Features of choice

When choosing components for construction, one should proceed from the practice of focusing not on cost, but on the specific characteristics of the product itself.

In addition, pay attention to the type of chimney itself, for example, products suitable for brick shafts will not be successful for metal or combined ducts. To select mounting foam, you need to distinguish between the following product features:

- Resistant to moisture and the formation of mold and other side effects.

- The ability to withstand significant temperature fluctuations, in the range from -60 to +150 degrees.

- If we take the sealant as the basis for comparison, then the refractory foam has significantly greater qualities of reliability and strength.

- Properties imply delayed ignition.

- Self-extinguishability. That is, the material was used in such a classification that, when a direct fire hits, it will not flow down like burning drops, but rather gradually fade.

- But, do not forget that foams, even of such characteristics as we are considering today, are quite demanding on the sun's rays, keep in mind when processing in open space.

Choice of foam for fire resistance

When choosing a mounting foam, focus on the so-called coefficient, it indicates the level of fire resistance. On the tube itself, you can find not only the main methods for application, but also the characteristics, but also the level of fire resistance

EI marking, so:

- A value of 30 means that there is a restriction for use in rooms where there is a congestion of 16 to 299 people. This is subject to possible evacuation. In this case, the properties are stored for 30 minutes.

- 60 and 90 means that when heated to 1000 degrees, the properties are preserved, and it is able to withstand the load. It is allowed to use in the shopping center and large stores.

- 120 and 150 is the maximum level, they are best used to create "belts of fire" for chimneys and boilers. Sealing the chimney can also be done using this category.

Types of fire-resistant polyurethane foam

- The main application - all foams are divided into two classes regarding resistance to negative temperatures. There is a fire-fighting winter mounting foam - it can be applied even if it is -5 -10 ° C indoors or outdoors. For maximum adhesion of the conventional compound, the temperature should not fall below +5°C.

- Fire resistance - according to GOST, for most premises with a high concentration of visitors, it is necessary to use class B1 fire-resistant polyurethane foam. Additionally, depending on the technical characteristics of the building, a sealant with the required fire resistance coefficient, EI marking, should be selected.

- The number of active components. Fireproof sealant can be of two types.

- One-component formulations harden under the influence of moisture. Before applying the one-component foam, it is recommended to wet the surface to be filled for better adhesion.

- Two-component foam does not harden due to external factors, but due to the chemical composition containing the necessary reagent. It is the two-component composition that is designed to work in winter, at negative temperatures.

- EI 30 - application is limited to rooms with a crowd of visitors from 15 to 300 people, subject to the possibility of rapid evacuation. The foam retains its properties for 30 minutes.

- EI 60, EI 90 - testing of foam with a fire resistance coefficient of EI 90 shows that for 90 minutes, when heated to 1000 degrees, it withstands a thermal load while maintaining all the main parameters. Depending on the technical characteristics of the premises, it can be used in buildings with a high concentration of visitors, shopping centers, etc.This indicator is slightly lower for a sealant with EI 60 - which is equal to 60 minutes.

- EI 120, EI 150 - maximum protection during a fire. Scope of application - premises with a high flammability, the creation of fire belts and separating partitions, sealing cable passages, etc.

When working with polyurethane foam, it is necessary to take into account the expansion coefficient. The maximum width of the mounting gap is 3-5 cm. This distance creates optimal conditions for both high-temperature protection and insulation.

Choice of foam by area of use

If you need a professional fire-resistant mounting foam, then you should pay attention to RUSH FIRESTOP FLEX 65. It is suitable for structures that require increased fire resistance during operation. You can use SOUDAFOAM FR for sealing voids

This foam can be used for:

You can use SOUDAFOAM FR for sealing voids. This foam can be used for:

- protection of window blocks;

- between floors and ceilings;

- to fill voids.

This composition is universal, because it can be used where fire resistance is required. With the help of SOUDAFOAM FR CLICK & FIX foam, it is possible to provide not only fire protection, but also to form a layer that will differ in sound and heat insulation abilities. Nullifire FF 197 has excellent adhesive properties and is a one-component product used in tandem with most building surfaces.

Professional sealing services for wooden houses

The company "Master Srubov" offers its services for the insulation of houses made of timber and logs located on the territory of Moscow, the Moscow region and adjacent areas.

We are official dealers of manufacturers producing premium sealants Remmers, Ramsauer, Oliva and others. Thanks to this, our customers can order sealing with branded products on favorable terms.

In our company, the main emphasis is on the quality of the services provided. We carry out triple quality control of the work performed. Masters undergo regular training and advanced training.

To contact us, go to the "Contacts" page, where you will find our coordinates and an application submission form.

Calculate the cost of painting and insulating your home right now

Is it possible to use heat-resistant mounting foam for installation work when building a chimney? If yes, which one is better?

In accordance with fire safety requirements, during the construction and installation of chimneys, fire-resistant materials must be used to seal any openings of holes, which would provide reliable fire-resistant protection of structures made of combustible materials.

Heat-resistant polyurethane foam can only provide heat-resistant protection for heating surfaces. It will burn out in a fire. There will be no fire protection. Fire will bring maximum damage in case of fire, and in case of fire, it is possible, too. It is necessary to use materials that are resistant to open flame, fire.

Therefore, heat-resistant foam cannot be used in accordance with the requirements of fire safety regulations, which must be observed in the first place when installing chimneys.

It is important to clearly understand what kind of chimney transitions we are talking about. For example, if we are talking about the passage of a thick-walled chimney pipe through even the wooden floor of the house, then this distance from the outer diameter of the chimney pipe to the edges of the gap opening can be filled with refractory (fire-resistant) mounting foam

For example, if we are talking about the passage of a thick-walled chimney pipe through even the wooden floor of the house, then this distance from the outer diameter of the chimney pipe to the edges of the gap opening can be filled with refractory (fire-resistant) mounting foam.

The temperature of the outer diameter of the pipe is much lower than the temperature of an open flame.

On sale there is a fire-resistant mounting foam that is able to withstand even an open flame and resist it for a long time.

Read the information on the packaging.

For example, the fire-resistant mounting foam "Soudal Soudafoam FR",

Mounting refractory foam "Ogneza"

The most important thing when choosing fire-resistant foam is to avoid fakes.

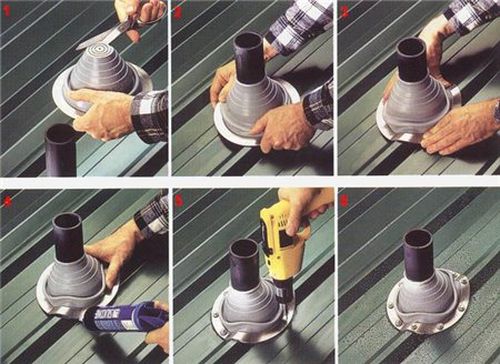

What exactly did you mean by the chimney transitions during installation - if you meant the joints and their sealing (I will post a photo for clarity, to make it clearer).

That is, it is strictly forbidden to seal the joints with foam! - heat-resistant foam can withstand temperatures, but will not withstand open fire, it will simply burn out, you need to seal the joints with asbestos cord, soaking it with water and caulking the gaps in the joints well with it.

If you have introduced chimney transitions between the roof, roofing, sealing in the walls, and so on - then yes! - In this case, you can use heat-resistant mounting foam! Without fear, it will not have contact with open fire!

be sure to take into account the fact that even the most advertised and expensive foam has its own resistance threshold, it cannot be broken, but it is better to pick it up and use it by 2/3, any of the most fire-resistant foam will not withstand more than 3-4 contacts with open fire - therefore, it is impossible to seal joints and transitions, cracks!

Heat resistant compounds

They are used for sealing the outer surface of a fireplace or stove, as well as joints of brick pipes with roofing material. It is also allowed to use when installing sandwich pipes, but not metal or stainless steel - the latter heat up too much.

The permissible heating temperature of the site is 350 C. These data must be indicated on the packaging.

The basis of most of them is silicone, enriched with the addition of iron oxide. The composition withstands constant heating up to 250 C and short - up to 315 C. Separate acid and neutral sealants.

- Acidic - when the composition hardens, acetic acid is released, so the material is not used for sealing sandwich panels, as well as in cases where the walls of the chimney or roof include concrete or cement, for example - with a brick chimney, where cement mortar was used as a mortar .

- The neutral composition during polymerization forms water and alcohol, therefore it is compatible with metals - for example, metal tiles, concretes and cements.

The remaining qualities are common to all representatives of this group:

- resistance to ultraviolet radiation, due to which the material is applicable on the roof;

- waterproof - guarantees 100% protection against moisture ingress;

- after polymerization, the sealant exhibits a certain plasticity, and therefore is resistant to low vibration loads and deformations. However, the same quality provides another feature - it is useless to paint silicone compounds;

- material has high adhesive properties. It is equally well fixed on concrete, brick, glass, metal and other;

- the hardening rate depends on the "freshness" of the paste and temperature conditions and can take from several hours to several days. The time data is given on the packaging of the material.

Heat Resistant Sealing Pastes

Sealant for metal stove pipes is selected from this category, since such a composition is able to withstand constant heating up to 1200-1300 C, and short-term - up to 1600 C. It is used to seal cracks in furnaces where contact with open fire is expected. True, only refractory compositions are suitable for the latter case. For chimneys on the roof, it is of course also used.

A stainless steel or other alloy pipe gets very hot.This creates additional difficulties when passing floors and roofs, and also requires special materials for thermal insulation and sealing. The only exception is the installation of a metal chimney on a condensing or pyrolysis boiler. Here, the temperature of the combustion products is only 150 C, so a heat-resistant composition will be more appropriate.

The basis of heat-resistant pastes is silicate. When polymerized, it forms an organosilicon compound that is exceptionally strong and 100% waterproof.

- Resistance to solar radiation or the action of rain and snow with silicate pastes is no less.

- Due to the complete chemical inertness, the sealant can be used with any material - concrete, cement, metal roof tiles or masonry stone.

- Adhesive properties are somewhat lower. Stainless steel chimney sealant can only be applied after the smooth surface has been treated with an abrasive compound.

- Silicate paste forms a rigid sealed seam. Vibration may crack it.

The video demonstrates the sealing of seams with sealing pastes.

When is protection needed?

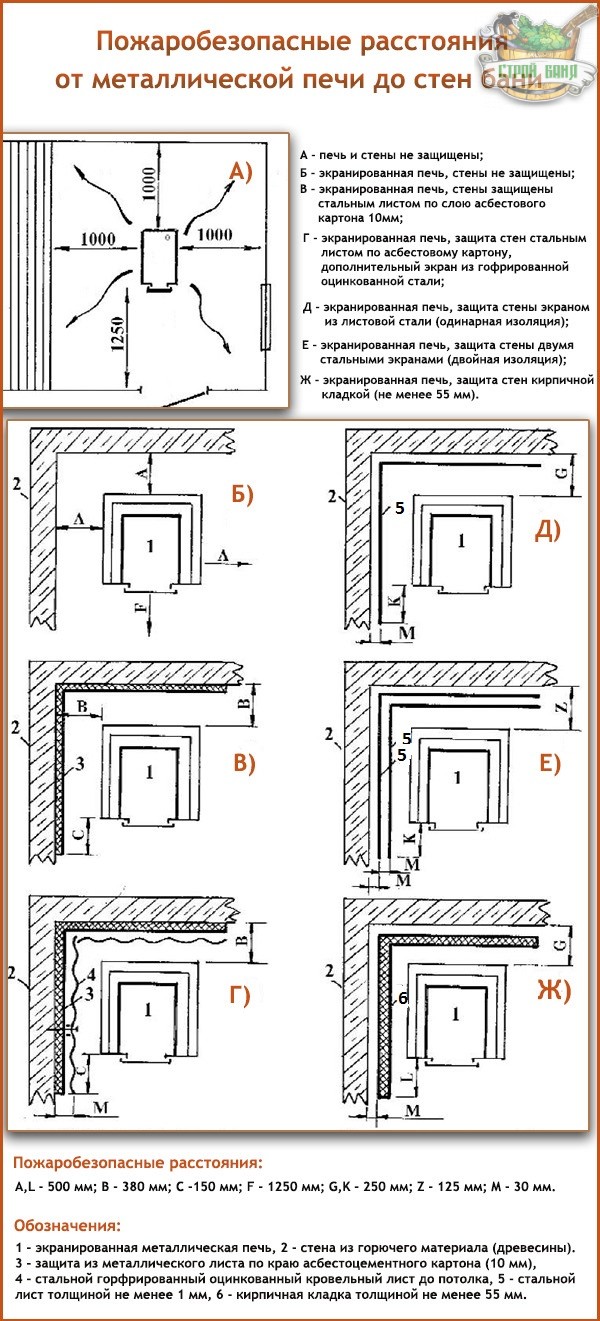

The need to install protective skins and screens does not always arise. If a fireproof distance is maintained between the stove and the nearest combustible surface, no additional protection is needed. At this distance, the IR rays scatter, weaken, and the amount that the wooden wall receives can no longer damage it.

It is believed that the safe distance from the wall to the brick oven (laying a quarter of a brick) is at least 0.32 m, from the wall to the metal furnace (not lined) - at least 1 m. For a metal furnace lined from the inside with brick or fireclay, the distance decreases to 0.7 m.

Thus, compliance with fire distances is more possible in large baths, where the issue of saving space is not relevant. In family steam rooms, where every centimeter of space counts, installing a stove 0.3-1 m from the nearest walls is not practical. In this case, the safety distances established according to the norms must be reduced with the help of screens and skins.

What it is

Ensuring fire safety is the main task that is set for builders during the construction of structures. Fire-resistant building products everywhere displace materials that easily melt and release toxic substances during thermal exposure. Fire-fighting polyurethane foam has a specific feature that distinguishes it from conventional products - the composition is resistant to open fire.

Foam has a certain classification regarding the level of flammability, which depends on the manufacturer, brand and modification. Refractory foam is a relatively new material introduced to the construction market. Products do not flow down when applied to vertical bases. In addition, the composition qualitatively fills the cavity.

Among the features of the material, it is worth highlighting a good level of adhesion to brick, metal bases, wood, various polymers, glass and cement. The product is essentially a one-component or two-component sealant based on polyurethane. The composition is already completely ready for operation. Immediately after application of the foam, the components of the product polymerize upon contact with the moisture contained in the air.

Among the main components of the foam, there are substances that give the product unique characteristics regarding heat resistance, as well as impermeability to smoke and gas.

It is necessary to highlight the main technical characteristics of the composition.

- Products are resistant to moisture, as well as the development of fungus and mold on the base.

- The foam is resistant to temperature fluctuations ranging from +1000 C to -60 C.The available additives give the material the opportunity not to lose its strength and elasticity.

- Based on the type of product, the time interval at which the product retains its resistance to elevated temperatures and does not ignite varies.

- Foam has self-extinguishing flammability. Upon contact with a source of fire, the substance does not drain from the base, and in the course of cessation of contact with fire, the material itself fades.

- The products have soundproofing qualities - the limit for most compositions is about 41 dB.

The disadvantages of fire-resistant polyurethane foam include its sensitivity to ultraviolet radiation. Therefore, it is necessary to provide the tool with an appropriate level of protection.

Protective screens around the oven

Protective screens are insulation shields that cover the side surfaces of the furnace and reduce the intensity of thermal radiation. Screens are metal and brick. As a rule, they are used for metal furnaces.

Method #1 - metal screens

The most common protective screens are factory-made steel or cast iron sheets. They are installed around the furnace, at a distance of 1-5 cm from the walls of the firebox. Depending on the need to insulate one or another side of the furnace, you can purchase side or front (front) screens. Many metal furnaces are initially made with protective screens in the form of a protective casing.

Protective screens reduce the temperature of external metal surfaces to 80-100°C and, accordingly, reduce the fireproof distance to 50 cm. The total distance from the firebox to the wall (together with a gap of 1-5 cm) will be 51-55 cm.

Installing protective screens is not difficult. Due to the presence of legs, metal shields are easily attached to the floor with bolts.

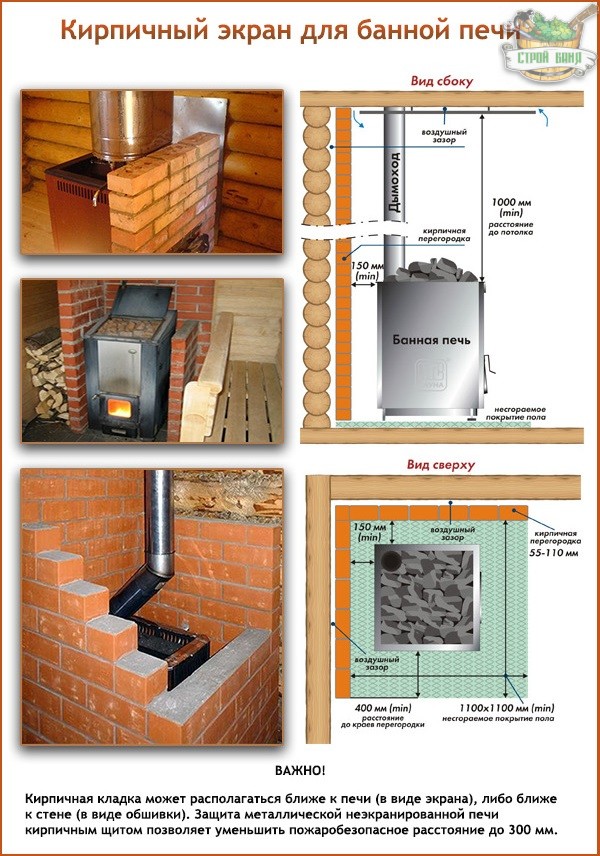

Method # 2 - brick screens

A brick screen can cover all the side surfaces of a metal furnace, representing its outer skin. Then the stove will be in a masonry casing. In another case, a brick screen is a wall that separates the furnace and the flammable surface.

For laying a protective screen, a full-bodied fireclay brick is used. The binder is cement or clay mortar. It is recommended to lay in half-brick (thickness 120 mm). But, with a lack of material, it is possible to allow the wall to be made a quarter of a brick (60 mm thick), although in this case the heat-insulating properties of the screen will be reduced by half.

Small holes are left in the lower part of the shield (sometimes with furnace doors) for air convection between the brick wall and the stove.

Brick walls of the screen must end at least 20 cm above the top surface of the furnace. Sometimes laying is carried out to the very ceiling.

The brick screen is not installed close to the walls of the furnace, the optimal distance is 5-15 cm. The acceptable distance from the brickwork to the flammable wall is 5-15 cm. Thus, the use of a brick screen allows you to reduce the distance from the furnace to the wooden wall to 22-42 cm (oven - ventilation gap 5-15 cm - brick 12 cm - ventilation gap 5-15 cm - wall).

Metal welded and cast

Stainless steel does not interact with water and does not oxidize in atmospheric air, which is the reason for the use of this material for the production of tubular products and allows them to be used in places with high humidity. The pricing policy of this pipeline differs significantly from any other in a big way, but the high costs justify themselves, since the fire-resistant stainless steel practically does not fail under the influence of high temperature conditions.

In production

Most often, stainless steel products are used in high-temperature chimney systems. The thickness of the steel they should be at least 1 mm.

Seamless fire-resistant pipes capable of withstanding heavy loads are used for high pressure systems. Such communications do not have flaws and perceive pressure evenly. But a more durable and reliable solution would be to use cast heat-resistant pipes. They are characterized by a large wall thickness and, accordingly, a high price.

For household needs

To seal joints and gaskets between insulation, it is necessary to use heat-resistant sealants, as well as use heat-insulating non-combustible materials.

When choosing steel pipes for chimneys, you should pay attention to the nickel content in the composition, which affects the interaction with sulfur compounds from combustion products. It is best to use titanium-alloyed materials in domestic conditions, although this is expensive.

The purchase of fire-resistant pipes must be accompanied by a certificate or related documents confirming the quality of the product.