Classification of a heat insulator by fractions

The variety of the material is determined by the size of the fraction, i.e. granulate size:

- Small. The parameters are 0.1-5.0 mm. It is used as loose mix for filling. It is also used in the production of concrete blocks.

- Average. Reaches sizes of 10-20 mm, called gravel. Construction experts consider this expanded clay fraction to be better for insulating the ceiling, floors and ceilings of buildings.

- Big. The sizes vary in the range of 20-40 mm. Expanded clay of this fraction is used for insulation of roofs, basements and semi-basements, as well as floors in the garage and cellar.

Today, the building materials market offers about ten varieties of expanded clay. The distribution of material types is carried out due to the density of the filling level. So, expanded clay of a large fraction has a lower density. Thus, the lower the grade and density of the granulate, the higher the quality.

Roof insulation with foam

Penofol is a modern rolled synthetic material. Despite the small thickness (only a few millimeters), penofol has excellent thermal insulation properties, due to the low coefficient of thermal conductivity.

The surface of the penofol is covered with a thin layer of aluminum foil, which also affects its thermal insulation characteristics. Moreover, the foil gives the material hydro and vapor barrier properties.

This allows you to replace conventional vapor and waterproofing materials with penofol.

Due to the above properties, penofl is perfect for insulating roofs and attics, both in residential buildings and in baths, garages and other buildings. The small thickness of the material allows you to forget about the restrictions regarding the thickness of the rafters. The convenient form of release provides ease of installation.

Penofol is used as an additional insulating material. It is mounted between the insulation layer and the outer finish of the roof / ceiling

When installing, it is important to leave small closed air cavities between the layers of materials.

Their thermal resistance, enhanced by penofol reflective insulation, is comparable to the resistance of a 50 mm thick mineral insulation board or brickwork of one and a half bricks.

Reflective material as an added bonus

The use of penofol reflective material to insulate the roof or attic floor will eliminate the need for an additional layer of vapor barrier. The low coefficient of vapor permeability of the penofol material makes additional layers unnecessary.

Penofol allows you to protect the structure from moisture, minimize heat loss. At the same time, it does not affect the volume of the insulation layer. The material goes well with any heaters, but can also be used independently.

To insulate the roof of a country house, a “cold” attic in a bathhouse or agricultural buildings, it is enough just to “hang out” penofol along the rafters.

Roof insulation with foam

Due to its unpretentiousness, penoplex can be used in different conditions. Click on the photo to enlarge.

- Low moisture permeability.

- Resistant to strong temperature changes.

- biological neutrality.

- Resistant to fire and high temperatures.

- High rates of heat and noise insulation coefficients.

- Eco-friendly, non-toxic, safety for human health.

All this makes penoplex a popular and popular material for roof insulation. Penoplex is easy to install, it can be cut with an ordinary knife. At the same time, it is resistant to mechanical stress and has a low weight, which makes it popular for insulating floors and flat exploited roofs.

Penoplex plates are made of high quality polystyrene foam by extrusion. During the production process, sealed air cavities are formed in the raw materials.

After hardening, the penoplex acquires a cellular homogeneous structure. Thanks to it, the material has high thermal insulation characteristics, as well as mechanical strength.

Where is it possible to use penoplex?

Extruded polystyrene foam is allowed for use in any climatic zones.

Its use can significantly reduce the cost of materials during construction and further operation of the building. After all, a five-centimeter layer of foam plastic is not inferior in characteristics to brickwork, 153 mm thick.

Roof insulation with foam plastic can be done using any type of material. Most often on sale you can find the following types of extruded polystyrene foam:

- Penoplex 31 Standard.

- Penoplex 35.

- Penoplex 45.

To insulate the roof in a private house, Penoplex 35 is most often used. It perfectly protects the waterproofing of the roof from sudden temperature fluctuations and other destructive factors.

It is used to insulate a pitched roof from the inside of an attic or a flat roof using the "rolled ceiling" method. In the second case, a coating of gravel or paving slabs is made on top of the insulation on the roof. This will help protect the material from the wind, increase the fire safety of the roof.

What is expanded clay

Expanded clay is a heat-insulating material made by firing natural clay that can be foamed. This is a clean, ecological material that can be purchased in any city at a very low price.

Expanded clay sand (up to 5 mm in diameter) is used in the fill and in the lower layers during insulation. Fractions from 5 to 40 mm are used to create a heat-insulating "pie" on roofs, attic floors, floors, foundations, blind areas and even walls.

Advantages:

- environmental friendliness - the material, even over time, does not lend itself to decay, decay and decomposition;

- does not emit toxic substances into the air;

- resistant to temperature extremes, frost-resistant;

- does not support combustion;

- rodents do not live in it;

- democratic price;

- expanded clay sand perfectly fills all the recesses and cavities;

- easy process of roof insulation with expanded clay.

Flaws:

- the material is fragile, and broken granules lose a significant part of their thermal insulation qualities;

- the cellular structure of the fractions allows them to be filled with water when heated, which somewhat reduces the ability to keep the mixture of cold and warm air.

A little about choice

At the moment, there are 10 grades of expanded clay: from 250 to 1000, depending on the density of the embankment. This or that number indicates the number of kilograms of material per 1 m³ of volume. There are about 20 buckets of expanded clay in one cubic meter.

What brand of expanded clay is used for roof insulation? It depends on climatic conditions and the strength of the attic floor. In addition, when insulating the attic, more than 1 brand of material is used.

Warming technology

Insulation of the roof with expanded clay in a wooden house begins with an inspection of the attic floor and the removal of all debris. What needs repair - you need to fix the problem immediately.

Further, the algorithm is approximately the same as when using other heaters.

We make waterproofing

The floor of the attic must be covered with waterproofing with a mandatory overlap of the strips (by 200-300 mm) and gluing the seams with reinforced tape.

Many prefer roofing material or parchment. Previously, people with a lack of finances used ordinary cardboard. Waterproofing should go 15 cm on the walls and floor beams. If the budget allows, the beams can be completely covered with foil.

This is how waterproofing is done under expanded clay

What should be the thickness of expanded clay?

It is better to make the lower layer from fine expanded clay sand, and for the upper layer, use fractions of 10-30 mm. Many immediately purchase a mixture of granules of different sizes. The material is poured between the beams, but not above their upper edge.

Expanded clay backfill is carefully compacted and leveled with a rule.

Expanded clay must be leveled

You can already finish the work at this stage, but if you are going to somehow use the attic (storing things, drying vegetables and herbs), you better organize flooring on the floor in the room.

To do this, another layer of vapor barrier is laid on top of the expanded clay and the installation of wood flooring / plywood / chipboard is carried out.

If there is a need to fully use the under-roof space, concrete pouring is performed on the attic floor. To do this, a reinforced mesh is laid on top of expanded clay and poured with a screed. After complete drying, the floor covering is mounted.

Useful video below - be sure to check it out.

https://youtube.com/watch?v=W7CNaXfxy4w

Pros and cons of expanded clay thermal insulation

Expanded clay ceiling insulation has several advantages:

- The heat insulator has a long service life.

- Fire safety, because the material is not subject to combustion and, when heated, does not emit toxic substances that are dangerous to humans, animals and nature.

- Due to the porous structure of the insulator, the weight of the insulation is much less than analogues.

- Does not attract insects, rodents and bacteria that promote mold and mildew.

- The low price tag allows the use of expanded clay on any construction site.

- Thermal insulation at a high level, coupled with sound insulation, provides an optimal microclimate in a private house.

- Absorption of moisture without increasing its own weight and without loss of performance.

- Expanded clay crumbs or crushed stone are not allergens. This is due to the natural origin of the material.

- Ease of use of bulk heat insulator.

- The fractional shape of the material creates a barrier to the exit of air, which further increases the heat insulation and carries out natural convection.

Along with positive features, the material has disadvantages:

- The effectiveness of expanded clay as a heat insulator depends on the thickness of the layer, i.e. backfilling to a depth of 20-40 cm is meaningless.

- It is necessary to protect the material from the effects of precipitation.

- The optimal application is considered to be overlaying on reinforced concrete products. This is due to the fact that monolithic beams are able to withstand high loads, and delay the granulate from spilling to the second floor.

- When planning work on the insulation of the ceiling in a wooden house, the expanded clay should be protected with a vapor barrier film. In this case, the PVC film is placed at the bottom of the heat insulator and at the top. Thus, protection from the effects of precipitation is created.

Construction industry experts do not advise using expanded clay insulation on a false ceiling, hemmed from the bottom side (first floor) with beams.

Considering the weight load, material volume and structure, there is a high probability of a breakthrough of such a structure. In this case, the collapse occurs inside the room.

The use of expanded clay to insulate the roof of a house

Scheme of roof insulation with expanded clay.

Roof insulation can be organized on your own, for this you do not need to hire specialists. Before you insulate it, you need to know what expanded clay is and why it is so highly valued for thermal insulation of buildings and structures. Expanded clay is a natural material. It has high strength and can last a long time, unlike synthetic insulation. It is based on clay. Because of all this, it does not rot, can withstand very low temperatures, which is especially appreciated in cold climates. It has a crumbly and porous structure. Porosity helps retain heat. The big advantage of this material is its fire resistance.

Warming is most often carried out with expanded clay gravel, sand or crushed stone. In addition to all of the above, expanded clay is a fairly light material, which simplifies the work. To date, many synthetic materials are not environmentally friendly, which cannot be said about expanded clay. It is absolutely safe for humans during operation. Expanded clay is waterproof, so you do not need to make an additional waterproofing layer. Its cost is low, which is of great importance in the consumer market. In addition, it gives a minimum load on the entire house and the roof itself. The main disadvantage is its fragility.

Claydite roof insulation technology

Scheme of single-layer attic insulation.

Before you insulate the roof with expanded clay, you need to know some of the features of this work. First of all, in order to obtain a good effect, it is advisable to take into account the features of the house, its structure, walls, roof slope when insulating the roof. The modern technology of roof (roof) insulation includes several main stages: internal cladding, vapor barrier, laying a layer of insulation and surface finishing work (laying plates or other coatings).

Expanded clay insulation is no different from the standard. If there is a reinforced concrete floor with slabs of the upper floor of the house, then the work is somewhat facilitated.

This will ensure a more complete and thorough filling of all voids and irregularities. The layer thickness should be 25 cm. Expanded clay gravel is leveled and rammed. This can be done manually or with a special machine. It is recommended to screed over the first layer. This will give the structure greater strength and rigidity, a more even surface. It is advisable to organize several ventilation channels between the inner and outer layers, so that it is possible to remove excess moisture and ventilate the space. Ruberoid is placed on top of the insulation layer

It is important that the rolls are overlapped and there are no gaps. On top of it - tiles or tiles

List of tools and equipment

Roof insulation will require a whole set of tools and materials. It includes: insulation (expanded clay gravel or crushed stone), a shovel, buckets, a log or stick for tamping, a rail for leveling the expanded clay layer, a waterproofing film, rolled material (roofing material), a knife, tiles or tiles. Based on the foregoing, we can conclude that roof insulation with expanded clay is an effective and simple way.

This material is distinguished by fire safety, lightness, strength, resistance to low temperatures and moisture, which is especially important for our country. In addition to thermal insulation properties, it has a noise-protective effect due to its physical and chemical characteristics.

It is durable, which is why it is so widely used. Expanded clay is used not only to insulate the roof (roof), it is perfect for insulating floors, hangars, that is, any horizontal structures.

He has 1 drawback - this is fragility, so you need to work with him very carefully. Backfilling of expanded clay on the roof is carried out quickly, no complicated equipment is needed for this

It is only important to comply with the basic requirements (layer thickness, organization of ventilation holes, etc.)

The thickness of the expanded clay layer directly depends on the strength of the roof. A thick layer can exert a large load. Bulk expanded clay materials should be combined, for example, with foam chips for the best effect. The seams when laying the rolled material must be sealed, for this they are glued with construction tape or mastic based on bitumen and rubber, which is more optimal.

Roof insulation with a layer of expanded clay

Roof insulation is most often performed using the following types of expanded clay:

Expanded clay gravel. It is a large material.The size of its granules does not exceed 4 centimeters. Well suited not only for thermal insulation of the roof, but also for the insulation of walls and floors in the house;

Expanded clay gravel. This material is also coarse-grained. Its granules have an angular shape and do not exceed 4 centimeters in size;

Expanded clay sand. It is a finely dispersed material. The particle size is up to 5 millimeters. When using this material as a heater, the layer thickness should not be more than 5 centimeters.

As mentioned above, it is quite possible to perform thermal insulation using expanded clay with your own hands.

Before you start thermal insulation work, you need to study certain subtleties of the insulation process.

First of all, you need to pay attention to the design features of the building.

Insulation of the roof of the house with expanded clay includes the following steps:

Inner lining;

Laying a vapor barrier layer;

Laying thermal insulation;

Surface finish.

Detailed description of works:

- The thickness of the expanded clay layer during roof insulation should be 25 centimeters. It should be poured directly onto the vapor barrier material. This work must be done quickly and very carefully so as not to damage the material granules.

- To improve noise and heat insulation, it is desirable to make the expanded clay layer thicker. However, you should remember about the maximum load that the roof of the house can withstand. In this case, it is best to choose the golden mean.

- Next, you need to properly level and compact the expanded clay layer. Then there will be fewer voids between the particles of the material, and the thermal insulation will be better. It is necessary to tamp the expanded clay with your hands or with a special machine. Further, it is recommended to perform a screed over the first layer. Due to this, the structure will become more durable and rigid, and the surface will be more even.

- It is also necessary to make several channels between the inner and outer layers. Moisture will be removed through these channels, as well as air will circulate.

- At the next stage, roofing material is laid on top of the heat-insulating layer. It needs to be flush mounted. In order for the seams of the roofing material to be airtight, they are isolated with bituminous mastic or construction tape.

- At the final stage, the installation of tiles or tiles is performed.

- Features of thermal insulation

- Advantages and disadvantages

- Warming technology

- Training

- flat roof

- pitched roof

Expanded clay roof insulation is the oldest and most commonly used method of home thermal protection. The comfort of living depends on the reliability of the roof, and this material helps to ensure this reliability for a long time. We will tell you today how to use expanded clay for roofing.

Roof insulation with expanded clay technology and nuances

To carry out the work you will need the following materials and tools:

- vapor barrier layer;

- waterproofing layer;

- Rail (it will be needed for tamping and leveling);

- Shovel;

- Several buckets;

- Knife with a sharp blade;

- Expanded clay.

Before the warming procedure, it is worth doing some preparation work. They will consist in cleaning and leveling the surface to be insulated. In addition, you will need to close up all cracks and crevices.

The subtleties of laying bulk insulation

The technology of roof insulation using expanded clay has a number of rules that must be reckoned with when carrying out work. If they are not taken into account, the results of labor will not only not please, but there is also a risk that the insulation layer will have to be redone.

With an angle of inclination above 5 °, the space between the rafters will need to be filled in the same way as the walls of frame houses are backfilled using loose insulation. This is done gradually, in small portions. At the same time, the wall is sheathed in parallel.

All types of work must be done from the outside. In this case, weather conditions can be an important factor.In the process of insulation, it is unacceptable to work during rain or fog, as well as other factors that provoke significant air humidity.

The backfill will need to be protected as much as possible from the possibility of moisture ingress. To do this, a waterproofing layer is laid on the outside of the building, and a vapor barrier is mounted from the inside, which prevents the ingress of water vapor from the living quarters. Tightness can be ensured by overlapping the film, the joints are additionally sealed with adhesive tape or bituminous mastic.

Since a sufficient layer of insulation has a significant mass, the roof structure must be characterized by high strength. It would be best if the floor material is a reinforced concrete slab (in case a flat roof is being built).

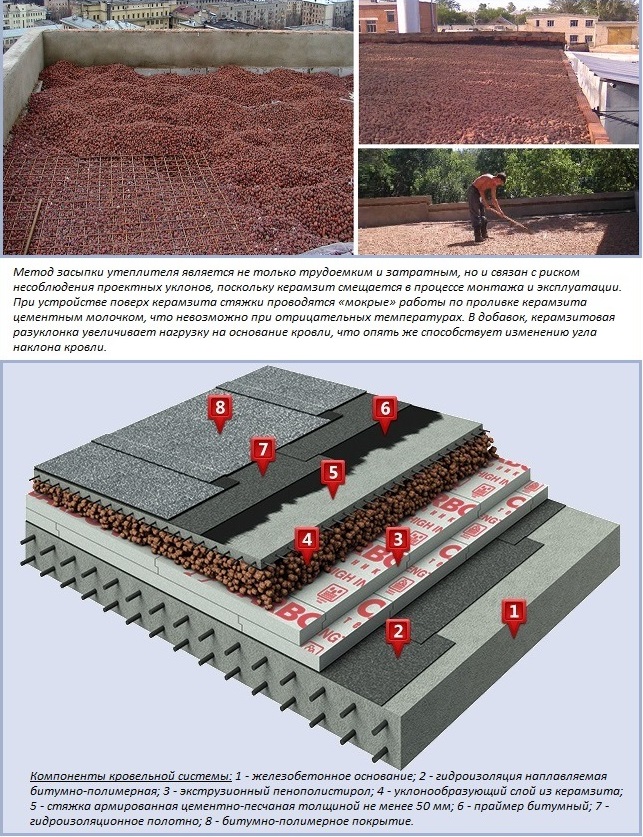

flat roof insulation

Basically, expanded clay is used for insulation of flat roofs. It is easy and convenient to carry out work on a horizontal surface, which allows you to fully appreciate all the advantages of this type of insulation.

First you need to clean the work surface of debris, paying special attention to the presence of small stones with sharp edges. If they are not removed, they can lead to damage to the vapor barrier sheet.

The vapor barrier layer must be distributed over the entire surface area requiring insulation

You can use high density polyethylene film for this. To make the protection highly durable, you can cover the surface in two layers.

The key stage of thermal insulation is, in fact, the backfill process itself. It is recommended to calculate the required thickness of the insulating layer in advance, taking into account all the nuances of a particular building object. This will allow you to complete all stages of work in a short time.

The most common backfill thickness of expanded clay insulation varies from 30 to 40 centimeters. If during operation it turns out that this layer is not enough, after the first winter it is necessary to insulate the ceiling from the inside of the house using mineral wool or foam.

After that, a screed is made using reinforcement. This technique allows you to perform ongoing roof maintenance work without risks.

The final stage includes laying one or two waterproofing layers. To give the roof a beautiful finished look, the roof covering is installed. To do this, they can use ceramic or soft tiles, sheets of slate or painted corrugated board, etc. materials.

Roof insulation with slopes

It will be more difficult to install thermal insulation if the roof is pitched

It is extremely important to achieve uniformity of the insulation backfill layer in the space between the rafters.

When the space between the rafters is completely filled, a layer of waterproofing is laid over the crate and the final roofing is mounted. The vapor barrier is fixed from the side of the room, not forgetting the tightness standards, using overlapping panels and carefully gluing their joints.

Expanded clay, although not a material that is easy and simple to work with, but this is covered by its versatility. The main thing is to follow all the rules for working with this material, and then it will perfectly perform its functions as a heater for various roofing structures.

Expanded clay

It is a light material, the structure of which includes many pores, which determines its high thermal insulation properties. It is produced by firing shale or clay itself at a high temperature (1000-1300 degrees) for quite a long time (20-40 minutes). Depending on the type of feedstock and processing technology, the density of the resulting expanded clay can be from 0.35 to 0.6 g/cm3.

There are the following types of it (depending on the shape of the fragments):

Expanded clay gravel. It consists of cellular elements of a streamlined oval shape, their size varies from 5 to 40 mm in diameter. Usually this type is used when there is a need to create a layer of insulation over 5 centimeters.

Expanded clay gravel.The size of the pieces is approximately the same as expanded clay gravel, but their shape is more like a cube, the edges and corners of which protrude sharply. The technology for its production is reduced to crushing larger fragments of expanded clay.

Expanded clay sand. The particle size is approximately 14 to 50 millimeters. The peculiarity of this type of building material allows you to create a layer of thermal insulation with a thickness of less than 5 centimeters without loss of insulation qualities. In addition, it is used in the range of 14-50 millimeters. Small dimensions allow the use of expanded clay sand with a thickness of the heat-insulating layer not exceeding 5 centimeters. It is also used as a filler in concrete or other mortar.

Advantages of expanded clay

This material for thermal insulation is very economical. When using expanded clay, you can carry out sound and heat insulation of your home with the least financial investment. The material has a high rate of fire safety and a high degree of environmental friendliness, since various types of clay are used for its production. It also has a significant service life. This is due to the fact that the material does not condense moisture.

Any material used for construction must meet environmental safety requirements. Expanded clay is made exclusively from pure clay, in which there are no various chemical additives. Therefore, it is completely safe for human health. In the production of oval varieties of expanded clay, clay is fired.

Expanded clay gravel allows you to fill various types of voids. In this way, thermal insulation of the roof is carried out. Often, when installing insulation, expanded clay gravel is mixed with foam chips, which increases the thermal insulation properties of the layer.

Disadvantages of material for roof insulation

One of the important disadvantages of expanded clay is its increased fragility. This point must be taken into account when carrying out work, and carefully handle the building material. When the material is poured into the cavity, some of its elements may be damaged, which leads to a partial loss of their properties.

Expanded clay should only be used as a dry backfill material. It is not advisable to mix it into cement or mortar.

Nevertheless, even without being a professional builder, it is still possible to use expanded clay. Everyone will be able to produce high-quality insulation of the building, while spending a minimum of time on the process.

The use of expanded clay for the insulation of the roof at home

The scheme expanded clay roof insulation.

You can organize on their own, without the need to hire professionals to do so. Before you insulate it, you need to know what the concrete block and why it is so highly prized for thermal insulation of buildings and structures. Expanded clay is a natural material. It has high strength and can last for a long time, unlike synthetic insulation. At the heart of it - clay. For all these reasons it does not rot, it can withstand very low temperatures, which is especially appreciated in cold climates. It is crumbly and porous structure. Porosity contributes to the conservation of heat. The great advantage of this material is its fire resistance.

Warming of the most frequently performed expanded clay gravel, sand or gravel. In addition to the above, concrete block is pretty light material, making it easier to carry out works. Today, many plastics are not environmentally friendly, which is not about the concrete block. It is completely safe for humans when operating. Expanded clay waterproof, so do not need to do additional waterproofing layer. The cost of it is low, which is important in the consumer market. In addition, it provides a minimum load on the house and the roof itself. The main disadvantage is its fragility.

The technology of expanded clay roof insulation

Driving a single-layer insulation of the attic.

Before you insulate roofs expanded clay, you need to know some features of this work. In the first place, to obtain a good effect when it is advisable to take into account the particular roof insulation the house, its structure, walls and a sloping roof. Modern (Roof) includes several basic steps: the inner lining, vapor barrier, laying down a layer of insulation and finishing work on the surface (stacking plates or other coating).

is no different from the standard. If there is a reinforced concrete ceiling slabs of the upper floor of the house, the work is somewhat easier.

This will provide a more complete and thorough filling of all voids and irregularities. The layer thickness should be 25 cm. clay gravel leveled and compacted. This can be done manually or using a special machine. It is recommended to make a screed on top of the first layer. This construction will give greater strength and rigidity, a flat surface. It is advisable to organize some ventilation ducts between the inner and outer layers to be able to remove excess moisture and ventilation space. On top of the layer of insulation roofing material is placed. It is important that coils overlapping fit and there are no gaps. Above him - shingles or tiles.

List of tools and equipment

Thermal insulation of the roof will require a whole set of tools and materials. It includes: insulation (expanded clay gravel or crushed stone), a shovel, a bucket, a log or stick to ram, rail to align the expanded clay layer, a waterproof film web material (roofing material), Knife, tiles or shingles. Based on the above we can conclude that the insulation of the roof with the help of expanded clay is an effective and simple way. This material is different fire safety, lightness, strength, resistance to low temperatures and humidity, which is especially important for our country. In addition to thermal performance, it is inherent in the soundproofing effect due to the physico-chemical characteristics. It is durable, so found a wide circulation. Expanded clay is used not only to insulate the roof (the roof), it is perfect for warming the floor, hangars, ie all horizontal designs.

Warming of beam and concrete ceilings with expanded clay

Insulation of the attic with expanded clay in a house with beamed ceilings.

Insulation of the attic with expanded clay and the floor in terms of technology differ quite a bit if the work is performed in a house with beamed ceilings. In houses where a concrete slab acts as a floor, the insulation technology is somewhat different. Therefore, we will consider how to insulate the ceiling with expanded clay from two angles:

- in a house with beamed ceilings;

- in a house with concrete floors.

In a house with beamed ceilings, there is space between the rough and finished floors, or the ceiling and the floor of the second floor. The height of the buffer zone is equal to the section of the bearing beams. Expanded clay for insulation of the ceiling or floor is poured there. Three Insulation Pie Components:

- expanded clay;

- diffusion membrane;

- vapor barrier.

The main thing is not to confuse the films in places. The vapor barrier must be laid between the insulation and the heat source. Waterproofing is laid between expanded clay and an unheated room.

That is, when insulating the attic with expanded clay, the vapor barrier is laid from below, and when insulating the floor, from above. Naturally, the joints of both layers of films must be sealed. When insulating the ceiling of the bath with expanded clay, Penofol should be used as a vapor barrier - this is a reflective insulation that consists of two layers. The first layer is a pillow made of foamed polyethylene with a thickness of several millimeters to a centimeter. The second layer - a foil that beats off infrared rays, is laid with a shiny side to the heated room. An important condition is the presence of an air gap between the fine finish and the reflective surface of 1.5 cm or more.

In houses with concrete floors, expanded clay insulation is carried out under the screed. There is nothing complicated in the technique, the main thing is to lay a plastic film between concrete and expanded clay and glue the damper tape around the perimeter of the room. The screed is poured over the beacons.

(, be the first)

How much will it cost to insulate walls with expanded clay

The cost of work on the creation of expanded clay insulation is largely related to the height and perimeter of the building, the number of floors and the selected material. The amount also depends on the method of how to insulate the walls with expanded clay - the optimal three-row, lightweight or combined. In most cases, the width of the claydite-concrete layer is about 300–400 mm, the claydite-cement layer is 100 mm, which corresponds to a meter-thick brick enclosing structure.

With an average cost of 1 cubic meter of expanded clay about 2000 rubles, and expanded clay concrete about 3500 rubles. it is easy to calculate that for a wall, the inner layer of which has a thickness of 250 mm, and the average is 100 mm, the costs will be approximately as follows:

- per 1 sq. m wall will be 0.4 cubic meters. m of expanded clay concrete blocks worth about 1400 rubles;

- the same area contains 0.1 cubic meters. m of expanded clay for 200 rubles;

- for a building with a height of 3 m and a perimeter of 32 m (for example, 8 x 8 m), the cost of only expanded clay concrete and expanded clay for wall insulation will be: 3 x 32 x (1400 + 200) = 153.6 thousand rubles.

The cost of cement depends on the proportion chosen, but in any case, it is several times less than the cost of expanded clay.

The price of the outer layer, which is taken as a facing brick or wood, can differ markedly depending on the chosen finishing option. Sometimes it is comparable in cost to insulation (from 1,000 to 1,600 rubles / sq. m), but it can also exceed the costs of expanded clay and expanded clay concrete by several times, reaching 3,000–6,000 rubles. for 1 square.