How to make diesel fuel with your own hands

Vegetable or animal fats are used as raw materials, which are a mixture of esters combined with molecules of glycerol-trihydric alcohol.

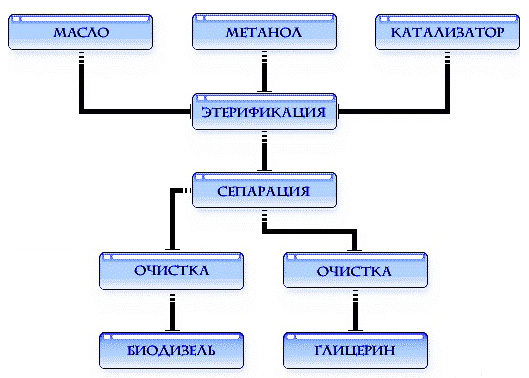

Biofuel (in this case, methyl ester) can be obtained by replacing the glycerin, which is part of the oil, with alcohol. This process is called transesterification. From one ton of vegetable oil and 110 kg of methyl or ethyl alcohol in the presence of 12 kg of NaOH alkali catalyst, 970 kg of biodiesel and 150 kg of glycerin can be obtained. The latter substance is used in the manufacture of soap and cosmetics.

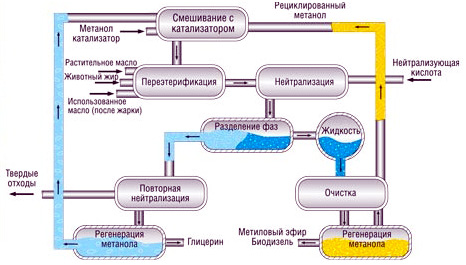

During the manufacturing process, vegetable oil is heated to 50 ºС and thoroughly purified by repeated filtration from mechanical impurities or food residues. Alkali is combined with methanol and the methoxide formed as a result of the reaction is added to warm (to speed up the reaction) vegetable oil, and the main volume of methyl alcohol is poured there.

The mixture is thoroughly mixed and allowed to stand for 4-8 hours at a temperature of 55 to 70 ºС. It exfoliates into glycerin at the bottom, biodiesel (ether) at the top, and a soap layer in the middle. Glycerin is drained through the lower hose, the soapy layer is also removed, and the diesel fuel is thoroughly cleaned by washing with water, followed by drying (heated to 65 ºС).

The good and the bad of biodiesel

It is considered a good fuel because it contains no sulfur and emits far fewer air pollutants when burned than its mineral counterpart (DF). It has excellent lubricating properties, which increases the life of the engine. It does not pose a danger when it enters the soil or water bodies - it decomposes in natural conditions in 28 days.

Biodiesel also has disadvantages:

- High temperature limiting filterability. In some types of biodiesel, the formation of paraffin agglomerates begins already at +15 ºС, in others, for example, in rapeseed oil, at several degrees below zero. Therefore, biodiesel can only be used in cold climates with a fuel heating device, which increases the car owner's costs for the purchase and installation of a heater.

- Biodiesel should not be stored for more than 3 months.

- The cost of industrial biodiesel is still high.

Why do you need to make diesel fuel with your own hands?

From the description of the process, it is obvious that every technically competent person can make fuel for diesel engines with his own hands. Sophisticated equipment is not required, the case can be organized in the garage.

Is there any point in such home production? If raw materials are purchased at real retail prices, biodiesel will turn out to be much more expensive than diesel fuel purchased at gas stations. If the ingredients are obtained cheaply or completely free of charge, then questions remain: are these efforts worth the result and is it justified to endanger yourself and others in a garage, private house or other place.

Buying and selling business equipment

Buying and selling business equipment

- home

- Small Business Ideas

- Manufacturing business

- How to get diesel fuel from vegetable oil

- Enterprise management

- Portal Policy

- Feedback

- about the project

- Company news

- Market overview

2000 - 2019 "Hyper-Press"Equipnet.ru - "Equipment for business"

All materials on this site, the copyright of which is owned by EquipNet.ru, may not be copied.

- entrance

- registration

If you are not registered on the portal, fill out the Registration form

After registration, you can add to directories for free:

Production at home

The first and one of the main problems is where to get enough raw materials.Well, if you are a farmer and grow rapeseed or are the owner of a restaurant where vegetable fat waste remains. If you don’t have access to a source of inexpensive raw materials, then you won’t be able to make biodiesel with your own hands. Buying oils will be unprofitable, especially given the second problem - fuel quality.

To safely use home-produced biodiesel in any car or heating boiler, it is necessary to ensure the quality of the product. Otherwise, you will face endless repairs and cleanings of your engines and boiler nozzles. And for this, the technology must be organized and verified at a high, and not a handicraft level. In turn, this will lead to the same costs, whose payback is in question.

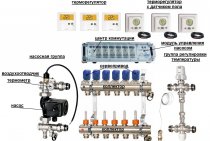

With low quality biodiesel, old cars and tractors with unpretentious engines and fuel systems can come to terms for a long time. The same applies to heating drip stoves and boilers with a Babbington burner, which are undemanding to the quality of the fuel. In this case, the simplest installation for the production of biodiesel is suitable; in other scenarios, the technology will have to be complicated. So, to build the installation you will need:

- 3 plastic containers, 2 of them are large and one is smaller;

- 5 ball valves;

- pipes and fittings (tees, elbows);

- electric heater with thermostat;

- pump.

To master the production of biodiesel at home, you need to place the containers on metal stands with the neck down, and make closing holes on top for pouring the components. You can also use metal barrels or homemade tanks made of steel pipes of large diameter. At the bottom of each vessel, you need to attach a fitting, and screw a tap to it, and then connect all the elements to each other with pipes, as shown in the figure:

The average capacity will serve as a reactor where the heating element needs to be built. Oil is poured into another large tank, and methyl alcohol is poured into a small one. Caustic soda is first added to the methanol to act as a catalyst. Having opened the valves in such a way that substances from the auxiliary tanks enter the reactor, the pump and the heating element are turned on, whose thermostat is set to a temperature of 60 °C.

In the video, Top Gear host Jeremy Clarkson explains and shows how to make biodiesel at home:

Biodiesel from rapeseed

With the appropriate technology for growing rapeseed from 1 ha of area, the resulting crop yields 20 tons of green fodder, 20 tons of green fertilizers, 3-3.5 tons of seeds, 13 q of oil, 16 q of cake (meal), 100 kg of honey, 500 kg of paper. It is intended for the production of rapeseed oil of different varieties, it must have a moisture content of 5-7%, contamination of no more than 1%, an erucic acid content of less than 2% and an acid number of no more than 3. Violation of these requirements worsens the efficiency of pressing and esterification, and can also cause deterioration in oil quality. This is influenced by the degree of maturity of the seeds and the conditions of its storage. With 3 tons of seeds with a moisture content of 7-8%, you can get 1 ton of biodiesel, 1.9 tons of meal (with an oil content of 8-12%), and about 0.2 tons of glycerin.

According to the State Statistics Committee of Ukraine, 54% of the grown rapeseed crop in 2004; 67% - in 2005; 78% - in 2006; 87% - 2007; 83% - 2008 exported to EU countries. Only a few farms produce biodiesel for their own needs, using mini-factories and research facilities, the productivity of which does not exceed 10 thousand tons of biofuel per year. The production and use of liquid biofuels on an industrial scale in Ukraine is practically non-existent. According to the Ministry of Agrarian Policy of Ukraine, such plants successfully operate in Lviv, Kherson, Odessa, Rivne, Vinnitsa, Donetsk, Ternopil and Poltava regions. The total capacity of the shops is about 600 tons per day.

For the period July-April 2008-2009 MY Ukraine exported 2630.08 tons of rapeseed. During the same period of 2009-2010, MY exported 1757.76 tons of rapeseed to foreign markets.The largest importers of Ukrainian rapeseed are the countries of the European Union (EU-27). They import rapeseed as a raw material for the biodiesel industry. In particular, for the period July-April 2010 MY, 469.32 thousand tons of rapeseed (27%) were exported to the Netherlands, 346.01 thousand tons (20%) to Belgium, 291.75 thousand tons (17%) to France %), Poland - 134.46 thousand tons (8%).

How biodiesel is produced

The raw material for this type of fuel can be any crop from which a large amount of vegetable oil is obtained. Most often, these are rapeseed and soybeans, their processing gives the maximum yield of raw materials and, accordingly, the final product in the form of biodiesel.

Animal fats, which are waste from meat processing plants, tanneries and other enterprises, also come into play. Burnt vegetable oils from restaurants and other catering establishments are also suitable.

It should be noted that biodiesel from oils of vegetable and animal origin is produced using a relatively simple technology. The main stages of the technological process are as follows:

- coarse and fine purification of raw materials (oil) from the smallest impurities;

- mixing oil and methyl alcohol with the addition of an alkaline catalyst in the reactor. The proportions of raw materials and methanol are 9: 1, the catalyst is sodium or potassium hydroxide;

- heating to 60 °C and stirring at this temperature for about 2 hours. The stage is called esterification;

- the resulting substance is settled in a separate container and stratified into 2 substances - the glycerin fraction and the actual biodiesel;

- the substances are separated in the separator, after which the fuel undergoes heat treatment in order to evaporate water from it.

Technological equipment for the production of biodiesel is also not very complex and consists of several tanks interconnected by pipelines, as well as pumps - the main one and several dosing ones. Since all stages are automated at the enterprises, the reactor and other tanks are equipped with temperature and level sensors, and the controller controls the pumps. All data about the ongoing process are displayed on the operator's display.

The history of development

Transesterification of vegetable fats was carried out in 1853 by scientists E. Duffy and J. Patrick, long before the first diesel engine was launched. June 10, 1893 in Augsburg, Germany, Rudolf Diesel tested his first single-cylinder engine, which was 3m long and weighed 4.5 tons. The engine exploded and nearly killed the inventor. To commemorate the event, June 10 has been proclaimed "International Biodiesel Day". In 1900, at the World Exhibition in Paris, Diesel, demonstrating his engine, received the main award.

Diesel believed that the future for his engines was to use biofuels. In 1912, he said, "The use of vegetable fats for fuel production may seem insignificant now, but in the course of time such fats may become as important as petroleum and coal-tar products are today."

During the 1990s, diesel engine manufacturers reoriented their engines to use diesel fuel made from petroleum, which has a lower viscosity than vegetable fats. The oil industry was able to carry out an invasion of the fuel market because the production of fuel from oil was much cheaper than from biological raw materials. As a consequence, the long-term decline in biofuel production. Only recently, against the backdrop of environmental concerns and shrinking cost differentials, has biofuels such as biodiesel become a viable alternative.

Research into the use of transesterified sunflower oil and its improvement to conventional diesel fuel standards began in South Africa in 1979. Until 1983, the research results were published.The technological process made it possible to produce biodiesel, the quality of which corresponded to the standards of conventional diesel fuel. The Australian company Gaskoks, obtained the technology from South African researchers, built the first biodiesel pilot plant in November 1987 and the first mass production plant in April 1989 (with the capacity to process 30,000 tons of rapeseed per year).

During the 's, plants were being erected in many European countries, notably the Czech Republic, Germany and Sweden. France has begun its own production of biodiesel from rapeseed oil, 5% of biodiesel is added to conventional diesel fuel, and 30% to diesel fuel used by public transport. Experiments are ongoing using 50% biodiesel. Meanwhile, countries around the world are beginning to develop their own production: in 1998, the Austrian Biodiesel Institute identified 21 countries with commercial biodiesel production projects.

In September, Minnesota became the first US state to have a statutory requirement that only diesel fuel be sold with at least 2% biodiesel content.

Conclusion

As it turned out, making biodiesel is not as easy as it might seem. Especially if you focus on advice taken from the Internet. This does not mean that home production of fuel is impossible, it just requires significant investment and effort.

Alternative energy is a promising area that many developed countries pay attention to. One of the most popular types of alternative fuel is biodiesel, the production of which is developing dynamically these days.

If you want to know what this type of fuel is, how to make biodiesel with your own hands, then this article should interest you.