Water heated floor under the laminate

Warm floors are increasingly appearing in new houses, apartments and are becoming just as necessary. heating system along with radiator. Moreover, underfloor heating can completely replace the traditional heating system. They heat the space more efficiently, create a comfortable microclimate in the room and have a beneficial effect on human health.

In this article, we will give the most economical option for a water-heated floor, on which you can lay a laminate. It is made without pouring concrete screed, which greatly facilitates the work.

This method is great for a frame house, where many do not understand how to make water heated floors. It is also suitable for apartments with individual heating.

The cost of arranging this water floor will be minimal, and you can lay it yourself, with your own hands, from ordinary building materials that are sold in every store.

Necessary materials

Since this version of the water-heated floor was designed for a frame house, and the laminate served as the finish, we will start the selection of materials with a rough flooring.

To do this, you need edged boards. As a rule, a board with a thickness of 50 mm is used. You can also use tongue-and-groove, but then the cost of the material will increase significantly.

You can choose to install other materials, such as plywood, chipboard or Green Board, at your discretion.

You will also have to buy edged boards with a thickness of 20 mm. This thickness is due to the diameter of the metal-plastic pipes. In our case, their diameter is 16 mm. If the diameter is larger, then the thickness of the board will increase.

The boards must be dried and, most importantly, have the same thickness. The thing is that a laminate will lie on them, and the height difference for the laminate should not exceed 2 mm.

Next, you will need the heating element of water heated floors.

As a cheap option, metal-plastic pipes with a diameter of 16 mm are perfect. They bend perfectly, and their length is practically unlimited, so the connections in this system will be minimal.

More expensive pipes made of cross-linked polyethylene are also sold. Their other name is PEX pipes.

Even for our water-heated floor, foil is required. It will evenly distribute heat from the pipes over the surface. Foil should be taken with a thickness of 50 microns or more.

For more convenient temperature control, a thermostatic valve is used. It also reduces or increases the flow of water in the pipe, but in automatic mode.

Thus, we need the following materials:

- Subfloor boards 50 mm thick,

- Edged boards 20 mm thick,

- Metal-plastic pipe D16,

- Foil 50 microns,

- Valve.

After purchasing and preparing materials, you can proceed directly to laying underfloor heating and laminate flooring.

We will consider the whole process step by step and give the necessary comments.

1. The very first step is laying the subfloor. Everything is quite simple here. Draft boards in a frame house are laid perpendicular to the logs and fixed with self-tapping screws.

Previously, one edge of the board is made semicircular, for turning the metal-plastic pipe.

These boards are attached to the rough base perpendicularly every 20 mm. Thus, grooves are created for the subsequent laying of pipes.

It is cut into strips with a width equal to two distances between the pipes and carefully inserted into the grooves formed by the boards.

Foil is needed to distribute heat and evenly heat the surface.

6. The final step will be laying the laminate

Before doing this, it is important that the water heated floor system works for a couple of days and you are sure of its reliability.

Thus, without large investments, you can get heated underfloor heating, which in terms of their characteristics are in no way inferior to factory ones.

For those who doubt this design, it must be said that it is quite simple and there is practically nothing to break here.

Water floor under laminate

In this article, we will tell you how to properly carry out this procedure yourself and consider the benefits of using a water coating.

Features of laying under the laminate

Laying a water floor under a laminate has its drawbacks. This is due to certain properties of the material:

- Deformation. The fact is that the laminate can be deformed due to temperature changes. To avoid this, it is necessary to choose the appropriate coating. So, for a water floor, you need a moisture-resistant and protected from mechanical stress laminate. The coating grade must not be less than 32, and the thermal resistance must not exceed 0.15 m² K / W. Thus, you will ensure a long service life of the coating.

Thus, water heated floors for laminate are a valid solution, however, you will need to choose a quality material and follow certain rules during operation and operation.

Please note that the instructions indicate for which type of heating the laminate can be used. For a water floor, a coating designed for electric heating should not be used.

Water floor heating efficiency

Using laminate to maintain the temperature in the room is not a good choice. In the event of a mistake when buying a coating, you risk not only significantly reducing the service life, but also harming your health. But if you still decide to use a laminate, you will need to follow certain rules during work.

In general, a water heated floor under a laminate is able to provide acceptable heating for the entire room. The coating heats up fairly quickly and holds the temperature well. At the same time, the thickness of the floor is small, especially in comparison with tiles.

In addition, if desired, you can easily install a parquet board or an array. An average heating temperature of about 28 ° C will be enough to maintain comfort in the room.

In addition to the right material, you will also need to follow certain rules during work. In addition, it is necessary to adhere to the procedure for performing work established by the manufacturer:

We recommend using the help of a professional construction team. Although the installation of the laminate looks simple, there are certain nuances that beginners often do not take into account. Because of this, creaks may appear during walking or the structure may shrink.

The underfloor heating equipment under the laminate does not forgive mistakes, so the installation must be taken very seriously.

The scheme for installing a warm floor is as follows.

How to fill the water floor

Laminate flooring requires a perfectly flat surface.

There are a lot of leveling methods, but not all of them are suitable for underfloor heating.

A possible cause of squeaking while walking may be an improperly leveled base before installing the flooring.

When choosing a mixture for pouring a surface, the following nuances must be considered:

- Thermal load. The cement mixture during a sharp change in temperature may crack and become unusable. So for the screed you will need to use special additives - plasticizers.

- Smooth coverage. Laminate is extremely demanding on the surface. Many beginners try to level the subfloor with tile adhesives. But this layer eventually lags behind the screed, which significantly reduces the life of the coating.

- Thermal conductivity. For acceptable space heating, the cement mortar must have an increased thermal conductivity.This factor quite strongly affects the effectiveness of the use of laminate or parquet.

All these nuances explain why it is often recommended to use ready-made mixtures for laying laminate. After all, it is almost impossible to make such a solution with your own hands so that it meets all the declared technical characteristics.

Possible installation errors

As you can see, a warm floor under a laminate on a concrete floor is, although not the best solution, but it is quite justified. If you follow the recommendations and rules, you will create a high-quality coating that will last a long time.

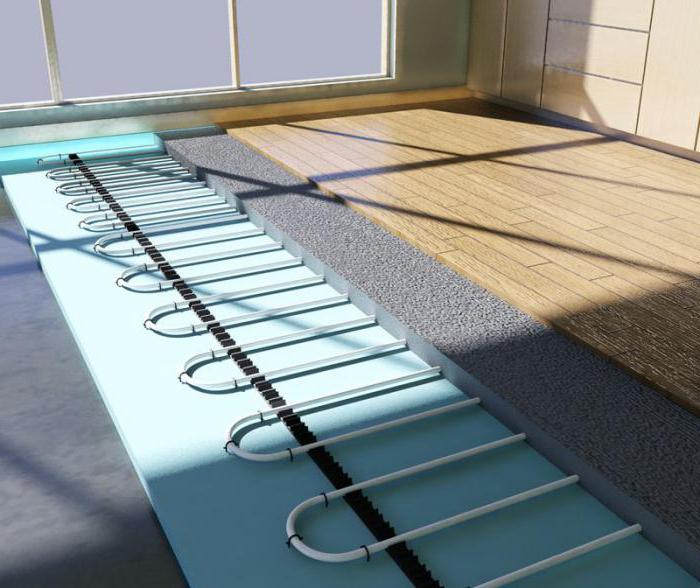

Slatted wood system

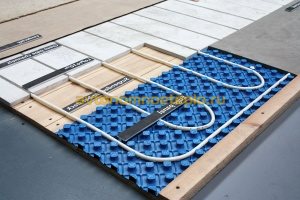

This design, according to which a dry screed is made for a warm water floor, is one of the wooden systems. The supporting role here belongs to the slats made of boards. The usual thickness of the material is 20 mm, with a moisture content of not more than 10%.

If the selected pipe pitch is 15 cm, then the width of the board strips should be 130 mm. With a step of 200 mm - 180 mm, 300 mm - 280 mm.

The strips will be used for the support system for the water floor heating pipeline. Laying can also be done on logs or an old wooden base. If you perform logs, then the thickness of the entire structure will be reduced by about 20 mm.

The scheme for the slatted wooden system is as follows:

- The surface is completely cleaned of debris and, if necessary, high-quality alignment. For each linear meter of the floor, a height deviation of 2 mm is allowed.

- Polyethylene serves as a layer of vapor and waterproofing for the dry method of installing a warm floor.

- The damper tape, which is attached to the walls in the room along the perimeter, should not remain aside.

- After the distribution of wooden planks on the base, they are fastened with self-tapping screws. Laying should be done across the exposed log or support boards. Everything must comply with the established plan for the step of the pipeline. When the pipes are distributed over the surface, they are covered with support strips. We must not forget about the gap between them, which should be equal to 20 mm. Planks, if possible, should be rounded in those areas where there is a bend in the pipe of a water-heated floor.

- The base plates are fastened with self-tapping screws to the planks of wood. Uniform heating of the floor base will be achieved when the surface is covered with planks by 80%.

- For acoustic protection, a polyethylene film is laid according to the resulting structure. During heating or cooling of the coolant, no extraneous noise will appear in the pipes.

- After that, it is possible to lay the GVL sheets, preferably in two layers, fasten them together with self-tapping screws. This layer will serve as the basis for further laying the flooring.

Recommendations for laying screed under underfloor heating

In order for the screed under the warm floor to turn out to be of high quality, you need to take into account some features and laying rules:

- When installing the heating system, before pouring the solution, it is imperative to clean the surface of construction debris, dust and dirt, otherwise the solution, having hardened, may peel off completely from the base.

- Laying the screed starts from the walls opposite to the entrance. Small holes are made in the screed (4-5 cm). This will ensure a strong connection of the new screed with the lower base, as well as a quick drying of the surface.

-

The optimal thickness of the concrete screed is 3-5 cm.

The optimal thickness of the screed for underfloor heating is from 3 to 5 cm

If you make a layer thicker than 5 cm, then the floor will heat up too slowly, and if it is thinner than 3 cm, the coating may overheat and crack. In the case when a thinner screed is needed, say 2 cm, a plasticizer must be added to the solution or self-leveling mixtures should be used.

Self-levelling mortar screed

- To prevent the floor from deforming and cracking under the influence of thermal expansion, it is recommended to use expansion joints along the walls and near the doors by laying a compensatory strip of polyurethane foam.

- When installing a dry screed, the backfill must be absolutely dry. To ensure a dense consistency of the screed, the particle size should not exceed 5 mm. There should be no empty space between the GKL sheets and the backfill used.

The first start-up of the heating system (one month after the screed was poured) is carried out in two stages:

- the first stage is a gradual increase in the temperature in the system from the minimum to the maximum value (during the first 7 days);

- the second stage is a gradual decrease in the temperature in the heating system from maximum to minimum (over the next 7 days).

Compliance with the above recommendations for laying the screed, competent testing and the correct launch of the underfloor heating system will allow you to use a smooth and warm floor covering for many years.

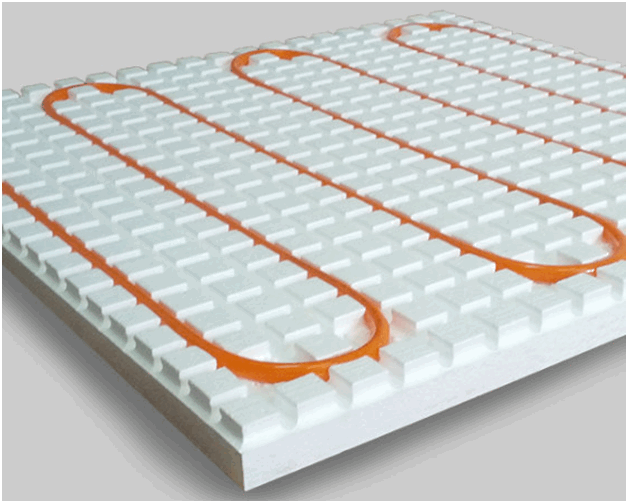

Installation procedure for pipes on polystyrene mats

It is easy to make a warm water floor without a screed with your own hands. First, the rough surface is cleaned of construction debris. If necessary, the base must be leveled.

A plastic film is laid out on the prepared surface. Its thickness must be at least 200 microns. Polyethylene waterproofing sheets are laid out with an overlap (10-15 cm). Joints must be firmly fastened with adhesive tape.

A damper tape is laid out around the perimeter of the room. It compensates for the possible expansion of the system when heated. Then the polystyrene mats are laid out. If their thickness is small, the joints must be coated with glue. Metal lamellas are laid out between the protrusions. Pipes are inserted into their grooves. On top of them lay out another layer of waterproofing.

Then you need to decompose 2 layers of GVL sheets. The joints of the first layer must not intersect with the previous layer. The thickness of this flooring should be 1 cm. The joints must be coated with PVA glue. Layers need to be fastened with self-tapping screws

It is important not to damage the pipes

After that, the finish coating is mounted. Under the laminate you need to lay a special substrate. When installing tiles, you should choose the right adhesive. It must be acrylic based.

Types of dry laying of water floor pipes

Dry floor installation is a general concept, which means several laying methods that differ in efficiency, materials used, and the complexity of the work.

The most popular dry laying methods are:

- Mats for water floors - are laid on a flat base, have special bosses for laying a water circuit. A gypsum fiber board or plywood sheet is laid on top of the mats. The selected floor covering is laid on top.

- Wooden floor. In wooden floorboards, a place is cut out with a cutter for a water circuit. After laying the pipes in the prepared grooves, the top is closed with plywood. The type of installation is used for finishing with a laminate, parquet board or other type of flooring using wood.

- Dry floor installation, without cement screed. The essence of this method lies in the fact that the space from the rough to the finish layer is filled with small granules of slag or other material with high heat-conducting characteristics. Dry concreteless laying technologies do not require a large amount of time required for drying. In the West, according to various sources, from 60 to 70% of the sexes are thus “flooded”.

Before choosing the required installation method, it is necessary to determine how effective this or that method will be in each specific case.

It is necessary to take into account the efficiency, the level of heat transfer and other technical characteristics

The effectiveness of water floors without screed

The chosen type of installation influences the efficiency of underfloor heating without screed.According to the study, floors with the use of special mats have the highest efficiency. In this case, special heat-reflecting plates are used, which increases the efficiency of the water circuit.

In the case of using dry mixes in which a water circuit is mounted, the efficiency is not more than 50%. Studies have shown that the heating system heats the air well between the subfloor and the GVL slab. And since air is a good insulator, the surface of the GVL plate warms up rather weakly.

Dry or wet floors - which is better?

There are several weighty arguments that encourage dry laying for warm water floors:

- Fast installation speed.

- Less expenses.

- Less requirements for the bearing capacity of the floor.

- The ability to do the work with your own hands.

At the same time, a dry-mounted water floor heating system has its drawbacks:

- Low heat dissipation.

- Restrictions due to the use of flooring.

Before choosing a dry or wet screed method, in each case, you will need to take into account the following nuances:

- Technical features of the building. Dry screed is performed in rooms where dampness is unacceptable. In this case, cases of the composition flowing to the neighbors from below are excluded, since the mixture is completely free of water.

- Timing. According to statistics, those who do not allow time to wait more than a month for the cement screed to harden usually decide to install a water-heated floor in a dry way.

Despite the existing shortcomings, dry screed is very popular. Its use is justified in the case when the installation time is limited. The height of the ceilings does not allow the use of traditional methods of pouring the screed, and independent work is also planned.

Underfloor heating without screed for laminate cable and mats

Laminate is a wood-based flooring that is not very cold in itself. But in winter, it cools down a lot, bringing discomfort to the residents of the apartment. So floor insulation under laminate is a fairly popular solution.

There is an opinion that it is impossible to make a heated floor with this coating. This is not true. Due to the low thermal conductivity, the heat-insulating substrate and the very composition of the coating, it is more difficult to achieve a high temperature on it than, for example, on a tile. But if the underfloor heating is installed correctly, it will not damage the laminate and will be able to heat it to a comfortable temperature.

Electric underfloor heating without screed for laminate

With laminate, various types of underfloor heating are used, including electric ones. If you do not want to spend a lot of time on their installation, purchase varieties for laying without a screed - in tile adhesive. Such heating systems are easy to install, and they are ready for work quickly - after the glue has completely dried (for exact terms, see the manufacturers of the adhesive solution, usually the glue dries in about 14 days).

Energy offers two such varieties:

Energy Universal is a universal heating cable that is mounted on a mounting tape and filled with either tile adhesive or screed. The reduced power of the cable (10 W/p.m) allows it to be used with coatings with poor thermal conductivity, such as laminate. In this case, the coating will not overheat, and the heat will be distributed evenly. Model power - 100 W / sq.m.

Energy Universal is a two-core cable that is convenient to connect, since the other end does not need to be returned to the mains.

Energy Light is a single core heating mat that can also be used with laminate floors. The mat is convenient because the cable is already fixed to the mesh, and the mesh itself is attached to the base with adhesive tape. Therefore, when installing it, you omit several stages at once: calculating the laying step, attaching the mounting tape to the floor and fixing the cable in it.

What you need to know before installing underfloor heating under laminate

1. Specific power of a warm floor - no more than 100 W/sq.m At too high temperatures, the laminate, like any wood coating, can dry out, deform, because of which it will start to “walk” and look unsightly. To avoid this, choose not too powerful heating systems.

2. Maximum heating temperature +26 °С For the same reason, and also because of the harmful formaldehyde fumes that can be released during strong (from + 30 ° C) heating of some types of laminate, it cannot be heated above + 26 ° C. Use with underfloor heating only coatings of class E1 and E0 (the class indicates the content of formaldehyde in the composition) and be sure to set the mark on the thermostat to no more than + 26 ° C.

3. Look at the coating markings On the packaging of the coating there should be a mark that it can be used with underfloor heating, as well as the maximum heating temperature. Check the composition of the product - it should be as natural as possible.

4. Floor heating only Since the heating systems used for this flooring material have a low power, they will not be able to fully heat the room. They are used only to create heat underfoot.

5. The optimal thickness of the layer of tile adhesive (screed) is 10-20 mm If the thickness is higher, then the coating simply cannot warm up. If lower, the cable may overheat.

6. The thickness of the coating itself is no more than 25 mm According to the manufacturer's instructions, if the cable is thicker, it may overheat and fail. Fortunately, the thickness of the laminate rarely exceeds 10-12 mm.

7. Use a thermostat This device will help you control the heating temperature of the coating, turn off the warm floor when it is exceeded and prevent the cable from failing.

On our website you can buy underfloor heating under laminate for laying without screed. Energy floor heating warranty - 20 years.

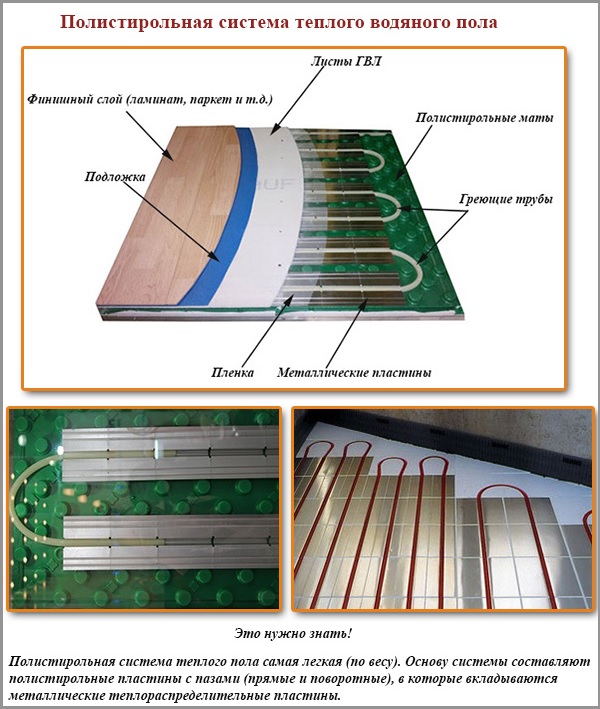

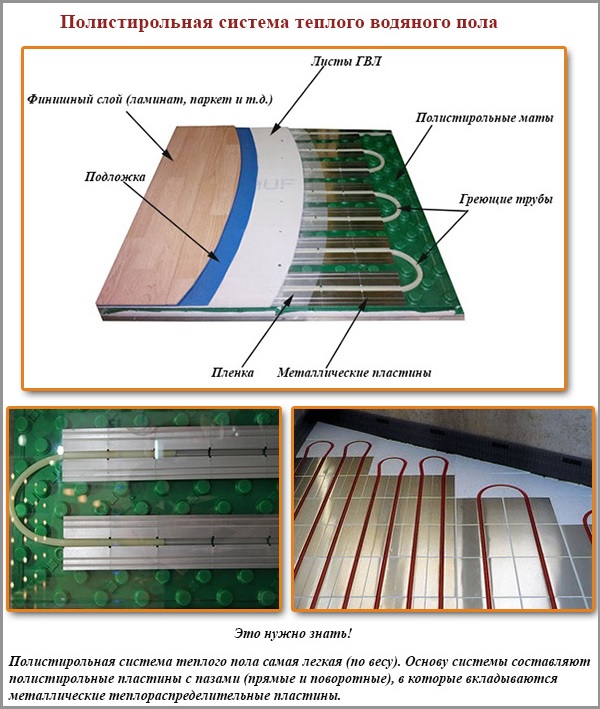

Polystyrene underfloor heating system

Let's start with the fact that special preparation for the installation of a polystyrene floor heating system is not required. You can mount the plates on a ready-made concrete base, on a plank, wooden floor. Due to the lightness of the construction itself, the polystyrene system can be installed in frame and panel houses. The structure in this case looks like this:

polystyrene plates consist of special heat-distributing elements - lamellas made of aluminum and galvanized steel. Directly in the grooves, the pipes of the main heating circuit are installed. The basis of the whole structure is to create the necessary rigidity, which is achieved through the use of a finish coating made from GVL sheets. The sheets of the finishing layer are stacked in a checkerboard pattern.

The plates used in the work can be of two types, ordinary, foam and extruded. The thickness of the plates required for underfloor heating is only 10-40 mm. Heating circuit pipes are mounted into the thickness of the plates, which are covered with polystyrene mats from above. Thanks to special grooves and bosses, the plates and sheets are securely fixed to each other. Polystyrene mats have mounting fasteners on the sides, thanks to which individual elements are fastened into a single, solid field.

Do not forget about metal plates (aluminum or galvanized iron). For this system, such plates are the main element of heat exchange, transferring heat from the heating circuit to the floor surface. With the help of plates, heat is distributed evenly over the entire floor area.

Arguments for choosing a dry floor heating

In addition to the fact that dry underfloor heating can be installed in different buildings, it also has several additional advantages over a concrete screed.

Here is a comparative example:

- The weight of the entire structure of a dry floor screed is several times less than that of a cement mortar, therefore, when it is used, a significant load on the floor beams is not created.

- In the absence of a concrete screed, which takes about 1 month to dry, a dry warm floor can be put into operation immediately after installation.

- Installation work is carried out twice as fast as when pouring cement mortar.

- The thickness of the floor screed is several times less than that of a wet floor, so its installation will not affect the height of the ceilings of small buildings in any way.

- It will take at least 2 days to install a water system with a concrete screed, a dry installation will take one day.

- Due to the fact that the dry floor system is made of special heat-conducting products, the room is heated several times faster.

- Following the instructions, the installation of the flooring can be done independently, without resorting to the services of specialists.

- Unlike a wet floor, installation of a dry structure can be done several times, which is so convenient when changing your place of residence.

And also a dry water heated floor does not deform when the temperature drops in the coolant and has good noise and heat insulation.

But, despite these advantages, when choosing dry styling, you need to pay attention to the following indicators:

- The heating system exposes to the negative effects of moisture.

- It is impossible to erect overall household items on the design of the flooring system.

If you lose sight of these indicators, deformation and mold of the elements of the system will occur. Therefore, unlike a wet floor, a floor screed without a special waterproofing layer is not recommended for use in wet rooms.

Comparison of underfloor heating with and without screed

Laying a water-heated floor without a screed has a number of advantages over the usual type of installation. The speed of creating a heating system in this case increases significantly. Dry mounting is lightweight. This allows you to significantly increase the life of interfloor ceilings.

The thickness of the finished structure is only 3.5-6 cm. This allows you to use a similar heating system for different rooms. You can install such a system yourself. In this case, you do not need to make great physical efforts or have in-depth knowledge and skills in carrying out such work. This is one of the easiest types of plumbing installation.

Materials for dry installation withstand temperature changes, and also have high heat and sound insulation. If necessary, the water floor system can be easily dismantled.

Considering reviews of a warm water field without a screed, it should be said about its shortcomings. Since there will be no screed on top of it, the heat will not be evenly distributed over the floor surface. Because of this, it is necessary to reduce the laying step between the pipes. As a result, you will need to purchase more pipes, coolant. The pump also needs to be more powerful.

At the same time, wooden structures, unlike concrete, differ in thermal insulation properties. This will require more energy to heat up. Also, the materials used in the installation are afraid of moisture.

Is there an alternative to concrete screed

Usually, we associate the laying of a water circuit for a warm floor with the installation of a new concrete screed. Is it really necessary to solve this difficult task at home, to engage in laborious and large-scale work. Logically, in order to protect the pipes of the heating system laid on the floor from damage and to give the entire structure the necessary rigidity and strength, it is necessary to create a solid and massive cast structure. If you are the owner of a private house and just played a housewarming party yesterday, there are no questions. The best option for installing a warm water floor is to fill a new screed.

The situation looks completely different in situations where you want to make a similar heating system on the upper floors of a private house or in a city apartment.

It should also take into account the fact that the new screed will significantly reduce the height of the ceilings in living rooms.

These factors become an obstacle to the implementation of the technological possibility to install heating at home according to the "warm floor" scheme. However, in this case, there is a successful, convenient and practical option - an alternative to traditional technology. A water heated floor without a screed is today a fairly common technology that has recently become quite widespread. The engineering solution is to use ready-made materials that fit into a kind of pie through which the pipes of the heating circuit pass. In a professional environment, such systems - structures are called floor (dry).

This technology is very well suited for residential premises that are not designed for laying a new screed. Usually these are inter-apartment floors, attic floors. Floor systems are versatile and can be used in almost any situation.