How to insulate a water pipe in the ground with your own hands

When choosing how to insulate a water pipe on the site, they take into account the material of its manufacture, the outer diameter, the cost of the insulation and the complexity of the installation work.

Rice. 11 Calculation of the thickness of the pipe heat insulator

Insulation installation

Usually, low-pressure polyethylene pipes (HDPE) with a diameter of 1 inch are used to supply water for individual water supply; installation of the insulation shell is carried out in the following way:

- A shell made of glass wool, mineral wool or polystyrene, foamed polyethylene is installed, fixing it with adhesive tape. When installing mineral or glass wool, it is necessary to monitor the tightness of the joints - otherwise water will get into the joint and the wool will nourish it, while the heat-insulating properties of the insulation will significantly decrease.

- After installation, a soft heat insulator can be protected from squeezing by soil with a more durable material, roofing material is usually used, wrapping the shell with it several times and fixing it with tape. The advantage of its use is hydrophobicity, which protects the insulation from moisture saturation.

- The insulated pipeline is lowered into the channel and covered with a light bulk composition to reduce pressure, expanded clay is usually used.

It should be taken into account that the installation of plastic segments must be carried out by fastening to each other with a slight shift of 20 cm, like an overlap joint.

Fig. 12 Insulation of a plastic water pipe in the ground with a foam shell

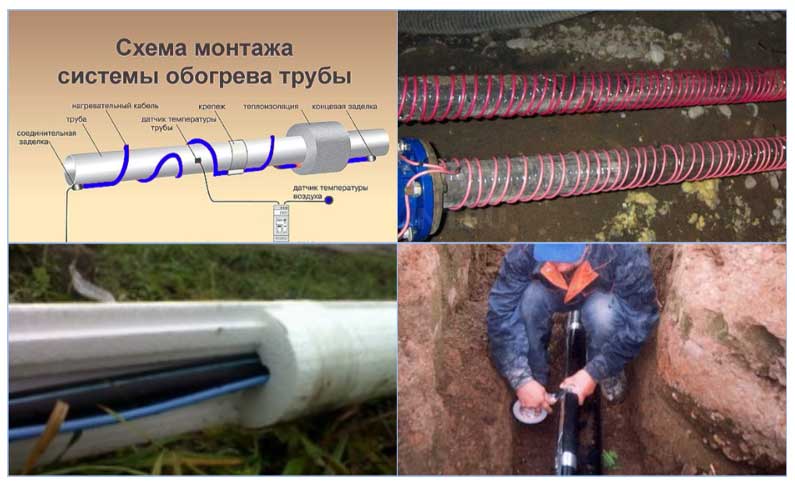

Cabling

Installation of an electrical cable will cost more, but the depth of the pipeline is minimal. The heating wire can be located inside or outside the pipeline; water pipes with an installed electric cable or with a cable channel for its installation are commercially available. Most often, the installation of a cable on the surface is used, while the depth of the pipeline does not exceed 50 cm. The installation of a cable heater consists of the following steps:

- The pipeline at the location of the cable (in a spiral or straight line) is pasted over with foil adhesive tape.

- An electric cable is laid on the glued tape and fixed with the same adhesive tape.

- On top of the resulting structure, a shell of basalt insulation is installed, which is connected with adhesive tape. When installing the heating cable along the line, it is practical to use foam insulation with special grooves.

- To control the operation of the system, it is desirable to install temperature sensors along the water supply line.

Rice. 13 How to insulate a water pipe underground with an electric cable

When deciding how best to insulate a water pipe in the ground with their own hands, many prefer a foam shell - it is easy to install, has the best physical parameters and has a low cost. It is more practical to use an electric cable for shallow water pipes and a borehole head - it can be used to simultaneously heat water in the main and well.

The main methods of warming an underground water main

There are several ways to insulate a water supply system with different principles of operation, some of them are used only in the industrial sector.

The use of insulating materials

The use of building materials with a low coefficient of thermal conductivity is one of the simplest methods, which is the most common when insulating pipes in the ground and on the surface. Materials can be placed around pipes or applied to their surface in the form of paint, resin or foam. The technology is widely used in the industrial sector, for the insulation of water supply and sewerage in private homes.

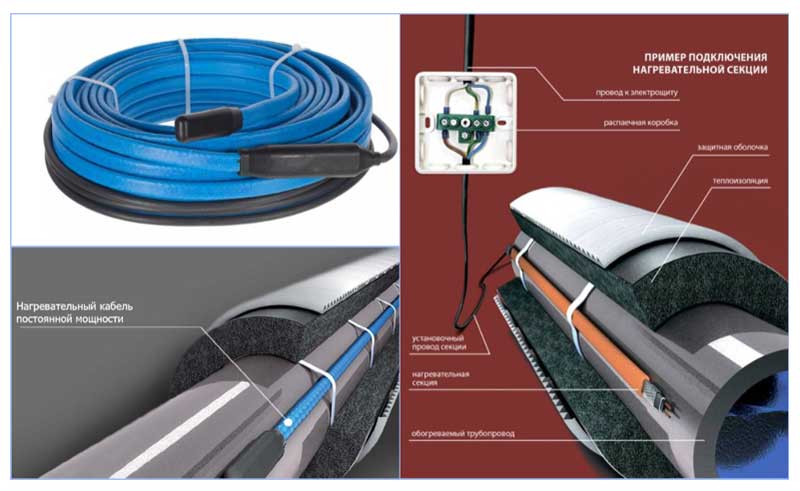

heating cable

An electric heating cable is placed inside or close to the pipe and heats it, preventing the water from freezing. The cables themselves are sold in specialized stores, their power ranges from 10 to 20 watts per linear meter, the use of a cable system allows you to bury the water supply at a distance of no more than 50 cm from the surface of the earth.

The advantages of using the cable are the ability to place it directly in the water, which allows it to be mounted inside the pipeline and lowered into the well to a considerable depth. The use of an electric cable inside the pipes at the same time as an external insulation device is the most effective and economical solution for freezing protection of the water main in individual water supply.

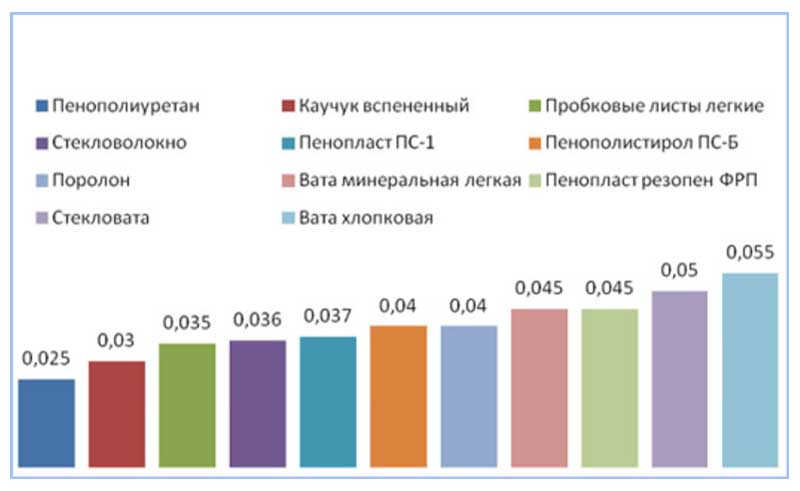

Rice. 3 Thermal conductivity of various materials

Air insulation

A more expensive method that is used in the industrial and municipal sectors. When it is used underground, the main is isolated from above with a heater, and warm air is supplied from below, warming the water supply.

The method is often used when the pipeline is placed in a large diameter pipe, inside which warm air passes. This method is usually used to isolate a water main that runs along the surface; it can also be used in individual areas if the pipeline is buried in the ground - an air gap will prevent water from freezing without heating.

Pressure insulation

With the help of pressure, the water supply system is protected from freezing in trunk systems with underground occurrence or in unheated rooms; a special receiver is used to increase the pressure. The pressure in the system with this technique exceeds 5 atmospheres, while standard pumping equipment for organizing individual water supply is designed to work with a pressure of no more than 3 bar.

Rice. 4 Electric heating cable - appearance

This technique was developed for use in industrial and municipal engineering communication systems; in everyday life, the use of high pressure is effective in the presence of high-quality pipelines and devices designed to work with high pressure. To implement the method, it is necessary to use an electric pump to pump water into the main line at a pressure of more than 5 bar. and turn off pumping equipment - theoretically, water at such a pressure should not freeze for a very long time in the absence of owners.

What should be the thickness of the insulation layer of the underground section of the pipe

The formulas for calculating the thickness of the insulation are quite complex; only qualified specialists in this field can deal with them. For an ordinary consumer, there is no need to independently calculate the thickness, you can always get advice from the seller or use the online calculator for calculations. Usually, data of branded heaters are embedded in such calculators, among which you can find the type that is most suitable in terms of parameters to the one being installed and use it for calculations. Also, the parameters of the pipeline, the air temperature and the physical characteristics of the flowing water are entered into the calculator.

Rice. 10 Online calculator for calculating insulation thickness

What is Energoflex and what are its advantages

Energoflex is a new generation brand of insulation. The scope of its application includes the laying of sewer lines, hot water supply, heat supply systems. It is effective, if necessary, to isolate the surface of pipes from temperature changes and freezing. At its core, the insulation has foamed polyethylene, which is produced by pressing a propane-butane mixture into it.

During production, a warm material with a porous structure is obtained. Its cells are closed. The air in them seems to be preserved without being released outside, which makes it possible to obtain an effective insulation.Closed cells do not let water or steam into the material, which allows us to speak of it as a reliable moisture barrier. Energoflex is able to absorb no more than 0.5% of its volume in 24 hours when it enters the aquatic environment.

In addition to the advantages mentioned, modern thermal insulation also has the following advantages:

Roll Energoflex

- low thermal conductivity (at the level of mineral wool);

- fire safety (operating temperature range is from -40˚ to +90˚; ignition occurs when the temperature mark reaches +360˚; it has the property of self-extinguishing);

- elasticity, allowing you to quickly restore shape;

- resistance to the influence of chemicals (possibility of application near groundwater);

- long service life, which in practice ranges from 20 to 25 years;

- environmental friendliness of the material allows you to work with it without protective equipment.

Specifications Energoflex

The advantages of the material determine the following technical characteristics:

- resistance to mechanical shocks and loss of shape;

- the material belongs to the flammability group G2, which means moderate flammability;

- damp steam diffusion resistance is more than 3000 units;

- light weight and flexibility allow you to mount the insulation without assistance;

- characterized by increased resistance to heat supply;

- thermal insulation is resistant to aggressive environmental influences;

- the material is not hygroscopic;

- demonstrates the characteristics of increased strength;

- does not rot even when in contact with groundwater;

- has the ability to reduce structure-borne noise.

To date, insulation is available in four forms:

- pipe thermal insulation (1 and 2 m long);

- rolled (length 10, 14, 20 and 30 m);

- sheet;

- slab.

Insulation can be used both inside and outside buildings. The wall thickness of the material is 6, 9, 13, 20 mm. Outdoor use requires effective protection against direct sunlight.

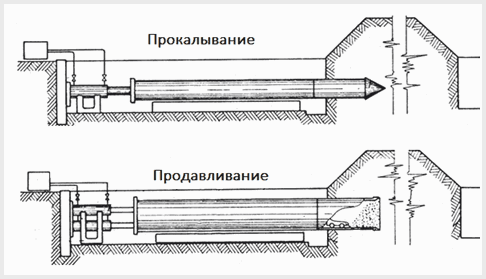

Trenchless piping options

There are technologies for laying pipelines in the ground without ditching.

These methods are intended to:

- reduce the volume of work with the land - a gain in time and costs;

- Minimize damage to infrastructure - lower costs for the renewal of decorative and pavement roads, unforeseen damage to highways;

- lay pipes in a straight line, without bending around obstacles of a small degree of difficulty;

- to reduce the damage from the production of works with the earth to the environment.

Today, the industry uses the following trenchless methods:

Sanitation is the replacement of obsolete pipes with new ones, which, for its part, is carried out in two ways: relining and renovation.

Relining is built on a broach in the middle of the working pipeline of a new polypropylene pipe with a smaller diameter, while saving the old one as a protection shell.

Renovation - the installation of a new pipe instead of the old one, worn out with the destruction, the fragments of which will also protect the new highway from external damage.

Piercing (punching) is the connection of 2 pits dug to the required depth by a puncture made at a certain height of the wall.

Of these methods, in everyday tasks and purposes, we will only perform the relining method. A cable is inserted into one end of the old pipe and pushed through until it exits the other end. Then a new whip is fixed to the cable and pulled back. The possibility of using this method depends on several points:

- condition of the lumen of the old pipeline;

- diameter of the new pipe;

- the flexibility of the new whip;

- the length of the repaired area;

- the ratio of the diameters of the old and new pipeline.

With a favorable combination of these factors, the technical implementation of the installation process of a new pipe is not difficult.However, this is all applicable to pulling a new line without thermal insulation, and the condition of the material for insulating the old pipe is unlikely to be good. Since it is not possible to make the heating pipes warmer in the middle of the old line, the method loses its appeal with regard to heating.

Due to this, when installing heat supply pipelines with a deepening into the soil in private housing, it is hardly possible to do without digging a ditch or, at least, alternative laying of a pipe on the ground with backfill.

Thermal waterproofing of pipes

With the help of simultaneous heat and waterproofing of pipes, the following problems can be solved:

- Firstly, to reduce the risk of freezing of the transported medium, which is especially important in the case of water supply and heat pipelines using ordinary water as a heat carrier.

- Secondly, to reduce the risk of corrosion of the outer walls of metal pipes, as a result of which the cost of the pipeline also decreases: after all, ordinary pipes made of structural steel protected by a waterproofing agent will cost less than specialized products made of stainless steel, copper or aluminum.

- Thirdly, the cost of operating the system is reduced - thermal insulation prevents heat loss, increasing energy efficiency, and waterproofing extends the "life" of a metal pipe.

Of course, such prospects are very tempting, so the thermal waterproofing of the pipeline is practiced not only in systems laid in "permafrost". Nowadays, heat and waterproofing is practiced in almost all above-ground lines and pipelines buried in the soil above the level of soil freezing.

The practice of thermal and waterproofing of pipelines and gas pipelines

At the same time, such solutions apply not only to water pipelines, but also to gas pipelines, oil pipelines and, without fail, to heating networks.

When arranging thermal and waterproofing, it is necessary to isolate the outer surface of the pipe, paying special attention to joints and transitions. Therefore, the outer heat and waterproofing coating of the pipe is a multilayer structure consisting of the following elements:

Therefore, the outer heat and waterproofing coating of the pipe is a multilayer structure consisting of the following elements:

- An epoxy coating that provides, despite a thickness of 0.3 millimeters, almost 100% waterproofing. Such coatings are made up of primer-type polymer compositions applied to the surface of a steel pipe.

- A rigid polyurethane foam coating applied over an epoxy primer. Moreover, in “hot” pipelines, the body of which is heated above 130 degrees Celsius, I lay a layer of fire-resistant material between the primer and the heat insulator, and mount a signal circuit with which to control the temperature.

- Polyethylene coating, which is mounted on a heat insulator. Rotting-resistant polyethylene will provide additional moisture protection if the pipe is laid underground.

- Galvanized casing, which covers pipes of above-ground water conduits and gas pipelines.

The service life of the thermal waterproofing coating depends on the duration of the "life" of the weakest link of the insulating sandwich.

The junction is protected in the following ways:

- With the help of epoxy coatings applied to the joint. Moreover, epoxy compositions are imported. After all, the solvent will damage the polyurethane foam base of the heat insulator.

- With the help of overlays or heat-resistant polymers (polyurethane foam, polystyrene, and so on), mounted at the joint using clamps.

- With the help of ready-made sleeves or cuffs, fixed with locks.

By protecting the joints, you can count on at least a 30-year life of the pipeline.And by supplementing the system of hydro- and thermal protection with a built-in heater, which controls the temperature of the body of the pipeline, it is possible to increase the period of trouble-free operation of the transporting system up to 50-60 years.

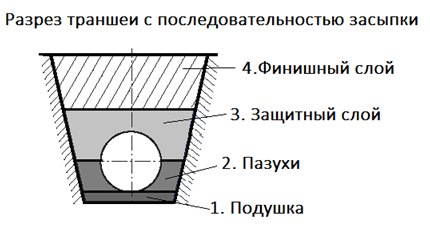

Trench backfill

Backfilling of the trench is started after checking the heating system in operation - if the pressure test of the circuit reveals defects in its tightness, it will be necessary to eliminate them.

Trench backfilling is a critical stage of work, the correct implementation of which determines the uniform distribution of loads and the durability of the pipeline section in the ground.

Backfilling of the trench begins with the laying of soft plastic soil on the sides of the pipe (in the sinuses). This is done evenly along the entire length of the pipeline, preventing its displacement to the sides. The soil laid on the sides is carefully compacted, after which the pipeline is backfilled from the same material with a protective layer of at least 15 cm over the entire width and length of the trench in accordance with the requirements of SNiP. The compaction of this layer is carried out to a lesser extent - this is a necessary condition for the formation of a strong protective arch of soil over the pipe, which rests to a greater extent on the sinuses on the sides of the pipe.

After the compaction of the protective layer is completed, the trench is completely covered with soil excavated during digging, removing large stones from it. Backfilling must be carried out evenly along the entire length of the trench, avoiding the formation of pipe sections with a large difference in vertical load from the soil.

A uniformly growing load from the backfill will be taken to a greater extent by the protective soil vault above the pipe, and the residual value of the compressive force for the pipe is not terrible - it is designed for it.

If the trench is filled in separate sections, then the difference in the vertical load on the buried and open segments of the pipeline will lead to rupture forces, which the pipe resists worse.

Silicone sealant

It is unlikely that there will be at least one home master who has never dealt with silicone sealant. Due to its properties, this material has been widely used in the issue of sealing various joints, slots and cavities.

Construction silicone is a viscous compound based on silicone rubbers that cures at room temperature under the influence of moisture in the air. It has good elasticity and excellent adhesion to many materials, in particular to metal and PVC. The wide temperature range (from -60°C to +300°C) and UV resistance allow silicone to be used not only indoors, but also outdoors.

Depending on the type of hardener, silicone sealants are acidic and neutral. The first option is cheaper, but it is not suitable for treating metal pipes and surfaces that come into contact with acids. Neutral sealants are more expensive. However, they are more popular due to their versatility and the absence of an unpleasant vinegar smell. Therefore, the waterproofing of sewer pipes is usually performed using a neutral composition.

Silicone sealant can be found at any hardware store.

The most convenient method of applying silicone is the use of a mounting gun. When the lever is pressed, the sealant is squeezed out of the tube and distributed evenly over the surface. If such a tool is not at hand, then you can use an ordinary hammer, the handle of which is used to create an extruding force.

The thinner the sealant layer, the faster the curing process. The optimal thickness is considered to be 2-10 mm. Although some manufacturers allow an increase in the diameter of the strand up to 15 mm.

Silicone sealant is applied before joining sewer pipes for better sealing of joints

Pipe waterproofing methods

Heat-resistant, durable, non-combustible material. Insulation is carried out by pouring or using shells. Suitable for insulation of underground metal oil and gas pipelines, heating mains. Polyurethane foam perfectly seals joints, protects against soil corrosion. Suitable for insulating reinforced concrete sewer channels.

PVC tape

It is more often used for sealing joints of external communications, it is installed during installation or repair. Before using the roll tape, check for the absence of defects and cracks.

Heat shrink tape

Seals the joints of pipelines. Polymer waterproofing tape consists of two layers, mounted by the method of "hot" connection on a pre-cleaned and heated pipe. After the material cools down, a continuous monolithic coating is formed, which protects the pipe from rusting.

Polymer based coatings

Folgoizol is elastic, consists of 2 layers (foil and cardboard impregnated with bitumen), has vapor barrier properties, is used for insulation of heating mains.

Hydroisol is cardboard, with a layer of bitumen and asbestos. The optimal combination of price and quality, but the material supports combustion.

Brizol is produced in rolls. Elastic, attached to pipes with mastic. The composition of the insulation includes bitumen, rubber, mineral additives and a plasticizer.

Fiberglass is a mixture of latex and fiberglass. Durable and can be used over a wide temperature range. Glass wool rolls are durable, flexible, do not support combustion, do not emit toxic substances. Used as external insulation, cladding is required on top.

liquid mastic

Forms a homogeneous seamless layer of insulation on the treated surface, which reliably protects against moisture. Ideal for use in hard-to-reach places, such as in the corners of structures.

Such a coating after hardening has no joints. The mixture is applied using a special device at positive air temperature. The material is elastic, so it can be used on surfaces that form cracks. In case of a defect, the damaged section of the coating is removed, a new layer of liquid rubber is applied to the pipe.

Bituminous mastic

A viscous mass is used to create a monolithic and durable connection. On sale there are two types of such insulation. The first option requires heating before application, the second type connects in a cold way thanks to the solvent that is part of the mastic. Before applying the mastic, experts recommend priming the surface and covering it with a reinforcing fiberglass mesh.

Polyethylene heat shrink sleeve

It is a piece of polyethylene pipe and has a diameter slightly larger than the diameter of the insulated pipe. The coupling is heated by a gas burner and put on one of the pipes. Next, the pipes are connected by any type of welding. After cooling, the coupling decreases in size and tightly wraps around the pipe. For additional protection, the free space under the coupling is blown with mounting foam. You can choose a coupling for a pipeline with a diameter of up to 120 mm.

Heat-shrinkable sleeves are made of polyethylene and seal the joints