Ways to solve some problems with self-repair of a gas unit

Various components of the heating installation can fail and for various reasons. These can be low-quality parts, violation of operating requirements, sharp blows to the component parts of the unit.

- The most common cause of failure of volatile devices is a settings failure. Repairing a gas boiler with your own hands should begin with checking the correct settings and the presence of open contacts. When troubleshooting, the unit is set to the “Winter” mode and the setting is set to the maximum heating temperature.

- If the pump does not work, then either you just need to replace the cable, or you will have to change the pump itself.

- If the burner is not supplied with gas, then you must make sure that the gas cock is open, the gas pipeline is not clogged, the voltage supply is in order. If the problem persists after all these actions, most likely, you will have to change the electronic board.

Turning off parapet boilers in severe frosts can be caused by the appearance of frost on the chimney. The formation of an ice crust is explained by the content of water vapor in the discharged combustion products. As a result of freezing of ice growths and obstruction of the exit of flue gases, the device automatically turns off and attempts to turn it on again will be unsuccessful.

Do-it-yourself gas boiler repair is far from always possible and only in cases of visible and simple malfunctions. Complicated breakdowns can be repaired qualitatively and reliably only by specialists with the necessary knowledge and equipment.

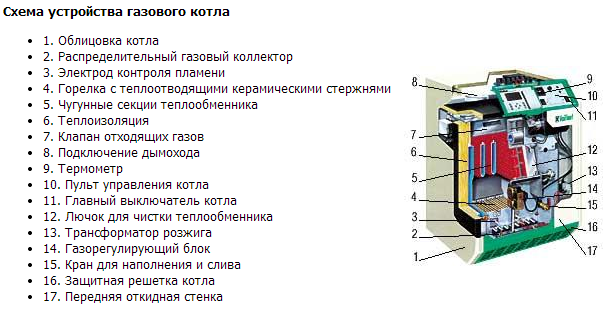

The main components of the gas boiler

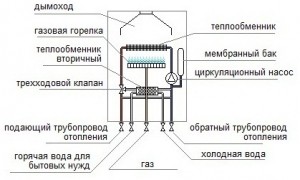

Heat is generated from the combustion of gas. The gas supply system is responsible for its uniform flow to the burner, which must be turned on at this moment. The heat obtained during combustion is transferred to the heat exchanger, which is responsible for transferring heat to the heating system. The role of a heat exchanger, as the name implies, is in the exchange of heat between two substances. It can be heating or cooling. Heat exchangers are arranged in different ways, but their main essence is that the resulting temperature of one liquid inside the heat exchanger is transferred to another liquid, which will then distribute this temperature through the pipes of the entire heating system.

Classification by number of power levels

- Gas heating equipment can be made single-stage, that is, operate at a constant power level.

- The second option is two-stage heating installations. Since the full power of the unit is not needed for the entire heating period, this design is more economical and allows you to extend the life of the equipment.

- The most progressive are boilers with the possibility of power modulation.

There are other signs by which gas units differ and on which the principle and efficiency of their work may depend:

- the material from which the body is made - steel, cast iron;

- heat exchanger material - steel, cast iron, copper;

- type of ignition - electric or piezo ignition.

The organization of an autonomous heating system allows you to avoid many of the troubles associated with the irregular functioning of central heating.And the creation of a comfortable indoor climate with minimal energy costs depends on the right choice of a heat generator.

About protection systems

Now let's talk about gas boiler protection systems. Modern models in the event of a power outage stop their work and automatically start when the power supply is restored.

If the gas supply is stopped, the automation will give a signal to close the solenoid valve that controls the flow of fuel into the boiler. But in this case there will be no automatic inclusion - you will have to perform a manual restart.

Wall-mounted gas boiler Electrolux of the Basic and Hi-Tech series

And new models are sure to be equipped with energy-saving features, as well as frost protection. The coolant temperature is controlled by special sensors. If it drops to 5 degrees, the boiler will turn on in order to warm up the heating system.

There is also a special function that turns on the pump once a day in the summer, when heating is not needed. This is to ensure that the rotor does not jam due to being idle for an extended period of time.

Without fail, gas boilers are equipped with self-diagnostic systems. They analyze the state of the boiler room nodes and inform the consumer by displaying error codes on the display. Your wall mounter can diagnose about 90% of faults with this system. And service specialists, knowing the error code in advance, arrive to carry out repairs, being already fully prepared.

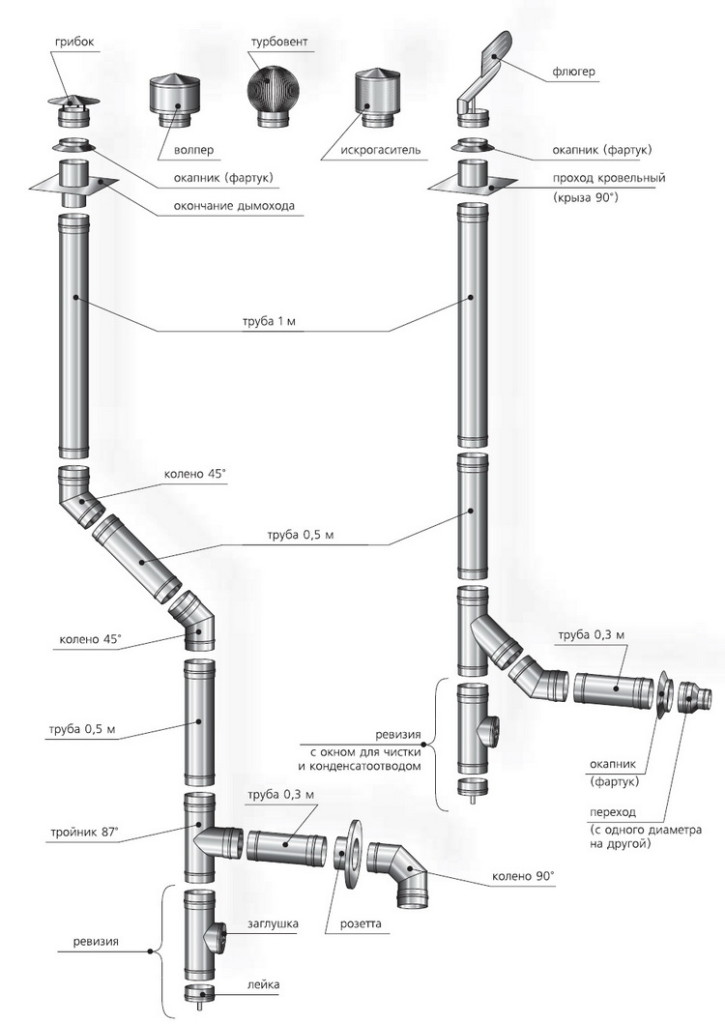

Smoke removal

Exhaust gas removal method

A very important question is how smoke is removed from gas boilers?

If the device is equipped with an open combustion chamber, then all the resulting flue gases will leave the room through a special chimney. And to maintain the combustion process, air from the room in which the boiler is located is used.

For this reason, it is important to ensure good ventilation and a constant supply of air. By the way, gas boilers with open combustion chambers are cheaper

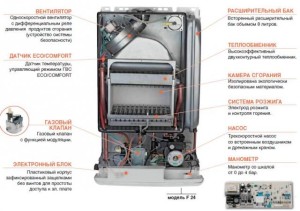

For models equipped with a closed combustion chamber, flue gases are removed by force. For this, a fan is provided in the design. It draws and under pressure ejects gases into the smoke channel, which is used as an aluminum or steel pipe. And the smoke duct itself is removed through the outer wall of the building.

The difference between gas units by type of burners

In the manufacture of gas heating units, two types of burners are used:

- Atmospheric burners have a simple design, are inexpensive, low noise during operation. The power of heating installations with atmospheric burners lies in the range of 10-80 kW.

- Pressurized burners, otherwise called fan or mounted burners, have a higher efficiency. The power of units with fan burners can reach a value equal to several thousand kilowatts.

Attention! Unlike atmospheric burners included in the basic boiler package, inflatable burners are sold separately and have a rather high cost.

Burner replacement

Replacing the burner of a gas boiler will require more attention and care. Purchase a new burner should be exactly the same model as the one installed on your boiler

Never install a burner that is not designed for your boiler model.

The beginning is the same - remove the boiler casing. Having gained access to the burner, we carefully examine the tubes and sensors connected to the burner. Their location should be remembered so that when assembling a new burner, do not confuse which one to connect to.

Due to the wide variety of boiler models, it is impossible to give specific recommendations, however, in any case, there will be:

- gas supply pipe to the burner;

- gas pressure sensor on the burner;

- gas valve.

There may be a control tube from the draft sensor or an electrical connection (wires) from the same draft sensor or temperature sensor. When using a burner of the same model as yours, it will not be difficult to remember and connect all the wires and tubes.

Replacing a carob burner installed in a wood-burning stove is even easier to handle. We unscrew the screws of its fastening to the plate and two tubes: gas supply and gas supply to the igniter. We take out the old burner, insert a new one, fasten the tubes, tighten the burner mounting bolts.

It is not worth repairing the primitive automation of such a burner, the result may lead to unsafe operation of the boiler. The most difficult is to replace the burner of a wall-mounted gas boiler, stuffed with electronics and a large number of sensors. But do not panic here either, the principle is the same: it is good to remember the location of all connections to the burner.

Trying to increase their importance, gas specialists say that such a burner should be "tied" to the boiler by flashing the electronic unit or adjusting the boiler. The burner is just iron, which cannot be adjusted in any way. Adjustments may require combustion as such, but this is no longer relevant to replacing the burner itself. If the burner is made for the model of the boiler on which it is installed, then the combustion will be correct, however, provided that they did not try to adjust it on the old burner.

Troubleshooting

Consider the possible malfunctions of wall-mounted gas boilers:

The cause of boiler failure is often the heat exchanger. Manufactured from stainless steel, this important assembly needs to be periodically cleaned of soot. This is done with a metal brush. The copper heat exchanger is cleaned with a metal sponge for cleaning dishes.

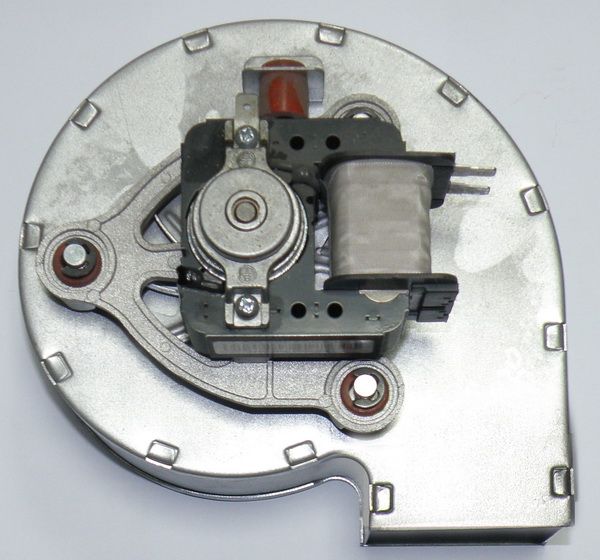

blower fan

blower fan

The blower fan is a rather weak link in the heating system, despite the low rotation speed, as well as the fact that its power comes from direct current.

If the fan speed does not match the set one, it is necessary to check the operation of the bearings - perhaps the problem is in them. To do this, after disassembling the fan and pulling out the stator, lubricate the bearings with high-quality carbon-based machine oil designed for operation at high temperatures.

If the fan housing heats up and the speed of rotation of the blades slows down, it is possible that an interturn circuit has occurred. In this case, you will either have to purchase a new fan, or replace the burned-out stator winding. This service can be provided in a specialized service center.

Our masters, having vast professional experience, are guaranteed to solve the problem of repairing the boiler and installing the heating system at home.

Fast Competently Reliable

Availability of components and spare parts for boilers

Departure of the repairman - replacement of the boiler within 30 minutes

Free visit of a heating engineer to calculate the cost of installing a home heating system

Urgent boiler repair

We are near you in your area MO

It is better to entrust the solution of the problem of repair, installation and adjustment of the heating boiler to qualified specialists of our company. We always promptly respond to your requests.

Your Home Service Wamteplo.ru

Maintenance and adjustment of the heating boiler

Choose the right engineer!

It is likely that you have already been advised by a heating boiler repair engineer from our company to carry out repairs, replacements, maintenance of boilers and heating systems. This is a small but good piece of advice that will really pay off your expectations.

Installation of the boiler and home heating system

Work Guarantee!

We do not always have the lowest price for boiler installation - but our customers know that the professional skills of our specialists allow them to solve any task with a guarantee, and the level of service, responsiveness and honesty are always included in our fair prices.

Disassembly and removal of soot from the inner surface of the boiler

- screwdriver;

- metal brushes (soft and metal);

- brush;

- open-end wrenches;

- rags or any cotton cloth.

Stages of work:

- Shut off the gas.

- Remove the boiler door and disconnect the wire leading to the piezoelectric element.

- Unscrew the thermocouple, the ignition electrode and the pilot burner tube one after the other.

- Replace with a new gasket under the pilot burner.

- Remove the nozzle, copper tube, burner.

- Carefully remove the thermometer sleeve and then remove the boiler cover together with the insulating sheet.

- Disconnect the terminals from the traction sensor and take out the flue.

Before cleaning, turn off the gas supply, wait for the structures to cool completely and only then disassemble.

After extracting all the details, they must be:

clean with a brush and metal brushes.

Channels should be blown with a vacuum cleaner.

Particular attention should be paid to the burner, since the internal channel can be easily damaged, it must be wiped carefully.

Wood-burning boilers are often used in houses for heating. And only a few think about what kind of firewood should be chosen for kindling. Usually they use whatever they have. Firewood with resin is especially harmful to chimneys. It settles on the walls of the boiler and the chimney pipe. Mechanical cleaning is required. At the same time, it is necessary to clean the chimney from tar and soot residues from the roof, so it will be easier to remove the combustion residues from the inside. Observe safety measures!

How does a gas boiler work for heating water

The main elements of the design of gas boilers include:

- gas-burner;

- heat exchanger for heating;

- secondary circuit for preparing hot water;

- thermostat;

- circulation pump;

- Control block;

- expansion tank;

- manometer.

Double-circuit gas boilers have two heat exchangers - one for heating, and the second for providing hot water. They are mainly made of stainless steel or copper.

The circuits can be separate or combined into one bithermic heat exchanger. The latter is a circuit inside which is another. The internal heat exchanger provides the preparation of hot water, and the external heat exchanger serves to move the coolant in the heating system. Thus, it effectively heats the water in the internal circuit.

Gas boilers for heating and water heating have a lot of advantages:

…

- compact size and relatively low weight;

- wall models do not require placement in a separate room;

- produce hot water without the participation of additional equipment;

- convenient in operation.

The disadvantages of double-circuit gas boilers include:

- limited volume of hot water produced;

- the impossibility of simultaneously supplying heated water to two points of water intake.

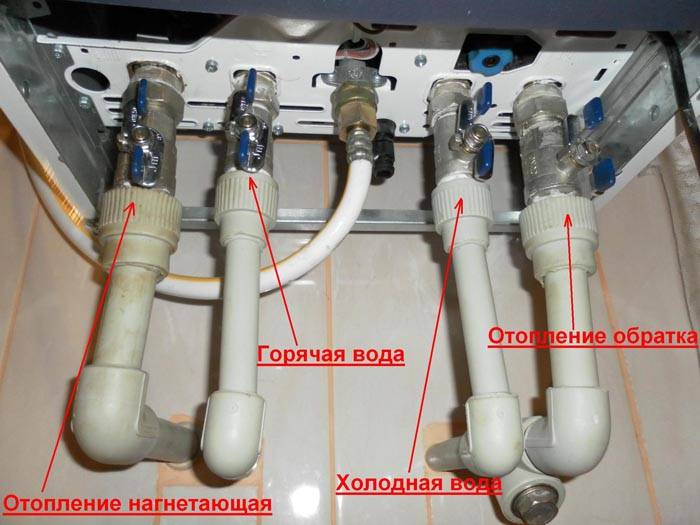

These units have 5 branch pipes, which are designed for:

- coolant supply to the heating system;

- hot water outlet;

- connection of the gas pipeline;

- cold water inlet;

- heating return line.

The gas burner heats the heat exchanger, and heat is transferred from it to the heating system. When the hot water tap is opened, the three-way valve closes the heating line, and the coolant flows from the primary heat exchanger to the secondary one, heating the tap water. Then the heated liquid exits the tap to the consumer.

Double-circuit gas boilers are at risk of failure of the secondary heat exchanger due to the poor quality of tap water. When it is heated, a precipitate forms, which clogs the DHW circuit, as a result of which it fails.To prevent damage, install a filter on the cold water inlet.

Control over the operation of a gas boiler for hot water supply is carried out by special automation, which selects the optimal operating mode.

…

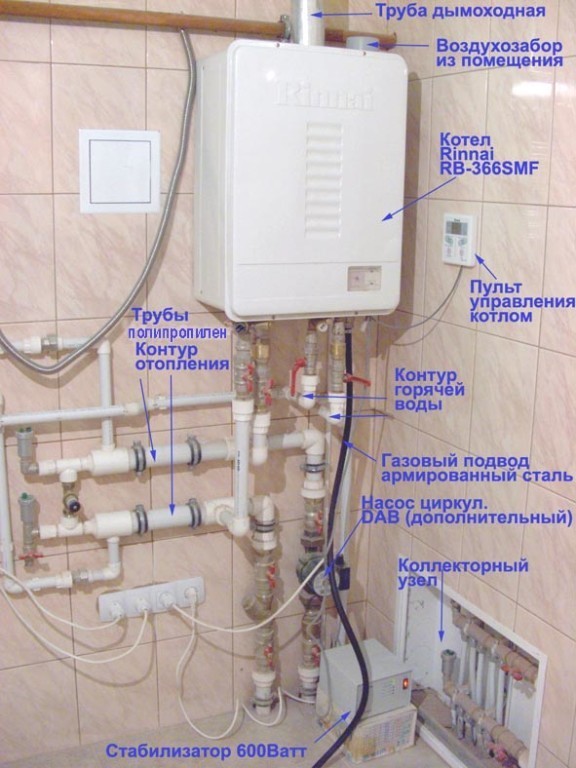

Combination with an electric boiler

In order not to be left without heating and hot water in winter, some are reinsured and install an additional electric boiler together with a gas unit. The electrical device duplicates the gas one and, if the latter fails, the first one can work instead of it. However, for this you need to install these units in parallel. Some installers offer to save money and connect the boilers in series, but this will lead to the fact that when the gas unit is stopped, the electric boiler will not be able to fully operate. It turns out that you have two sources of heating, but you are completely dependent on the performance of the gas boiler.

Note! The electric boiler is often used at night, since during this period electricity is cheaper, or as a backup source of warm water, if the volume generated by the gas unit is not enough.

Time to clean the heat exchanger

When it is necessary to flush the heat exchanger of a gas boiler is a common question. There are a number of signs by which you can be sure that the time has come.

One of the main ones:

- constantly on gas burner;

- the circulation pump has become noisier, which means it is overloaded;

- heating radiators began to heat up longer in time;

- gas consumption increases;

- the water pressure has become weaker (the first sign for flushing a double-circuit boiler).

In addition to cleaning the chimney, they also clean the boiler from soot. If the operation of the chimney is difficult, then in some cases it turns off, but this does not happen when clogged with soot. Combustion products are released into the air, and the owners breathe them.

It is recommended to clean the boilers once a year, especially if there is a year-round operation.

How is the work inside the boiler regulated?

If the temperature, according to the measurement results, turned out to be below the norm, the automatic system switches the heater to heating mode, the water is heated in the heat exchanger and, with the help of a pump, if any, is supplied to the pipes, spreading heat throughout the room.

The heating system is closed, that is, water, which is a heat carrier, constantly circulates through the pipes, without changing its volume.

If the volume is violated, the whole system may not work correctly. Usually one way or another this is noticed, for example, if a gas boiler makes noise, this may be evidence of a lack of water in the heating system, which in turn leads to overheating of the boiler. In such cases, check the thermostat setting (the device responsible for maintaining a constant temperature), if it is normal, check the water level and add it if necessary, providing the system with the necessary volume for normal operation.

Composition and types of devices

Gas boilers consist of three mandatory components:

- gas burner

- fittings controlling the gas supply

- heat exchanger

The last element is usually made of copper, but there are also options for devices with steel or cast iron heat exchangers.

Also, the wall-mounted gas boiler is equipped with a built-in pump that circulates water, a safety valve, an expansion tank, electronic controls, self-diagnosis and protection. Such a multicomponent composition allows us to call gas boilers mini-boilers. Moreover, the principle of their action is similar to the latter.

The automation of the boiler, focusing on the readings of thermostats and sensors, fixes how much the system needs heat. And then starts the work of gas fittings. The water used as a heat carrier is heated in the heat exchanger to the desired temperature and is supplied to the heating circuit with the help of a circulation pump. This is the principle of operation of a single-circuit gas boiler.

If you want to use the device not only for heating, but also for hot water supply, then you need to buy a double-circuit boiler. This is also a kind of gas boiler house, the principle of operation of which is based on the presence of a hot water heating circuit for the DHW system.

Such a boiler cannot simultaneously work for both heating and heating. When the DHW circuit is switched on, the operation of the heating system is stopped or slowed down. But in standard urban conditions, this is completely unnoticeable. Indeed, in order for the temperature in the room to decrease significantly, it is necessary that the boiler has worked in the water heating mode for at least 2-3 hours. Therefore, the scheme is entirely justified and effective.

Cleaning the heat exchanger

It is produced with a solution of hydrochloric acid, purchased in the distribution network and intended specifically for this purpose. Cleaning is carried out for the main heat exchangers of wall-mounted gas boilers and heat exchangers for hot water preparation. The cross section of the channels of such heat exchangers is small, which is why they are prone to contamination with salt deposits.

Cleaning the water jacket of floor gas boilers, as a rule, is not carried out. To perform cleaning, the heat exchanger must be removed. To do this, remove the boiler casing, unscrew the supply pipes to the heat exchanger, after draining the water from the boiler.

Remove the heat exchanger from the boiler. Wear rubber gloves and use a plastic container to collect the spent acid. The method is not complicated

Carefully pour the acid solution into the heat exchanger until it is completely filled. In the event that the heat exchanger is clogged with scale, there will be an active release of foam

Leave the heat exchanger for 10-15 minutes.

We drain the spent acid into a container and refill the heat exchanger with a new portion. We are waiting for the same ten minutes. Drain the solution and rinse the heat exchanger with running water. We put a piece of hose on the nearest water tap and spill the heat exchanger with water. Fill the heat exchanger again with acid solution. If there is no active foam generation, and when the heat exchanger is spilled with water, no significant flow resistance is visible, then the heat exchanger is washed out and can be replaced in reverse order.

Cleaning the burner

The method of cleaning the burner from soot has already been described above. However, with strong soot, it is not always possible to cope using only mechanical cleaning. For such cases, special chemicals are used. It makes no sense to recommend anything, all means are quite effective. The cleaning method is reduced to applying a solution in the form of a solution to the surface to be cleaned, holding it for a certain time and then removing the exfoliated carbon deposits, more often mechanically. In more detail with the method of cleaning with one or another means, you need to familiarize yourself with its purchase.

In particularly severe cases, for example, when coolant gets on the burner, it must be completely removed from the boiler, immersed in a cleaning solution for several hours. Then remove the burner, ignite in the flame of a portable gas burner. After one more application of the solution, using a metal ruff or brush, remove the remaining deposits.

Advantages of cooperation with Joule-service company

If you are looking for a reliable contractor who is ready to carry out design, maintenance, installation or commissioning of boiler equipment with high quality and on time, contact the Joule-service company. By cooperating with us, you can count on such advantages.

Regulation compliance. Performing the installation and dismantling of DKVR boilers, service or commissioning, our specialists strictly adhere to the requirements of SNiP and fire safety rules.

Efficiency. Work on the preparation of the project and the re-equipment of the turnkey boiler house will be completed in a short time. Employees of the company work according to the agreed schedule, avoiding unwanted delays and long downtime of heating systems.

Quality equipment and materials. When creating, servicing and reconstructing boiler plants, our specialists use certified components from well-known world manufacturers.

Detailed information can be obtained from our managers. Call the hotline or request a call back by filling out a simple online form on the page.

| Technical, service maintenance of boiler houses | |

| Monthly service 11 departures | Checking and adjusting the protection and alarm parameter map |

| Supply voltage measurement | |

| Checking gas shut-off valves (including tightness) | |

| Diagnosis of the boiler automation unit and the heating circuit | |

| Annual maintenance 1 time per year | Checking and adjusting the protection and alarm parameter map |

| Supply voltage measurement | |

| Checking gas shut-off valves (including tightness) | |

| Checking and adjusting the regime card | |

| Cleaning the combustion chamber | |

| Checking and adjusting boiler sensors and thermostats | |

| Checking and adjusting the automatic control of the heating circuit | |

| Checking the boiler safety group | |

| Checking and adjusting circulation pumps | |

| Checking and adjusting expansion vessels | |

| Checking and adjusting automatic switching on, off and switching of the power and control and signaling board | |

| Price annual maintenance of the boiler house from 300 kW to 3 MW RUB 300,000 |

The cost of maintenance of boiler houses over 3 MW is calculated individually.

The prices posted on the site are for informational purposes only and are not a public offer determined by the provisions of Article 437 of the Civil Code of the Russian Federation.

You can send an application for service maintenance of the boiler room by e-mail info@joulservice.ru.

Or make a phone call +7 499 922 0123.

In the application it is desirable to indicate:

- Address (place) of the object;

- Boiler power;

- Type of fuel;

- The main equipment in the boiler room (brand of boiler equipment).

Typical malfunctions of gas boilers

Typical malfunctions of gas boilers

There are a number of typical problems, which in most cases can be dealt with on your own. Problems will also be listed, in the event of which you can only protect yourself before the arrival of a specialist.

The smell of gas

The smell of gas

If there is a distinct smell of gas or smoke in the room, immediately turn off the boiler and leave the room, opening it for ventilation.

Scheme of functionality of a gas boiler

Flame sensor failure

If the combustion sensor or the gas supply pipe is broken, turn off the boiler, close all gas valves and allow the unit to cool completely.

After some time, return to the room to check it for the smell of gas. If everything is in order with the draft, try turning on the boiler again. If there is no traction, call a repairman immediately.

Boiler overheating

Overheating is one of the most common problems in modern gas boilers. The reason for this may be a malfunction of the automation equipment or a clogged heat exchanger.

You can clean the heat exchanger with your own hands. The most common materials for the manufacture of heat exchangers are copper and stainless steel. There are usually no problems with cleaning them, but still be extremely careful.

Primary heat exchanger for Beretta wall-mounted gas boiler

According to manufacturers' recommendations, heat exchangers should be cleaned of soot every few years (each manufacturer specifies a specific interval in the instructions for their equipment).

Primary heat exchanger (heating circuit) of the Rinnai SMF gas boiler

To clean the heat exchanger, simply remove it and clean it thoroughly with a wire brush. In the case of a copper heat exchanger, it is better to replace the brush with a metal sponge used for washing dishes.

Boost fan malfunctions

The problematic place of fans are their bearings. If the fan of your boiler has stopped developing the set number of revolutions, try to eliminate the malfunction as soon as possible.

Fan (3311806000) for Daewoo gas boiler

To do this, remove the back of the fan, remove the stator and grease the bearings. Machine oil is fine for lubrication, but if possible, it is better to use a higher quality carbon compound with heat-resistant properties for this.

Fan RLA97 (Aa10020004) for Electrolux gas boiler

Also, an interturn short circuit can lead to problems with the fan. Only a specialist can cope with the elimination of this malfunction. Hand over the stator for repair to replace the winding, or immediately replace the faulty unit with a new device.

Chimney problems

Gas boiler chimney diagram

Often, excessive clogging of the coaxial chimney leads to the appearance of various malfunctions in the operation of a gas heating boiler.

Chimney

Remove the chimney and carefully clean all of its components from soot. So you will not only return the previous level of efficiency of the unit, but also significantly increase the efficiency of the boiler.

Boiler turns off

The boiler can spontaneously turn off for several reasons. This is usually due to a malfunction of the combustion sensor. This problem, in turn, most often leads to contamination of the gas pipe.

Draft sensor 87°C for Thermona boiler

Remove the nozzle, rinse it thoroughly with water, clean it with a cotton swab and blow out any remaining moisture. Return the pipe to its place and try to turn on the boiler. If it doesn't work, call the wizard.

Sources

- http://wamteplo.ru/

- https://profi.ru/remont/otoplenie/remont-kotla/

- https://svoimi-rykami.ru/stroitelstvo-doma/otoplenie/remont-gazovyx-kotlov-svoimi-rukami.html

- https://www.rmnt.ru/story/heating/remont-gazovogo-kotla-svoimi-rukami.1204205/

- https://www.Thermostream.ru/remont-gazovih-kotlov/

- http://1pokotlam.ru/kotly/gazovye/remont-gazovyx-nastennyx-kotlov.html

- http://kotel-otoplenija.ru/remont-gazovyh-kotlov-svoimi-rukami