Temperature controllers

Finally, we should mention thermostats. Their main element is a thermostat, which regulates the operating mode of the system depending on the temperature in the room.

Popular with readers - heating cables for pipelines, is it worth using.

But the thermostat cannot work without a temperature sensor.

According to the method of placing the temperature sensor, thermostats are distinguished, which adjust according to the floor temperature, or according to the air temperature in the room.

In addition, thermostats can be equipped with various functions that provide additional convenience when using the system.

It should be noted that this information is generalized, since each of the electric floor heating systems has many of its own features and nuances. But in the future we will definitely tell you about each of the floor heating systems separately.

Material calculation

You can use ready-made tables from the manufacturer of cable underfloor heating, and according to the calculation of the heat loss of each room, the required wire laying step and its total length per room are selected.

For film (infrared) systems, the calculations are even simpler: you should choose the number of elements that will cover the required area.

The calculations also include a wire for connecting the regulator and underfloor heating from the meter and from the regulator directly to the system elements.

According to the calculations and the received power of all underfloor heating, it is necessary to check the general electrical input for the ability to withstand such a load. If the input is insufficient, then replace it and install suitable automatic fuses.

The main factors influencing the choice

Many factors influence the choice of electric underfloor heating.

Firstly, this is in what capacity they will be used - as the main heating, or as an additional one.

As the main heating system, the best would be to use a cable system.

When using such a warm floor, energy costs will be somewhat less than when using thermomats.

At the same time, tiles will be the best flooring for such a system.

Thanks to the use of an additional screed, the heating of the floor will be uniform. However, cable installation is much more difficult than thermal mats or infrared film.

To use a warm floor as an additional space heating, as well as to heat small rooms in which there is no central heating, it is better to use thermomats or film.

When choosing, you should also take into account the area of \u200b\u200bthe room.

For effective heating, it is necessary that the area covered by the system occupies at least 70% of the floor area of the room.

In this case, it is necessary to take into account the future placement of furniture, since it is not desirable and not advisable to place the system under it.

It is necessary to determine the operating modes of the system. But for this, more attention should be paid to the thermostat, which will control the warm floor.

And be sure to make sure that the electrical network of the apartment or house can withstand the load when the system is operating at maximum power.

For example, with additional heating, the system needs power from 100 to 160 watts for heating 1 sq.m. gender.

And when using it as the main heating, you will already need 180 or more watts of power, depending on the type of underfloor heating used.

Advantages and disadvantages of electrical systems

Further, we will consider electric underfloor heating, as simpler to install, and which are more relevant for those who decide to improve comfort in the house.

Electric underfloor heating has a number of advantages over water.

Installation

It is relatively simple. Of course, an additional screed is required to install an electric underfloor heating, but it is small and relatively easy to make.

Infrared and thermomats do not even require that, it is enough to remove the floor covering and lay the heating elements and lay the covering back.

Heat

Electric floors provide uniform heating. At water floors, water circulates in pipelines, which cools down as it moves and transfers heat.

Electrical cables use special cables that generate heat when current flows.

Moreover, the amount of heat generated has certain norms, which allows you to accurately calculate the power of these cables.

Leakage in water floors

With a poor-quality connection of pipelines, a leak may occur, which will be very difficult to eliminate.

This is not possible with electrical systems.

And in case of problems with the operation of electrical systems, it will be easier to eliminate them, since it is much easier to get to the cable or thermomat.

Electric floors can be installed in separate rooms, or, for example, on balconies or loggias.

floor heating rate

In electric floors, it is very high. Their temperature will rise within a couple of minutes after switching on.

Disadvantages of electric floors:

First of all, these are increased economic costs when using this type of underfloor heating, compared to water, which are connected to a common heating system.

In the case of infrared floors, they cannot be used with tiles as they will shield the heat.

Another important nuance is the unevenness of heat loss.

Near the walls and technological openings in the room, heat loss will be much greater than in the middle of it.

To compensate for this, the installation of electric underfloor heating is carried out in a special way, so that closer to the edges the heat transfer is greater than in the middle of the room.

Stages of installing a water-heated floor in a private or country house

- Content:

- Is it possible to heat a country house with a water floor

- How to make a water floor

- What is the best way to connect an underfloor heating system

- Pros and cons of using water floors

As an additional or main source of heating for a private house, water-heated floors are often used to effectively heat the building. However, there are some features associated with the installation of the heating circuit and the subsequent operation of the system.

The device of a water-heated floor in a private house has both its positive and negative sides, which are important to consider.

Distribution of heating elements and control units

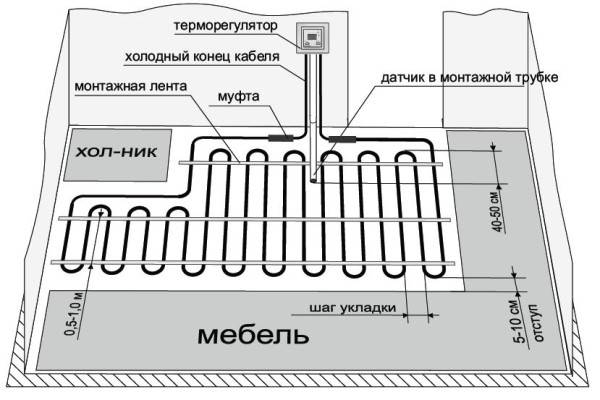

First, a plan for installing a warm floor on paper is created. At the same time, it is taken into account that the heating wire or film should not be installed in places where massive furniture and household appliances will stand. In places where heating pipes or other heat sources pass, it is also worth providing a buffer zone without heating elements. This is due to the peculiarity of electric underfloor heating. Unlike hydraulic systems, all heating elements of one circuit are heated in the same way and if there is a restriction on the output of heat in the form of furniture without legs or additional heat comes from outside, then the elements overheat and fail. Furniture in this case can also be damaged by overheating.

The result is an irregular figure inscribed in a rectangle depicting a room. And it is precisely along the contour of this figure and inside it that an electric warm floor will be laid.

This is the biggest disadvantage of underfloor heating. Rearranging furniture can significantly affect the performance of the system.

For different rooms, even if they are symbolically demarcated, it is better to form separate underfloor heating circuits with their own separate regulators and power supply. In the case of pouring the screed, a damper tape is laid between them on the floor surface.

When the layout has already been thought out on paper, you can transfer the markings directly to the floor.

In a convenient place on the wall, the position of the regulator for the warm floor is marked. At this point, a hole is made for the mounting box and the strobe is lowered to the floor. After the preparatory work and planning, you can begin to calculate the required amount of materials.

Mounting process

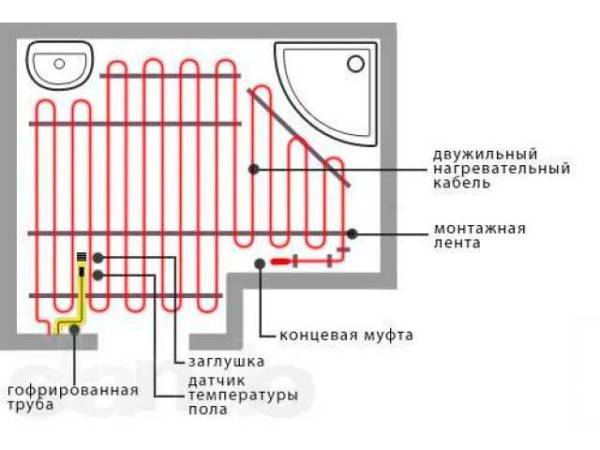

Before laying the wire, its resistance is checked and checked against the passport. A run-up of about 10% of the passport data is allowed. Installation of an electric underfloor heating can be carried out both with fixing it to the reinforcing mesh using screeds (without tightening it), and with the help of special fastening tapes.

Infrared warm floor is simply spread over the insulation layer. According to the technology proposed by the manufacturer, it may be necessary to fix it with special tape or for special ears on the strip.

In places where the wire passes over the dividing line of two floor slabs, it should be hidden in a piece of corrugated pipe 10-15 cm long. This will reduce the risk of cable breakage in case of possible thermal expansion of the slabs.

The junction between the heating cable and the power wire is located at a distance of 10-15 cm from the gate so that the connecting clips are subsequently recessed into the screed.

When all the elements are placed in their places, the resistance of the wire is checked again. Only if it differs slightly from the measurements made earlier, it is possible to test the heating elements by turning on the warm floor.

A corrugated pipe descends from the regulator along the gate, the other end of which is placed in the middle between the nearest strips of the heating cable. A temperature sensor is inserted inside the corrugated pipe, with which you can regulate the operation of the warm floor. Once again it is worth checking that the sensor is easy to get and there will be no problems with its replacement.

If everything is normal, then the entire system is de-energized, and the regulator is removed before the end of all finishing work. A warm floor screed is being formed. After it has completely dried, the operation of the system is checked again and, if everything is fine, the floor covering is mounted. If a screed is not needed, as is the case with a film underfloor heating, then a laminate or linoleum is immediately laid.

Read more about the construction of traditional concrete or cement screeds here.

As you can see, making a warm floor with your own hands is quite simple and much easier than hydraulic.

Types of electric underfloor heating

According to experts, electric underfloor heating is performed in two main varieties: cable and film (infrared). Let's take a brief look at each of the described technologies. As the name implies, in the first design, a cable is used as a heating element.

The wiring is laid manually with a certain step, and near the enclosing structures, the cables are mounted at a smaller distance relative to each other, less often in warmer places (when using a film, this scheme is not used).

Cables can be single or double stranded, although the latter type is more commonly used. Experts note that the energy consumption of the heating element will depend entirely on the thermostat settings. The design of the electric underfloor heating may include self-regulating cables that set the heating temperature regardless of the controller settings.

A feature of the use of the infrared floor is the fact that the generated thermal energy is not transferred to the air masses, but to the surrounding objects that absorb and give off heat.Thanks to these qualities, it is possible to achieve uniform heating of the premises. Such a heating element as a film has a small thickness compared to a cable, which affects the size of the screed and the height of the premises. In addition, infrared floor heating is much more efficient than its predecessor.

The film can be laid under any type of floor covering. If the heating system is mounted under tiles, then the base base must be leveled with sheets of drywall or plywood. This is due to the fact that the materials under consideration have a low thermal conductivity and this will improve heat transfer. The main disadvantage of the infrared floor is the increased cost compared to the analogue.

Features of installation of each type

Now about what exactly are electric floors, and how they are installed.

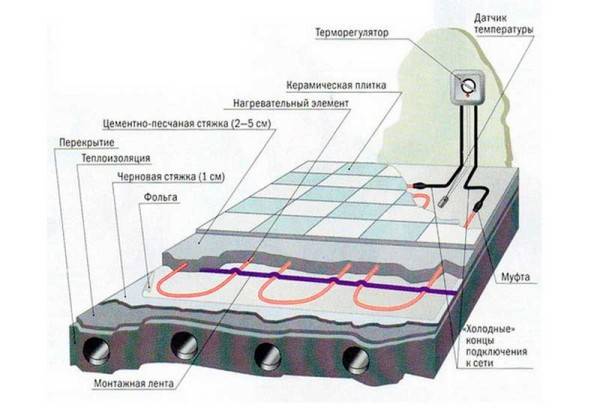

Cable floors

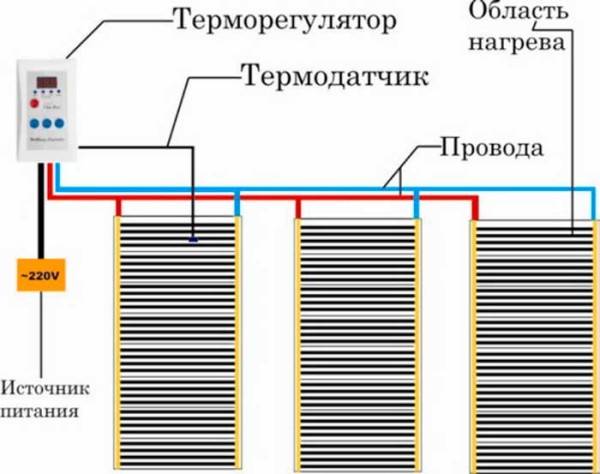

They consist of a thermostat to which a cable is connected. The length of the cable depends on preliminary calculations.

A wire also leaves the thermostat, at the end of which a temperature sensor is placed.

This sensor is also placed in the floor, between the turns of the cable, its task is to control the temperature.

Before laying the cable, a layer of thermal insulation is laid on the main floor screed.

The cable is then placed on the surface of the insulation. Its laying may be different, but there must be a certain distance between its turns.

Then the cable is fixed with mounting tape and screws. In this case, you need to remove the contacts from the cable to connect the thermostat.

Then the laid cable, together with the mounting tape, is poured with a thin layer of screed.

After it dries, a floor covering is applied to the surface.

All that remains is to connect the cable to the thermostat, and it to the power supply system.

Thermomats

They consist of a thin cable, which is already fixed on a special mesh.

Their laying does not require additional work. It is enough to dismantle the floor covering and lay out the thermomats in rows.

The floor covering sits on an adhesive base. Moreover, the thickness of the glue should be more than 1 cm. In this case, the thermomats will be located in the adhesive layer.

After installation, the thermostats are connected to the regulator.

infrared floors

Installing infrared underfloor heating is even easier. Preliminary work will be the application of a layer of thermal insulation on the main floor screed.

Then the film is spread, and then the floor covering is applied. After that, it remains only to connect to the regulator and the network.

Surface preparation. Features of base insulation

If necessary, the old screed layer is completely dismantled to the base. The entire surface is cleaned.

Next, a waterproofing layer is laid with a wall approach of about 10 cm. A damper tape is fixed to the wall around the entire perimeter of the floor. It will compensate for the thermal expansion of the floor when heated. As a result, you can cut off excess waterproofing and damper tape.

In order for the thermal energy not to go down, it is necessary to isolate the base of the floor. Depending on the location of the room and the type of surface, as well as the target orientation of the heating system, the appropriate insulation is selected:

- If a warm floor is an addition to the main heating system, then it is enough to use polyethylene foam with a reflective foil coating as a substrate for a warm floor (penofol).

- For apartments with heated rooms on the floor below, sheets of expanded polystyrene or extruded polystyrene foam with a thickness of 20 to 50 mm or other durable insulation of suitable thickness are suitable.

- If the installation of a warm floor is carried out on a previously unheated loggia or veranda, then a more solid layer of insulation is formed up to 100 mm of expanded polystyrene or a similar layer of mineral wool.

A reinforcing mesh is laid on top of the insulation.You can do without it, since the screed layer will be thin and it is enough to add a plasticizer and microfiber to the solution. (For information on how to form a semi-dry screed with reinforcement with synthetic fibers - read here).

Types of warm floors

At the moment, it is possible to provide a dwelling with two types of underfloor heating - electric and water.

Electrical, in turn, are divided into:

- infrared;

- Cable;

- Film and thermomats (film can work in the infrared spectrum, so they can be attributed to item 1).

Each of them has its own characteristics, what unites them is that their source is electrical energy.

infrared floors.

They are a special film that fits under the floor covering.

Since this film is itself thin, only the laying of a heat-insulating layer is required as preparatory work with the floor.

It is enough to spread the film on the floor surface, and lay the floor covering on top - linoleum, carpet, etc.

A feature of infrared warm floors is the heating process - they do not heat the air, but give their heat to objects.

Because of this, this type of electric underfloor heating is not used with tiled flooring.

Cable system of heat-insulated floors.

It consists of a cable laid by special laying on the surface of the main floor screed. The same cables can be used to heat roofs and gutters in homes.

To increase the efficiency of work, an insulating layer is laid under the cable.

To level the floor surface after laying the cable, another screed is performed, as a result of which the cable is inside it.

But this screed has a small thickness, no more than 3 cm. After that, a floor covering is already placed on this screed.

This type of underfloor heating heats the flooring, which then releases heat to the air in the room.

Thermomats

If it is not possible to lay the cable, you can use thermomats.

They are a special fiberglass mesh, on which a very thin cable is attached.

Laying this type of underfloor heating does not require additional screed.

After laying the thermomats, they are immediately covered with a floor covering.

Heating for this type of flooring is identical to cable.

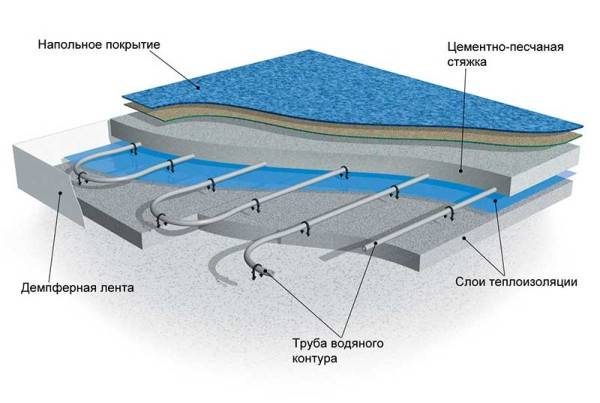

Water heated floors

This is a system of pipelines placed in the main floor screed and connected to the central heating system.

They are more economical in terms of costs than electric ones and are more suitable as the main type of heating.

However, it is better to plan the laying of this type of underfloor heating at the initial stage of finishing the apartment.

Laying water-heated floors already in a finished apartment is very difficult, since it will be necessary to completely remove the floor screed to lay a heat-insulating layer, and then pipelines, followed by a floor screed.

Sometimes this type is unacceptable for apartment buildings, since the weight of the floor with such a system can increase significantly.