How to bend plastic pipes using a pipe bender

In the process of assembling the pipeline, it is often necessary to bend the pipe. If metal-plastic products are used for installation, then this work is not a very difficult task. Metal-plastic is a plastic material, but when working with it, a number of rules must be applied. We will figure out how to bend metal-plastic pipes.

Metal-plastic is often used for the installation of engineering systems of residential buildings. This material is suitable for the installation of plumbing, ventilation and heating systems. Do-it-yourself bending of metal-plastic pipes is not a very difficult task, however, if this work is done incorrectly, this can lead to product failure due to deformation.

Pipe bending is a process during which the position of the central axis of the product changes. In this case, a tensile stress is created on the outer wall, and a compressive strain is created on the inner wall.

The pipe should be bent, maintaining the optimum bending radius. This indicator depends on:

- pipe size;

- ratio of inner and outer diameters.

What fixtures are used?

It is not difficult to manually bend the pipe at home, but at the same time, the risk of spoiling the workpiece is too great. Therefore, it is necessary to use a pipe bender for metal-plastic pipes. This device is:

- mechanical;

- with hydraulic drive;

- electromechanical.

The use of a pipe bender allows you to bend metal-plastic without damage. Advantages of using the equipment:

- extremely low risk of spoiling the workpiece;

- simple use;

- the ability to perform bending on products of various sizes.

Hydraulic

The hydraulic model is significantly more expensive than the spring pipe bender, but it is much easier to work with. This model is equipped with a built-in pump, thanks to which it is not necessary to exert great physical effort to bend.

The pipe bender has a durable metal housing that provides protection for the hydraulic part of the device. The operator controls the operation of the device using a lever. There are models of pipe benders with an open or closed frame.

Expensive models of pipe benders are equipped with an electric hydraulic pump, cheaper options have a manual hydraulic drive. The second option is convenient in that it can be used without being connected to a power source.

Another version of the pipe bender is called the crossbow. There are three types of such devices:

- winding;

- running in;

- reference.

When using a device of the first type, the bent segment is pressed against a roller having a certain size. The larger the working roller diameter, the larger the bending radius will be. When the device is turned on, the roller begins to rotate, winding the bent segment of the metal-plastic pipe until the desired degree of bending is obtained.

Three rollers are installed in equipment of this type, one of them is clamping, it is he who exerts pressure on the pipe and creates a bend. The other two rollers are supporting. Equipment of this type is used if it is necessary to bend a large-sized metal-plastic product.

So, before starting the assembly of the pipeline, you need to learn how to bend a metal-plastic pipe at home. To perform this work, it is worth using a simple spring pipe bender.

Professional equipment with a hydraulic drive is expensive and it is not rational to purchase it for performing one-time work.

The use of a spring pipe bender allows you to bend metal-plastic products as quickly and simply as possible.

Standard requirements for bending radius

When bending pipe elements, their walls should not change their profile, cross section and throughput (change in inner diameter) - this is achieved due to a certain turning radius, which is set by the standards.

When determining the minimum limits of rounding, the methods for obtaining it are taken into account - the best downward indicators are provided by mandrel pipe benders with winding technology and heat treatment, which makes it possible to reduce the size of the circle.

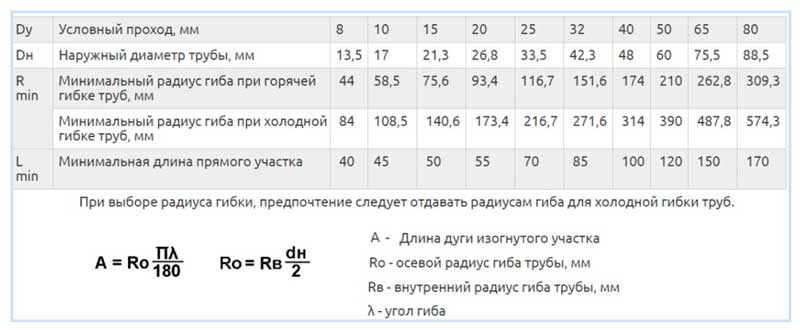

The indicator also depends on the material of manufacture and the dimensions of the product: outer diameter (Dn) and wall thickness (S), the tables also show the length of the straight section, which is necessary to obtain the indicated values.

When working, it is important to know the dimensions of the fragment on which these radius values \u200b\u200bare obtained - they are calculated by summing the lengths of two straight sections and an arc calculated using a special formula

Rice. 2 Minimum pipe bending radius of steel pipelines and arc length calculation

The data given in the tables guarantee, subject to the dimensional parameters, the required GOST ellipse and ovality up to 12.5%.

According to GOST 17365-71V for pipelines for aggressive environments, the following minimum pipe bend radius is indicated:

- for elements with outer diameter D up to 20 mm. – not less than 2.5 D;

- at D, more than 20 mm. the radius must not be less than 3.5 D.

In this case, the thinning of the walls in the bend zone should not exceed 20% for steel and 25% for aluminum.

Application hydraulics advantages

In many manual and almost all industrial pipe bending units, a hydraulic drive is used, which has the following advantages over a mechanical screw:

- stepless supply of the drive to the bent product;

- the ability to develop large static forces in reciprocating motion, unattainable when using only electric drives;

- small dimensions of the main units;

- high speed;

- reliability and durability;

- lack of rubbing nodes and good lubricity.

Rice. 10 Bending method of steel metal billet

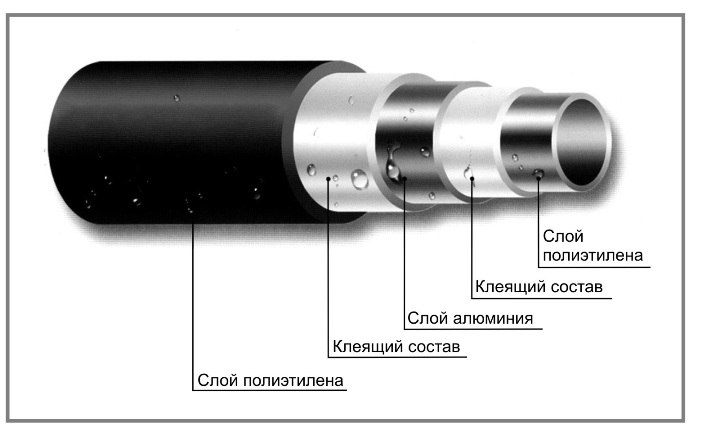

The structure of metal-plastic pipes

The basis of the metal-plastic pipe is a layer of polyethylene. It is he who provides the high strength of such products, so that the pipe can perform a bearing function. With the help of an adhesive composition, aluminum foil is attached to the polyethylene layer, which, when using a pipe, will prevent the diffusion of oxygen. The edges of the pipe are welded end-to-end with a laser. The linear expansion temperature of pipes produced in this way becomes comparable to that of metal pipes. Protective and decorating functions are performed by the outer layer of white color, which is polyethylene.

Thus, a metal-plastic pipe is a structure consisting of the following layers:

- polyethylene layer,

- layer of glue

- aluminium foil,

- another layer of adhesive

- outer layer of polyethylene.

The structure of the metal-plastic pipe

The unique multi-layer construction of these products ensures a long service life. Cross-linked polyethylene, which makes up the inner layer, allows you to create the necessary level of smoothness of the inner surface and protect the pipe from scale and other deposits, so the inner diameter of the metal-plastic pipe remains unchanged under normal operating conditions. Thanks to two polymer layers, the aluminum core is reliably protected from the formation of galvanic pairs with brass and steel pipeline elements. In addition, polyethylene layers reduce the thermal conductivity of pipes and the intensity of formation of condensate on their surface.

Methods for bending a square metal profile

Bending a profile of a square or rectangular section, although it is used in industry, a bent metal profile is more in demand in everyday life.When constructing greenhouse floors, an arched profile is required, which can be made using a simple device. The principle of operation of this device consists in rolling a profiled blank through a system of three rotating rolls, the two outermost of which are stationary, and the third one moves in the longitudinal direction, setting the bending angle.

If it is necessary to obtain a smaller radius of curvature in a rectangular profile, use thermal heating of the metal profile with a blowtorch or gas burner with simultaneous physical impact.

Rice. 6 Lever bends in manual fixtures

Characteristics of metal-plastic products

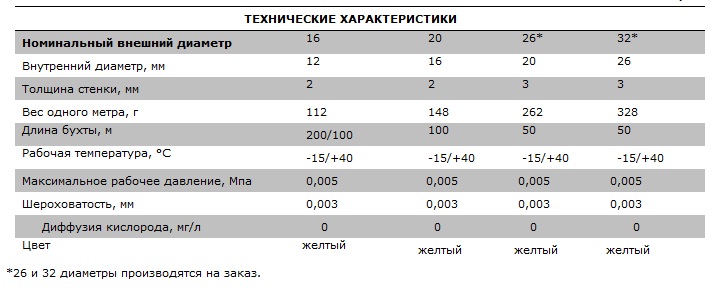

Main technical characteristics

- The wall thickness of a pipe with a diameter of 16 mm is 2 mm, and a pipe with a diameter of 20 mm is 2.25 mm. At the same time, the aluminum layer in such products is 0.2 mm and 0.24 mm, respectively.

- 1 linear meter of a 16 mm pipe weighs 115 g, a 20 mm pipe weighs 170 g.

- 1 linear meter of a pipe with a diameter of 16 mm contains 0.113 liters of liquid, and a 20 mm pipe contains 0.201 liters.

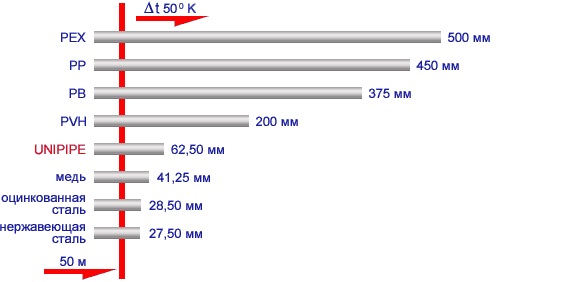

- The expansion coefficient of metal-plastic pipes is 0.26x10-4 per 1 degree.

Thermal expansion of metal-plastic is 10 less than that of PEX pipes

- The surface roughness coefficient is 0.07.

- Such pipes are characterized by a thermal conductivity coefficient of 0.43 W / m * K.

- Adhesive and welded joints with aluminum are respectively 70 and 57 N/mm2.

- With a transverse rupture, the strength index will be 2880 H.

- The minimum bending radius of a 16 mm pipe by hand is 80 mm, and that of a 20 mm pipe is 45 mm.

- The diffusion of oxygen during the operation of such products is characterized by an indicator equal to 0 g/m3.

Technical characteristics of pipes of various diameters

Permissible temperature and pressure

The pressure that pipes made of metal-plastic can withstand should be specified separately:

The operating temperature is in the range of 0-95 degrees at a pressure in the pipeline of 10 bar. The operating temperature is limited to 0 and 25 degrees if the liquid is supplied under a pressure of 25 bar.

- The maximum working pressure at the upper temperature threshold of the working medium is 10 bar.

- Violation of the integrity of the pipeline at a medium temperature inside the pipe of 20 degrees is 94 bar.

Conditions under which the service life of pipes is maximum

If the temperature and pressure remain unchanged, then the service life of metal-plastic pipes is:

- for 1 hour at t=20 degrees and a minimum pressure of 5.71 MPa,

- for 1 hour at t=95 degrees with a minimum pressure of 3.3 MPa,

- for 100 hours at t=95 degrees with a minimum pressure of 2.93 MPa,

- for 1 thousand hours at t=95 degrees with a minimum pressure of 2.57 MPa.

It is worth noting the resistance to high temperatures, which metal-plastic pipes possess: the characteristics of the products remain stable even with short-term heating to 110 degrees.