Plate dowels durability for a long time

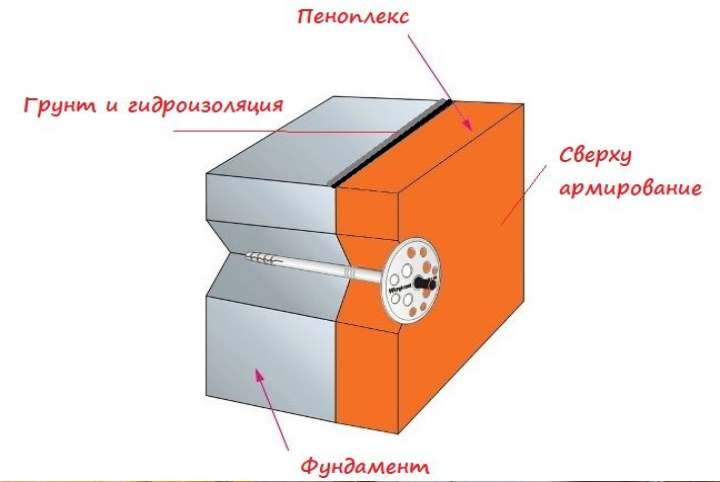

The use of dish-shaped dowels is justified in the case of a large area of insulation, or uneven facade surfaces. For mounting on dowels, you need: a puncher (impact drill), a drill of the appropriate diameter and length, a hammer. Holes are drilled with a recess in the base of 50-60 mm. Holes are filled with mounting foam. Then the dowel is hammered with a hammer so that the fungi of the dowels do not protrude above the surface of the plate. It is best to use dowels complete with metal screws to increase the reliability of the connection. It is enough to install 5 dowels on one plate. Adjacent sheets are fastened with one dowel. It must be installed in the seam between the plates.

Fixing methods and types of glue

When figuring out how to glue the foam to the wall, you should know that there are three main ways to fix the material:

- with glue;

- using dowels;

- with the simultaneous use of glue and dowels.

The first option is practiced more often with internal work, the third - with external work. Fixing heat-insulating plates only with dowels is rarely carried out, since it does not provide the proper level of reliability. When insulating the roof, the foam can simply be embedded in the crate.

For gluing foam, it is permissible to use various means. All of them can be conditionally divided into two groups - dry compositions and ready-made adhesives.

Dry products

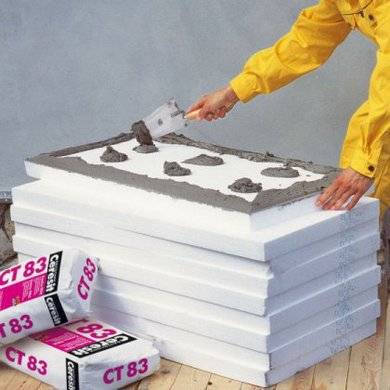

If the question arose of how to glue foam plastic to concrete during facade thermal insulation work, it is worth choosing dry mixes. They contain cement, sand and polymer fillers. Well-known means - Ceresit CT 83, "T-Vanguard-K", Armierungs-Gewebekleber.

For internal finishing works, dry compositions based on gypsum are used. Their main purpose is the installation of drywall. Popular mixtures - Knauf Perlfix, Volma.

To prepare the glue, the powder must be diluted with water according to the instructions. After drying, the mixture hardens, forming a strong rigid connection of the foam with the main surface.

Advantages of powder products:

- the time spent on preparing the glue - it should be properly combined with water and mixed thoroughly, achieving a uniform consistency;

- the need for additional equipment and tools - mixing containers, a construction mixer;

- release of cement or gypsum dust during operation.

Ready-made adhesives

When solving the problem of how to quickly glue the foam, it is recommended to pay attention to ready-made adhesives. The main option is an aerosol product based on polyurethane foam in cylinders

This foam adhesive is very easy to use. One cylinder is enough to fix about 10 m 2 of plates. The mixture cures in an average of 30 minutes, providing a secure hold that is resistant to moisture and temperature changes. The only downside is the relatively high price. Popular means - Penosil, "Titan Styro 753", Ceresit CT 84 Express.

Foam based on polyurethane foam can be used if there is a problem than gluing the foam to foam, concrete, brick, cellular blocks, OSB panels. It is suitable for indoor and outdoor use.

Other ready-made adhesives:

- Silicone sealant. It is advisable to use it if you need to fix small elements of thin foam on a flat surface.

- Universal building polymer adhesive or "liquid nails" (Dragon, "Installation Moment"). It is indispensable in solving the problem of how to glue polystyrene to metal. To improve adhesion, the surface should be cleaned of rust, paint and grease. In addition, with the help of "liquid nails" it is convenient to fix the insulation to the ceiling.

Tips and instructions for gluing foam

First of all, you need to remember a number of general rules for gluing foam, which must be taken into account regardless of the selected adhesive composition:

Before sticking the sheets, you need to prepare the surface. First of all, it is cleaned of old paint, dirt, rust, etc., after which it is degreased.

It is this distance that allows for the most reliable adhesion of the foam to the metal surface. If dry mixes are used, then the sheet will need to be additionally pressed over the entire area with plywood.

For work you will need the following materials:

- Degreaser. The metal surface can be treated with industrial alcohol, gasoline, white spirit, kerosene and specially designed compounds for this purpose.

- Means for gluing sheets. Choice of: foam, silicone sealant, spray adhesive, PVA, liquid nails.

- Burlap if possible.

- If foam or spray adhesive is used, a special cleaning solvent must be prepared.

During work, you will need the following tools:

- Wooden board or sheet plywood in case of using dry adhesive mixtures.

- Unnecessary clean rags.

- Protective gloves.

- Knife for cutting foam boards.

- Spatulas.

- The gun in case of use of polyurethane glue-aerosol.

- Yardstick.

Gluing is very simple, everything is done in the following sequence:

- The metal surface is cleaned and degreased.

- The selected adhesive composition is applied to the foam sheet.

- The sheet leans against the surface with a slight pressure. When using a dry mix, it is additionally pressed with plywood or a wooden shield until the glue dries.

Thus, working with foam is simple, easy and profitable. The set of tools and materials is minimal. Before buying a composition, be sure to make sure that it is suitable for use in your climate zone, does not contain gasoline, acetone and other solvents. Successful work!

1 Foamed plastic what's what and why

The correct technical name for the well-known expanded polystyrene - foamed plastic. Looking closely at this material from a short distance, you will find that it consists of a large number of small balls that are held together - these are polystyrene granules that have been foamed under high pressure and temperature and compressed in a press.

Because of this technology, in the structure of expanded polystyrene there are a lot of microcells invisible to the eye, in which air resides. Due to this, the material receives airy lightness and the properties of a very excellent heat insulator. Consumers fell in love with it for a very small price - in fact, it is a very inexpensive insulation, and workers appreciated its technical specifics. We will dwell on this in detail, because simultaneously with the demand for the material, like mushrooms after it rained, countless myths about its shortcomings grew.

Expanded polystyrene is very durable - polystyrene keeps its shape for at least 25 years in outdoor conditions and at least half a century when used in the middle. You will definitely be surprised, because some people talk about its fragility. In fact, ultraviolet radiation and the systematic influence of moisture can reduce the operating time. But only these same factors can reduce the life of virtually any building material, as well as heat insulators of various kinds.

Foamed plastic is not afraid of fungi and mold - due to this, it can also be used in a wet environment, for example, in a basement. Polystyrene granules do not actually absorb moisture. However, they say that a variety of rodents easily make holes in polystyrene foam. Again, this is only partly true - if the rodents have something to feed on, they will make holes even in concrete.deprive them of food or exterminate with poison, and you will not need to think about their relationship with styrofoam.

Expanded polystyrene does not support combustion - no matter what they say, however, this material is several times safer than the same wood. In order for it to catch fire, a temperature twice as high as in the case of wood is needed, and when ignited, it releases much less heat. The material is not hazardous to human health and the external environment - among the popular myths, there is also a myth about the alleged danger of material for human health. But dozens of studies have disproved this myth for a very long time. Look behind you, there are a lot of much more harmful materials around you.

Of the bad qualities of expanded polystyrene, a small fortress should be called - it breaks off easily, and also a not very big blow can leave a dent on its surface. Due to this, it must be protected from damage from mechanical factors - classically, mixtures for plaster are used to do this. They also protect the material from the influence of ultraviolet radiation.

https://youtube.com/watch?v=Ea94bC7aIp0

Houses are different, and they need to be insulated in different ways.

The use of various technologies and materials in construction leads to the fact that it is impossible to give a universal answer to the question: what to consider when attaching foam plastic to the walls of a house? For different surfaces and operating conditions, methods for fixing and preparing surfaces have been developed. You need to know this in order to control those who carry out the insulation of the house. And even more so for those who insulate the house with their own hands, using their potential.

Houses can be made of stone and wood building materials. Already at the stage of surface preparation, features in the work are beginning to appear.

When preparing concrete and brick surfaces, it is necessary:

- clean the walls from dirt, deposits, paint, fuels and lubricants, and then dedust;

- treat with copper sulfate (antiseptics) the places where the fungus spreads;

- remove efflorescence on brick;

- clean and repair cracks in the insulated wall;

- apply a deep penetration primer;

- smooth out irregularities with putty;

- apply a deep penetration primer after filling.

Preparing a tree is much easier. It is treated with impregnations that prevent wood decay. It is possible not to process wall material such as oriented strand board or thermowood. Then the base is made of impregnated timber, which provides ventilation of the facade.

Advantages and procedure for working with aerosol adhesives

More convenient and easy to use is an adhesive that is available in the form of an aerosol. Working with such glue does not require special training, it is very quickly and easily applied. Polyurethane spray adhesive can be used for both exterior and interior foam applications. One such cylinder is enough for an average of 10 square meters of foam. Glue hardens in no more than 30 minutes.

It is very simple to work - you just need to insert the cylinder into the mounting gun and you can proceed. The glue is applied in strips along the perimeter of the foam sheet at a distance of 2-4 cm from its edges. Also, the stripes must be applied diagonally. We must try to do everything quickly. After applying the glue, the sheet must be pressed against the wall with a little effort.

A bottle of such glue costs a little more than a bag of dry mix. However, spray adhesive is more economical and convenient to use.

What and how to glue

The fact that the foam has a number of positive qualities, it became known. Now you need to understand how difficult this insulation is to install and what composition is better to glue it with. In the process of insulation, it may be necessary to glue the foam to any surface: plastic, wood, metal or concrete. The most difficult material in this regard is metal. How can I glue foam to metal?

First, it is worth considering the general rules for gluing polystyrene foam to any surfaces:

- glue is applied to the panel in at least five places;

- until the glue has completely dried, no work should be carried out with the panels so as not to provoke their shift;

- if pasting will be done outside, you need to choose the adhesive composition so that it matches the weather and temperature conditions of a particular area.

You can glue the foam to the surface: liquid nails, mounting foam or silicone sealant.

To glue the foam, liquid nails, silicone sealant or polyurethane foam are suitable - any glue that does not react with the foam. Otherwise, glue containing acetone, gasoline or other solvent will "burn through" the foam and the work will be ruined.

In the preparatory cycle, you need to clean the metal surface of dirt, old paint and rust, and then degrease it. Liquid nails, glue and silicone are applied in strips or points at a distance of 5-7 cm from each other. This method will provide the best attachment of the foam sheet to the metal surface. To glue the plate as securely as possible, you should press it over the entire area with wooden shields or plywood.

Mounting polyurethane foam has an amazing ability to adhere to any material. This substance has many positive qualities:

- foam is easy to use and does not require special skills;

- with the help of foam, it is possible to quickly and efficiently carry out the installation of a foam plate on any surface, even glue it on a metal plane;

- foam is relatively cheap, sold in cylinders and, in addition to gluing to the main surface, it can also seal the seams that occur between the plates.

But there is one feature of working with this material - the foam dries quickly, the tube becomes clogged and the cylinder becomes unusable, although the composition itself from it is not completely used up. To solve the problem, there is a special flushing solvent, which must be bought at the same time as the foam bottle.

Along with foam, a one-component polyurethane adhesive is used. It is also available in cylinders, but to use this building material, you should also purchase a special gun.

Some craftsmen use a skillful combination of liquid nails and glue. Liquid nails set quickly, and there is no need to support the foam sheet with plywood, as is the case with glue. But the reliability of liquid nails is lower than that of glue, so the method of fastening only with nails is not very reliable, especially if you glue the panels to the ceiling. If 2/3 of the panel is spot-treated with glue and 1/3 with liquid nails, then the support is not needed, and the design is more reliable and durable.

The scheme of applying glue to the foam.

For gluing small metal surfaces inside buildings, double-sided tape may be suitable. This material is quite expensive compared to other adhesives, so it makes sense to use it in case of a very small repair.

If it is possible to glue burlap to the metal, then there will be no problems with the subsequent attachment of the foam. The usual building PVA perfectly adheres to burlap and foam.

So, the necessary materials:

- degreaser: gasoline, kerosene, industrial alcohol, white spirit (only alcohol does not leave a thin film) and special products are suitable;

- the composition on which the plates will be glued: a bottle of glue, foam, liquid nails, silicone sealant, PVA;

- sackcloth;

- Solvent rinse for cleaning foam or adhesive cans.

Tools:

- grinder for cleaning a metal surface;

- a sheet of plywood or a wooden shield to press the glued part until dry;

- gloves;

- rags;

- gun for a balloon with polyurethane glue;

- spatulas;

- knives for cutting foam;

- roulette.

Mounting options for foam

Dry mixes based on cement

By giving preference to cement-based dry adhesives, you choose a low price, availability and reliability of fastening. In order to proceed with the installation, you will need to dilute the mixture according to the instructions using a construction mixer, and then simply apply with a spatula to the back of the plate and press it against the wall surface. Insulation glued in this way will be fixed more than securely.

Adhesive foam

Another common method of attaching insulation. The principle of fastening is similar to the two described above - the plate is also glued to the wall. A feature of this fastening is the material of the wall surface - it is recommended to use adhesive foam for gypsum and plastic coatings. Glue foam is sold in cylinders and applied with a glue gun. It's fast and convenient.

"Fungus" or dish-shaped dowels

Earlier, we considered four types of fastening for foam plastic, they were based on one and the method - gluing the sheet to the wall with various compositions. For the highest quality of installation, we recommend the fifth method, namely, fastening with plate-type dowels or, as they are also called, “fungi” or “umbrellas”.

Penoplex has a low weight and there is an opinion among builders that any adhesive method will be enough, but in the final version, the layers of insulation and cladding will weigh a lot and it is necessary to consider more reliable options - fastening with dowels. In order to secure a foam sheet with high quality, you will need five fungi - four in the corners and one in the center, a puncher, a hammer and a drill.

Dowels for fastening penoplex - varieties

Consider with you the types of dowels for attaching foam to surfaces. The most important difference is the material of manufacture of the dowel. So, dowels are:

Plastic mushrooms. These fasteners are recommended for use on brick and concrete surfaces, but only for light types of insulation. Plastic is a less durable type of material than metal, so its reliability is somewhat lower.

Metal dowels. An excellent option for attaching any insulation, including the heaviest options. Metal, unlike plastic, is highly durable and will last for many years. The disadvantages of a metal dowel are only the high cost and the possibility of metal corrosion. Dowel with a thermal head. The body of the dowel is made of steel, and the head of the nail is made of metal of low thermal conductivity. This option is technologically the most preferable, but expensive.

Self-tapping screws cheap and cheerful

Fastening with self-tapping screws using a screwdriver is permissible when insulating a wooden wall along a previously installed crate. At the same time, it is recommended to install a washer under the head of the self-tapping screw to avoid surface destruction and increase the reliability of fastening.

The most widely used is the combined method of fastening using bituminous (adhesive) compounds and dish-shaped dowels.

The resulting insulation layer is hermetic, able to withstand high mechanical loads and has an increased insulation coefficient.

After the insulation is installed, a reinforcing mesh is installed, followed by cladding.

Now you don’t have to think: “How to glue penoplex? How to fasten correctly? The use of materials purposefully designed for foam plastic to the walls will allow you to avoid unnecessary waste of effort, money, time and get a durable do-it-yourself thermal insulation layer.

Related video:

Adhesive types

We list the most commonly used glue options at present.

- For rooms with high humidity, MV-40 is suitable, which has moisture-resistant properties. You can also choose T-Vanguard-K.

- For residential premises, they usually use "Express" or "Universal".

- If we are talking about the installation of external building structures, then it is best to choose liquid nails or mounting glue. Suitable, for example, Moment Installation.

- Titanium is good for reinforced concrete bases.

- Neoprene-2136 spray or contact type Akrol are selected for bonding to foam.

- Olfix and Ceresit are universal glue options. They are perfect for working with any kind of surface, including concrete.

- Atlas Stopter K-2 kley is selected if it is planned to glue the insulation on a mineral base.

- Weicon Easy Mix PE-PP-45 is selected for bonding polypropylene to polyethylene.

After carrying out the work, the seams will need to be processed with the help of Tilit or adhesive tape specially designed for this.

The choice of glue is largely determined by the purpose of the room that you plan to insulate, whether you will attach it to wood, metal, concrete, etc. Choosing on your own, without having much experience in the implementation of construction and installation work, can be difficult. Therefore, it is always advisable to consult with specialists.

View Full Version : How to stick

For this, I use bituminous mastic either Cordon or Barrier. Now I don’t remember which one is anti-noise with rubber crumb, and which one is just mastic. You need one that is crumb-free. I do not advise you to take cheap mastic from Bikar - it is very liquid, you can’t stick anything. Last summer I pasted over the roof like this, in the winter - a motor shield. First, 2-3 layers of anti-noise, dry everything, then penofol.

Thanks for the links!

Good day to all. Interested in how you can glue penofol to metal? (Or whatever it is. This one is sold with foil at construction markets) I want to glue the motor shield from the side of the engine.

Liquid nails work well too. Before use, test whether they dissolve penofol.;)

If you haven’t bought it yet, then find a self-adhesive one on the same market. Sticks to a clean surface. I insulated the entire roof with them, I wanted to tear off one place a little bit, figs, only in tufts. It costs significantly more.

Is it called the same?

Yes, only with the addition of "self-adhesive". 🙂

I glued it with mastic, smelled like “glue moment”, and it looked similar.

Greetings! I glued isolons and penofols many times with glue 88 and Moment. I bought it in banks, it’s much cheaper, just smear it with an ordinary brush, wait a bit and press it down. Holds tightly, in particular pasted over the hood from the inside for several years. But after use, the glue in the jar dries quickly.

What does isolon look like? Something familiar name :confused:

In order: From the beginning, the motor shield from the side of the engine must be glued with vibration isolation. I used Stardartplast's Bimast Bombs.

On it with a second layer of isoflex. He is self-reflecting.

Isolon will not give ANY soundproofing effect! Tested on myself, pasted over the hood effect zero!

Glued with a solution of mounting foam with acetone. Holds great, then barely peeled off :(.

In order: From the beginning, the motor shield from the side of the engine must be glued with vibration isolation. I used Stardartplast's Bimast Bombs.

On it with a second layer of isoflex. He is self-reflecting.

Isolon will not give ANY soundproofing effect! Tested on myself, pasted over the hood effect zero!

Glued with a solution of mounting foam with acetone. Holds great, then barely peeled off :(.

And how to breed? Squeeze foam straight out of the can and solvent into it?

And how to breed? Squeeze foam straight out of the can and solvent into it?

Puff foam into a 2 liter plastic bottle and add acetone. Shake or stir with a stick. The foam turns into a yellow liquid. Viscosity does not really matter, excess acetone will evaporate. Further, as usual, with a brush. When dry, the glue foams a little.

P.S. Similarly, glue for plastics is made in acetone, the Pirogov filter cloth is dissolved (previously used) in the petals.

Puff foam into a 2 liter plastic bottle and add acetone.Shake or stir with a stick. The foam turns into a yellow liquid. Viscosity does not really matter, excess acetone will evaporate. Further, as usual, with a brush. When dry, the glue foams a little.

Expert answers

Wall:

yes, my friend used a glue gun or liquid nails

mixa petrov:

why not

Andrew B.:

Easy. Liquid Nails. But preferably not in the cold.

It is not possible, but it is necessary - with the help of mounting foam or special glue

E.S.:

Liquid Nails. Or polyurethane foam (frost-resistant).

log:

Counter question, what the hell? Heat-noise isolation? Can. Only it is necessary to use non-solvent-based adhesives, the foam will corrode. In principle, building sealant is also suitable, it is not aggressive. such here in tubes is on sale with the special gun. You can not buy a gun, but squeeze it out with a hammer handle, accuracy is not required here.

Irina Zvereva:

we glued. ok for 15 years now. They say mice love to live in Styrofoam, but so far we haven't seen...

Olka:

my husband also glued it with foam plastic in his garage, glued it on liquid nails, it seems to hold on for almost a year.

Ded:

So that it does not crumble for a long time, it is better to screw 5x5 cm bars, a bolt with a smooth head, a nut from the inside, drown it in wood, foam plastic between the bars, it is not necessary thicker. On top of the protruding bolts plywood. Makes a good, practical sandwich, good luck

penoplex must be used .. penoplex ... and glued on liquid air ..

Vladimir Fedorov:

Outside, you need to cover the foam, otherwise the destruction of the foam cannot be avoided.

Svetik:

Yes, it will crumble right away. It must be sewn up with something.

Boris Stepanov:

No problem - mastic for gluing ceiling tiles, liquid nails, glue moment, silicone sealant. This is what does not destroy the foam and allows you to get a relatively strong connection. Why is it relative - because the connection of two materials cannot be higher than the strength of the most fragile - in your case, foam. This is not the strength of the adhesive, but the strength of the connection. So you don't need very strong adhesives.

Scarifier:

You buy a dish-shaped dowel for thermal insulation, cut off the hat and fasten the penoplex through it with a long self-tapping screw in different places.

I WILL NOT GIVE UP TO DRINK BUT I WILL BE SMOKING:

What are big-head nails bad for?

Konstantin Brovko:

It is better and easier to glue with liquid foam or low expansion professional foam.

Tanyush_Ka_Kolyanovna__))):

liquid nails for polystyrene boards (transparent such, in a tube as a sealant)

Mounting features

Izolon (penofol) is covered with aluminum foil, which allows you to keep the heat in the best way. Its adhesion to the surface of the insulation can be chemical or physical, that is, cross-linked. Isolon may have additional characteristics such as thickness or color. If you are looking for a win-win insulation for your home, then this option will be the best choice. It is also perfect for insulating elements of air conditioning systems and pipelines, production mechanisms. Foamed polyethylene is used for both external and internal work. The material has quite significant advantages.

Among them are:

- small thickness;

- ease of installation;

- ecological cleanliness.

Installation of insulation is possible without the use of special tools. Working with polyethylene foam does not require additional protection of the respiratory tract and skin. The material is so light that the load-bearing capacity of the adhesive will not be critical.

Types of glue

Glue for penoplex is the consumable material, the acquisition of which should be treated with special attention, since the quality of the work performed depends on its composition. Gluing is best advised by experts to compounds such as ATLAS PLUS

This is a high quality blend that works with mineral based substrates. Glue is widely used in restoration work.You can glue the facade of the building, since the mixture perfectly withstands temperature changes, is resistant to high humidity. When used, you will leave a sufficient amount of glue, so the option is not economical

ATLAS PLUS is also highly praised by professionals. The indisputable advantages of the adhesive are its increased elasticity and adhesion. It is very convenient that this product can be glued even in damp rooms where the walls are not dry. These are complex surfaces on which this type of glue is easily applied.

The main representative of mineral adhesives is "Sarmat". A fairly versatile tool, the advantage of which is its low cost.

Among polyurethane mixtures, Titanium is often purchased, however, its cost is much higher.

It is also possible to carry out work on gluing penoplex with the "Moment". This universal tool has proven itself quite well among consumers. Glue "Moment" is able to glue quickly and efficiently.

When choosing an adhesive, it is important to understand that its composition should not contain substances hazardous to health such as benzene, formaldehyde, solvents. Working with such mixtures can be very dangerous.

In addition, when buying, it is best to choose a larger tube size, since the surface of the foam is often uneven, which leads to increased use of material and adhesive mixture.

Styrofoam properties

Proper fastening of foam sheets at the joints.

In addition to resistance to stress, moisture resistance and slight breathability can be noted. Styrofoam absorbs water only in microscopic doses. Given these properties when insulating basements, foam boards can be glued without damage to themselves, they are able to be in direct contact with the ground, do not decay, and mold and fungus do not form on them, no matter how damp the basement turns out to be.

Not to mention such useful properties as soundproofing, environmental friendliness, durability and flame retardancy. The foam is not subject to deformation and size change when interacting with dampness or under the influence of temperature factors. When sheathing the outer walls with it, it does not warp from heat and sunlight and does not deteriorate from constant contact with moisture. It is not subject to freezing and dampness. Now it becomes clear such popularity of this building material.

Styrofoam has a number of properties that make it a little more difficult to work with it.

It has low mechanical strength, therefore, if it is decided to glue the foam plastic, close attention should be paid to the smoothness and evenness of the surface on which it will be fixed. Protrusions and significant level differences will provoke fractures in the material

Styrofoam is easily destroyed upon contact with nitro-paint and paints and varnishes, so you need to pay special attention to the choice of the composition with which you will glue. https://www.youtube.com/embed/LMQsSpLU04w

What is foam

The second name of the foam is polystyrene foam. This is a soft material that consists of a plastic air mass. Its structure is cellular and has a white color. The cells are reliably separated from each other, so the material has good thermal insulation properties.

Styrofoam features:

- Good thermal insulation. This material retains heat very well and therefore it is used as wall insulation.

- Low level of toxicity.Due to this, polyurethane is safe, and it is used in various fields.

- Small mass.

- Moisture resistance. It resists moisture well, absorbs only 4% of moisture from the total volume.

- Resistant to parasites and mold.

- Simple processing. Due to the fact that it has a soft composition, it is easily cut with a saw and hot wire.

Kinds:

- Polystyrene. It consists of white granules, which are obtained by heat treatment of polystyrene. During this treatment, a blowing agent is used. The size of the granules is from 7 to 17 mm. The structure of the granules consists of closed cells that are 98% filled with gas.

- Polyurethane. This material is obtained by combining diisocyanates and polyesters. These substances are combined with pressure. The structure is not the same - the cells have different shapes and sizes. The cells are very closely adjacent to each other and due to this the density of the material is very high. The foam of this type has high strength and durability.

- Polyethylene. This material is flexible and elastic. Polyethylene has a small thickness - only 5 cm. This type of foam is used for packaging products.