Choice of built-in or external

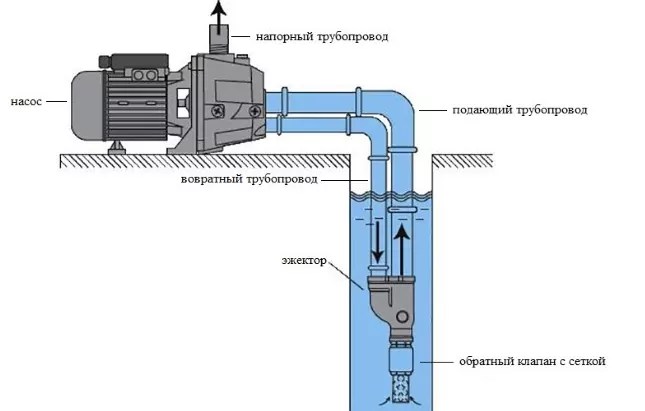

Depending on the installation location, remote and built-in ejectors are distinguished. There is no big difference in the design features of these devices, but the location of the ejector still affects in some way both the installation of the pumping station and its operation.

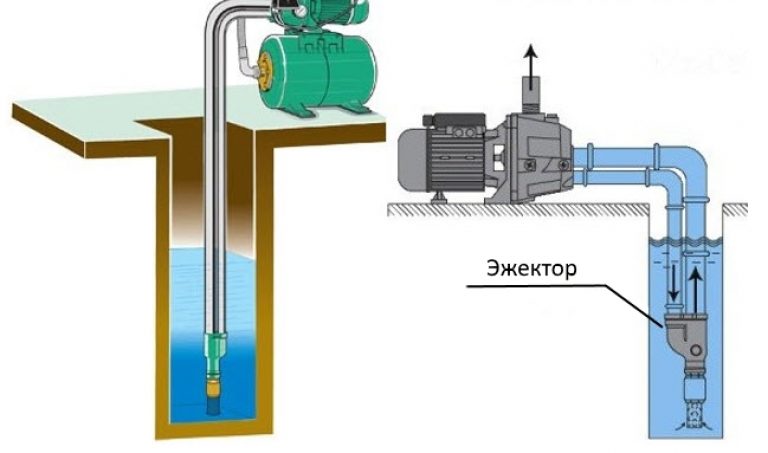

So, built-in ejectors are usually placed inside the pump housing or in close proximity to it. As a result, the ejector takes up a minimum of space, and it does not have to be installed separately, it is enough to perform the usual installation of a pumping station or the pump itself.

In addition, the ejector located in the housing is reliably protected from contamination. Vacuum and reverse water intake is carried out directly in the pump housing. There is no need to install additional filters to protect the ejector from clogging with silt particles or sand.

However, it should be remembered that such a model demonstrates maximum efficiency at shallow depths, up to 10 meters. Pumps with a built-in ejector are designed for such relatively shallow sources, their advantage is that they provide an excellent head of incoming water.

As a result, these characteristics are enough to use water not only for domestic needs, but also for irrigation or other business operations. Another problem is the increased noise level, since the sound effect from the water passing through the ejector is added to the vibration of the running pump.

If a decision is made to install a pump with a built-in ejector, then you will have to take care of sound insulation especially carefully. Pumps or pumping stations with a built-in ejector are recommended to be installed outside the house, for example, in a separate building or in a well caisson.

The electric motor for a pump with an ejector must be more powerful than for a similar non-ejector model.

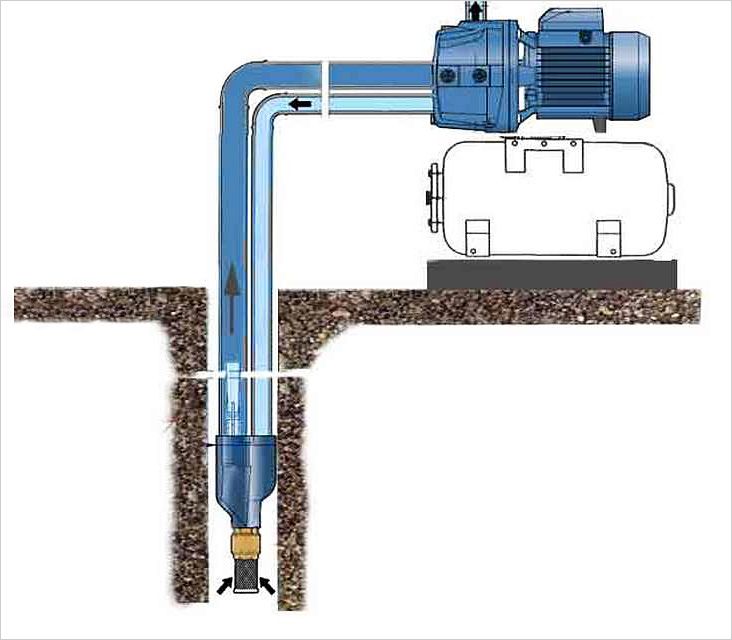

A remote or external ejector is installed at some distance from the pump, and this distance can be quite significant: 20-40 meters, some experts even consider 50 meters acceptable. Thus, a remote ejector can be placed directly in a water source, for example, in a well.

The external ejector not only increases the performance of the pump, but is designed to increase the depth of water intake from the source, which can reach 20-45 m

Of course, the noise from the operation of an ejector installed deep underground will no longer disturb the residents of the house. However, this type of device should be connected to the system using a recirculation pipe, through which water will return to the ejector.

The greater the installation depth of the device, the longer the pipe will have to be lowered into the well or well.

It is better to provide for the presence of another pipe in the well at the design stage of the device. Connecting a remote ejector also provides for the installation of a separate storage tank, from which water will be taken for recirculation.

Such a tank allows you to reduce the load on the surface pump, saving some amount of energy. It is worth noting that the efficiency of the external ejector is somewhat lower than that of the models built into the pump, however, the ability to significantly increase the depth of the intake forces one to come to terms with this drawback.

When using an external ejector, there is no need to place it directly next to a water source. It is quite possible to install it in the basement of a residential building. The distance to the source can vary within 20-40 meters, this will not affect the performance of pumping equipment.

Difference from injector

An ejector is a device in which kinetic energy is transferred from the working medium at high speed to the non-working, that is, passive medium, by means of their displacement.

Injector - device

where gases and liquids are compressed.

The main difference between these devices lies in the way energy is transferred to the passive medium. For example, in the injector, the supply occurs due to pressure, and in the ejector, the supply occurs due to the creation of a self-priming effect.

Almost everywhere you can connect an autonomous water supply to the house. However, the main problem is the depth of groundwater. If the water in the prepared well is at the level of 5-7 meters, then no special problems can be expected, because then you can use almost any type of pump that is suitable in terms of power and performance. If the water is much deeper, then an ejector for pumping stations comes to the rescue.

How to extend the life of the ejector

To extend the service life, pumping stations with an ejector must be operated in compliance with the following rules:

when installing the station, it is important to correctly calculate the ratio of the power of the device and the depth of the source from which water is extracted.

constantly monitor the pressure in the pipeline

To measure the pressure in the system, you can use a pressure gauge used for car tires or purchase a station with a special built-in sensor;

for sources with great depth, it is necessary to purchase a powerful pump, which must be installed as close as possible to the water intake;

the use of a built-in ejector is justified only at high power stations;

with a source depth of 15 to 40 meters, it is necessary to use a remote ejector installed inside the well and located in the water.

when using a surface type pump, it is important to correctly install the pipes coming from the surface of the ejector - strictly vertically. If the pipes are not properly positioned, air will enter the system, air pockets will form, which will negatively affect the operation of the system and reduce the duration of its operation.

Subject to all operating rules, ejector pumping stations operate smoothly and provide tap water to the house, irrigation and other equally important household needs.

Features of installation and operation

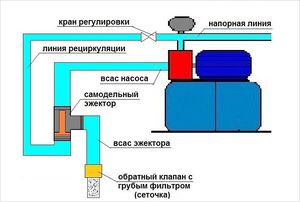

The operation of the ejector will be effective only on powerful pumps, at least 1 kW with high performance, and the installation depth of the ejector is not more than 20 m, installation deeper sharply reduces the efficiency of the ejector. To ensure that there are no failures during the operation of the pump with an external ejector, it is necessary to place the supply pipes to the ejector strictly vertically. Be sure to have a coarse filter in front of the pump, since such pumps are very vulnerable to abrasive particles that can damage the pump. Before the pump, on the recirculation pipeline, it is imperative to install a tap so that you can adjust the amount of return water, thereby adjusting the suction efficiency of the ejector.

Water supply station with ejector

Device. Operating principle

An ejector is essentially a device that transfers energy from one more mobile medium to another, which is less mobile. In the narrowing sections of the unit, a special zone of lower pressure is formed, which thus provokes the suction of an additional medium. Thus, there is a possibility of movement and removal from the suction points, due to the interaction of the original environment.

Units equipped with an internal format ejector are intended directly for specialized pumping of liquids from a relatively shallow type of wells, the depth of which does not exceed eight meters, as well as various specialized storage tanks or reservoirs.

The immediate distinguishing feature of this interaction is precisely the capture of liquids, which is located at a lower level from the nozzle. Based on this, preliminary filling of the unit with water will be required. The working wheel will pump the liquid, which will redirect it to the ejector, as a result of which an ejecting jet will be formed.

It will move along a specialized tube and accelerate. Naturally, the pressure will decrease. Due to this effect, it will also decrease inside the suction chamber.

One of the varieties of such surface units is a pumping station with an ejector. They differ in that the external element is immersed in a water supply source.

As a rule, the scope of such devices is similar to their counterparts. A definite difference lies in the different depths of use and application.

Ejector pumping station

A pumping station with a built-in ejector is a set of equipment originally designed to perform work under certain conditions. The main parameters that are taken into account when choosing are power and performance. The first characteristic means the ability to maintain pressure in the system, as well as the ability to hold a water column and transfer liquid over a distance through a horizontal pipeline.

The second characteristic is performance. This is the amount of fluid pumped per unit of time. This parameter cannot be greater than the flow rate of the well. If we are talking about buying a pumping station with a built-in ejector, then the technical documentation indicates the general output characteristics. This means that no additional calculations will have to be made.

The equipment is connected according to the attached instructions. The hoses are attached using the clamps included in the kit. The pipeline assumes a threaded connection. The main thing is to provide a place for installation so that rain and frost cannot disable the system. For this, a caisson is made or a separate building is built. The canopy is suitable only for summer cottages, not intended for year-round use.

A pressure gauge is installed as an additional equipment for a pumping station with an ejector, if this is not provided by the manufacturer. Thanks to this device, you can control the pressure in the pipeline. Naturally, it is installed at the exit from the station. If the well depth is within 15-40 meters, experts recommend installing a surface pump with an external ejector.

Wiring diagram

The best connection scheme provides for connecting the station to the ejector only with a vertical pipe. Otherwise, airing is possible, which leads to a decrease in system performance. If this is not possible, you need to take care of shut-off valves to bleed air if necessary.

How an ejector works

The principle of operation of the ejector is based on the movement of water in the pipe, which, getting into the smoothly tapering part of the ejector, increases its speed, as a result of which a zone with reduced pressure is formed, where water is sucked in from the outside. The remote ejector of the pumping station works by supplying water through the recirculation pipeline, the flow, entering the converging part, increases the speed, forming a zone with low pressure, where water begins to be sucked in from the outside to compensate for low pressure. In other words, the ejector pushes the water to a height from which the pump can already suck it up on its own.

The efficiency of the ejector is characterized by the ejection coefficient, which shows the amount of water sucked off per unit amount of recirculated water. In our case, the ejection coefficient for water is 0.12, that is, with a water flow rate in the ejector of 1000 l / h, the ejector will suck in about 120 l / h.

Choice of built-in or external

Depending on the installation location, remote and built-in ejectors are distinguished. There is no big difference in the design features of these devices, but the location of the ejector still affects in some way both the installation of the pumping station and its operation.

So, built-in ejectors are usually placed inside the pump housing or in close proximity to it. As a result, the ejector takes up a minimum of space, and it does not have to be installed separately, it is enough to perform the usual installation of a pumping station or the pump itself.

In addition, the ejector located in the housing is reliably protected from contamination. Vacuum and reverse water intake is carried out directly in the pump housing. There is no need to install additional filters to protect the ejector from clogging with silt particles or sand.

However, it should be remembered that such a model demonstrates maximum efficiency at shallow depths, up to 10 meters. Pumps with a built-in ejector are designed for such relatively shallow sources, their advantage is that they provide an excellent head of incoming water.

As a result, these characteristics are enough to use water not only for domestic needs, but also for irrigation or other business operations. Another problem is the increased noise level, since the sound effect from the water passing through the ejector is added to the vibration of the running pump.

If a decision is made to install a pump with a built-in ejector, then you will have to take care of sound insulation especially carefully. Pumps or pumping stations with a built-in ejector are recommended to be installed outside the house, for example, in a separate building or in a well caisson.

The electric motor for a pump with an ejector must be more powerful than for a similar non-ejector model.

A remote or external ejector is installed at some distance from the pump, and this distance can be quite significant: 20-40 meters, some experts even consider 50 meters acceptable. Thus, a remote ejector can be placed directly in a water source, for example, in a well.

Of course, the noise from the operation of an ejector installed deep underground will no longer disturb the residents of the house. However, this type of device should be connected to the system using a recirculation pipe, through which water will return to the ejector.

The greater the installation depth of the device, the longer the pipe will have to be lowered into the well or well.

It is better to provide for the presence of another pipe in the well at the design stage of the device. Connecting a remote ejector also provides for the installation of a separate storage tank, from which water will be taken for recirculation.

Such a tank allows you to reduce the load on the surface pump, saving some amount of energy. It is worth noting that the efficiency of the external ejector is somewhat lower than that of the models built into the pump, however, the ability to significantly increase the depth of the intake forces one to come to terms with this drawback.

When using an external ejector, there is no need to place the pumping station directly next to the water source. It is quite possible to install it in the basement of a residential building. The distance to the source can vary within 20-40 meters, this will not affect the performance of pumping equipment.

Ejector design option 1

The simplest ejector can be assembled on the basis of a tee and a fitting - these parts will perform the function of a Venturi tube in a very simplified version. Shaped elements for the ejector can be used from various materials (metal, plastic). In this case, the ejector design is assembled from a brass tee and push-in fittings for metal-plastic pipes.

The diameter of the fittings for the design of the ejector is taken depending on the performance of the pumping station and the diameter of the suction and recirculation pipelines, the diameter of the suction pipeline cannot be less than 25 mm. In our design, a tee with a diameter of 20 mm will be used with a 26 mm suction pipe and a 12.5 mm recirculation pipe connected to it.

- Tee ½" mm.

- Fitting ½ "mm and with a 12 mm outlet.

- Adapter 20×25 mm.

- Angle 90º (external/internal) for metal-plastic pipe ½"×16 mm.

- Angle 90º (outer/inner) for a metal-plastic pipe ¾ "×26 mm.

- Angle 90º (external/internal) ¾"×½".

The lower base of the resulting cone should have a diameter a few millimeters smaller than the outer thread diameter of the fitting, and its thread must also be shortened so that a maximum of four turns remain. With the help of a die, you need to drive the thread and cut a few more turns on the resulting cone.

Now you can assemble the ejector. To do this, we screw the fitting (2) with a narrow part inside the tee (1) so that the fitting extends 1–2 mm beyond the upper edge of the side branch of the tee, and so that at least four turns remain on the internal thread of the tee in order to be able to screw the branch (6). If the remaining free thread of the tee is not enough, it will also be necessary to grind off the threads of the fitting; if the length of the fitting is not enough, you can put a piece of the tube on it. A non-return valve must be connected to the outlet (5) through which water will be sucked in, so that when the system is started, water does not spill out of the suction and recirculation water supply, otherwise the system will not start. You also need to seal all threaded connections with any sealant.

Such an ejector will not have a high ejection coefficient due to the imperfect design of the Venturi tube, so it can be used to lift water from a depth of no more than 10 m.

Jet pumps

The procedure for connecting the ejector as an independent device consists of two stages:

- An additional pipe is being laid according to all the rules that were taken as the basis for the installation of a pipeline for water supply. An additional pipe is needed to supply the injection medium.

- Connecting the nozzle to the suction unit. It is required to mount a coarse filter and a return pipe. It is recommended to install a valve to regulate the operation of the system.

A valve is required if the water level in the pit is higher than that for which the pump is designed. In this case, the discharge flow can be adjusted.

Features and principle of operation of the installation

At the plants for the production of equipment for water disposal, 2 types of pumping equipment are manufactured - with an internal and external ejector pump.

Devices with an internal ejection device pump out water from shallow (8 m or less) wells, reservoirs and wells.

A feature of such equipment is the presence of the "self-priming" function, as a result of which the water level is regulated, which is below the level of the inlet pipe.

In this regard, before turning on the device, it is necessary to fill it with water.

After the device is filled with water and turned on, the impeller of the installation with an internal ejector pump sends water to the ejector inlet, thus forming the necessary jet. It moves along a thin tube and the water pressure becomes faster.

When the pipe is connected to the inlet, water begins to flow to the station.

The water then enters the chamber, which sucks in the liquid. In this case, the water pressure becomes less and the liquid flows through the diffuser to the outlet, slightly increasing the flow rate.

A device that uses an external ejector for a pumping station differs from an internal ejector pump in that it is used only at a depth of 10 m or more.

It is also difficult to install external ejector pumps on these devices. The pipes that connect the pumping devices to each other are installed only in a vertical position. Otherwise, a lot of air will enter the inlet line and it will stop working normally.

The best option for using devices with a remote ejector is the installation of the device at a depth of 20 m. With an increase in the lifting height, its performance decreases.

As a result, the external pumping device has a lower efficiency than the internal one.

Pumping station with remote ejector

Manufacturing

A fairly simple device-unit is quite possible to manufacture by independent forces. Which will require some parts, such as a tee of a specialized diameter and a fitting that will be located inside it. The correct length ratio must be observed, which should not be more or less, which will not allow such a device to function normally. For fastening, you will need a special adapter equipped with corners, which will allow you to form the desired turn.

The creation process provides for several specific points, which includes the process of preparing the required fitting itself. A part of a special 6-sided sample should be turned, which will make it possible to place a special cone from it, having a base smaller than the external thread in diameter. After that, the deformed part should be corrected with a specialized thread-cutting tool.

The fitting must be screwed into the tee piece until it stops. Be extremely careful when connecting the length ratio, which is quite an important factor. Be sure to seal the connection with any available sealant.

Check the ratio of manufactured parts, and then a specialized adapter should be organized from pre-prepared samples, which is designed to be equipped on a pipe.

A well-assembled station will provide a fairly long and trouble-free operation, thanks to its simple constructiveness, but, of course, you must be extremely precise in manufacturing. If you don’t really want to engage in such manufacturing, then you can simply purchase it in specialized stores, where there is always a pumping station for free sale.

Device Features

The device of the ejector is very simple, it can even be assembled by hand from ordinary materials. The design of the device consists of such parts as:

- Diffuser;

- Node to offset;

- Water suction chamber;

- Nozzle narrowed down.

vacuum. The liquid, passing through the nozzle, narrowed down according to its design, gradually increases the speed. After that, the liquid, getting into the mixer, creates a low pressure in it. Thus, the pressure of the liquid that enters the mixer through the water suction chamber is greatly increased.

It is also worth noting that for the ejector to work properly, it must be installed on the pump so that some of the liquid that rises with the pump remains inside the device, or rather, the nozzle, creating the necessary pressure constantly

. It is thanks to this principle of operation that it is possible to maintain a constant accelerated flow. The use of such a device can significantly save energy.

3 Device and types of ejector pumping stations

Ejectors on the water intake unit can be installed in 2 ways. The first implies that the ejector is one of the constituent elements of the design of the pumping station. In the second case, the ejector is an external node.The choice of a particular option will depend, first of all, on the requirements that apply to the water intake installation.

3.1

Built-in ejectors

This option implies that the creation of pressure for the ejector is carried out in the installation itself. Due to this, the dimensions of the pumping unit can be significantly reduced. Pumping stations with a built-in ejector are almost immune to the presence of various kinds of small particles in the water.

That is, there is no need to filter the water. This type of water intake installations is mainly used for taking water from a depth of more than eight and a half meters. Allows you to create a pressure of the necessary power to provide a garden plot of large sizes, where water is used mainly for irrigation.

However, pumping stations with built-in ejectors have such a disadvantage as an increased noise level during operation. For this reason, it is not recommended to install this type of water intake in the immediate vicinity of a residential building.

It is best if such an installation is mounted in a separate utility room. The electric motor for this type of pumping installation should be selected in such a way that it can provide the necessary water circulation system.

3.2

External ejectors

When using an external ejector, an additional water collection tank must be installed separately from the water intake unit. In such a tank, the pressure necessary for the operation of the system and additional discharge will be created, which, in turn, will significantly reduce the degree of load exerted on the pumping unit. The external ejector itself should be connected to the immersed part of the plumbing system.

To ensure the normal functioning of the external ejector in the well, it will be necessary to lay two pipes, however, this may impose certain restrictions on the allowable diameter. This constructive solution, despite the fact that it reduces the efficiency of the water supply system by about thirty-five percent, allows pumping water from a depth of up to fifty meters and significantly reduces the noise level during the operation of the pumping unit.

It has absolutely no effect on the degree of efficiency. This is what explains such a wide popularity of this type of water intake stations among the population. All equipment is located in one place, which significantly increases the operating period, greatly simplifies the process of carrying out various kinds of preventive maintenance and setting up the plumbing system.

Types of ejectors at the installation site

When purchasing an ejector to equip a pumping station, keep in mind that such a device can be built-in and external. The device and principle of operation of these two types of ejectors are practically the same, the differences are only in the place of their installation. Built-in ejectors can be placed in the inside of the pump housing, or mounted in close proximity to it. The built-in ejection pump has a number of advantages, which include:

- minimum space required for installation;

- good protection of the ejector from contamination;

- no need to install additional filters that protect the ejector from insoluble inclusions contained in the pumped liquid.

Centrifugal pump with integrated ejector

Meanwhile, it should be borne in mind that built-in ejectors demonstrate high efficiency if they are used to pump water from sources of shallow depth - up to 10 meters.Another significant disadvantage of pumping stations with built-in ejectors is that they emit quite a lot of noise during their operation, so it is recommended to locate them in a separate room or in a caisson of an aquifer. It should also be borne in mind that this type of ejector device involves the use of a more powerful electric motor that drives the pumping unit itself.

A remote (or external) ejector, as its name implies, is installed at a certain distance from the pump, and it can be quite large and reach up to fifty meters. Remote-type ejectors, as a rule, are placed directly in the well and connected to the system through a recirculation pipe. A pumping station with a remote ejector also requires the use of a separate storage tank. This tank is necessary in order to ensure the constant availability of water for recirculation. The presence of such a tank, in addition, allows you to reduce the load on the pump with a remote ejector, and reduce the amount of energy required for its operation.

Pump with external ejector

The use of remote-type ejectors, the efficiency of which is somewhat lower than that of built-in devices, makes it possible to pump out a liquid medium from wells of considerable depth. In addition, if you make a pumping station with an external ejector, then it can not be placed in the immediate vicinity of the well, but mounted at a distance from the source of water intake, which can be from 20 to 40 meters

At the same time, it is important that the location of pumping equipment at such a considerable distance from the well will not affect the efficiency of its operation.

Conclusions and useful video on the topic

In this video, the issue of the suction depth of a surface pump and options for solving the problem using an ejector are discussed in detail:

The principle of operation of the ejector is clearly demonstrated here:

The ejector is a simple but very useful device. This is a convenient and practical way to improve the performance of pumping equipment in a private house. But the installation of the ejector, especially the remote model, must be done correctly, this is the only way to ensure a noticeable increase in water pressure.

Everyone interested in the issue of choosing and connecting an ejector, we invite you to join the discussions and leave comments on the article. The comment form is below.

An ejector is a device within which kinetic energy is transferred from inlet to outlet, increasing the exit velocity. The ejector is designed in such a way that it works according to Bernoulli's law and in most cases it is designed for jet pumps. This device is designed to modernize the water supply system when supplying water from a great depth.