The feasibility of using automatic and manual switching between two boilers

Consider the following five options with different units in conjunction with an electric boiler, which is in reserve and must turn on at the right time:

- Gas + Electric

- Firewood + Electric

- LPG + Electro

- Solar + Electro

- Pellet (granular) + Electro

Pellet and electric boiler

The combination of connecting two boilers - a pellet boiler and an electric boiler - is best suited for automatic switching on and manual switching is also allowed.

The pellet boiler may stop due to the fact that it has run out of fuel pellets. It got dirty and wasn't cleaned. The electric must be ready to turn on instead of the stopped boiler. This is only possible with automatic connection. Manual connection in this option is only suitable if you permanently live in a house where such a heating system is installed.

Boilers for diesel fuel and electricity

If you live in a house with such a system for connecting two heating boilers, a manual connection is quite suitable for you. The electric boiler will work as an emergency in case the boilers fail for some reason. Not just stopped, but broken and in need of repair. It is also possible to switch on automatically as a function of the time. The electric boiler can work in pairs with liquefied gas and a solar boiler at the night rate. Due to the fact that the night rate is cheaper for 1 kWh than 1 liter of diesel fuel.

Combination of electric boiler and wood burning

This combination of connecting two boilers is more suitable for automatic connection and less for manual connection. The wood burning boiler is used as the main one. It heats the room during the day, and the electric turns on to heat it up at night. Or in the case of a long stay in the house - an electric boiler maintains the temperature so as not to freeze the house. Manual is also possible to save electricity. The electric boiler will turn on manually when you leave and turn off when you return and start heating the house with a wood-fired boiler.

Combination of gas and electric boilers

In this combination of connecting two boilers, the electric boiler can act both as a backup and as a main one. In this situation, a manual connection scheme is more suitable than an automatic one. The gas boiler is a proven and reliable unit that can work for a long time without breakdowns. In parallel, it is not advisable to connect an electric boiler to the system for safety net in automatic mode. In the event of a gas boiler failure, you can always turn on the second unit manually.

Connecting the electric boiler to the heating system

An electric heating boiler is a simple device, the “composition” of which includes a heat exchanger, a metal container and a controller. Its peculiarity lies in the fact that electricity is converted into heating the coolant (water, oil or antifreeze), and not solid fuels.

Today, such devices are widely used for heating offices, warehouses, garages, shops. The electric boiler is also popular as a component of the heating system in a private house. This is primarily due to the ease of use of the device. However, such a heat generator has other advantages:

- The power control system allows you to adjust the temperature in the house as accurately as possible;

- Silent;

- Works only on electricity, therefore, absolutely environmentally friendly;

- Safe due to the absence of open fire;

- Such a boiler is devoid of mechanisms that directly affect each other, which means it is resistant to wear;

- Compact;

- Does not require constant attention;

- Efficient (efficiency is 100%);

- Does not require special permission for self-installation.

The only negative is that it often malfunctions during a power outage or power outages. In addition, already at first after the purchase, the question arises: “How to connect an electric heating boiler?”. You can do this without the help of a master, with your own hands, given a number of features.

Wiring diagram for two manual boilers

Nothing is required here, except for shut-off valves. Switching between boilers is carried out by manual opening / closing of two taps located on the coolant. And not four, in order to completely cut off the idle boiler from the system. Both boilers most often have built-in expansion tanks and it is more profitable to use both of them at the same time, because the volume of the heating system very often exceeds the capacity of one expansion tank taken separately. In order to avoid the useless installation of an additional (external) expansion tank, it is not necessary to cut off the boilers from the system completely. It is necessary to block them according to the movement of the coolant and leave them simultaneously included in the expansion system.

Connection nuances and strapping schemes

Before performing the calculation of the heat supply scheme, a thermal calculation and the choice of equipment for an electric boiler for heating are carried out. Here, the control indicator is the temperature difference of the coolant at the inlet and outlet of the boiler.

Technologically, the process proceeds in such a way that initially the network water moves along a small circuit in order to obtain the operating temperature of the hot medium, then it moves to consumers along the main heating circuit to provide the required internal air temperature at the facility. Therefore, in order to fulfill all technological conditions, it is necessary to tie several circuits.

Typical projects for piping heating EC are provided for the following options:

- with forced circulation circuit;

- with a natural contour of the movement of hot water;

- classic wiring harness scheme;

- using primary-secondary rings.

Tying an electric boiler with a natural hot water circuit

Tying an electric boiler with a natural hot water circuit

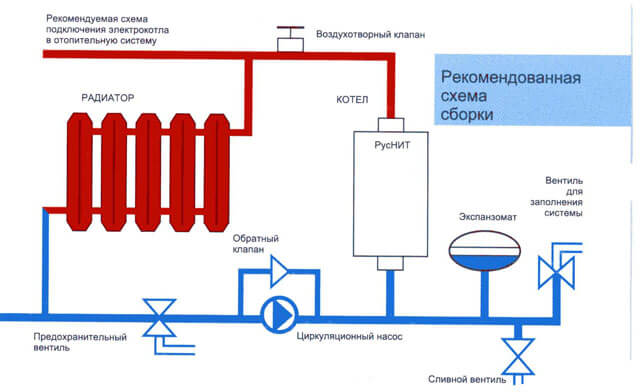

Electric boiler piping scheme

When performing the piping scheme, it should be borne in mind that in addition to calculating the power for an electric heater, one must not forget about its main purpose - to control the temperature drop of the liquid at the device inlet and outlet.

Initially, after reaching a certain temperature, the coolant moves along a small circuit, and only after it has passed, the heated water is transported through the system, heats the electric batteries and thereby heats the room. Thus, in order to ensure the necessary temperature conditions and the high-quality functioning of the heating structure, several circuits must be mounted.

To complete the binding you will need:

- pipes of different diameters;

- heating radiators (read: "Tying heating radiators with polypropylene - simple and affordable");

- circulation pump;

- manometer;

- balancing crane;

- distribution valve;

- pass filter.

Of the equipment and tools, a welding machine and wrenches should be available.

As for additional and fasteners, then of them you will need:

- tees, adapters;

- safety, check, air valves;

- bolts, nuts, couplings.

The piping of an electric heating boiler is carried out according to one of four different principles:

- with forced circulation of water;

- with natural circulation of the coolant;

- classic version of the wiring;

- using primary-secondary rings.

The space heating system with natural water circulation consists of:

The scheme providing forced circulation includes the following elements:

- room temperature controller;

- radiators;

- electric boiler;

- expansion tank of open type;

- safety block consisting of a safety valve and a pressure gauge;

- tap to replenish the amount of coolant;

- pump;

- check valve;

- anti-condensate pump;

- minimum temperature sensor.

If the heating structure operates using a wall-mounted electric heater, then all its elements are also included in the piping, which, in addition to heat supply, can provide hot water supply and the operation of the “warm floor” heating system.

The process of connecting equipment according to the instructions is not a problem if all the instructions written in it are followed exactly. But self-assembly applies exclusively to single-circuit systems. In the case when it is planned to install a double-circuit electric heating boiler. the work is complex and then the strapping is done at a professional level, both direct and mixing. Both types of piping are needed to control the temperature level. How to make a boiler piping, see the detailed video:

Useful features and disadvantages

It is also worth considering installing a universal solid fuel boiler with built-in electric heaters. Some models even have a hob, which does not require additional external finishing.

Electric boilers can easily endure a power outage for up to 6 months. This makes them a good option in case of irregular use of the system or in the event of power outages needed to heat a private house.

The disadvantage of using an electric boiler is the need for powerful supply cables with a large cross section.

Rules for the assembly and operation of a system in which an electric boiler with a solid fuel boiler

A few rules that must be observed when installing the heating system shown here.

1. Before starting the solid fuel boiler, turn on the circulation pump.

2. Check valves are a must! (see diagram)

3. At least part of the radiators must be left without thermal heads, so that, in the event of a coolant circulation interruption, the boiler (solid fuel) does not overheat.

4. Pipes from a solid fuel boiler to tees are used only metal (steel or copper).

5. It is IMPOSSIBLE to regulate the operation of the circulation pump of a solid fuel boiler using a room thermostat! This pump must always be on.

6. The same in other words: the room thermostat can only be controlled by an electric boiler.

Well, here, it seems, that's all, an electric boiler with a solid fuel boiler was installed. (It would be just as fast in practice :)). In the next article, we will do the same for a system with several branches of radiators.

The two-boiler scheme has been very widely used recently, and there is quite a lot of interest. When two thermal units appear in one boiler room, the question immediately arises of how to coordinate their work with each other. Let's try to answer the question of connecting two boilers to one heating system.

This information will be of interest to those who are going to build their own boiler house, who want to avoid mistakes and for those who are not going to build with their own hands, but want to convey their needs to those people who will assemble the boiler house. It is no secret that each installer has his own ideas about how the boiler room should look and often they do not coincide with the needs of the customer, but the customer's desire is more important in this situation.

Let us analyze examples of why in one case the boiler room operates in automatic mode (the boilers are coordinated among themselves without the participation of the consumer), and in the other it is required that it be turned on.

Features of connecting an electric boiler

On the one hand, the installation of a heating boiler cannot be called a very difficult job, and on the other hand, the arrangement of a home heating system requires compliance with a certain technology for installing an electric boiler. The advantages of the electric boiler shown in the photo over other types of heating devices are that it can be installed at any point in the heating system, and it will function well, but subject to the correct piping of this heating device, according to the connection diagram of the electric heating boiler.

The electric boiler works equally effectively in designs with natural and forced circulation of the liquid heat carrier. The appliance should be installed at the lowest point of the electrical heating system. thereby achieving the highest level of battery warm-up. The supply pipe must be positioned at a minimum height.

Regardless of the heat supply scheme with an electric boiler, it must necessarily have a device grounding. The device can be connected to the electrical panel, but the zero phase must not be used. This is not just dangerous: the equipment perceives such actions as a short circuit. Proper connection of the electric boiler to the network is one of the conditions for the reliable operation of the heating system. It is also necessary to select high-quality components, and besides this, you need a professionally executed piping of an electric heating boiler. Properly done work will provide a slight difference in the temperature of the heat transfer fluid at the inlet and outlet of the device. For this, the correct placement of the electric boiler with its subsequent connection is of great importance (read: “Connecting the electric boiler to the heating system: instructions“). Only if these rules are observed, the coolant will be able to give heat to the radiators as efficiently as possible.

Where to install and how

Different models have different power, which affects what kind of line they need. According to this criterion, two types of electric boilers are distinguished today: floor and wall. The first type is distinguished by high power (more than 60 kW), the second, respectively, is smaller (from 5 to 60 kW).

Important: for any type of power generator with a power of more than 12 kW, a three-phase network is required. In other cases, a two-phase

In addition, during installation, the lower pipe must be located below the radiator so that water (oil or antifreeze) does not linger in the system.

As for the installation site, it can be any room, the main thing is that the device always has unhindered access. However, as practice shows, most often they choose a kitchen or some non-residential premises for this. Much more important is the absence of combustible materials on the wall where the boiler will hang. If you doubt that you understood everything correctly, we advise you to find a suitable video and check this information with a good example.