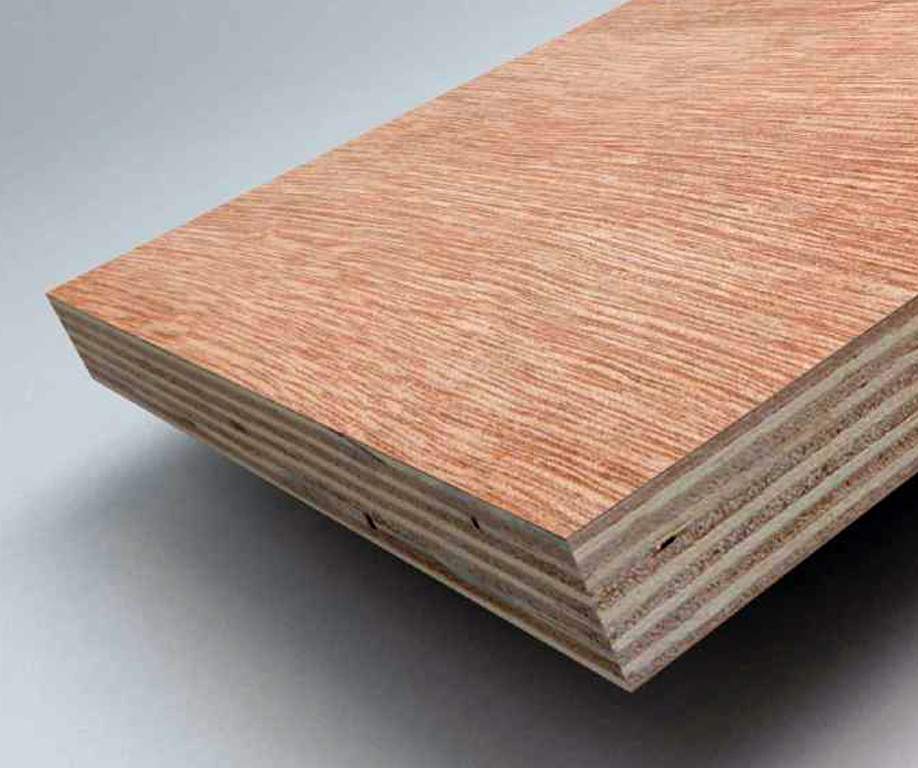

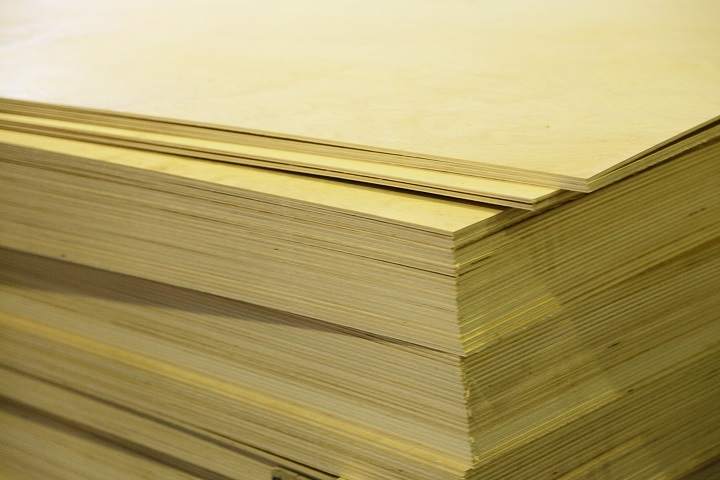

Moisture-resistant plywood is a multi-layer sheet, a kind of “layered cake”, consisting of perpendicularly laid and glued together wooden sheets (veneer). It is very durable, quite light and versatile. It can be used everywhere - from the construction of aircraft and ships, to the interior decoration of apartments and houses.

Before you buy moisture-resistant plywood, let's figure out what it is and what you need to pay attention to when choosing.

Production material

Most often there are 2 types of wood that are used for the production of plywood: birch and coniferous woods (fir, pine, cedar or spruce).

- Birch is a noble material. The color of birch plywood is light, closer to white. It is dense, its strength reaches 30-80 MPa.

- The needles resist moisture better, but they are coarser and contain resin. The color of coniferous plywood is yellow. It is light and, as a rule, cheaper than birch, its strength index is 25-55 MPa.

- The moisture resistance of both materials is high, but birch is more susceptible to decay and the appearance of fungus.

Analyzing the given data, we recommend using birch plywood for flooring, and coniferous plywood for walls and roofing.

plywood types

The following types of plywood are distinguished, based on the adhesive base:

- FS - medium moisture resistance. Glue - urea-formaldehyde resin.

- FSF - high moisture resistance. Phenol-formaldehyde resins are used in production.

- FOF - high moisture resistance with additional protection. The composition is the same as that of FSF, but plywood with this marking has a lamination on both sides.

Birch plywood is made in all three versions. Coniferous is not suitable for lamination, so it is made only in the types of FS and FSF.

Plywood grade

Depending on the quality of the veneer, plywood is divided into 4 grades:

- Grade 1 - during production, defects in material and polishing are not allowed.

- Grade 2 - a small number of shortcomings is acceptable.

- Grade 3 - knots up to 6 mm are allowed, no more than 10 pieces per 1 m2.

- Grade 4 - defects in grinding and quality of wood are not regulated.

Plywood is produced both with the same quality of veneer on both sides, and with different ones. For example, there is plywood 2/2 - this means its grade on both sides of the second. Or maybe 1/4 - this means that one side of it is front (first grade), and the other is rough (4 grades).

Grinding

Plywood can be sanded on one side (Sh1), on both sides (Sh2) or be completely unsanded. Pay attention to the labeling, it is always indicated in the price lists.

Thickness and dimensions of plywood

Standard plywood sheets meet the following parameters:

- Thickness from 3 mm to 40 mm.

- Width from 1220 mm to 2070 mm.

- Length from 1525 mm to 3000 mm.

Manufacturer country

There are 2 main plywood producing countries on the Russian market: Russia and China. The build quality is pretty much the same.

But we note that Chinese manufacturers have begun to use combined technology more often - this is when the front layers of plywood are made from expensive and high-quality veneer, and the inner ones from cheaper ones. Russian manufacturers are guided by GOSTs, and use the same materials for all layers.