Material Features

Styrofoam is expanded polystyrene - a lightweight material, 98% consisting of air bubbles glued together, which are enclosed in a polystyrene shell. The benefits of styrofoam include :

- minimum weight (insulation does not add serious loads to the roof structure);

- low coefficient of thermal conductivity due to the high content of air, which is an excellent heat insulator;

- resistance to moisture (can be used in a humid environment without loss of thermal insulation properties);

- resistance to temperature extremes;

- fire safety (the material does not ignite; upon contact with an open fire, it begins to melt);

- environmental safety and hypoallergenicity;

- resistance to biological damage (the fungus does not develop, is not damaged by rodents);

- ease of processing tools and installation;

- no tendency to deformation;

- long service life (25-80 years);

- affordable cost.

Styrofoam is one of the materials that are sensitive to external influences.

It must be transported with care. The material should be protected from mechanical damage and exposure to direct sunlight.

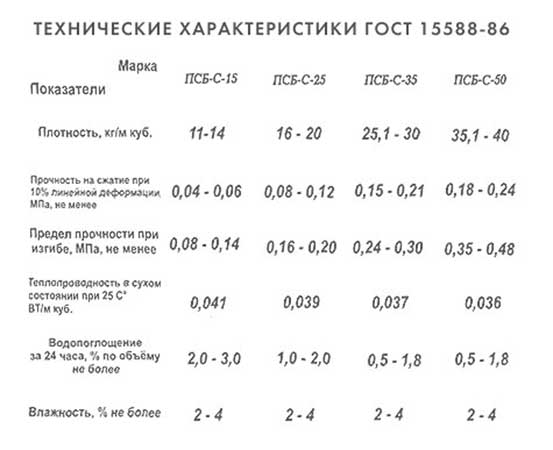

When choosing polystyrene foam for roof insulation and building structures, it is important to take into account the technical characteristics of the material of various grades. Manufacturers recommend using foam:

- PSB-15 (density 15 kg / m 3) 50-100 mm thick for thermal insulation of pitched roofs, including mansard ones, as well as ceilings;

- PSB-25 (density 25 kg / m 3) 50-100 mm thick for wall insulation;

- PSB-35 (density 35 kg / m 3), or extruded polystyrene foam - for thermal insulation of flat roofs, attic floors, floors. Such material can withstand high mechanical loads.

Varieties of insulation polystyrene foam technical characteristics

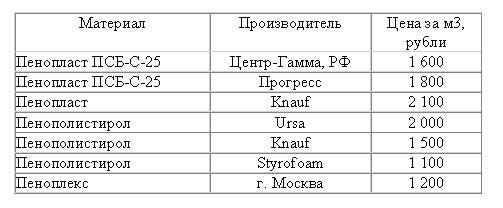

- Styrofoam. The manufacturing technology of foam plastic is quite simple, and this cannot but affect its cost. Today it is perhaps the most inexpensive heater. It is a glued cell filled with air bubbles, which are enclosed in a polystyrene shell.

Due to this composition, the material acquires hydrophobic qualities. The fact that it is able to repel moisture allows you not to look for an answer to the question of whether a vapor barrier is needed when insulated with polystyrene foam. There is no special need for laying a hydro- and vapor barrier layer.

Among the advantages of foam can be noted:

- its lightness; very low thermal conductivity; easy installation; good soundproofing properties; fire safety.

Styrofoam, going on sale, has a different density coefficient.

- cellular polystyrene foam with a low specific gravity has a low strength, so it is mainly used for thermal insulation under the skin; medium-density material is mainly used for facade insulation with polystyrene foam, followed by plastering; with a specific weight of 35 kg / cu. m. Styrofoam can be used for thermal insulation of surfaces under sufficiently large loads, for example, for insulation outside a flat roof.

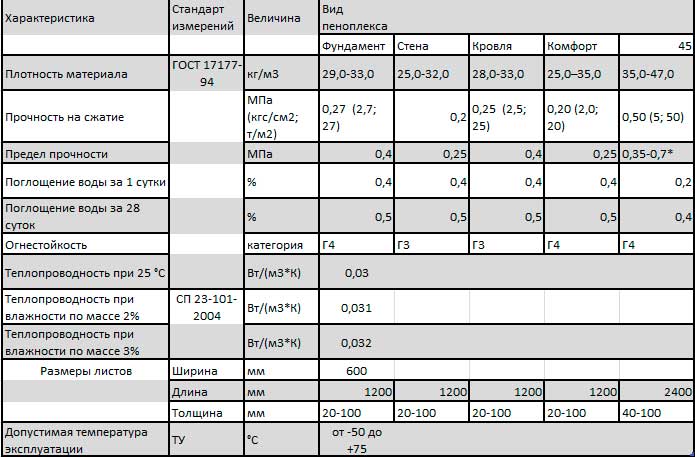

- Extruded polystyrene foam (EPS) is a melt of polyethylene saturated with gases. It is obtained by extrusion: expanded polystyrene is extruded by forcing a viscous melt of raw materials through molding holes of the same size no more than 100–200 microns.

Penoplex goes on sale in the form of sheets. They can also have different densities and vary in color. The thickness of expanded polystyrene is 3–7 cm.

- foam plastic is stronger than ordinary foam; its thermal conductivity coefficient is even lower - one might say,that he has the lowest rate of all available heaters; it does not crumble, but it is easily cut and processed in other ways; the density and water-repellency of the foam plastic are higher than the same indicators of the foam; not of interest to rodents, insects or microorganisms; the tongue-and-groove system at the edges greatly facilitates installation, besides, there is no need to fill the joints; XPS boards are more expensive, which is why it is more often used where polystyrene is not suitable for one reason or another.

How is insulation with polystyrene foam performed from the inside and outside?

Styrofoam insulation

The technology for installing foam plastic and extruded polystyrene foam is practically the same, because in both cases we are dealing with foamed polymer insulation in slabs. The only difference is that they have different performance characteristics.

Styrofoam is made by the method of repeated steam exposure to polystyrene. As a result, the granules significantly increase in volume, and are interconnected. Nevertheless, the foam plastic has low fracture strength, and due to significant mechanical impact, it crumbles into granules.

The extrusion method consists in the fact that, first of all, the granules are melted, and only after that they are exposed to freon and carbon dioxide. As a result, extruded polystyrene foam acquires strength, an integral structure in which gas cells have a closed shape. Extruded polystyrene foam is the latest technological material with a long service life, and its functional properties are much better than those of polystyrene

It is worth paying attention to this when making roof insulation from polystyrene

To date, penoplex is a household name, it is quite often indicated when designating polystyrene foam.

Extruded polystyrene foam for roofing

Even a perfectly functioning heating system cannot cope with the load that small living quarters create if the roof is not insulated in the house. It has been established that at least 10% of heat loss occurs in attic spaces and building coverings if there is no or poorly functioning thermal insulation system. Modern techniques allow, using extruded polystyrene foam for roofing, to quickly create thermal protection of the roof shell during construction or during repairs carried out in the building and correctly attach extruded polystyrene foam to a tree.

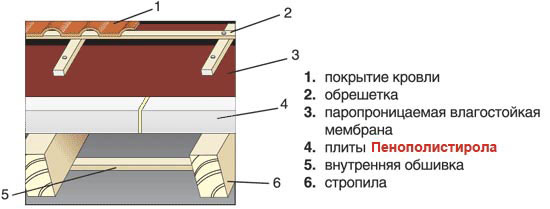

Closed roof structure

Roof insulation with foam plastic over closed rafters is not much different from thermal insulation over open rafters. The difference lies in the crate of the insulation layer. It is installed under the rafter system. Sheathing is made of wooden boards, lining, plastic or drywall.

Often, roof insulation is carried out in order to equip the attic floor. In this case, the choice of foam as a heater is primarily due to its light weight and ease of installation. Installing rolled or heavy materials on inclined surfaces is problematic.

Surface preparation

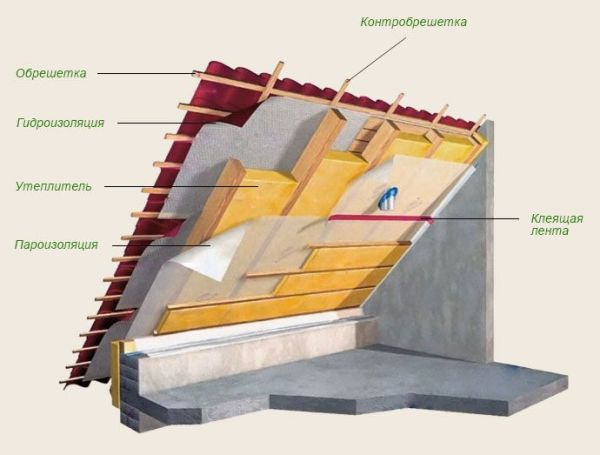

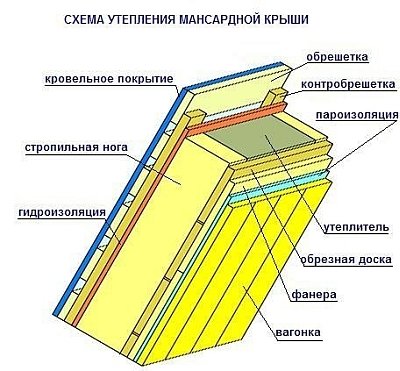

Thermal protection of the mansard roof from the inside begins with the treatment of wooden surfaces with an antiseptic. Further, if there is no roof waterproofing, it must be mounted between the roof and the insulation. In this case, it is imperative to leave a ventilation gap between the insulation material and the waterproofing.

Insulation laying

The next step in the insulation of the attic floor is the installation of foam boards between the rafters. In this case, you need to remember about the necessary gap between the plates and the waterproofing of 20-50 mm. The sheets are installed neatly, without empty spaces between them and the rafters. The resulting cracks are eliminated with mounting foam and small pieces of foam.

vapor barrier

Next, the vapor barrier layer is laid. This can be a foil material, which additionally has heat-reflecting properties, or special perforated films, or membranes. The vapor barrier is fixed with a furniture stapler. In this case, the material does not need to be strongly stretched, it should sag slightly. The seams are sealed with a special tape.

At the last stage, the attic floor is finished. Lining, plywood, drywall, plastic, fiberboard, chipboard are used as finishing cladding. It is installed either directly on the vapor barrier, or on a thin crate. At the end, the surface can be varnished or wallpapered.

Technology

Pitched roof ↑

Styrofoam insulation outside

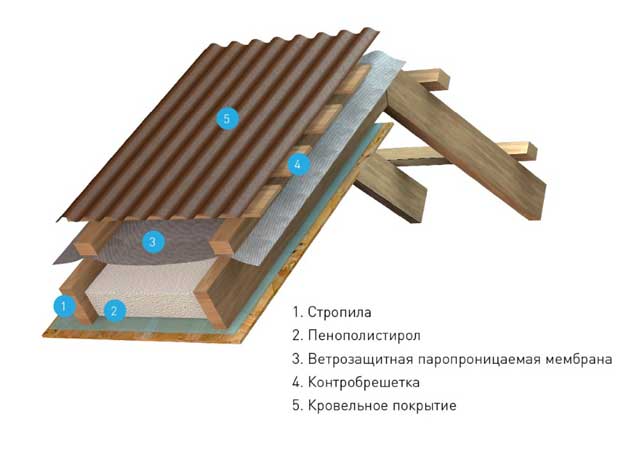

External thermal insulation is carried out parallel to the roof device. Here, as a rule, insulation is used with extruded polystyrene foam or polystyrene foam having a high density.

The process of insulation with polystyrene foam is performed in the following sequence:

- install the truss system; further equip the counter-lattice. To do this, wooden slats are stuffed on the rafter legs from below; foam is laid on them, placing the sheets between the rafters, flush with their upper edge; then comes the turn of the windproof vapor barrier film; install roofing material.

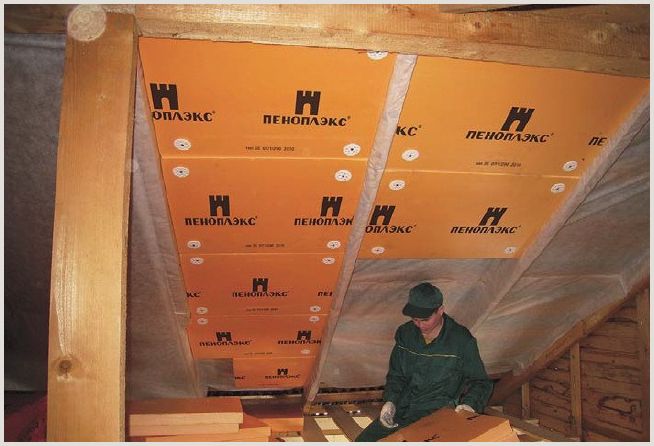

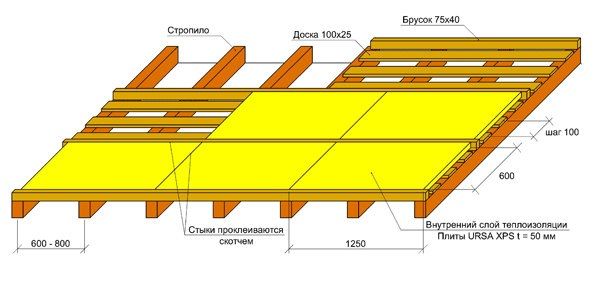

Attic insulation with extruded polystyrene foam

- Penoplex sheets are laid in the inter-rafter space and fixed with brackets or corners. Additionally, the insulation can be supported with thin slats, placing them across the rafters. The laid and fixed sheets of heat-insulating material together with the mounting rails must form a flat surface. Between the waterproofing layer and the heat-insulating material, it is necessary to provide a gap of approximately 200–500 mm. It is necessary for ventilation of the roofing pie. Penoplex sheets should be cut a little wider than the pitch of the rafters so that there are no gaps between them. If there is still a gap between the rafters and the insulation, it is filled with either pieces of XPS or foam, preferably polyurethane. Its excess can be cut off with a sharp knife immediately after hardening.

- Then the vapor barrier film is mounted. It is fixed to the rafters with staplers. The canvases are laid with an overlap of 100-150 mm and glued with a special tape. The final stage is a clean finish. A counter-lattice is stuffed over the vapor barrier layer, which will become a frame for the attic sheathing.

Works with a flat roof

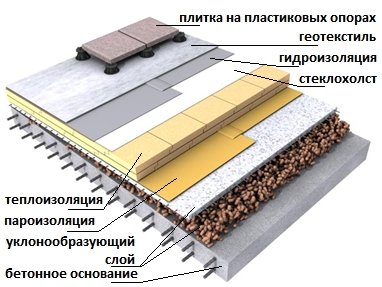

When choosing foam for thermal insulation of a flat roof, they are guided by its strength and absolute hydrophobicity. A multilayer cake is formed, the bottom layer in which foam is placed.

For an exploited roof, it has the following form:

- The reinforced concrete floor slab is poured with a cement-sand screed and a waterproofing material is laid; Foam sheets are laid on the base. Thanks to slotted locks, the surface is quite dense. For greater reliability, the joints are glued with special adhesive tape. When laying the second layer, the slabs are laid “in a run”. XPS boards are covered with filtering geotextiles. It freely passes water, but retains solid particles; Pour gravel or pebbles without sand; The last layer, as an option, lay paving slabs.

In the case of an unused roof, the roofing pie has a different look:

- a vapor barrier material is laid on a reinforced concrete slab and fixed with glue; laying XPS boards; with a slight slope, a layer of expanded clay is poured; pour a cement-sand screed about 4 cm high and install a reinforcing mesh; lay a layer of waterproofing; build a soft roof.

The roof of a high-rise building, if it is not insulated from the outside (especially for old buildings), freezes in winter and heats up in summer. And the residents of the upper floors suffer from this.

You can cope with this situation by performing thermal insulation of the roof from the inside.

- The easiest way is to glue the penoplex to the reinforced concrete slab. Insulation sheets are additionally fixed with special dowels and covered with finishing layers. It is also recommended to use a reinforcing mesh. For insulation, you can also use lightweight foam. In this option, it is preferable to install the crate and lay the heat-insulating material between its elements. The crate is then sheathed with drywall or other finishing material, say, plastic panels.

Insulating the inside of a flat roof

There are situations when, during the operation of an already finished roof, it is necessary to equip additional insulation. Therefore, if you asked yourself the question whether it is possible to insulate the roof with foam plastic from the inside so as not to disassemble the roofing pie, then in this case the answer will be positive. You just need to decide on the thickness of the insulation.

Roof insulation with polystyrene foam from the inside involves fixing the sheets to the ceiling with glue or dowels. The main thing is to properly process the base before this to ensure the best adhesion of the material.

Pay special attention to the tightness of the sheets to each other. To eliminate the voids formed at the joints during mating, use a sealant

For subsequent finishing of the ceiling, you can install a tension or suspension system. If you plan to use drywall or other materials, then before that the ceiling is sheathed with a wooden frame, the slats of which must have a thickness greater than the thickness of the insulation.

Sometimes the technology of roof insulation with polystyrene foam is violated.

Most often, masters make such mistakes:

- Lay damaged sheets or damage them after installation. As a result, depressions appear, in which cold bridges form over time.

- The wrong width of the heat insulator was used, as a result of which the quality of tightness decreases.

- Instead of a vapor barrier membrane, a polyethylene film is laid, which is why condensate subsequently accumulates on it.

- Obviously low-quality material is purchased, and there is also a non-compliance with the general rules of roofing.

For a visual acquaintance with how to properly insulate the roof with foam, you can study the step-by-step video instruction.

Basic principles for installing foam insulation

Styrofoam should be laid on clean and dry surface. In principle, this material can only be installed complete with waterproofing, but in order to ensure long-term operation of the roof, it is advisable to add a vapor barrier layer, otherwise condensate will begin to accumulate on the insulation from the inside. The foam itself will not suffer from it, but wooden structures can begin to rot, become moldy.

Roof insulation with polystyrene foam can be performed in various ways, including :

- gluing (on liquid nails, facade frost-resistant adhesives, mastics);

- mechanical fastening (anchors, wooden slats, umbrella nails);

- flooring;

- investment in the crate.

Mounting methods can be combined if necessary.. For example, sheet insulation is inserted into the crate and additionally fixed with a dowel with a thermal head (umbrella nail). Or the material is glued to the surface and fastened with screws.

The technology of roof insulation with an inclined surface with foamed polystyrene

Insulation of a roof with an inclined surface of EPS is carried out inside or from the outside. The first option is used for obsolete covered and broken gable roofs.

Insulation of a covered roof with an inclined surface from the inside

The technology of roof insulation with an inclined surface with foamed polystyrene from the inside of the roof takes into account the following actions:

- Covering the entire interior of the roof with battens and truss systems with waterproofing material. To do this, roll canvases are used, which are laid with an overlap. All joints are sealed with sealing tape.

- EPPS sheets are fixed. They are fixed with the help of an adhesive composition or nails with large caps. Joints Locked with specialized adhesive-foam for foamed plastic (without white spirit, kerosene, acetone, etc.). The heat insulator can be laid in one or 2 layers (depending on climate conditions and the purpose of the roof). For any layer of XPS, sealing is required.

- A layer of vapor barrier is laid on top of the material for insulation, the joints are locked with adhesive tape for construction work.

- The penultimate layer is cladding with fiberboard, plywood, green drywall and other materials.

- For used roofs, cladding is carried out. To do this, lining made of wood and other materials with low thermal conductivity are used.

Important! In the process of thermal insulation, it is necessary to remove the direct contact of the XPS with the chimney system. Insulation of the edges of the chimney (minimum 20 cm) is carried out using non-combustible materials for thermal insulation

External thermal insulation of the roof with an inclined surface foam

The technology of external insulation of a roof with an inclined surface is somewhat different. Before you begin to insulate, a support is placed. This is done using bars or planks to fix the initial row. In this case, the height of the J-profile should be equal to the thickness of the material for insulation. The support is installed parallel to the roof eaves along the entire length of the slope and is located next to the thermal circuit. It prevents the displacement of the plates.

If we are talking about the thermal insulation of the roof of a wooden structure, then grooves are cut in the flooring at the joints of the walls with the roof, which are filled with a soft heat insulator (polyester fiber or other similar material can be used). This is done to eliminate gaps that appear due to seasonal deformations of the tree.

The second stage involves the laying of XPS boards. It is necessary to start from the supporting element in the direction from the overhangs to the ridge. In places of structural connections for precise joining, the heat insulator is cut at the required angle. At all joints of the plates, a specialized adhesive is applied. For good reliability, it is fastened with dish-shaped dowels. When using 2 layers of artificial latex, the plates are installed with a shift in the joints.

XPS is a combustible material, strong heating is critical for it

Due to this, it is important to provide a ventilated contour between the roof covering (especially when metal tiles are used) and the heat insulator. To do this, after laying the slabs from above, a frame frame is installed parallel to the truss systems.

Frame frame above the heat insulator for equipping the ventilated circuit

This is done using strips with a thickness of at least 30 mm. As a result, there is a gap sufficient to ventilate the under-roof space and prevent overheating of the insulation. To avoid cracks during installation on rails, holes are pre-drilled in 50 cm increments.

Next comes protection against the negative effects of moisture, the material is selected taking into account the type of final roofing. A counter-lattice is installed on the waterproofing layer, and a final coating is placed above it.

Flat roof insulation from the inside

During operation, it may turn out that a flat roof needs additional insulation. In order not to dismantle the roofing cake, it is recommended to insulate the roof with foam plastic from the inside. It is necessary to choose a heater of the required thickness.

Expanded polystyrene sheets can be attached to a reinforced concrete ceiling with glue and dowels

It is important to prepare the substrate surface to ensure high adhesive adhesion. When laying the plates, the elements should be tightly adjusted to each other.

It is advisable to use a sealant in the process so that there are no voids at the joints between the sheets and at the interface with the walls.

To finish such a ceiling, you can use a tension or hinged system. If plasterboard or other materials are to be sheathed, a wooden crate is first attached to the ceiling, the thickness of which should not be less than the thickness of the insulation.

The most common mistakes when insulating with polystyrene foam

- Installation of defective sheets or damage to the installed boards - depressions and cavities contribute to the formation of cold bridges.

- Incorrectly selected width of the heat insulator also causes leakage.

- The use of a polyethylene film instead of a vapor barrier membrane provokes the formation of condensate.

- Use of low-quality materials, violation of work technology.

You can learn in detail how to insulate the roof with foam plastic by watching a thematic video with step-by-step instructions.

The nuances of the work

1. The scheme of thermal insulation of the roof using foam plastic implies a preliminary calculation of the number of blocks. To do this, you need to measure the area of \u200b\u200bthe roof from the inside and outside, the step between the rafters, the size of one slab. It is recommended to purchase material with a margin of 8-10 pieces, since during the cutting process there is a risk of deformation and loss of polystyrene foam.

2. There are several mounting methods. This is installation using an adhesive composition or a mastic mixture, fixing with anchors with wooden slats, laying between the elements of the crate and flooring technology. There is a manual for each scheme, and the method of working with foam depends on the design features of the roof.

3. To prevent condensation on the wooden beams, it is recommended to use a vapor barrier, on top - a waterproof membrane.

4. Styrofoam boards for roof insulation have a smooth surface, so a slight roughness is required for better adhesion. To do this, use a knife, a needle roller or a stiff brush. If the products are embossed, such measures are not necessary.

Before starting work, you need to prepare the following consumables and tools:

- The calculated amount of foam.

- Vapor barrier film.

- stapler.

- Knife and scissors.

- Wooden slats and bars.

- Fasteners.

- Waterproof membrane.

- Glue, foam.

flat roof insulation

Expanded polystyrene slabs are a popular option for external insulation of flat roofs. The base of the roof should be well cleaned and covered with a waterproofing film. Expanded polystyrene boards can simply be laid down, glued, fastened with dowels

It is very important to lay the plates without gaps, as tightly as possible.

The vapor barrier membrane can be laid under the heat insulator on a concrete base, then expanded polystyrene plates are mounted, covered with a layer of expanded clay, on top of which a cement-sand reinforced screed is laid. Expanded polystyrene as a heater can also be part of such a roofing pie :

- reinforced concrete base;

- bitumen-polymer waterproofing;

- plate heat insulator;

- geotextile;

- gravel backfill.

This allows you to create an exploitable roof, designed for high loads.

There are more complex versions of the roofing cake, the top layer of which is the soil for planting. Roof insulation with foam plastic is widely used to create such inversion roofs.

Insulation of the roof from the inside with foam

When the roof is insulated from the inside with foam, the panels are laid between the rafters.The high density of the sheets allows them to be fixed in the frame with improvised means, which does not increase the load on the structure.

The building can be thermally insulated if the following conditions are met:

- The drainage system is mounted taking into account the slope of the structure.

The height of the attic roof allows you to close the stacks from the inside.

After installation, a guaranteed ventilation gap remains between the waterproofing and the roof lining.

The protective shell is installed as follows:

Apply antiseptic to all beams and slats. The work is made easier if the outer roof cladding has not yet been installed.

Cover the rafters from the side of the street with a waterproofing film and fix in any way to the beams. The membrane is necessary so that water does not get into the room from the outside, and moist air from the insulation "pie" freely comes out. Do not stretch the cloth, leave a slight sag. Lay the cuts with an overlap of 15-20 cm on adjacent pieces and on the walls. Connect the joints with reinforced adhesive tape.

If the operated house is being finalized, lay the film from the inside of the attic, while controlling the gap of 50-60 mm between it and the roofing material.

When covering the roof with soft bituminous tiles, it is allowed not to lay the waterproofing tape, because. the cladding itself is waterproof. Only corners and cornices are covered. In the case of soft roof insulation with foam plastic, the membrane is placed directly under the cladding. If the top is made of metal, the protective coating should include soundproofing elements to drown out the noise from the rain.

Fasten the crate to the rafters and install the outer cladding. Check that under it there is a ventilation gap of 50-60 mm to the film, which is necessary to remove moisture. Through it, the moisture remaining in the roofing "pie" is vented. To organize the air flow in the cornice and the upper part of the roof, special holes are made. You can also ventilate the space forcibly using special devices.

Measure the distance between the rafters, add 0.5 cm and cut the blocks from the blanks. Increasing the size will allow the panels to hold themselves between the beams, making installation easier.

Place the panels in such a position that there will be a gap of 10-15 mm between them and the outer film. It is necessary so that the insulation does not close the pores of the diaphragm.

To ensure the required thickness of the coating, the panels can be laid in two rows, while the lower one should overlap the joints of the upper one.

The method of fastening depends on the design of the roof. You can fix products in this position with thin slats or special corners that are sold in the store. Manufacturers also allow gluing and mechanical fixation with wide head dowels, anchors, etc. Options can be combined.

Seal the gaps between the panels, as well as near the rafters with scraps. It is allowed to eliminate defects with mounting foam.

Cover the beams from the attic side with a waterproofing film and fix with a construction stapler to the rails. The fabric should sag slightly. The membrane will not allow the rafters to get wet from the moist air rising from the lower rooms. Lay the pieces of fabric overlapping each other and on the walls. Glue the joints with reinforced adhesive tape. Optionally, you can upholster the rafters with boards.

For vapor barrier, it is desirable to use a special three-layer membrane reinforced with a polymer frame. Foil-coated modifications have also proven themselves well.

Thermal protection of a pitched roof over open rafters

Pitched roofing is the most common type of residential roofing. When it is thermally insulated, one should take into account the impact on the insulation material of weather phenomena and the weight of the roof structure.The heat-shielding layer needs to be strong and it should not be interrupted so that cold bridges do not appear.

When laying the insulation system on top of the rafters, the wooden structure remains visible inside the room and additionally performs a decorative function. Plywood or boards are mounted on top of the rafter system. Then the surface is covered with a layer of waterproofing. For this, polymer-bitumen materials are usually used. At the same time, a waterproofing layer of the underlying type and a vapor-tight layer will be obtained. You need to place the waterproofing layer under the heat-insulating layer on the warm side.

Diffusion waterproofing membranes are sometimes used. They are mounted on top of the insulation. For additional reliability and tightness, a vapor barrier can be laid under the insulation material.

Expanded polystyrene plates must be laid with a dressing of the layer according to the type of brickwork.

Start the process from the eaves. Here the plates rest against a wooden lath of the same thickness as the insulation. All gaps that appear are filled with mounting foam.

We insulate the roof with foam plastic step by step method

However, many have doubts as to whether these materials can be used for thermal insulation of the roof. Indeed, in addition to such undeniable advantages as lightness, good ability to retain heat and hydrophobicity, they also have a number of disadvantages - poor thermal stability and fire hazard. In fact, these materials are

For example, in the manufacture of plastic foam, the pre-foamed granules of the raw material are only sintered together during the cooling process. Because of this, its cell size is much larger than that of polystyrene foam. The thing is that in the manufacture of the latter, the raw material is foamed not by hot steam, but by extrusion. Thanks to this technology, expanded polystyrene is actually a monolithic material. It has a large number of sealed cells, the inside of which is filled with carbon dioxide.

Also, be aware that foam is a less dense material and it can absorb moisture. Expanded polystyrene is completely devoid of this drawback.

Pitched roof insulation

The choice of a heat insulator is recommended to be made at the design stage of the roof so that the pitch of the rafters matches the width of the sheet material. If we insulate the roof with foam, then this approach can significantly reduce material consumption. The construction market presents sheet polystyrene foam insulation, which can be laid without gaps between the rafters with a step width of up to 2 meters.

In addition, it is important to perform a heat engineering calculation taking into account the climatic features of the area in order to determine the required thickness of the heat-insulating layer. The minimum recommended parameter is 100 mm

Foam boards are laid on the crate between the rafter legs. For reliable fastening, you can use glue and dowels. Small gaps often remain between the slabs and rafters. They should be blown out with mounting foam or filled with sealant, otherwise cold bridges will form in these places, where condensate will accumulate and adversely affect the wood of the elements of the truss system. At the next stage, it is recommended to lay a vapor barrier, and then finish with drywall, clapboard or wood board.