Mechanism of action

Automatic foam fire extinguishing is recommended to be used to eliminate the ignition of flammable liquids, combustible substances, fuels, solvents, paints, alcohols, and other chemical compounds.

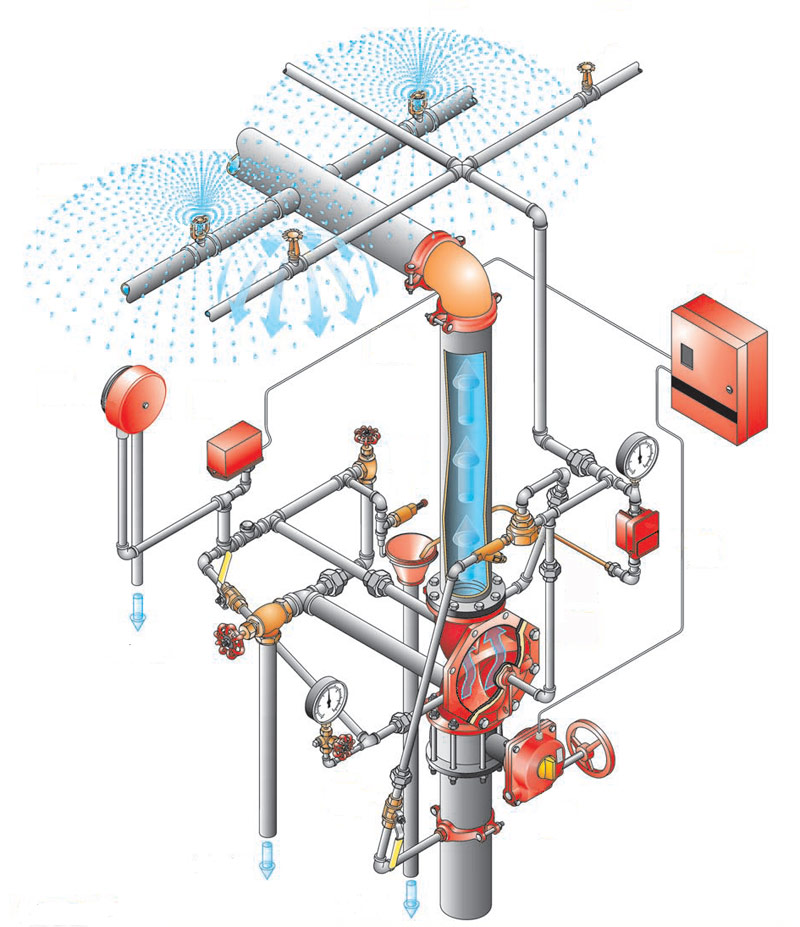

Foam fire extinguishing scheme:

- The emerging fire, the maximum increase in temperature, smoke are determined by a special sensor.

- The signal from the sensor is automatically transmitted to the control panel.

- The control panel turns on the fire suppression system

- The compression mixture under pressure is transferred through the pressure foam pipeline to the distribution network.

There are two ways to form a fire extinguishing mixture in a stationary system:

- The dosing pump releases a certain amount of foaming agent into the water stream. The resulting mass appears during the elimination of the source of ignition. It shows itself most effectively when used on large areas of premises.

- Neutralization of the fire with a ready-made compression solution. This improves the suppression of fire hazardous activities by reducing the response time of the system. The fire-extinguishing mass is supplied to the source of ignition faster. It is recommended to use for small premises, observing a number of conditions:

- monitor the shelf life of the finished fire extinguishing solution (at the same time, its shelf life is less than that of the foam concentrate itself);

- the tank where the fire extinguishing mass is stored must be covered with special substances (for example, epoxy mastic) to prevent contact of the stored substance with concrete.

Application conditions

The main external factors that have a great influence on the so-called foaming are product quality, humidity, temperature and the tool used.

For example, when there is little moisture in the air, the polymerization will take a rather long time.

The result of this will be the appearance of too large pores. To avoid this, it is recommended to artificially add moisture to the assembly seam. The lowest humidity is usually in the heat or in the cold.

With the temperature factor, everything is more complicated, but solvable. There are materials of summer and winter type, they are classified as one-component and two-component.

One-component polyurethane foam is a polyurethane sealant.

Two-component polyurethane foam for professional builders is packaged in large containers, and it must be mixed in clearly measured parts before use using a mixer gun.

A nozzle is put on it, the result is a fine-meshed material of high quality.

The two-component foam is characterized by the ability to quickly harden and very high-quality polymerization. Excess from the outside is removed with a knife after only ten minutes after spraying it.

The main advantage of two-component foam is its increased output volume. But given the complexity of its preparation and application, as well as the high cost, we can conclude that it is advisable to use this foam only for professional work.

For the most part, the polymerization reaction occurs when it interacts with air, at the output we get polyurethane.

Foaming agent - liquefied butane, isobutane or propane mixed in certain proportions (this substance is called a propellant). The resulting prepolymer creates foam, it increases in its volume by twenty times.

Mounting foam can expand and fill places that are very difficult to access. Quite quickly, the material hardens due to the moisture contained in the atmosphere. During the day, everything freezes, turning into a stable composition.

The great advantage of this material is its strength and stability, as well as the absence of harmful components. The porous structure makes foam one of the best insulators.

Mounting foam is used to work with any material. This is stone, and concrete, and iron, and wood, and plastic.

Let's summarize: which mounting foam is best to choose - household or, nevertheless, better professional.

Household and professional foam are almost the same in terms of components, and both the first and second are perfect for most jobs. Remember: never use plain mounting foam to install windows and doors. Do not forget to look at GOST density, tension and its linear deformation (ask specialists for answers and explanations).

You can learn how to use mounting foam correctly from the video.

Why Install Door Frames?

When installing interior doors, quite often the depth of the doorway is somewhat wider than the thickness of the door frame, which is why the frame is placed flush with one of the wall planes. While the reverse side of the opening remains open and requires aesthetic transformation.

And in order to solve such a problem today, several options can be used, whether it is the construction of slopes (made of plastic, MDF or mortar), or the hiding of hard-hitting areas with the help of door extensions - special decorative panels that are an integral part of the box.

So, if we talk about the advantages of decorating door slopes with the help of plastic panels or plaster mixtures, then we can single out the relatively low cost of these materials. But at the same time, the doorway is an object of an increased level of operation, which is why the use of materials that are not resistant to mechanical stress (plastic, MDF) for decorating the doorway is not always acceptable.

If we talk about the advantages of door extensions, then it is necessary to highlight the following of them:

- Ease of installation due to the fact that the extensions are a specialized product for hiding the ends of the doorway.

- A wide range of door extensions, both in color and in the material from which they are made, allows you to choose these products for almost any task. By the way, it is very convenient to purchase extensions as a set: door leaf + door frame + extensions + platbands (all products will be made in the same style).

- The doorway, decorated with extensions, looks stylish and elegant and is the logical conclusion of the whole structure.

Automatic foam fire extinguishing installations. Kinds

According to the method of influencing the ignition source, automatic devices are distinguished:

- General-surface devices. Provide protection against ignition of the entire existing surface. Such installations are effectively used, for example, to protect storage facilities with flammable liquids.

- Local-surface installations. Designed to extinguish a fire in certain areas of controlled areas, objects, devices, etc.

- General constructions. The principle of operation is based on filling the burning objects with a fire-neutralizing mixture.

- Local volumetric devices. They fill a certain part of the volume of technological structures, premises.

- Combined installations. The action scheme consists in combining the principles of local-volume and local-surface fire extinguishing. In this case, a double effect occurs: the fire-extinguishing compression mixture is simultaneously supplied to the volume of the object, as well as to its surface.

Automatic foam fire extinguishing installations, based on the multiplicity of the applied compression mixture, are:

- Fire-fighting installations of low expansion (generators, foams, foam sprinklers, barrels). Heavy foam of low expansion from 4 to 20 is generated;

- Medium fire extinguishing installations (stationary systems).Medium-heavy foam is produced with a multiplicity of 20 to 200;

- High expansion fire neutralization installations (light foam generators). Lighter high expansion foam from 200 to 1500 is used.

Fire-fighting foam fire extinguishing devices based on the type of dispenser are divided into:

- Devices using Venturi tubes;

- Dosing tanks;

- Systems with dosing hydraulic motor.

The main criteria for choosing mounting foam

Ordinary household foam is produced in a one-time version, a straw is attached to the cylinder. Typically, such a product does not have a high density, it has a noticeable secondary expansion. Most often, such a composition is purchased to fill cracks and voids, where special accuracy and precision in work are not required.

For professionals, polyurethane foam in cylinders for a special gun is intended. The material has a high density, after drying it retains its original volume, the foam yield is much higher. Thanks to the gun, the flow of the insulator can be adjusted, which allows economical use of the product

One cylinder can be used several times, washing the gun after each use.

An important characteristic of the mounting foam is the temperature range of application. Having bought a summer composition, you can work at a positive temperature from +5 to +40 ° С

The all-weather product has a wider operating range -10. +30°С. And for sealing seams and filling voids in frost, it is better to use the winter option, which can withstand temperatures down to -20 ° C.

On a can of polyurethane foam, you can also find fire markings. If the product is labeled B1, then the composition is refractory. The designation B3 indicates the combustibility of the material. This factor is important to consider when sealing chimneys or heating boilers.

Experts have selected 7 of the best polyurethane foams in our review. When compiling the rating, the following criteria were taken into account:

- safety of application and operation;

- technical specifications;

- price;

- professional opinion;

- reviews of domestic users.

Manufacturers

Choose among manufacturers that have been in this market segment for quite a long time and are reliable.

Good reviews have all-weather mounting foam "Imperial", produced by the corporation "TechnoNIKOL", or professional mounting foam "TechnoNIKOL" 65 Constant. Bostik PRO Standart 65 foam has also shown itself well (for many years).

The production of polyurethane foam is a very multi-tasking process based on high technologies. This process is constantly evolving, because manufacturers need to adapt to market changes, and to the changing material of production, and to the organization of a rather dangerous production (combustible materials are used). Note that the result of production is largely influenced by the culture of production at any individual factory. After all, using the same recipes, it is impossible to get absolutely similar foam at different plants.

Each of the manufacturers, of course, has its own advantages, and possibly disadvantages.

It should be noted that large companies, along with their advantages, also have disadvantages: they react very slowly to the requirements of a constantly changing market, they have very poor control over their products, and constant competition and conflicts within firms are expressed in a constant rise in prices, therefore, there are ongoing cost savings.

There is an undeniable rule (as with most products, materials or services) - high quality is impossible at a low price of a product or service.

Quality can be 100 percent guaranteed only by the use of expensive components in the production, which are used in the preparation and additional spending on stable, well-established control of the entire production process and quality control.

Very often, consumers in our country put up with very low quality mounting foams, because since the Soviet times, the feeling of saving money due to the low cost of products has been customary.

Cheap materials have many negative characteristics, and together they will increase the price of the result. The main rule: if at the exit from the cylinder you get more material, then the less money you will pay for the entire volume.

The second basis for understanding the quality of a truly good foam is that inexpensive components in the production will never produce a quality foam at the end.

The most "popular" method used by manufacturers to reduce the cost is an increase in ballast components (usually chlorinated paraffins).

Most of the chlorinated paraffins make the foam much heavier, as a result: the volume of the foamy mass at the outlet decreases, its solidification increases in time, and expansion increases.

Rating of the best mounting foams

| Nomination | place | Name of product | price |

| TOP of the best mounting foams | 1 | Penosil Gold Gun 65 | 616 ₽ |

| 2 | soudal | 365 ₽ | |

| 3 | Makroflex Standard | 350 ₽ | |

| 4 | Titan O2 | 430 ₽ | |

| 5 | Ultima | 176 ₽ | |

| 6 | TechnoNIKOL 65 Constant | 421 ₽ | |

| 7 | Moment Mounting | 194 ₽ |

Penosil Gold Gun 65

Mounting foam Penosil GoldGun 65 is chosen mainly by professional builders. They note the perfect combination of price and quality of the Estonian product. Experts also note the lack of shrinkage and slight re-expansion, which makes the composition predictable. The foam deserved special praise from specialists for the highest possible yield. The material finds a wide range of applications, from the installation of window and door frames to filling all kinds of voids.

According to experts, Penosil GoldGun 65 polyurethane foam deserves the highest rating for its high quality, reasonable price, consistently white color and record yield in terms of volume. You can criticize the foam only for the fear of low temperatures.

Scope of stationary automatic foam extinguishing devices

- Cargo-loading devices for transportation of oil products, fuels and lubricants, flammable liquids.

- Premises with installed oil pumping, oil refining equipment.

- Warehouses for the storage of flammable materials (paints, solvents, alcohol, primer, etc.).

- Engine rooms with installed technological equipment (generators, compressors, internal combustion engines, etc.).

- Premises with installed main/emergency power sources, fire pumps, auxiliary equipment.

- Places of accumulation of equipment equipped with a fuel tank (vehicles, equipment for moving dry cargo, auxiliary equipment).

- Oil tankers, river, sea vessels of different classes, destinations.

https://youtube.com/watch?v=iawMiLZGIEo

Automatic foam extinguishing units are not used with substances/equipment:

- Liquefied gases with a low boiling point (propane, butadiene, etc.).

- Gases in their natural state.

- Substances that release oxygen, oxidizers.

- Substances that react with water.

- High voltage electrical equipment.

6 Moment Mounting

At the best price, it is possible to purchase mounting foam Moment Montazh in different regions of the country. You can buy a can of this insulating substance at any provincial store. It is available for use with or without a pistol. The most common commercially available all-weather foam is suitable for jobs such as installing windows and doors, filling voids, and sealing joints. A distinctive feature of the material is the density and uniformity. The foam has good adhesion to various building materials. After complete drying, an insulation is formed that does not have toxicity or harmfulness to the human body.

The advantages of domestic foam Moment Montazh include an affordable price, good quality. Sometimes there are fakes that have an unpleasant odor and yellow color. Such foam is able to squeeze out door frames or window sills when hardened.

Disadvantages of using professional materials without a gun

If you use mounting foam without a gun, the cylinder of which is designed specifically for this type of application, you should also be aware of the disadvantages of such work. The gun, of course, greatly simplifies the sealing work performed, but not only this explains the recommendations of specialists to buy all the necessary tools for repairs.

Sealing through a tube has the following disadvantages:

- 1.

Big expense. When repairing, it is necessary to carefully control the intensity of the output of the material when the valve is pressed. Too much pressure inside the package causes excess material to escape. Most often, the overrun is 200%, and sometimes 300%. - 2.

Not all valves of professional cylinders can be connected to a tube. If the product is designed exclusively to work with a gun, the sealant simply cannot be removed from the package. - 3.

Time costs. Working with professional products without special tools can take a lot of time. Using a gun, even a large seam can be sealed within 20-30 seconds, while manual sealing will take 15-20 minutes.

In order to carry out repairs quickly, efficiently and without unnecessary financial costs, it is recommended to pre-calculate the required volume of sealant. In most cases, for simple household work, a household cylinder is sufficient, which is designed to be used with a tube, which will speed up and reduce the cost of repairs. If the seal includes large-scale sealing, it is better to purchase a professional sealant with a special gun.

It often happens that you need to fill a small hole or gaps during cosmetic repairs of an apartment or house

. The best option is to pour mounting foam into the cavity, which, expanding, will tightly clog any hole. Ease of use is the main advantage that has led to the popularity of this sealant based on foamed polyurethane.

Differences between professional and amateur balloon

Mounting foam is available in two packaging options: for domestic use and professional. Amateur foam is completed with an adapter tube, which is screwed onto the valve and actuated by pressing the fingers on the special stops of the tube. To work with professional foam, a special tool is required - a gun.

Obviously, buying a pistol, the cheapest model of which costs the same as a foam can, for a one-time procedure is wasteful. The advantage of using the professional version is that the opened container can be stored for several months if it is not removed from the gun adapter.

Builders call amateur bottles "disposable", meaning that the opened container must be used immediately. But you can use a simple way to achieve that use a bottle of household mounting foam repeatedly

. Professionals do not do this, as they save time and do not mess with such trifles, but for a home master, this advice

will useful

.

How to preserve a bottle of household foam

So, you foamed the holes and used up no more than a third of the polyurethane sealant. What's next? Throw away the remaining foam? Do not rush to throw away your money, there is a way to mothball the balloon. More precisely, even two ways.

If it is supposed reuse the started can of amateur polyurethane foam

within a month, it is enough to bend the plastic tube through which the sealant is supplied, and fix the place of the fold with adhesive tape. Now we press on the valve so that pressure is created in the tube. The container can stand in this form for up to two months. It is enough to remove the adhesive tape, straighten the tube, and the bottle is ready for use.

If foam is required only after four to five months, another method is used. In this case, acetone should be used. Carefully remove the tube and rinse with acetone. We also drip acetone into the hole in the outlet valve of the cylinder. To be sure, repeat the flushing of the valve two or three times. Now the balloon can stand up to six months.

Sometimes the sealant still dries in the outlet valve of the cylinder. How to solve this problem, see the article "How to open a cylinder with mounting foam frozen in the exhaust valve."

4 Makroflex Standard

The most popular mounting foam for homeowners and professional builders is Makroflex Standart. This brand is so promoted in our country that you can meet products in the most remote parts of Russia. Foam is intended for sealing cracks and voids, although it is often used as a heat-insulating material. Often spray cans flash when installing windows and doors, eliminating gaps in old houses, garages, sheds, etc. Good adhesion to a wide variety of building materials should be attributed to the strengths of the foam. At the same time, it has a homogeneous structure and does not suffer from secondary expansion.

Thanks to the promotion of the trademark, Makroflex Standart polyurethane foam is in demand in our country. Affordable price is perfectly combined with technical properties. But the reverse side of the popularity was a large number of fakes. In addition, the reviews note the shrinkage of the material after drying.

Foam fire extinguishing station

As an addition to stationary fire extinguishing systems, as well as completely independently, a foam fire extinguishing station can be used. It is a self-contained block-box with all the necessary fire-fighting gear and equipment, capable of functioning for a certain time without connecting additional communications, without reducing its effectiveness.

Distinctive features of the fire station:

- fast, effective elimination of the source of ignition;

- autonomous operation without additional communication leads (predetermined time);

- constant readiness for operational fire extinguishing;

- storage of all components of the fire extinguishing mass;

- storage of a pre-agreed set of fire fighting equipment, equipment.

The block-box of the station consists of a foam generator, water storage tanks, a foaming agent, compressed air / nitrogen cylinders, a compressor, an electronics unit, a pumping station, accompanying communications and a piping system.

The autonomous station can be switched on (inertia - about 3 s) automatically, by remote control or manually.

The compression fire extinguishing agent is supplied to the place of fire through the installed pipeline, or through the sleeves of fire-fighting equipment laid in an operational manner. In this case, the source of water can be its own container inside the block-box, as well as the local fire-fighting water supply.

An autonomous fire extinguishing station is characterized by low capital costs (compared to the equipment of the premises with a stationary system), facilitated operation (does not need special technical personnel for maintenance and intended use), preliminary design is not required.

Autonomous stations and stationary automatic foam extinguishing plants are widely used due to good performance, high efficiency, wide range of applications. The ability to eliminate the source of fire in a short time, a relatively inexpensive price, a large selection of types and models of fire extinguishing installations contribute to their popularity as a high-quality method of extinguishing fires of varying complexity.

How to install a door leaf

Door manufacturers offer a wide range of products. The door is immediately completed with a door frame.All you need is to measure the doorway and go to the store. Remember that there must be a gap between the wall and the box for the foam, which guarantees the reliability and strength of the installed structure.

Installing an interior door is easy if you follow the instructions. Working with the door leaf requires preparation, so the first thing to do is to purchase a tool kit, which includes:

Door fittings:

To install the interior canvas, follow several steps:

- dismantle the old door. To do this, remove the door leaf and disassemble the door frame;

- assemble a new door frame. To assemble it, release the racks from the packaging and fasten them together with self-tapping screws. The assembly of the box is carried out - with rectangular corners of the racks or beveled;

install the door hinges on the frame. To secure the hinges, you will need tools such as a cutter, a screwdriver, an awl, a thin drill and a drill. Sometimes a circular saw and a pencil are used to fasten the loops;

Foam with a straw - the threat of expansion

The main disadvantage of household foam with a straw is a significant secondary expansion

Hardening, it can increase several times, so it is extremely important to comply with all conditions of use.

Instructions for using household foam can be seen on the back of the cylinder, but we will consider it in more detail and step by step:

Surface cleaning and preparation. Before applying the foam, it is necessary to carefully check all the cracks and holes for the presence of small debris and, if necessary, degrease the surface with acetone.

Surface moistening. Mounting foam needs contact with moist air to harden, so surfaces must be moistened before using the spray can - a conventional spray gun is quite suitable for this purpose.

Preparing the foam bottle. A little trick - before using the foam, you need to hold it for several hours in water with a temperature of about 20 ° C - after this procedure, it will be better to lie down. Before starting work, shake the bottle for a minute so that all components are evenly mixed - this will ensure maximum foam output.

Attaching a tube or gun to a cylinder. The tube is simply screwed onto the valve, but with a gun the situation is somewhat more complicated - we will consider the issue of its choice and use below.

Foam work. According to the correct technology, mounting foam is applied in small segments (about 10 cm) in the direction from bottom to top - this helps to avoid unnecessary spreading of the material. It is necessary to ensure that the gap is not filled by more than 50% - during hardening, the volume will increase greatly, which can lead to damage to the structure being processed.

It is extremely important not to touch the uncured foam - any physical impact and violation of the structure worsens the solidification and negatively affects the volume and density.

It is necessary to ensure that the cylinder is always in the “upside down” position - this will ensure the most complete consumption of the foam.

Difficult moments:

| Problem when using | How to solve |

| Foam hole wider than 3cm | Mounting foam must be applied in several steps, waiting for the hardening of each of the layers. Before re-applying the foam, it is imperative to moisten the hardened base. |

| through slots | In no case should such holes be filled with foam from both sides - this can lead to severe deformation of the structure. Foam is used only on one side, the reverse side is usually filled with silicone sealant. |

| Installation of door and window frames | To reduce the pressure on the structures, the use of dowels and additional spacers is recommended (they are removed after hardening).Otherwise, the foam, expanding, can thoroughly warp the frames of doors and windows. |

The container of household foam must be used completely, otherwise the composition will harden during storage and will be unusable. With professional foam, such problems do not arise, but there are some nuances.

Work with the selected polyurethane foam without a gun instruction

The principle of sealing openings without a gun is exactly the same as when using special tools. When the surface to be treated is ready, shake the can well. Manufacturers recommend vigorously shaking it for 30-40 seconds, which will ensure that the sealant comes out uniformly from the package.

Now you should remove the protective cap from the sealant and fix the PVC tube that came with the household product on the valve. For professional products, tubes will have to be purchased separately. The free end of the tube is brought to the closed opening. The gap must be filled with foam by 30-40% (sometimes 50%) of its size, this is due to the fact that the sealant increases significantly in volume during hardening. Partial filling makes it possible to reduce consumption and the overall cost of repairs. If, after the sealant dries, its obvious deficiency is revealed, you can always add another layer, although this is most often not required.

Foam starts to come out of the pressurized bottle when the valve is pressed. The triggered valve causes the sealant to enter the tube, and then to the surface to be treated. Complete drying of the sealant is almost always completed within 8 hours after application. If, after drying, the foam is swollen and its individual parts protrude too much from the sealed seam, it is very easy to cut off the excess with a clerical knife.

Mounting gun price or quality

A professional gun provides accurate and metered application of mounting foam, reusable use of the cylinder and accuracy when working. There are many modifications of such a tool, but the device diagram and the principle of operation are approximately the same:

- The tip of the gun - as a rule, its diameter is several times smaller than the diameter of the tube itself. This feature allows you to repeatedly increase the pressure when the foam exits, which, in turn, guarantees a good volume.

- Barrel (tube) - the channel through which the foam comes out. It can be one-piece or collapsible (two parts), which simplifies the care of the instrument.

- Adapter - an adapter for connecting to the neck of the foam cylinder. In high-quality models, it is covered with Teflon.

- Adjusting unit - allows you to dose the output of the foam and its pressure.

- Mounting nut - with its help the barrel is attached to the handle. This design allows the tube to be removed for cleaning or replacement.

- Trigger - serves to adjust the supply of mounting foam.

- Pen - made of various types of plastic and metals. Aluminum handles are considered the most reliable and comfortable.

The principle of operation of the mounting gun is based on simple mechanics: after attaching to the cylinder, the foam passes through the supply valve into the barrel, where it remains until the trigger is pressed. Pulling the trigger opens the valve on the tip, releasing foam. The regulating mechanism allows you to control the amount of foam supply.

Since there is nothing superfluous in the design of the pistol, choosing such a tool is quite simple. There are only a few factors to consider:

- The quality of the materials from which the gun is made. It is better if it is completely made of hard metals. There are high-quality plastic models, but this is a rarity.

- Detachable Design: Monolithic guns are cheaper, but the price of a demountable tool will pay for itself many times over with cleaning and replacement of parts.

- Working pressure in the gun. This characteristic cannot be checked in the store, but there is a little trick.When buying a gun, immediately purchase a can of cleaner (it contains acetone). At home, you need to screw the gun onto a bottle of cleaning fluid, press the trigger to put it inside, then remove it and leave it for a couple of days. If, after this time, acetone shoots when the trigger is pressed, the pressure is normal. If not, you can return the defective product to the store, acetone does not leave any marks on the surface of the barrel.

Tools and materials

1. Mounting foam

Foam can be both well-known construction brands and noname, in principle it does not matter, the main thing is that it be polyurethane foam. I have been using various brands of foam for many years and the only difference I have found is the price. If you do not have a professional pistol (and when installing 3-5 doors, there is no need for such a pistol), then you need to buy foam with disposable nozzles inserted into the lid. The required amount of foam depends on the gap between the door frame and the wall or partition and on the width of the door frame. As a rule, one cylinder with a capacity of 750 ml is enough to install one door.

3. Wedges

Usually, wedges are made from improvised material: scraps of wooden beams, old door frames, baseboards, trim, etc. But in some cases, if the doorway is quite vertical and the gaps between the door frame (chute, jamb) do not exceed 1.5-2 cm, then you can use ready-made wedges:

These wedges are sold in sets of 20-100 pieces. in the departments of shops and supermarkets dedicated to laminate flooring. To install 1 door, you must have (or make) from 8 to 32 wedges.

4. Struts

Usually spacers are made from old skirting boards or platbands. For this purpose, you can also buy a beam with a section of 2.5-3x4-5 cm. I have never seen ready-made spacers for installing doors on sale, but I do not exclude this possibility. The number of spacers depends on the design and thickness of the door frame, as well as the thickness of the foam layer. If the door frame has a threshold and the thickness of the frame is 3 cm or more, then 1 spacer in the middle is sufficient. For boxes with a thickness of about 2 cm, it is advisable to put 3 spacers. For boxes with a thickness of 1.5 cm or less (and there are such), it is better to use fasteners in a wall or partition.

Foam fire extinguishing system device

Stationary foam fire extinguishing installation includes:

- Generator of air-mechanical fire extinguishing agent

- Compression foam mixer

- Foam dispenser

- Water supply barrel

- Pipeline for water supply

- Tank for placement of fire extinguishing mixture

- Sprinklers:

- drencher (air-mechanical mixture comes out of the hole without a thermal lock)

- sprinkler (equipped with a thermal lock that melts when the temperature rises):

- water-filled (used in rooms with an air temperature of at least 5⁰ С);

- air (installed in rooms without heating).

After receiving a signal from the automatic control panel, the mixing container is filled with water. In this case, the compressor adds a strictly metered amount of foaming agent to the water. The air-compression mixture passes under pressure through the mesh cassettes. From the body of the foam generator, it comes out already in an increased volume, and then it is fed into the sprinklers. The dosing pump injects the compression mass into the foam line.

conclusions

In order for the process of installation and operation of door extensions not to cause any difficulties, it is advisable to follow the following recommendations during the work.

Firstly, as an adhesive, it is necessary to use mounting foam with a low coefficient of linear expansion (for example, TITAN, MACROFLEX, etc.), and only under the gun.

Secondly, when cutting extensions, always take into account the size of the gap formed during the cutting of the material (1 - 2 mm).

Thirdly, never allow the use of sealants to hide hard-to-reach cracks. With the correct measurement and cutting of the material, the extensions should clearly adjoin each other (without gaps).

Fourthly, when setting up the extensions (even before foaming), it is imperative to foresee options for expanding the extensions in advance in order to perform this operation as quickly as possible. Also, for the convenience of placing extensions, it is advisable to install spacer wedges in the cavity between the wrong side of the extension and the wall opening, which are subsequently (after the foam has hardened) dismantled.

An introductory video on how to install door extensions with your own hands

https://youtube.com/watch?v=FMX65RKyhec

If you liked the material, I will be grateful if you recommend it to friends or leave a useful comment.