Caisson classification

A caisson is a hermetic container designed to protect the wellhead from frost, precipitation and other negative phenomena. Its shape can be varied, but sufficient for a person to go down inside to service the equipment. The caisson for the well can be made of several types of materials:

Scheme of the device of the caisson.

- Plastic is the most convenient and practical option that has the best cost. The plastic design is lightweight, its installation is simple and quick, it does not require special experience. The rigidity obtained in this case is not too high, although this can be compensated by pouring a concrete ring along the contour.

- A caisson for a well made of concrete is also practical, durable, but its installation is complicated, it requires certain knowledge when planning. After installation, it is necessary to provide excellent thermal and waterproofing.

- Brick models are of the highest quality, but it is practically impossible to implement them with your own hands. An experienced technician is required as installation is complex.

- The container made of metal is obtained as strong as possible, durable, with excellent performance properties. The metal is susceptible to corrosion, so waterproofing work is necessary. But the strength and ability to withstand loads in such a design are high.

Types of homemade caissons

Caisson for a brick well

Caisson for a brick well

The master can make a special chamber for placing pumping equipment, automation, a hydraulic accumulator in it from such materials:

Reinforced concrete rings. This option is only good because with a high GWL and strong heaving of the soil, the camera will not budge due to its mass

But here it is important to consider that the joints of the rings often have fistulas. The caisson will be periodically flooded

The installation of such a protective chamber will require serious costs: the delivery of reinforced concrete elements, the rental of special equipment for their installation.

Monolithic concrete pour. It is considered more durable than the design of the rings. In addition, although the work is time-consuming, even one master can do it. With proper reinforcement, the final concrete caisson will be strong, airtight, durable. More often, such a chamber is made square due to the peculiarities of the formwork installation. As well as under the reinforced concrete ring, a solid base is required under concrete.

Metal. Such a chamber is mounted less and less, since steel is prone to corrosion, and therefore to destruction over time. To avoid this, when constructing a metal caisson, it will be necessary to additionally process the material with special paints. In addition, the quality of welds is not always ideal, which leads to the formation of holes and further flooding of the chamber.

Brick. The best option for the caisson, if the master wants to independently install the camera. This type of it is especially relevant if there are remains of blocks from the built cottage on the site. The brick caisson differs in durability and reliability. The main thing is to treat its outer walls with bituminous mastic for complete sealing.

Polymer. Here you can use a large barrel, or buy a plastic caisson with stiffeners. Working with polymer tanks is easier than with others. In addition, plastic caissons serve from 50 years or more.

Do-it-yourself installation steps for caissons

Installation of a monolithic concrete caisson

A monolithic concrete tank is poured in this way:

- Formwork is installed on the prepared base, stepping back from the walls of the pit left 20-30 cm. You can drive the frame out of the boards gradually (30 cm each) or immediately to the full height.

- A reinforcing mesh is installed in the formwork.

- Prepare a solution of cement, sand and gravel in a ratio of 1:3:5, respectively. Bulk is diluted with water until a mixture of a creamy thick consistency is obtained.

- The finished solution is poured into the formwork in portions and gently rammed with a metal bar to drive out the remaining air.

- As soon as the tank has completely hardened, the formwork is removed and holes are made in the walls with a puncher for the output of cables and water mains. All technical gaps are sealed with cement-sand mortar.

- The outer walls of the finished caisson are coated with bituminous mastic.

The top of the chamber can be equipped with a wooden shield covered with roofing felt, or a monolithic slab can be poured, first installing a wooden formwork made of durable boards

It is important to leave a hole in the slab for the hatch

Caisson from reinforced concrete rings

Since it is difficult to make a caisson for a well from concrete rings with your own hands, you will need the help of special equipment here. Before installation, the elements must be treated on both sides with bituminous mastic. After it dries, the rings are alternately lowered into the pit on a pre-prepared base. It is advisable to coat all joints with mounting foam and, after it dries, go through the mastic again.

With the help of a perforator, technical side holes are made, and the gaps are sealed.

The top of the caisson from the rings can be made of a concrete slab with a hatch or just a welded metal shield.

brick caisson

Taking into account the fact that the bottom of the pit has already been prepared (there is a concrete platform), strips of roofing material should be laid along the perimeter of the future masonry. Only after that they start laying. You need to lay a brick from the corner, moving towards the opposite from one side and the other. The thickness of the solution between the blocks is 1-1.5 cm

It is important to install metal sleeves where the outlets of the water pipes and cables are supposed to be. Then the walls of the caisson are driven out to the desired level

As soon as the chamber is completely dry, it is plastered and coated with bituminous mastic from the outside and from the inside. After the waterproofing has dried, the chamber is backfilled.

Polymer caisson

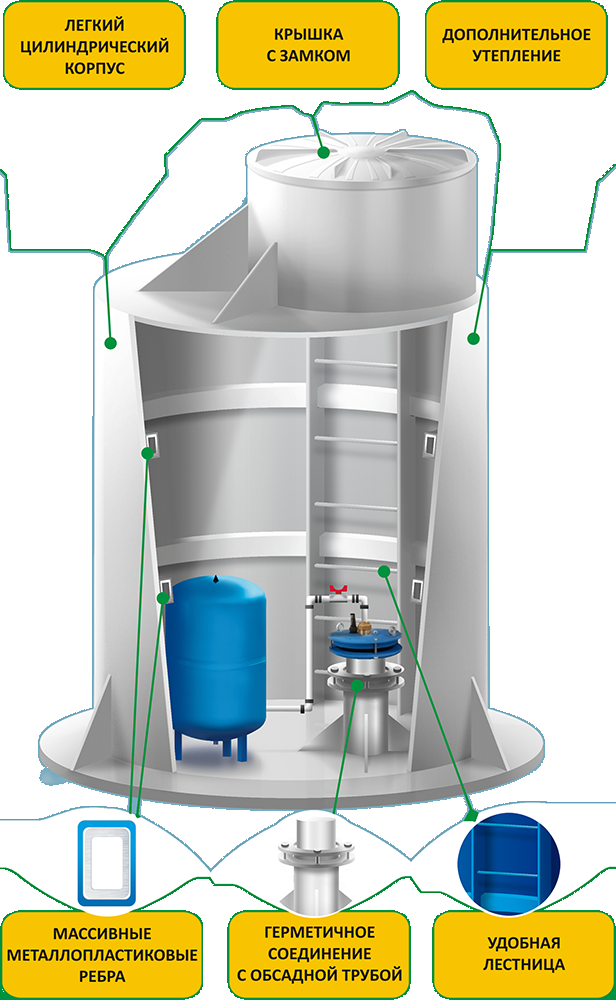

Plastic caisson with stiffeners

Plastic caisson with stiffeners

You can make a caisson for a well from a plastic barrel or buy a ready-made solid structure with stiffeners. The second option is preferable, since the tank will be able to withstand the pressure of heaving soil.

Often, it is permissible not to make a powerful concrete base for the installation of a polymer tank. Enough sand bedding 10-15 cm thick.

Polymer caisson installation technology:

- The camera is installed on wooden beams, having previously formed a technical hole in the bottom for the casing string.

- Carefully put the caisson on the pipe and lower it down.

- Under the output of pipes and cables, it is desirable to make additional holes immediately on the surface.

- The backfill of the polymer chamber is made from a sand-cement mixture. It is slightly moistened and compacted well in layers.

- Equipment in a plastic caisson is best placed 10 cm from the walls of the tank.

Preparatory work

The initial stage in the installation of any caisson is the preparation of a foundation pit for it and the construction of a foundation. The pit is dug according to the dimensions of the future chamber plus 20-30 cm from all sides, including the bottom. As a result, the neck of the caisson should rise 20 cm above ground level. This makes it possible to exclude precipitation from entering the protective structure.

The bottom of the pit is well rammed. Sprinkle a sand cushion with a layer of 10 cm and compact it well. If it is planned to install a concrete, brick or caisson from reinforced concrete rings, a cement pad 15-20 cm thick must be made. It is better to reinforce it. Once the base is ready, you can proceed to the device of the caisson.

Varieties of caissons

For the manufacture of equipment, a material is used that will provide sufficient thermal insulation and the required sealing, which must be inside.

There are the following types of caissons:

- From plastic. It provides good sealing. The material is lightweight, so the device is easy to transport and install. But the structure itself is not rigid enough and, in order to prevent it from surfacing, the chamber is poured with concrete along the contour.

- From metal. The most commonly used steel. This material is durable and will last a long time. If the chamber is made correctly, then it will provide sealing, it will not float. But the material is susceptible to corrosion, so waterproofing is required.

- From concrete. The container is durable, but does not withstand moisture. Therefore, as in the case of the installation of metal structures, waterproofing is required. The installation is heavy, so it is problematic to transport and assemble the structure.

- From brick. Thermal insulation characteristics are higher compared to other materials, no additional insulation is required. Only a person who is well versed can install the camera. This option is durable, economically beneficial.

- From polymer sand. The system itself is inexpensive, airtight and durable. In addition, it is easy to operate.

All types have both advantages and disadvantages. Before choosing a structure, you need to think about what the owner wants to achieve during installation, about the speed of work, the cost of the caisson, the durability of operation, etc.

Types of materials for the construction of the caisson

Before starting the installation of a caisson for a well, one should choose the material of construction by comparing the characteristics of various options.

- Plastic models are resistant to moisture, and their light weight ensures ease of installation. The disadvantage of the material is its relatively low strength. You can cope with this by contouring the tank with concrete mortar.

- Concrete structures require some effort during installation. In addition, when making a caisson from concrete rings, you will need to pay for the services of special lifting equipment. At the same time, concrete caissons can be considered quite reliable and durable.

- A do-it-yourself caisson for a well can be made of metal. This material also has the proper strength and durability. However, taking into account the operating conditions during construction, it will be necessary to ensure the most reliable waterproofing of such a product to prevent corrosion and carefully monitor the integrity of the protective layer during operation.

- Installation of the caisson on the well can be carried out using the brickwork method. For reliability, such structures will require a protective layer to ensure tightness during manufacture. The purchase of building material will require investment, but for the caisson, you can use the brick left after building a house or garage.

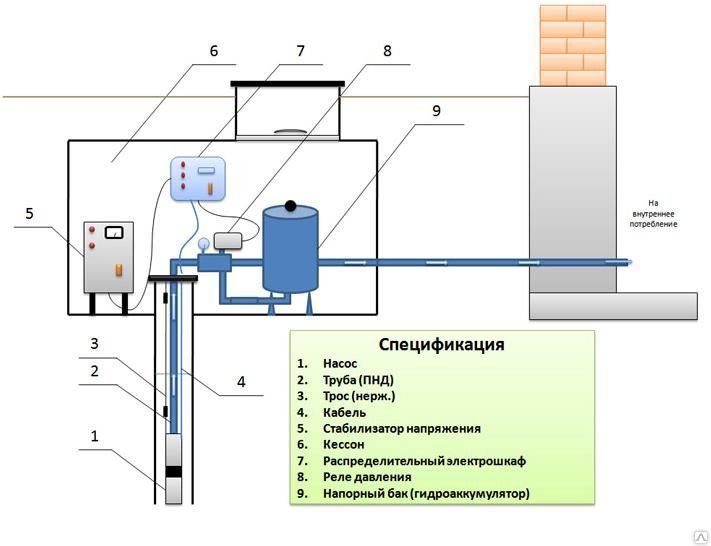

Caisson device for a well

Wiring communications in a private house also implies the presence of a clean drinking water supply system. For the correct installation of the plumbing system, it is necessary to take into account several important points. Firstly, the water supply must either be located at a depth below the freezing level of the soil, or be equipped with an active heating system. Such a system is not cheap, so a caisson buried at a depth of about two meters is considered a cheaper, but no less effective way to organize water supply.

Caisson device for a well

A caisson is a sealed container of a cylindrical or square shape, made of waterproof materials. It helps protect well water from mixing with groundwater and from freezing in winter. In the harsh Russian winter, the caisson is additionally insulated with a foamed polymer or foam. From below, the casing pipe of the well enters the caisson, and water supply pipes exit from the side.

The dimensions of the caisson in each individual case are calculated individually.It makes no sense to make a large caisson, since in this case you will simply spend extra building materials. Usually, the caisson is built with the expectation that it would be convenient for one person inside the caisson to carry out maintenance and repair work. For these purposes, as a rule, it is enough to make a caisson with a diameter of one meter and a height of about two meters. Such dimensions will be enough to freely place a pump inside the caisson, automation for its control, pressure gauges and filters and protect it from freezing.

Necessary tools and materials

During the construction of the caisson, the joints between the concrete rings must be carefully sealed.

During the construction of the caisson, the joints between the concrete rings must be carefully sealed.

If the master decided to mount a monolithic concrete caisson, the following materials should be prepared:

- cement M-400 and above;

- medium-sized crushed stone (30 mm);

- river sand;

- reinforcing mesh or rods;

- bituminous mastic;

- formwork boards.

For the installation of a brick caisson, prepare:

- cement M-400 and above;

- crushed stone (fraction 20-25 mm);

- river sand;

- brick blocks (the number of pieces is calculated by the estimated width and height of the walls, divided by the width and height of one block);

- bituminous mastic.

Of the tools you will need:

- a concrete mixer or a special pallet for preparing the mortar manually;

- shovel bayonet and shovel;

- tamper;

- roulette;

- hammer and nails;

- Master OK;

- mallet;

- buckets;

- building level;

- gas-burner.

For all other types of caisson (made of polymer or rings), the containers themselves, plus a shovel and rammer, will be required.

How to make a caisson yourself

To do it yourself, first you need to decide on the material, system parameters.

Monolithic concrete structure

A square shape is suitable for the device, it is also much easier to build formwork.

First you need to decide on the size of the pit, which is dug under the structure. The length and width are standardly equal, so they can be calculated as follows: measure the size of the caisson from the inside, add the thickness of 2 walls (10 cm).

It is also necessary to calculate the depth of the pit, which should be 300-400 cm more than the height of the chamber. If everything is calculated, then the drainage layer can be installed at the bottom of the pit.

If further concreting of the base of the structure is not planned, then the following procedure is chosen

But when it is necessary to fill the bottom with concrete, the height must be taken into account. In addition, the pit should be such that the surface of the cover of the structure is flush with the soil.

In order to have more space for a person when repairing the system, it is best to place the camera not in the middle in relation to the casing, but on the side. And the equipment will be conveniently placed.

Construction of a monolithic concrete caisson.

The work is carried out as follows:

- Start by digging a hole. At this point, you can immediately dig a trench for water pipes to the house. Then they begin to install drainage, which consists of 2 layers: sand (up to 10 cm high) and crushed stone (up to 15 cm). With such drainage, even if water gets inside the caisson, it will not remain inside, but will quickly go into the soil.

- After you need to equip the formwork. Often the wall of the pit is used as the outer layer of the formwork. The side of the pit must be covered with polyethylene to avoid seepage of water from the concrete into the soil. After you need to make a frame using reinforcement.

- Mix concrete solution. Pour it in small parts, compacting well with an electric vibrator. If there is no device, then you can use a pin, a thin pipe and weld the handles. This device is quickly lowered into the concrete, and then slowly pulled out to get rid of air and water bubbles, thereby making the concrete denser.

- After it is necessary to dry the structure, regularly spraying the surface with water so that the concrete does not crack. If it's hot, you can cover it with a damp cloth.

- After a week, the formwork can be removed. And in 4 weeks to install the equipment.

Caisson from concrete rings

The borehole system of concrete rings provides for the following:

- First, the pit is prepared. The calculations are the same as in the previous manufacturing method.

- Fill the bottom with concrete and drill a hole for the pipe.

- They take concrete rings, which are pre-coated with a special waterproofing compound. Let dry.

- After each ring is lowered into the pit, while connecting the joints with a mixture for bonding. The seams are foamy.

- There may be voids around the structure that need to be filled.

From concrete rings, a caisson for a well.

Budget camera made of bricks

Brick caisson device:

- First, a foundation pit is dug out, a strip foundation and a trench are installed at the bottom, which are covered with sand and rammed.

- It is necessary to lay waterproofing on the foundation (for example, roofing material).

- Brick laying starts from the corner, be sure to fill the seams with a special solution.

- After bringing the masonry to the desired height, let it dry, plaster.

Sealed metal container

The process is like this:

- Dig a hole again, suitable for the size and shape of the chamber.

- A hole for the casing pipe is cut out at the bottom.

- Install the cover, clean the seams of slag. The seams must be double-sided to ensure the tightness of the caisson.

- The structure must be treated with a protective layer.

If necessary, the chamber can be insulated, after which the caisson can be lowered into the pit and a column, sleeves, and cable can be installed. The sleeve is welded, everyone falls asleep.