a design is allowed.

The main thing here is to correctly calculate the load - it will not work to heat large areas with an electric water heater. But for TS, arranged in the bathroom or in the kitchen, this source is enough.

Types of electric water heaters

All the abundance of models of water heaters on the market is divided into two groups:

The former are connected to the cold pipeline circuit and provide virtually instantaneous heating of the water when turned on. But at the same time, high loads work on the power grid, because the power of these devices is 6-10 kilowatts. Thanks to this for underfloor heating these heaters are not suitable.

The main thing! Flow type heaters are powerful consumers of electrical energy.

Flow type heater

Unlike flow heaters, storage type heaters are a large container with a tubular heater. The power of such devices is 1.5-2 kilowatts, and the volume is 50-100 liters. According to the device, they can resemble a thermos - the water in them quickly heats up and slowly cools down. In addition, storage devices are equipped with a thermostat, thanks to which the water is heated to the temperature set by the client.

There are boilers of considerable volume on the market - 250-300 liters. But they are rarely used for household needs. By the way, these devices can be actually designed for use in heating systems, they have different placement of the inlet and outlet for water.

When designing a heated floor, it is important to take into account the power consumption required for an electric storage water heater to heat the room. Naturally, 1 kW per 10 squares of the room is taken for calculation

It turns out that an average boiler will be able to heat 15-20 squares of a room.

Heat loss must also be taken into account. They average 100 watts per 10 squares. Moreover, this figure depends on certain factors:

- room type,

- quality of floor insulation,

- room floor,

- device technique heating circuit.

Due to this, when calculating the system, it is better to make a not very large margin - so there will be no situation when the boiler capacity is insufficient.

Invisible connection points

In order for the design to work completely, the following invisible points must be taken into account during design and connection:

- placement of an electric water heater - it is better that it is close enough to the heated room,

- the difficulty of the heating circuit - the longer and more difficult the pipe circuit, the water flows very slowly through it, therefore, heat losses increase,

- the power of the electric water heater should exceed the calculated energy consumption by 15-20%,

- In order to improve the performance of underfloor heating, it is recommended to connect a circulation pump to the system.

At the same time, it will be necessary to provide for a very high load on the boiler. Because of this, he needs to arrange regular preventive maintenance.

It is not very difficult to make a heated floor from a heating electric water heater. He will be able to provide sufficient heating of the room, and the installation process of the system is the simplest.

However, it is necessary to take into account the low power of such a device and rely on heating small areas.

Characteristics of gas models

Modern modifications of gas boilers must be equipped with electronic controls that regulate temperature parameters, ensuring the safety of the system.

In order for automation and a circular pump for a warm water floor to work in the event of a power outage, it is advisable to stock up on a local source. A few hours of work will provide car batteries. In situations where there is a risk of frequent power outages for several days, you will have to purchase a diesel generator.

The principle of operation of the boiler is based on the circulation of the coolant through the exchanger, during which it is heated by flue gases resulting from the combustion of fuel. During the transfer of thermal energy, the gases are cooled, and at a certain temperature, condensate is formed, which causes the appearance of additional heat. This feature significantly increases the efficiency of heating equipment.

Gas boilers function flawlessly under conditions of uninterrupted gas supply, without requiring special procedures for routine maintenance. In designs where an electronic mechanism for ignition of the boiler is provided, the operation of the burner is regulated in accordance with the specified temperature indicators with the removal of all harmful combustion products through forced ventilation. Boilers with piezo ignition, working automatically, also stop the flow of gas if the flame goes out, but combustion is restored manually.

Boilers. Design features

A heating system based on electric heating of water is not considered anything special. A storage electric water heater is a device in which water is heated by the operation of electricity. According to the principle of operation, storage water heaters are divided into two types:

For models with a storage tank, an important design element is a tubular-type heating element that provides water heating. Heating elements in most cases are placed in an accumulative tank, where water comes from the tap. The mode of turning off and on the TENOs is provided by automation.

In terms of technology, a storage electric storage water heater strongly resembles a thermos. In the inner case, water is heated. The outer case of the device performs protection functions, protecting the inner tank from mechanical damage and reducing the amount of heat loss. The space between the cases is filled with insulation material (mineral wool or foamed polystyrene).

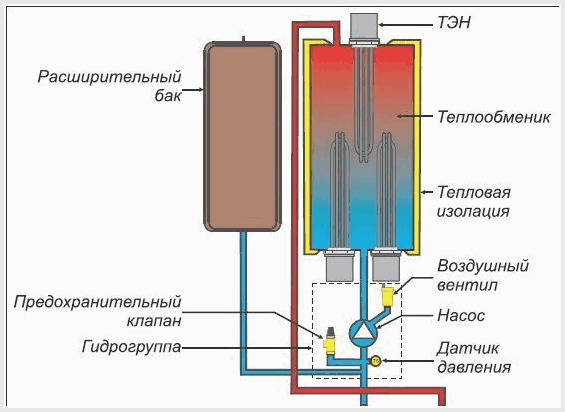

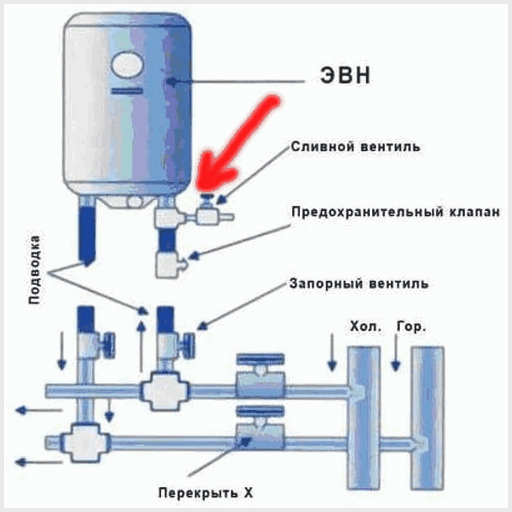

With good operation of the device, depending on the power of the heating elements of the tubular type and the volume of the tank, the water is heated for 2-3 hours. The water in the storage electric water heater keeps the set temperature for a long time (12-24 hours) due to the double casing. The figure-scheme shows the internal structure of an electric storage water heater, which is connected to an independent heating system with underfloor heating.

Due to the high performance, the storage storage electric water heater, according to its own design, is most suitable for equipping the operation of underfloor heating in your apartment.

If we talk about a flow-type electric boiler, then the important scheme is completely different. There is no storage tank, and the overall process takes place in the middle of a small flask, which is equipped with a tubular heater. Unlike storage devices, instantaneous water heaters are equipped with tubular heaters with high power (6-20 kW), which are able to provide active heating of the water flow very quickly.

Important! The water in the flow type heater is heated to the desired temperature within a few minutes (30-120 seconds), due to this, the load on the home electrical network quickly increases

CONNECT THE DHW BOILER

Let's make a hot water system in your house. There is such a thing as a storage water heater. This is a barrel of water that is heated by an electric heating element. So, in our DHW (hot water supply) system, we also use a storage water heater, only it will be heated not by a heating element, but by a boiler and the heating power is not in steam, but in a couple of tens of kilowatts. Such a heater is called an indirect heating boiler (BKN). The BKN device is shown in the figure below.

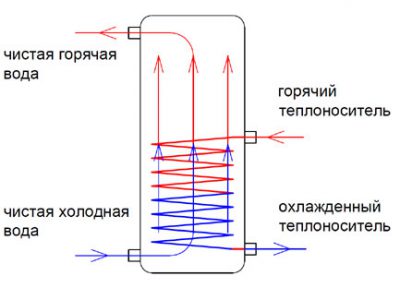

BKN is a barrel through which clean water flows (from a well). Inside the barrel there is a heat exchanger (usually a coil) through which the coolant heated by the boiler circulates. Pure water and coolant do not mix.

For each person living in the house, it is recommended to lay 50 liters of BKN volume. Those. if four people live in your house, then the volume of BKN is 4 * 50 \u003d 200 liters. The heating power must be at least 1/4 of the volume, i.e. in this case 200/4=25 kW. BKN of these parameters allows you to get hot water without restrictions for almost all domestic applications.

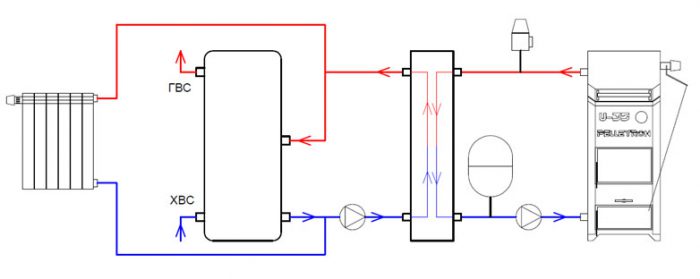

Let's connect the BKN to our heating system.

This BKN connection scheme works perfectly and allows you to do without expensive three-way valves, the use of which is often doubtful. Stop, you say, where did the radiator bypass line go? And we removed it, now it is not needed, since the BKN takes on the role of the bypass in this scheme, because the flow through it never stops.

So, we installed BKN in the system and now we have hot water

Wonderful! But you can do even better!

You know that feeling when you open a hot faucet, and cold water comes out of it and you have to wait for hot water. Let's get rid of this expectation by installing a DHW recirculation system.

Noticed the changes? We have added a so-called DHW recirculation pump. It does not pressurize the DHW system, but constantly pushes hot water past your faucet. It is worth opening a tap and hot water will not overcome tens of meters of a cooled pipeline, but only 30-50 centimeters. Those. hot water from the tap comes almost instantly. Yes, and do not forget to put a check valve behind the mixer.

Do you know why a DHW recirculation system is needed? It allows you to connect heated towel rails even in summer, when the heating system is turned off and only hot water is running.

So, DHW recirculation is connected.

Now everything is very good! But what a chill still remains!

Yep, my feet are cold. We forgot warm floors. Let's connect them.

Trying to connect underfloor heating to an indirect domestic hot water heater. Rationale

The calculation and design of a heating system for any of us is a task in which there must be two answers - saving money and achieving the desired result. In many cases, we try to make it easier for ourselves, to conduct heating in our own apartment very efficiently, while spending little money.Actually, this reason makes us look for other options for connecting heating circuits. The idea to use a storage water heater for this purpose is not considered exemplary, but such an option has the right to life.

The main difficulty lies in the fact that the operation of a storage water heater in such an embodiment will be considered an inappropriate use, which naturally can lead to premature failure of the heating device. Domestic storage water heaters are designed to provide household residents with hot water at home. Hanging an additional load on an electrical device means fundamentally changing the manufacturability of the device.

The decision to use a storage electric water heater as a source of heating a heat carrier can only be directed by an urgent need and a desire to quickly get rid of the problem with heating a home.

Features of electric boilers

According to the degree of autonomy, one of the key criteria, depending on which the boiler is selected, is its electric variety, due to the absence of combustible substances. Having automatic settings, it does not require human intervention, automatically restoring the mode in cases of a short-term power outage. Attracts and its reliability, compactness, affordable price.

Arrangement with such a warm floor boiler does not require expensive piping, due to the initial temperature of the water, which is the heat carrier, at 25 ° C. It is enough to mount the collector to connect several circuits.

Connecting the underfloor heating to the boiler

A modern electric boiler for a warm water floor has three varieties.

- Safe electric boilers operating on heating elements have already gained recognition, as they have a fairly simple technical structure. The main weakness of this type of device is the short service life of the heaters, which is compensated by their low cost and simple replacement technology.

- Electrode boilers are a fairly new type of heating equipment, characterized by durability. Compared with the previous analogue, they are more capricious, since for perfect functioning a certain composition of the coolant is required, which must conduct current. This is due to the principle of operation of such a boiler: between two electrodes under an alternating voltage of 50 Hz, placed in a liquid, the movement of ions begins with the release of heat. Positively charged particles move towards the cathode, and ions with a negative charge move towards the anode. The electrodes change polarity 50 times per second, so heating occurs quickly.

- Induction models are based on heating a conductor placed in a magnetic field. The role of the core is played by the boiler body in the form of a labyrinth through which water flows. Such a device is reliable, requiring only control of the constant presence of a coolant in the system. The high cost limits the widespread use of induction boilers.

Environmentally friendly, not polluting the atmosphere of the house with combustion products, the electric boiler is convenient because it can be placed almost anywhere. The only difficulty may be the need for local wiring. Among the shortcomings, an increase in energy consumption is noted (consumption per 30 cubic meters ≈ 1 kW / h). In private households, where frequent power outages are possible, it is advisable to install a combined type that provides for the option of a backup boiler with solid fuel.