Features of heating with heated air Industrial and manufacturing facilities

We list these nuances that our specialists usually face at industrial facilities:

- High power of heating equipment, large overall dimensions of air ducts, as a rule - complex geometry of their laying schemes

- More complex design solutions in heating systems

- As a result, the need for a special operational service of the enterprise, responsible for the smooth operation of the heating system

- No high aesthetic requirements. As a result, air ducts and equipment, as a rule, are not covered with suspended ceilings and plasterboard partitions.

- More complex installation, including at high altitude

Types of heating systems with gravity circulation

Despite the simple design of a water heating system with self-circulation of the coolant, there are at least four popular installation schemes. The choice of wiring type depends on the characteristics of the building itself and the expected performance.

To determine which scheme will work, in each individual case it is required to perform a hydraulic calculation of the system, take into account the characteristics of the heating unit, calculate the pipe diameter, etc. You may need the help of a professional when doing the calculations.

Closed system with gravity circulation

In the EU countries, closed systems are the most popular among other solutions. In the Russian Federation, the scheme has not yet been widely used. The principles of operation of a closed-type water heating system with pumpless circulation are as follows:

- When heated, the coolant expands, water is displaced from the heating circuit.

- Under pressure, the liquid enters a closed membrane expansion tank. The design of the container is a cavity divided by a membrane into two parts. One half of the tank is filled with gas (most models use nitrogen). The second part remains empty for filling with coolant.

- When the liquid is heated, pressure is created sufficient to push through the membrane and compress the nitrogen. After cooling, the reverse process occurs, and the gas squeezes the water out of the tank.

Otherwise, closed-type systems work like other natural circulation heating schemes. As disadvantages, one can single out the dependence on the volume of the expansion tank. For rooms with a large heated area, you will need to install a capacious container, which is not always advisable.

Open system with gravity circulation

The open type heating system differs from the previous type only in the design of the expansion tank. This scheme was most often used in old buildings. The advantages of an open system is the possibility of self-manufacturing containers from improvised materials. The tank usually has modest dimensions and is installed on the roof or under the ceiling of the living room.

The main disadvantage of open structures is the ingress of air into pipes and heating radiators, which leads to increased corrosion and rapid failure of heating elements. Airing the system is also a frequent "guest" in open circuits.Therefore, radiators are installed at an angle, Mayevsky cranes are required to bleed air.

Single pipe system with self-circulation

This solution has several advantages:

- There is no paired pipeline under the ceiling and above the floor level.

- Save money on system installation.

The disadvantages of such a solution are obvious. The heat output of heating radiators and the intensity of their heating decreases with distance from the boiler. As practice shows, a single-pipe heating system of a two-story house with natural circulation, even if all slopes are observed and the correct pipe diameter is selected, is often redone (by installing pumping equipment).

Two-pipe system with self-circulation

The two-pipe heating system in a private house with natural circulation has the following design features:

- Supply and return flow through separate pipes.

- The supply pipe is connected to each radiator via an inlet.

- The battery is connected to the return line with the second eyeliner.

As a result, a two-pipe radiator type system provides the following advantages:

- Uniform distribution of heat.

- No need to add radiator sections for better warm-up.

- Easier to adjust the system.

- The diameter of the water circuit is at least one size smaller than in single-pipe schemes.

- Lack of strict rules for installing a two-pipe system. Small deviations regarding slopes are allowed.

The main advantage of a two-pipe heating system with lower and upper wiring is the simplicity and at the same time the efficiency of the design, which allows you to level errors made in the calculations or during installation work.

System installation rules

The correct functioning of a gravity heating system implies, first of all, the accuracy of selecting the diameter of the pipes, as well as the absolute observance of the required slopes during installation work - in order to avoid the creation of counter slopes. If you have some experience, you can carry out all these works on your own, without resorting to specialists.

Particular attention should be paid to the absence of bends and turns at the riser - at the exit from the boiler. Such a result of work is considered ideal, in which the riser, up to its top, has a vertically even appearance.

If it is necessary to turn, it will be optimal to choose the corner of the minimum size, and the diameter of the pipes is equal to one and a half inches. At the same time, the number of pipes is in direct proportion to the flowing circulation: the more of them will be used, the more intensive the circulation will be.

When taking water - coolant - from the riser, it is necessary to maintain a level exceeding the uppermost of the radiators, and the boiler must be placed so that it is below the level of any of the heating devices.

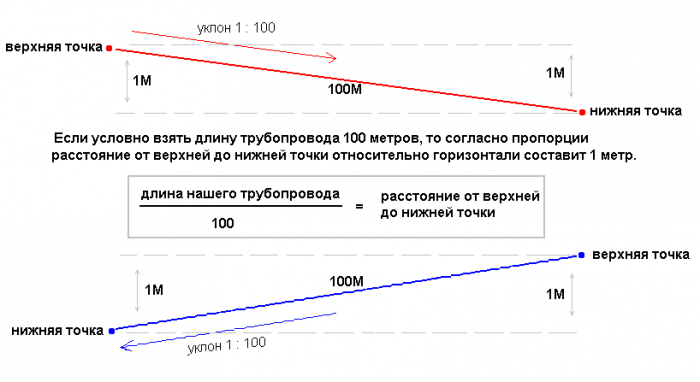

For pipes, you need to set a slight slope - in the direction of the boiler. In this case, a slope with the calculation of one centimeter per meter of pipe will be acceptable. This is the only way to guarantee circulation.

If we compare two circulation schemes - natural and forced, then the first type can be said to have a large volume of water. The reason lies in the difference in diameters.

Caution must be exercised when choosing pipes - or rather, pay attention to the material of their manufacture: in no case should you purchase products made from polyethylene and polypropylene. Their use is fraught with the risk of melting, which can be caused by boiling water in the pipes. The latter can be caused by the lack of a pump, as well as due to the presence of a high level of load on a gas heating boiler installed in a private house.

The most reliable option in this situation would be the purchase of iron pipes, which, in turn, expands the range of unfavorable factors for using a gravity system - the price of such pipes is quite high, and the dimensions used create an insufficiently aesthetic appearance

The latter can be caused by the lack of a pump, as well as due to the presence of a high level of load on a gas heating boiler installed in a private house. The most reliable option in this situation would be the purchase of iron pipes, which, in turn, expands the range of unfavorable factors for using a gravity system - the price of such pipes is quite high, and the dimensions used create an insufficiently aesthetic appearance.

One of the main components of the system is an expansion tank, the choice of which should be carried out taking into account the fact that when heated, the water begins to expand. To prevent deformation processes, it becomes necessary to install an expansion tank. The correct selection can be made if you refer to the instructions. The tank is installed at the highest point of the heating gravity system.

In conclusion, it is worth emphasizing two main advantages of this system - a high level of inertia and the absence of the need for electricity in the building, which is planned to be equipped with this type of heating. In principle, the latter property is the main one when choosing a system suitable for houses where there is no electricity supply.

Pipe selection

Also, the choice of material is greatly influenced by the boiler, since in the case of solid fuel, preference should be given to steel, galvanized pipes or stainless steel products, due to the high temperature of the working fluid.

However, metal-plastic and reinforced pipes require the use of fittings, which significantly narrows the clearance, reinforced polypropylene pipes will be an ideal option, at an operating temperature of 70C, and a peak temperature of 95C.

Products made of special PPS plastic have an operating temperature of 95C, and a peak temperature of up to 110C, which allows them to be used in an open system.

How to choose a heating pump

Best suited for installation are special low-noise centrifugal-type circulation pumps with straight blades. They do not create excessively high pressure, but push the coolant, accelerating its movement (the working pressure of an individual heating system with forced circulation is 1-1.5 atm, the maximum is 2 atm). Some models of pumps have a built-in electric drive. Such devices can be installed directly into the pipe, they are also called "wet", and there are devices of the "dry" type. They differ only in the rules of installation.

When installing any type of circulation pump, an installation with a bypass and two ball valves is desirable, which allows the pump to be removed for repair / replacement without shutting down the system.

It is better to connect the pump with a bypass - so that it can be repaired / replaced without destroying the system

Installing a circulation pump allows you to adjust the speed of the coolant moving through the pipes. The more actively the coolant moves, the more heat it carries, which means that the room heats up faster. After the set temperature is reached (either the degree of heating of the coolant or the air in the room is monitored, depending on the capabilities of the boiler and / or settings), the task changes - it is required to maintain the set temperature and the flow rate decreases.

For a forced circulation heating system, it is not enough to determine the type of pump

It is important to calculate its performance. To do this, first of all, you need to know the heat loss of the premises / buildings that will be heated

They are determined based on losses in the coldest week. In Russia, they are normalized and installed by public utilities.They recommend using the following values:

- for one- and two-story houses, losses at the lowest seasonal temperature of -25 ° C are 173 W / m 2. at -30 ° C, losses are 177 W / m 2;

- multi-storey buildings lose from 97 W / m 2 to 101 W / m 2.

Based on certain heat losses (denoted by Q), you can find the pump power using the formula:

c is the specific heat capacity of the coolant (1.16 for water or another value from the accompanying documents for antifreeze);

Dt is the temperature difference between supply and return. This parameter depends on the type of system and is: 20 o C for conventional systems, 10 o C for low-temperature systems and 5 o C for underfloor heating systems.

The resulting value must be converted into performance, for which it must be divided by the density of the coolant at operating temperature.

In principle, when choosing the pump power for forced circulation of heating, it is possible to be guided by averaged norms:

- with systems that heat an area up to 250 m 2. use units with a capacity of 3.5 m 3 / h and a head pressure of 0.4 atm;

- for an area from 250m 2 to 350m 2, a power of 4-4.5m 3 / h and a pressure of 0.6 atm are required;

- pumps with a capacity of 11 m 3 / h and a pressure of 0.8 atm are installed in heating systems for an area from 350 m2 to 800 m2.

But you need to take into account that the worse the house is insulated, the greater the power of the equipment (boiler and pump) may be required and vice versa - in a well-insulated house, half of the indicated values \u200b\u200bmay be required. These data are average. The same can be said about the pressure created by the pump: the narrower the pipes and the rougher their inner surface (the higher the hydraulic resistance of the system), the higher the pressure should be. Full calculation is a complex and dreary process, which takes into account many parameters:

The power of the boiler depends on the area of the heated room and heat loss.

- resistance of pipes and fittings (read how to choose the diameter of heating pipes here);

- pipeline length and coolant density;

- number, area and type of windows and doors;

- the material from which the walls are made, their insulation;

- wall thickness and insulation;

- the presence / absence of a basement, basement, attic, as well as the degree of their insulation;

- type of roof, composition of the roofing cake, etc.

In general, heat engineering calculation is one of the most difficult in the field. So if you want to know exactly what power you need a pump in the system, order a calculation from a specialist. If not, choose based on average data, adjusting them in one direction or another, depending on your situation. It is only necessary to take into account that at an insufficiently high speed of movement of the coolant, the system is very noisy. Therefore, in this case, it is better to take a more powerful device - the power consumption is small, and the system will be more efficient.

The choice of components and material of manufacture

After the advent of polymer pipes, the gravity heating system made of polypropylene (PP) has become very popular. This material is easy to process, a minimum of equipment is required to connect individual sections.

However, not every type of these pipes is intended for installation as a heating element. Consider the main selection criteria:

-

The presence of a reinforcing layer

. The gravity heating system made of polypropylene can be affected by high temperatures - up to 95 ° C. To maintain the original shape of the pipe, a stiffening element is required, which is a layer of foil or fiberglass; -

Wall thickness

. A gravity heating system with a closed expansion tank can build up a lot of pressure. To avoid damage to the line, polypropylene pipes must be of class PN20 or higher. The thickness of their walls depends on the diameter.

This pipe can be used for arranging an accelerating manifold. However, in order to achieve a temperature difference, the return line is recommended to be made of steel. In addition to lowering the temperature of the coolant before entering the boiler, this material helps to reduce the hydraulic resistance.

After completing the calculation for a gravity heating system made of polypropylene or steel pipes, you can proceed with its installation.To achieve optimal efficiency, experts recommend making small but important changes to the standard scheme:

-

Highway slope

. The optimum gravity pressure for the heating system can be achieved by sloping pipes after the air vent and on the return line after the last heating device; -

Installing a circulation pump on the bypass

. It will help to reduce the inertia of the system. The heat carrier heating time can be very long, so the pump can increase its speed along the main line until the desired temperature is reached; -

Minimum turning points in the pipeline

. They create excess hydraulic resistance, which affects the decrease in the speed of water movement; -

Installation of protective elements

. By installing a check valve for gravity heating, water circulation in the wrong direction can be avoided. This is especially necessary for a top-wired system with multiple circuits.

Tips for arranging and using a gravity valve for heating when installing a warm floor, additional elements, can be viewed in the video:

The stage of design and construction, when the heating scheme of a private house is determined, is a rather crucial moment in the process of thermal insulation. After all, an improperly planned system “threatens” your house with a lack of high-quality heat, “oversaturation” of the house with “interior” elements in the form of extra heating radiators, the inability to quickly control the operating mode of the system ... and at the same time, the money spent is yours.

Analyzing a huge number of schemes that are presented on the pages of literature and sites on the topic of insulation and heating, you can get a little "lost". Therefore, we will focus on several of the most commonly used schemes, having studied their advantages and disadvantages.

As you probably already know, there are two types of schemes:

- scheme of the heating system with;

- with forced circulation of the coolant.

There are also single-pipe and two-pipe heating systems that can be implemented both in systems with natural circulation and in "forced" ones.

The coolant in such systems can be:

- ordinary water;

- antifreeze (non-freezing liquid for heating systems)

What it is

If a system with forced circulation requires a pressure drop created by a circulation pump or provided by a connection to a heating main, then the picture is different. Heating by natural circulation uses a simple physical effect - the expansion of a liquid when heated.

If we discard the technical subtleties, the basic scheme of work is as follows:

- The boiler heats a certain volume of water. So, of course, it expands and, due to its lower density, is displaced upwards by a colder mass of coolant.

- Having risen to the top point of the heating system, the water, gradually cooling down, by gravity describes a circle through the heating system and returns to the boiler. At the same time, it gives off heat to the heaters and by the time it is again at the heat exchanger, it has a greater density than at the beginning. Then the cycle repeats.

Useful: of course, nothing prevents you from including a circulation pump in the circuit. In normal mode, it will provide faster water circulation and uniform heating, and in the absence of electricity, the heating system will work with natural circulation.

The operation of the pump in a natural circulation system.

The photo shows how the problem of interaction between the pump and the natural circulation system is solved. When the pump is running, the check valve is activated, and all the water goes through the pump. It is worth turning it off - the valve opens, and water circulates through a thicker pipe due to thermal expansion.

The main pros and cons of using air heating technology

- High efficiency. In some systems, its value can approach 90%. For comparison, a heating system with a coolant has an efficiency of less than 60%

- The ability to heat a large area, including in the central areas of the premises

- Low installation and operating costs

- Compatibility with the ventilation network. Availability, subject to connection to a ducted air conditioner, to use the system for cooling in the summer

- The absence of a liquid heat carrier in the air heating system, which eliminates the occurrence of emergency situations (frost, leaks)

- Low level of inertia. Rooms heat up very quickly

- The ability to stop the system even in severe frosts without the risk of its failure

But there are obvious disadvantages of these systems, from which we can distinguish:

- Warm air tends to rise up, so for the most efficient and uniform heating, it is advisable to lay a network of air ducts in the lower part of the room or hide them under the floors. Unfortunately, it is often impossible or very difficult to do this, especially at industrial facilities.

- The use of air heating technology can cause all the dust that is present on the floor surface in the house to rise. If you do not clean the premises often, the air will be dusty.

- The complexity of the calculations of such a system. In order for air heating in a small private house or at a large-scale industrial facility to function effectively, this system must be professionally calculated. These calculations are quite complex and much more complicated than the calculations required when organizing a water heating system. They need to take into account many parameters. It is necessary to calculate: heat losses in the serviced premises, type and required power of the heat generator, optimal air flow rate, air exchange rate, necessary and sufficient cross-section of air ducts and other specific engineering parameters

After analyzing the above, it becomes obvious that the air heating system is located at the junction of two engineering sections. These sections are heating and ventilation.

Accordingly, the Contractor to whom you entrust the execution of work at your Facility must have such specialists or generalists who have experience in the calculation, selection and installation of such systems.

It must be taken into account that if the air heating system is executed with errors, then it will not only fail to cope with its intended purpose - to provide the necessary comfortable temperature in the winter. But it can also be noisy and quite expensive.

With hidden laying of air ducts, reworking such a heating system that does not work correctly is a very costly and problematic event.

If you are looking for a contractor for air heating of your private house or industrial Facility, we are glad to offer you our services!

Send a request for system calculation

Types of heating systems with gravity circulation

Despite the simple design of a water heating system with self-circulation of the coolant, there are at least four popular installation schemes. The choice of wiring type depends on the characteristics of the building itself and the expected performance.

To determine which scheme will work, in each individual case it is required to perform a hydraulic calculation of the system, take into account the characteristics of the heating unit, calculate the pipe diameter, etc. You may need the help of a professional when doing the calculations.

Closed system with gravity circulation

In the EU countries, closed systems are the most popular among other solutions. In the Russian Federation, the scheme has not yet been widely used. The principles of operation of a closed-type water heating system with pumpless circulation are as follows:

- When heated, the coolant expands, water is displaced from the heating circuit.

- Under pressure, the liquid enters a closed membrane expansion tank. The design of the container is a cavity divided by a membrane into two parts. One half of the tank is filled with gas (most models use nitrogen). The second part remains empty for filling with coolant.

- When the liquid is heated, pressure is created sufficient to push through the membrane and compress the nitrogen. After cooling, the reverse process occurs, and the gas squeezes the water out of the tank.

Otherwise, closed-type systems work like other natural circulation heating schemes. As disadvantages, one can single out the dependence on the volume of the expansion tank. For rooms with a large heated area, you will need to install a capacious container, which is not always advisable.

Open system with gravity circulation

The open type heating system differs from the previous type only in the design of the expansion tank. This scheme was most often used in old buildings. The advantages of an open system is the possibility of self-manufacturing containers from improvised materials. The tank usually has modest dimensions and is installed on the roof or under the ceiling of the living room.

The main disadvantage of open structures is the ingress of air into pipes and heating radiators, which leads to increased corrosion and rapid failure of heating elements. Airing the system is also a frequent "guest" in open circuits. Therefore, radiators are installed at an angle, Mayevsky cranes are required to bleed air.

Single pipe system with self-circulation

This solution has several advantages:

- There is no paired pipeline under the ceiling and above the floor level.

- Save money on system installation.

The disadvantages of such a solution are obvious. The heat output of heating radiators and the intensity of their heating decreases with distance from the boiler. As practice shows, a single-pipe heating system of a two-story house with natural circulation, even if all slopes are observed and the correct pipe diameter is selected, is often redone (by installing pumping equipment).

Two-pipe system with self-circulation

The two-pipe heating system in a private house with natural circulation has the following design features:

- Supply and return flow through separate pipes.

- The supply pipe is connected to each radiator via an inlet.

- The battery is connected to the return line with the second eyeliner.

As a result, a two-pipe radiator type system provides the following advantages:

- Uniform distribution of heat.

- No need to add radiator sections for better warm-up.

- Easier to adjust the system.

- The diameter of the water circuit is at least one size smaller than in single-pipe schemes.

- Lack of strict rules for installing a two-pipe system. Small deviations regarding slopes are allowed.

The main advantage of a two-pipe heating system with lower and upper wiring is the simplicity and at the same time the efficiency of the design, which allows you to level errors made in the calculations or during installation work.