Preparatory work before pouring

Before pouring a warm floor, you need to perform a number of preparatory activities, including:

- arrangement of the base for the solution;

- installation of all heating circuits.

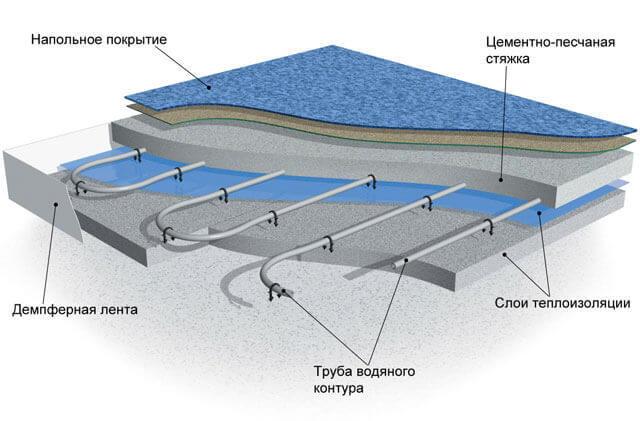

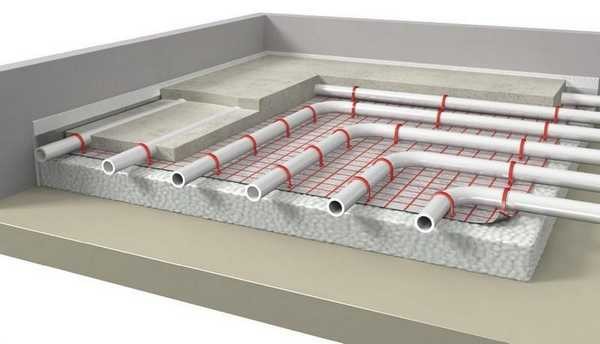

When a warm floor is created, the screed is poured after laying the so-called “pie”.

It is done in a certain sequence:

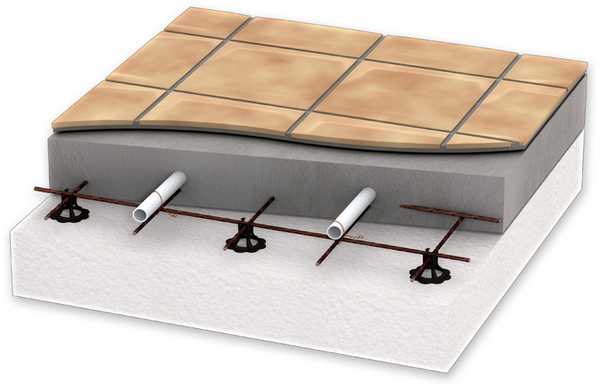

- To ensure waterproofing, a polyethylene film 200-250 microns thick is laid on the rough base.

- Then, to create thermal insulation, a thin layer of polyethylene foam is used, one side of which is covered with heat-reflecting foil. You can use extruded polystyrene foam with a thickness of 5-10 millimeters.

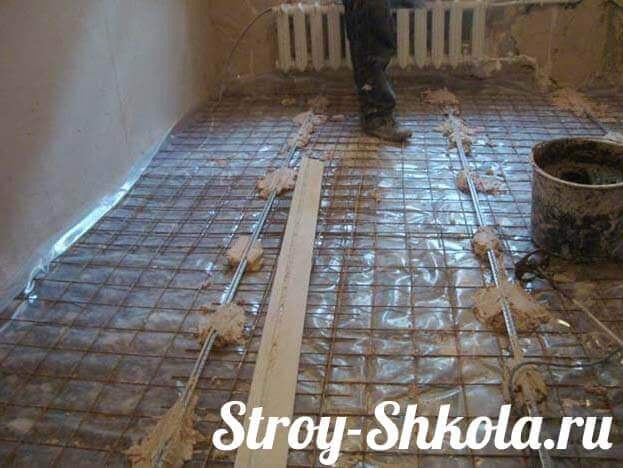

- At this stage, a base is mounted for fixing pipes and metal meshes with cells of 10.15 centimeters for reinforcement.

- After that, they begin to fix the heating circuits. for which metal-plastic or polypropylene pipes with a cross section of 20 millimeters are used (in more detail: “How to make a warm floor from polypropylene pipes with your own hands“).

- In order to increase the strength of the screed, additional reinforcement is sometimes made. To do this, another row of mesh is laid on top of the pipes.

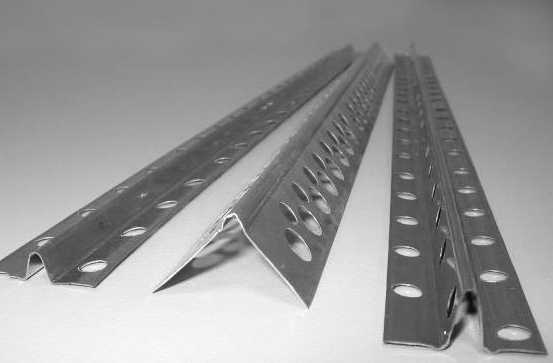

- To obtain an even base, beacon profiles should be fixed - this is one of the requirements for how to properly fill in a warm floor. It is necessary that the gap between the landmarks be less than the length of the rule. Beacons are mounted using mortar or self-tapping screws and focusing on the level. They begin to install them from the zero (it is also the highest) point of the floor.

- final layer is laying the solution under the construction of a warm floor. Before that, you need to determine how to fill in a warm water floor. The screed should rise above the level of the heating circuit by 3-7 centimeters. This thickness allows you to distribute thermal energy evenly and provide the same surface temperature.

Preparatory work

Preparatory work is important in any type of repair, as the final result depends on them. When screeding with a semi-dry mixture, the entire preparation process can be divided into the following steps:

- thorough cleaning of the base;

- laying a layer of vapor / waterproofing;

Rice. 5 Laying waterproofing

- preparation of the surface of the walls;

- installation of rails - beacons.

Rice. 6 Laying beacons for leveling the floor

Pay special attention to cleaning. Use a vacuum cleaner with high power to completely eliminate dust and any other contaminants that may lead to poor results.

Waterproofing is also important. It should be carefully laid with a solid cloth on the floor. Along the entire perimeter of the room, it is necessary to isolate the walls with a special damper tape. But as a beacon, you can use the slats, exposing them to the base of the cement mortar.

Making a solution

At this stage, it is worth considering carefully whether you can mix the solution of the desired consistency and composition yourself. If you are not sure of yourself, then get a better ready-made mixture, which is kneaded, following the instructions on the package. In order to check the correctness of the solution, you can stick your hand into it, clench your fingers into a fist. If water comes out, then you made the solution too liquid. If there is no such reaction, then you did everything right.

After all the previous steps are completed, you can safely proceed to the pour itself. To do this, the entire floor covering is divided into several zones and filled with a mixture. Make sure that the thickness of the coating does not exceed 40mm. And constantly level the filled surface with movements to the right and left and towards yourself - this method will lead to the best results.

Laying the mixture necessarily entails the grouting process.But it is worth starting this type of work twenty minutes after pouring

Please note that you should not postpone this process for a long time, since after six hours such work will not make sense.

In order to grind the surface with high quality, it is necessary to use a special trowel, which is sold in every decent hardware store. Using this machine allows you to compact and perfectly level the surface. It is worth noting that this work only seems difficult. In fact, it is quite possible for one person to cope with it in a couple of hours.

Rice. 7 Mixing mortar

Please note that after the completion of all work, it is possible to start the water floor heating system in about a month, depending on the materials used. The system should enter a full-fledged operating mode for several days.

During this time, excess air will escape from the pipes.

Having become acquainted with the main stages of work on pouring a warm water floor, we can conclude that this is not an easy task - it also requires time, effort, and financial costs. But if you do everything according to professional instructions, then the result will exceed all expectations.

Beacon fill

Before starting work, you should learn how to properly pour the screed on underfloor heating using beacons. Adhering to the technology, they perform a screed after completing all the plastering work, installing windows and door frames in the room. This is what you need to do in order to create the actual temperature conditions for installing underfloor heating.

The preparatory stage involves the thorough removal of influxes, dust, debris residues. Next, you need to carefully, without haste, set the beacons under the rough screed. Floor slabs can play the role of the base, but they will need to be made even if there are deviations from the level. The surface of the wall from below should be puttied to a level of 15 cm, so that later a damper tape can be mounted into the layer.

Now we move on to the arrangement of the rough screed. Upon completion of the floor pouring, differences are allowed for the area. occupied by the water circuit. according to GOST. no more than 5 mm. That is why the installation of the subfloor must be carried out along the lighthouses. To ensure the highest level of insulation in the room. experienced experts recommend using expanded clay concrete screed. Further. gradually line the insulation material under the screed on a special adhesive composition. and the seams are sealed with mounting foam.

After installing the insulation, it will be necessary to reinforce the surface with a special mesh. The material should be laid on nickels so that it deviates from the thermal insulation by 4 cm. After that, expansion joints must be made, pipes / mats / electric wires should be laid (depending on the type of underfloor heating that is being installed).

The finishing floor is poured with a solution with plasticizers and screenings (crushed stone fractions of small diameter). You can also use ready-made leveling mixtures that are intended for underfloor heating systems. At the end of the work, 25-28 days should be given for the floor to dry and harden, and then start heating. The self-levelling compound will dry much earlier - in 1-2 weeks. The floor covering is laid on the dried screed, after which the heating system is turned on.

Production of a semi-dry screed

Laying a semi-dry screed is also carried out after the installation of the water floor is completed. A damper tape must be glued around the perimeter, the pipes must be securely fastened.

For work you will need:

- container for kneading;

- T-shaped beacons;

- level gauge;

- rule;

- trowel;

- cement and sand;

- fiberglass.

The workflow is almost the same as described above. On the surface of the water floor, beacons are exposed to the solution, leveled horizontally.Next, the solution is kneaded to the desired consistency, the pressure in the pipes is raised to 0.3 MPa, and the mixture is distributed between the guides. In the process of work, it is constantly necessary to control the thickness of the layer above the pipes - it should not be less than 3 cm. The solution must be very carefully leveled and laid as tightly as possible. If recesses form under the rule, more mortar is added there and leveled again.

When the screed is completely laid, you must wait 20-30 minutes and proceed to grout. The trowel not only perfectly levels the surface, but also compacts the screed at the same time. Please note. That the more time has passed after pouring, the weaker the effect of grinding. After 6 hours, it is too late to grout, because the mixture will have time to grab.

Grout semi-dry screed

Until the screed is completely dry, you can not turn on the heating. This applies to both filling methods. On the first day the system is launched, the temperature of the water in the pipes should not exceed 25 degrees. The next day, it is increased by another 5 degrees, and so on for several days in a row, until the system enters the operating mode.

Self-levelling screed

For the manufacture of this screed, the installation of guides is not performed. Before pouring, it is necessary to carefully fix all the elements of the water floor, remove everything superfluous from the surface, raise the pressure in the pipes to 0.3 MPa. Then the dry components are poured into water, mixed with a drill with a nozzle, and distributed over the surface using a filling hose. The mixture should cover the pipes with an even layer with a thickness of 30 mm or more. For a better distribution of the composition, a wide spatula is used.

Next, you need to roll the filled layer with a special roller to remove possible voids. With poor rolling, air may remain under the pipes, which will reduce the strength of the screed. After leveling the surface, the floor is covered with a film until dry. At this time, any air currents and direct sunlight must be excluded, otherwise the screed will dry unevenly and deform.

Comparative table of properties of various screeds

New or Popular

- Floor pie in a wooden house - installation instructions

- Concrete floor hardener - varieties and instructions for applying the material

- How to make a warm floor: features of the choice of components, step-by-step installation instructions

- Draft floor in a wooden house: 5 best options, diagrams and a step-by-step construction guide

- Floor installation in a private house

- Sealing gaps in wood flooring

- How to lay laminate flooring

- How to make a floor in the country

Screed recommendations

The area of each zone should be no more than 30 "squares", and the length of the sides should not exceed 8 meters. The ratio of length and width should be no more than 1:2, this must be known even before pouring the screed on the warm floor. If the room has a complex shape, it is divided into square or rectangular sections.

During work, you will need the following tools and materials:

- damper tape;

- insulation;

- a polyethylene film having a thickness of 200-250 microns;

- sand, cement, fiber, plasticizer for concrete;

- mounting grid;

- rubber boots;

- knee pads;

- broom, industrial vacuum cleaner;

- beacon profiles;

- laser level;

- screwdriver and puncher for installing beacons;

- long rail and rule;

- a special nozzle for a puncher or a construction mixer;

- container for solution, designed for 80-100 liters;

- polyethylene or metal-plastic pipes with a diameter of 20 millimeters;

- nylon ties for attaching to the net.

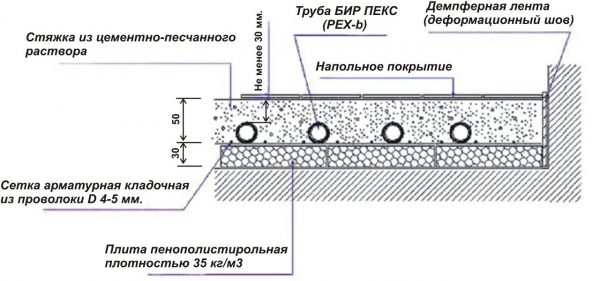

To prepare a mixture for pouring a warm floor, use a solution of a brand not lower than M400 and add a plasticizer. The minimum thickness of the filling of a water-heated floor above the level of the pipes is 3 centimeters.

Filling the warm floor is carried out after hydraulic testing. The pressure inside the pipes during pouring should be 0.3 MPa.The thermal test is carried out not earlier than one month after the completion of the concrete pouring. At first, the temperature of the conductor cannot be higher than 25 degrees, then every day it is allowed to increase it by 5 degrees until the desired value is reached.

Recommendations for laying pipes are as follows:

- for the contour it is worth using solid products;

- in those places where they cross the expansion joint, they must be protected by a corrugated sheath with a length of at least one meter;

- pipes are attached to the floor on a wire with a soft lining or using V-shaped brackets.

How to pour concrete screed

It is not enough to choose the type of screed for pouring; you also need to know how to perform this filling correctly. Any mistake in the manufacture of such a coating reduces the effectiveness of underfloor heating, leads to the destruction of the screed. Prior to the pouring stage, work must be completed to prepare the base, lay the waterproofing and reinforcing layer, and install the heating system. The damper tape is also attached around the perimeter of the room before laying the warm floor. And only after that you can start making the screed.

How to make a warm floor screed. Scheme

Screed device diagram

For work you will need:

- metal profile for guides;

- dry gypsum;

- container for mixing the solution;

- level;

- trowel;

- rule.

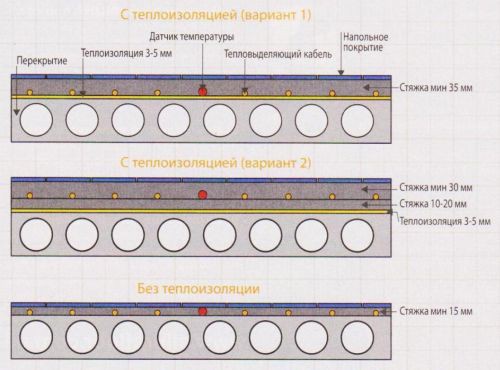

Underfloor heating screed options

Step 1. Using a level gauge on the wall, mark the line for pouring the screed. Please note that the thickness of the solution above the pipes should not be less than 3 cm.

Step 2. Knead the gypsum mortar and lay it out with a trowel in small piles along one of the walls at a distance of 20 cm. Lay the guides on the mortar and level them. A distance of 1.5-1.8 m is left between the beacons. Since the gypsum dries very quickly, you should not lay out the solution for beacons immediately over the entire area, do it in 2-3 steps.

Step 3 Prepare a concrete solution: mix the dry ingredients in the right proportions, pour in water, add a plasticizer.

The solution is poured between the guides and, using the rule, is distributed over the surface.

Step 4. When pouring the floor, the pressure in the pipes should be 0.3 MPa, otherwise the screed cannot be laid. The solution is poured between the guides and, using the rule, is distributed over the surface. You need to work very carefully so as not to step on the pipes. Filling is carried out in portions, dividing the room into several sections. If the floor area is more than 40 m2. a damper tape 5-10 mm thick is laid between the sections. It is best to use a special intercontour tape that has a T-shaped profile. It has standard parameters: width 10 cm, height 10 cm and thickness 1 cm. The tape is available in lengths of 2 m and is very inexpensive. Mounting it is much more convenient than a regular tape. Expansion joints prevent the screed from cracking during thermal expansion. The pipes passing in the seams must additionally be closed with a corrugation.

In the photo - a deformation seam and a pipe joint closed by a corrugation

When the entire floor is filled, the screed is covered with polyethylene and left to dry. A day later, the beacons are taken out, the recesses are sealed with a solution. Again covered with a film, and then periodically the floor is moistened with water so that cracks do not appear. As soon as the screed gains the necessary strength, and the moisture level drops to 5-7%, you can lay the top coat.

How to fill a warm water floor, we will understand the methods and tools

You can find out how to fill in a warm water floor, how to do it correctly, by reading the article. The main condition for success is careful attention to the implementation of all stages of work.

How to pour a warm water floor

In order to create coziness and a comfortable atmosphere in an apartment or any other room, it is not enough just to paste beautiful wallpapers and install high-quality furniture. Of great importance is the condition of the flooring. It should be even, smooth and warm.Recently, heated water floors have become especially popular. They allow the owners to independently regulate the air temperature in the house, increasing it in the winter and completely turning off the heating in the hot summer.

Rice. 2 Concrete screed is one of the most practical options for pouring a warm water floor

Water heated floors are especially popular in families with small children. After all, the baby loves to play right on the floor

Therefore, it is very important for the health of the younger generation that this floor be warm and comfortable.

If you have no inclinations for construction and repair work, then, of course, it is better to turn to professionals. But, if you decide to do all the work on floor insulation yourself, then the tips given in this article will seem useful to you.

Screed thickness

The layer of the poured solution for the warm floor must certainly be the same over the entire area of \u200b\u200bthe room. Thus, it is possible to achieve efficient operation of the heating system, because the floor covering will warm up evenly. That is why it is necessary to start work only if the base surface is as flat as possible. In situations where the subfloors are not even, have large level differences, they should first be leveled.

Sometimes a thin layer of screed (about 5 mm thick) is sufficient. Then experts recommend placing part of the layers of the structure under a rough screed. That is, lay polyethylene (acting as a hydro-barrier) and heat-insulating material, and then fill them with a layer of mortar with a thickness of 2 cm. Next, the base is allowed to dry thoroughly for 28 days, heat-reflecting material is rolled out on it and proceed to install the heating element. This technology is a little longer in implementation, however, it is more correct. Under other conditions, it will be necessary to perform a more impressive screed in thickness. If heated floors are created in an apartment in a high-rise building on the second floor and above, then the thickness of the system will be 8.5 cm, and its structure will be as follows.

Above 1 cm below pipe or electric heating element, 2 cm pipe or 0.5 mm electric heating element and 3 cm above it or electric heating element.

In total, the screed layer of a water-heated floor will be 11.5 cm thick, and for electric floors - 9 cm. We also note that the thickness of the solution layer will be largely determined by its type. So for the water floor, the indicators will be as follows:

- if you are using a conventional cement-sand mortar, remember that the minimum layer above the pipe or electric heating element must be 5 cm thick;

- if a solution based on plasticizers is used, then its thickness above the pipe or electric heating element will be less than 5 cm;

- if a warm water floor is installed independently, then the solution layer above the pipes or the electric heating element of the structure must be no less than 2-2.5 cm thick if reinforcement is used, and at least 3 cm of the solution if the reinforcing mesh is not involved in the process work. Then the total thickness of the concrete layer for the water floor will be about 6 cm.

Filling the screed, taking into account the type of underfloor heating

Many people who decide to install electric floors in their home on their own ask a reasonable question about how a screed for a warm floor is made. In fact, this process is not overly complicated and does not require a long time.

But it must be carried out taking into account the paramount factor - the type of floor heating that is planned to be installed.

If it was decided to organize heated water floors on your own, you will need to understand the basic rules for pouring the screed for such a system.A screed under a warm floor will raise the entire heating system up to a certain level, but if we compare this option with other alternatives, it becomes clear that this is a rather economical option. The structure is layered. It is made from the following materials:

- waterproofing;

- insulating material;

- foil layer;

- pipes of the heating system;

- reinforced screed;

- clean floor.

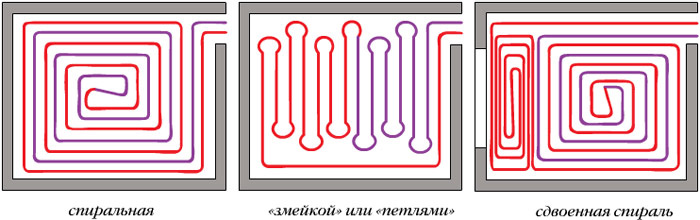

To prevent the pipes from floating up, they should be fixed by attaching them to a reinforcing mesh or insulation. In this case, pipe installation schemes may be different. Pipes can be laid in the following ways:

The prepared concrete solution is poured through the pipes, starting to move from the far wall, and towards the door. In this case, the room should be divided into zones with a reference to the lighthouses. Concrete poured onto pipes should be carefully leveled with a rule to avoid warping the thickness of the base. When using semi-dry mixtures, after 6-7 hours after the organization of the screed, it should be sanded.

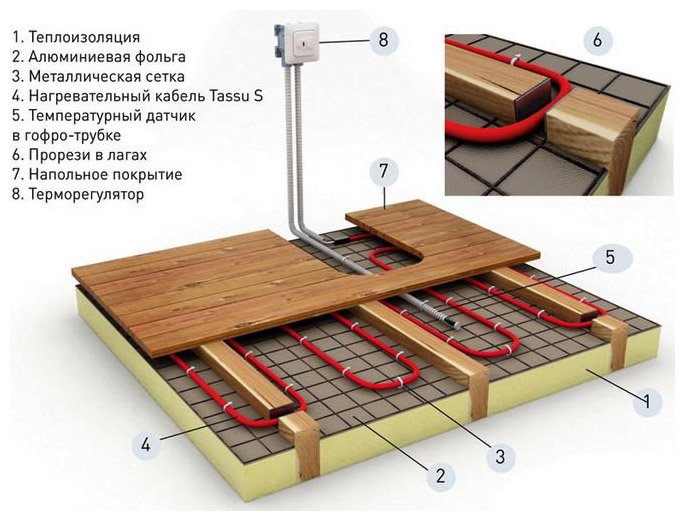

Electric

The above describes how to pour a warm water floor on your own, without paying for the services of a hired team of builders. Now let's dwell on the details of how the electric floor heating is poured. It is filled in in this case a little differently.

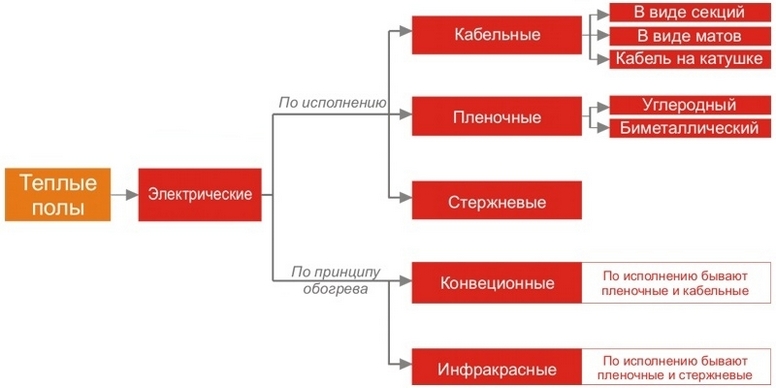

First, we note that electric heated floors are diverse in their structure, which determines the specifics of installation work:

- cable;

- film;

- using heating mats.

Film floors can be laid on top of a layer of concrete, while the other two options are poured into the screed.

In general, such floors are organized in the same way as water floors, but taking into account the fact that electrical cables or mats are mounted directly on the reinforcing mesh, which is suspended between the lags. The cables should not touch the thermal insulation material, and a plasticizer must be added to the electric floor screed solution. After fixing the cables or mats on the reinforcing mesh, the solution is poured onto the structure and wait 4 weeks for it to completely harden. The dried floor will need to be sanded, and then covered with a finishing material.

Tools and materials

Before you start pouring the underfloor heating screed, you will need to take care of the availability of all tools and materials that are relevant for this type of work. From the materials you will need the following items:

- damper tape for creating thermal seams;

- insulation material (in the form of a roll, mats);

- polyethylene in the form of a film with a thickness of 200 to 250 microns;

- materials for the preparation of concrete mortar (carefully sifted sand, cement, fiber, plasticizers for concrete);

- mounting grid;

- beacon profiles;

- nylon ties for fixing on the net;

- pipes made of polyethylene or metal-plastic, the diameter of which is 20 mm when organizing underfloor heating of a water type.

Among the tools relevant for pouring the screed on electric floors, you will need the following:

- laser level to check the base for evenness;

- screwdriver (a tool is required for mounting beacons);

- perforator with a special nozzle for mixing concrete mortar. Can be replaced with a construction mixer;

- a container for preparing a solution, with a volume of 80 to 100 liters (tank or basin);

- a rail and a rule of significant length for leveling the concrete solution on the floor surface.

Do not forget about your own safety when doing work. Rubber boots will help protect your feet from cement, dust, dirt. And special knee pads will help not to damage the knees in the process of performing the screed.

So that garbage collection after work does not take a lot of effort, it is worth getting a good broom, and even better - an industrial vacuum cleaner for cleaning.