Parquet is valued for its durability, durability and attractive appearance, and at the same time it is one of the most expensive and capricious floor coverings. Its professional installation will also cost a lot, so many decide to lay the parquet floor on their own. Strict adherence to the instructions will avoid errors in work and ensure the perfect condition of this chic coating for many years. Consider the most commonly used technology, and find out how parquet is laid on a concrete screed

Parquet and its budget alternative

Planed, perfectly smooth solid wood boards are called parquet. This material is among the elite, respectively, and the price for it is quite high. Planks have the following dimensions:

- length - from 15 to 90 cm;

- width - from 3 to 12 cm;

- thickness - from 1.5 to 2.5 cm.

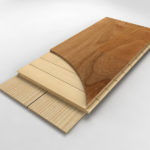

More affordable and less picky in relation to the subfloor material is a parquet board. It is a multi-layer coating, the top layer of which is represented by fine wood veneer, and the 2 lower layers are softwood. The length of such boards is up to 220 cm, and the width is up to 25 cm.

- The structure of the parquet board

- Parquet board with ash veneer

Is parquet suitable for your apartment?

Laying parquet on a screed is an effective solution for flooring equipment. However, before making such a decision, one should carefully evaluate the reasonableness of such a decision. After all, wood is a natural material that is very susceptible to temperature fluctuations and high humidity. Therefore, it is reasonable to use it only in rooms with guaranteed suitable temperature and humidity conditions.

With excessive dryness, the parquet shrinks, loses its shape, appearance, cracks form, and if you lay it in a damp room, then saturated with moisture, the parquet planks will rise. Optimal parameters:

- Humidity 40–60%;

- Temperature not less than +18°С, but not more than +24°С.

How is parquet installed?

The technology of laying parquet on a concrete screed, subject to all the necessary nuances, is not particularly difficult. Conventionally, the whole process can be divided into several stages.

- Checking the quality of the screed or arranging a new one.

- Waterproofing.

- Plywood flooring (chipboard, OSB).

Important! Parquet can be laid directly on the screed only if the base moisture content is low - up to 6%, and even better - up to 3%. It is strongly recommended to use an additional layer of plywood, chipboard or OSB.

It is recommended to lay parquet on a screed without plywood in two ways - on staples or by stretching. It is not worth gluing the strips due to the large difference in the thermal expansion of materials. If, nevertheless, a decision is made to use an adhesive composition, it must be elastic.

- If necessary, sanding and varnishing parquet.

A parquet board can be laid on a concrete floor without fear without the use of a plywood substrate. To find out how to lay parquetWe recommend watching the tutorial video:

Preparatory stage

Cases when the surface of the base (concrete slab) is perfectly flat (permissible difference - no more than 1 mm per m2), hard and dry, are extremely rare. Therefore, the laying of piece parquet is carried out not on concrete, but on a cement-sand screed, or its analogue - self-leveling floor on a gypsum or cement-gypsum basis.

Additionally, the subfloor is inspected for cracks and other imperfections, which are filled with putty or cement mortar.

Please note that before laying parquet, it is necessary to completely clean the surface of the base from the remnants of old coatings, oil stains, construction and household debris. It must be dusted, carefully cleaned, treated with a primer.

Important! Freshly poured screed must be given time to dry without fail. If its thickness is up to 5 cm, then it will take 4-6 weeks.

waterproofing

After the base has been prepared, a special film with waterproofing properties should be laid on it. Laying the strips overlaps by about 20 cm. The edges are fastened with adhesive tape, the stock of the film is displayed on the wall for laying it under the plinth. The underlay used during the installation of laminate or parquet boards is not suitable for parquet.

The role of restrictive wedges is performed by a special self-adhesive rubber cord, which is installed around the perimeter of the room. The same element compensates for the possible thermal expansion of the slats.

plywood flooring

If it is decided not to take risks and lay a stabilizing plywood layer on the screed, which will protect the parquet from swelling and damage, the following is done:

- Thick plywood sheets (the thickness should be 2/3 of the thickness of the parquet) are sawn into squares (40 × 40 or 70 × 70).

- The screed is treated with a primer.

- A special glue is applied to the surface.

- After such processing, plywood squares are laid, and it is performed with an offset, and gaps of 3 mm are left between the sheets.

- The gap between the laid plywood and the wall should be approximately 1 cm. At the end of the work, it must be filled with sealant.

- Before installing the parquet, the plywood is sanded to eliminate possible differences.

Laying parquet planks

Parquet planks are brought into the room where the work will be carried out a few days before they begin in order to acclimatize.

With proper preparation of the base, laying parquet on the screed should not cause difficulties. It is necessary to start this process from the end side to the window.

Installation of parquet on brackets

If we lay the planks on the screed using steel brackets, then the procedure is approximately as follows:

- To the wrong side of each plank, with the exception of the last row, at a distance of 15–40 cm from each other, we stuff special brackets, which can be purchased at hardware stores. This manipulation is performed in such a way that half the length of the bracket remains free.

- We coat the ends of the parquet planks with adhesive (you can use PVA) and lay them in a row.

- The installation of the second row takes place in such a way that the remaining free edge of the bracket securely enters the adjacent bar.

- We repeat this process by analogy with the required number of rows.

- The final row of planks is glued to the previous one without the use of staples.

Stretch parquet

If we are talking about stretch parquet laid on a screed, then the procedure is as follows:

- A hole 1 cm in diameter is drilled in each plank.

- The central row is being assembled, which will later become the basis for the entire canvas.

- The spikes of the parquet planks are mounted in grooves with an offset of a quarter or half of the length, so the holes made in the body of the parquet must match.

- After assembling the floor, it is necessary to stretch special fastening cords made of plastic, which have the necessary elasticity to transfer possible seasonal changes in the geometry of the material.

Fastening parquet to plywood

When using plywood flooring laid on a screed, the planks are attached to it with parquet glue applied with a special spatula. Further, it is recommended to shoot the parquet to the edge along the edge - several studs or nails in one element.This will not only make the mount more secure, but will also squeeze out excess glue and ensure a more even fit of the planks.

Finishing parquet

After the installation is completed, the floor covering must undergo a rough grinding procedure. Before it, all minor defects, cracks and chips are covered with putty. Then the base is finished with fine-grained nozzles of the grinding machine.

Upon completion of grinding, a primer and a protective coating are applied to the parquet, and the gaps near the walls are closed with skirting boards.

Having laid parquet on the floor, in order to extend its service life, do not forget about the need for appropriate care: treatment with special care products, annual application of wax protection, careful handling. Then the noble flooring will delight you for a long time with its attractiveness, reliability and convenience.