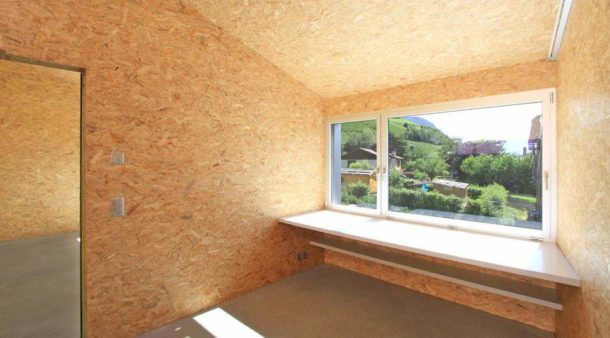

In apartments and private houses, when carrying out repair work, OSB is increasingly used. This material is gradually replacing the usual sheets of chipboard and fiberboard from construction. But many ordinary people face problems when it comes time to glue wallpaper on the OSB board. How to do it right?

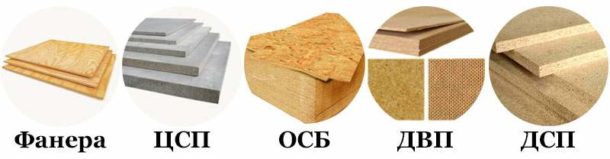

Types and characteristics of OSB boards

This material consists of several layers of sawdust and shavings, pressed and fastened with a special compound consisting of glue, paraffin and various resins. Such impregnation not only turns wood waste into a single whole, but also serves as a reliable protection against moisture. After pressure treatment, the sheet gets a beautiful glossy surface.

In terms of its characteristics, such as strength, deformation resistance or rigidity, it is superior to plywood, hardboard, chipboard and drywall. Builders are attracted by the ease of processing of these panels, their ability to hold various fasteners well. They are compatible with all types of finishing works: puttying, painting, wallpapering, varnishing, tile installation.

On sale there are 4 types of plates from OSB-1 to OSB-4. The higher the number, the higher the strength of the sheet. Three and four have increased moisture resistance.

Important! When finishing inside residential premises, it is necessary to pay attention to the environmental friendliness of the material. OSB boards must be labeled "ECO". Environmental safety class E0 or E1 is allowed, but the material of the latter type should not come into contact with air, therefore, it needs a mandatory rough finish.

All other types of OSB boards can only be used for outdoor work, as they are capable of releasing compounds harmful to the human body.

What happens if you just stick wallpaper on an OSB surface?

Such an experiment can have negative consequences:

- Oriented strand board only at first glance seems to be even. After drying on thin wallpaper, all the irregularities and roughness of the surface will definitely appear. Interpanel seams will also appear, as well as attachment points with self-tapping screws.

- Under the influence of temperature, stains from the released synthetic resins and paraffin will appear on the wallpaper over time.

- Impregnation of the OSB board impairs adhesion, so the glue or primer will slide off its surface.

- Wallpaper glue can cause the material to swell, so it is necessary to create a barrier against its penetration into the panel.

To avoid this, you need to listen to the recommendations of experts. It will be possible to qualitatively glue wallpaper on OSB only after carrying out the necessary preparatory work.

When can I get by with minimal processing?

As already mentioned, it is impossible to glue wallpaper on plates marked E1 without creating a protective layer. For OSB class E0, the following options are possible:

- Dense and large-relief vinyl or non-woven wallpaper, as well as fiberglass and glass wallpaper, can be glued to the slab without leveling the surface, a primer and sealing joints are enough. For light-colored canvases, it is recommended to additionally cover the plate with white insulating paint.

- Due to the ability to hide irregularities, liquid wallpaper can also be applied to a primed slab with pre-treated joints.

- Smooth or thin wallpapers are glued only on a slab lined with plaster or putty.

Conclusion: for some types of wallpaper, provided that the plate belongs to class E0, in preparation for gluing, you can limit yourself to sealing joints and priming, omitting several laborious steps.

Surface preparation

The formation of the desired base for wallpaper includes the following steps:

- Grinding and leveling of plates.

- Primary primer.

- Processing of panel joints and recesses at attachment points.

- Installation of fiberglass reinforcing mesh.

- Applying a layer of plaster or putty.

- Secondary primer of the leveled surface.

Sanding OSB boards

The purpose of this operation is not only to level the surface of the panels, but also to remove the top impregnation layer, which makes it difficult to apply the primer composition.

Grinding is performed using fine-grained sandpaper manually or using a grinding machine.

Ground application

This stage allows:

- Create a waterproofing layer that will prevent the boards from swelling when in contact with the wallpaper paste.

- Eliminate the slightest irregularities remaining on the OSB surface after grinding.

- To improve the adhesion of the material, initially low due to the properties of synthetic resins and paraffin.

- Eliminate the possibility of stains from impregnation on the wallpaper in the future.

The primary primer is carried out in two or three layers. It is recommended to coat the panels with an acrylic or latex based mortar.

Important! The primer should have antifungal and water-repellent properties.

Joint sealing

Particular attention should be paid to the processing of joints and the sealing of the heads of self-tapping screws. These shortcomings will definitely appear after wallpapering.

OSB, like any other wood-based element, has the ability to change geometric parameters under the influence of temperature or moisture. Therefore, when mounting between the plates, a gap of several millimeters is left. To seal it, it is recommended to use silicone sealant. Even if the house is constantly heated, the possibility of an accident cannot be ruled out. With a sharp change in temperature, the plasticity of the silicone solution will not allow cracks to form between the fragments.

You can level the joints of the sheets with mounting foam or plastic putty on wood with the obligatory use of sickle tape.

The heads of hardware in the absence of silicone-based sealant are coated with oil paint. It won't let rust show up.

Installation of fiberglass mesh

Professionals advise not to be limited to mounting the sickle on the seams, but to cover the entire area with fiberglass reinforcing mesh. It will improve the quality of adhesion of plaster or putty to the surface.

Grid installation is carried out from the slope with entry to the adjacent wall. Fiberglass is fastened with a stapler after 10-15 cm, for reliability, you can use glue at the same time.

Plaster and putty

Depending on the curvature of the walls, both of these alignment methods or only the last one are used.

For application to OSB, compositions intended for wood with high elasticity are chosen: nitro putties, as well as acrylic-based or oil-adhesive solutions.

Leveling mixtures are applied until all surface imperfections are eliminated, and after hardening they are rubbed with fine sandpaper or sanding mesh.

The application of plaster or putty is not necessary if liquid wallpaper, fiberglass or thick wallpaper with a textured pattern is used.

secondary primer

Re-applying the primer not only improves the adhesion of the wallpaper to the puttied surface, but also protects the latter from the penetration of moisture from the adhesive. They proceed to this stage after the putty has completely dried.

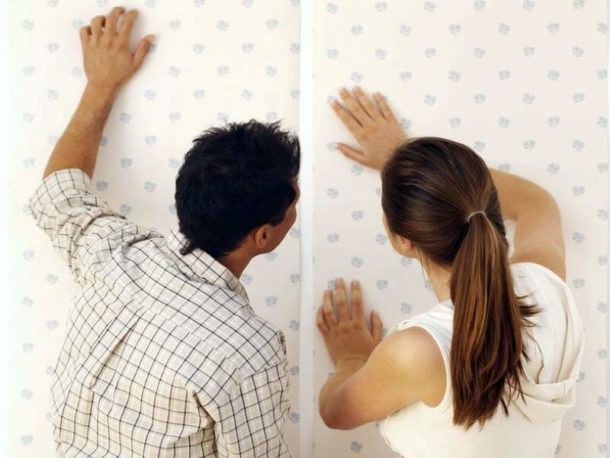

Wallpapering

The procedure is no different from the standard one: cutting pieces of the desired length, taking into account the fit of the pattern, and gluing in accordance with the recommendations of the adhesive and wallpaper manufacturers. It is useful to consider some nuances:

- The gluing scheme must be chosen so that the joints between wallpaper fragments do not fall on the seams between the OSB boards.

- As a rule, glue is applied to the wall and to the fragment to be mounted. For each type of wallpaper, you need to wait a certain time before attaching them to the wall.In some cases, so that the glue from the wrong side does not dry out ahead of time, the masters advise to fold the glued strip in half, bending its top and bottom to the center.

- On the wall, each fragment is carefully leveled with a roller or soft cloth to eliminate air bubbles.

After gluing, it is required to ensure a constant temperature in the room for a day and take care of the absence of drafts.

The process of gluing different types of wallpaper is described in detail in the following articles:

- technology of working with non-woven fabrics;

- paper backing vinyl;

- the nuances of gluing vinyl sheets on non-woven fabric.

How to glue wallpaper on plywood and chipboard?

Plywood and chipboard are prepared for wallpapering in the same way as OSB. The only difference is that these sheet materials have a smooth, even surface, so they do not need to be pre-sanded.

Preparation for wallpapering fiberboard (hardboard)

With fiberboard, everything is more difficult due to the high hygroscopicity of the material. It cannot be treated with a deep penetration primer; without putty, seams will be visible through the finish.

There are 3 options for preparing hardboard for wallpapering.

Method number 1:

- The surface is covered with white alkyd paint or primer on a similar basis in 2 layers. This will create a moisture-proof barrier, increase adhesion.

- When gluing canvases, PVA is added to the wallpaper glue at the rate of 50 ml per 1 liter.

This method is only suitable for dense embossed wallpaper, through which the seams will not show through.

Method number 2:

- The hardboard is primed with undiluted PVA glue.

- Fiberglass or fiberglass mesh is glued to the surface with the help of PVA.

- Fiberboard is puttied with a plaster composition. The layer thickness is about 1 mm.

- Putty plates are polished.

- A deep penetration primer is applied.

- Wallpaper is glued in the usual way.

The only drawback of the method is the one-sided protection of fiberboard from moisture. At high humidity, the sheet material may be deformed.

Method number 3 includes the following steps:

- Impregnation of hardboard with hot drying oil even before installation, which will make the fiberboard moisture resistant.

- Treatment with a primer with quartz sand - "Concrete-contact", - making a smooth surface rough.

- Plastering the slab with a thin layer. Fiberglass mesh in this case is optional.

- Coated with acrylic primer.

- Wallpaper pasting.

Summing up

We found out that it is possible to glue wallpaper on OSB, chipboard, fiberboard and plywood, but only after preliminary preparation. The first three materials are processed in a similar way, more capricious hardboard requires a special approach. When preparing OSB boards, it is important to take into account the environmental class. You can see the whole process better if you watch the video below.