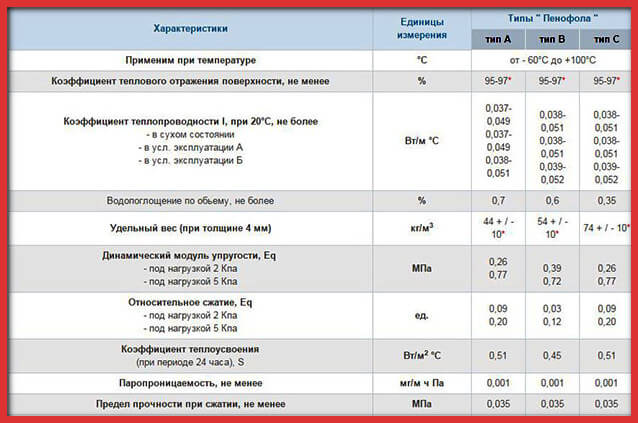

Specifications Penofol

The material has waterproofing properties, as well as low thermal conductivity. Some types of Penofol, for example, type "A" products are highly specialized, and are suitable for rooms with an average room temperature.

The main technical characteristics of Penofol insulation:

- Thickness. The thickness of the material is directly proportional to the level of thermal conductivity. Penofol is available in the following thicknesses: 3, 4, 5, 8 and 10 mm. Most often, a heater is used, the thickness of which is 1 cm. Such material retains heat in the room for a long time and has increased sound insulation.

- Thermal conductivity. An important indicator for every heater. The basis of the material is 2 characteristics: absorption and reflection of heat flow. The aluminum surface reflects more than 90% of the heat in the opposite direction. Insulation with a thickness of 0.5 cm in terms of thermal conductivity corresponds to a mineral wool slab, the thickness of which must be at least 1 cm.

- Resistance to prolonged exposure to moisture. Penofol does not absorb liquid, regardless of external or internal installation. The resistance to moisture is not affected by the temperature regime, the change of day or season.

- vapor permeability class. It is 0.001 mg/(m h Pa), which is quite low. Therefore, for this insulation it is not necessary to use an additional layer of vapor barrier. The material perfectly retains any level of evaporation.

- Sound transmission. Penofol has a high level of sound transmission, even class "A" with a single layer of aluminum, has a sound transmission of 32 dB. Installing insulation on top of the material used (for example, wall paneling) will only improve the sound insulation in the room.

- Flammability. An important safety criterion for any category of insulation. When exposed to fire, Penofol melts rather than burns, while releasing carbon dioxide. In case of prolonged ignition, carbon monoxide of a weak consistency may appear.

Insulation Penofol meets all established operating criteria. It can be laid both under the main building material and on top of it. It is used in wooden, brick, concrete and clay buildings.

Unique characteristics of Penofol

Penofol - a heater defined as a heat-noise-moisture-insulating material. It is made from environmentally friendly substances, and has a small thickness and low weight. In industrial and civil construction it is used for:

- basement insulation;

- wall insulation;

- attic insulation;

- ceiling insulation;

- roof insulation;

- floor insulation;

- hydro-thermal insulation of pipes;

- thermal insulation of the air conditioner;

- hydro-thermal insulation of external walls;

- strengthening waterproofing and massive insulation;

- dust protection;

- ceiling repair;

- strengthening walls;

- door insulation;

- insulation of water heating elements.

In the automotive industry, Penofol is used as a material for sound insulation and insulation of the vehicle interior.

How to fix reflective insulation on a concrete wall

How or with what can reflective insulation be glued or attached to a concrete wall? Thank you.

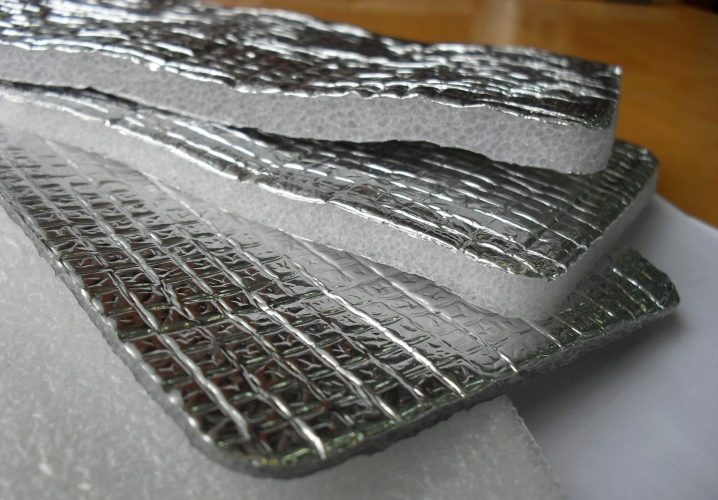

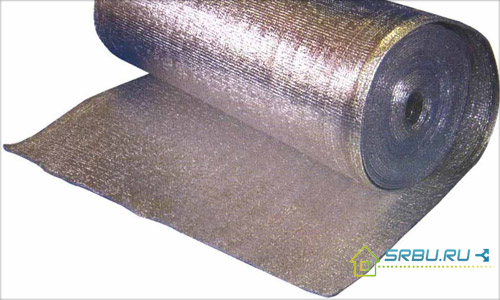

Reflective insulation is called a light, flexible material with a thickness of 4 mm or more, consisting of a layer of foamed polyethylene or other polymer, on which aluminum foil or metallized film is glued on one or both sides. Foil thermal insulation materials are environmentally friendly, easy to install and significantly reduce heat loss.

Manufacturers of reflective thermal insulation materials do not exclude the use of glue during installation, but they draw the attention of consumers that they are most effective if an air gap of 2 to 10 mm is created between the wall and the thermal insulation. After all, air is also an additional heat-insulating layer.

The method of attaching reflective thermal insulation to a concrete wall is chosen depending on the type of material, possibilities, location and purpose of the room. In any case, the concrete wall must first be cleaned of dust and treated with an antiseptic, and if necessary, dried.

When insulating balconies or cold external walls with a heat insulator with a double-sided foil coating, it is necessary to fill a crate of slats with a thickness of 5-7 mm on concrete and fasten the material to it with a construction stapler or glue. A second crate is mounted on top of the heat-insulating material for laying with an air gap of the finishing coating.

When mounting on reflective materials with a one-sided metallized coating, it is allowed to use adhesives based on rubber or acrylic, such as 88-NP, Akrol contact, Neoprene 2136 spray, etc. You can also use mounting foam, sealing sealant and double-sided reinforced construction tape . The adhesive composition is applied on the reverse side of the material dotted in a checkerboard pattern or randomly, so that after gluing to concrete, the required air gap of about 2 mm remains.

Cloths of reflective insulation are glued end-to-end and the seams must be glued with aluminum tape. As a result, an airtight coating is created on the wall, resembling a thermos, on which you can mount a lath crate for attaching a finishing material.

Finally, if an increase in the thickness of the walls is undesirable or impossible, self-adhesive foil heat-insulating material can be used for insulation. For its installation, it is only necessary to prepare the concrete surface and remove the protective film from the wrong side of the web, and after gluing, seal the joints with foil tape. But when fastening to the crate, the efficiency of self-adhesive metallized insulation is higher.

How to fix reflective insulation on a concrete wall? Tips on how to fasten reflective thermal insulation to a concrete wall, depending on the type of material, purpose and possibilities of the room

What is penofol

Self-adhesive penofol is a new insulating coating that has not only good thermal and waterproof insulation, but also the functions of protection against various types of radiation. The material has received a wide vocation in the construction industry due to the latest manufacturing technology with a one-sided self-adhesive side, which significantly increases the speed of installation of such insulation

Can be installed on the roof and retain more than 80% of the internal heat of the building, protects the walls, prevents the obvious effects of heat stroke in summer and sudden frost in winter. Penofol has a thickness of 3 mm to 10 mm, the width of the roll is from 20 mm to 120 mm. The most common sizes of self-adhesive polyethylene are: width 58 cm, thickness 3-5 mm.

Shielding properties, protection from moisture, retain heat and provide overall energy savings - all this is affected by the thickness of the foam

. Penofol has characteristics similar to foam boards, while its dimensions are much smaller, the coating is very thin. Consider a few basic properties of penofol:

- Lack of smell and toxicity.

- Lightweight, soft, no dust.

- Easy to install.

- Heat reflection, thermal insulation, sound insulation, anti-radiation, anti-vibration and shielding.

- Sun barrier, waterproof, energy saving.

- Keeps warm in winter and cool in summer.

- Saves heat and electricity.

Penofol specifications:

- resistance to extreme temperatures from + 0 °С to 150 °С;

- due to the "mirror" reflection of the surface, thermal air flows arise, providing convection in the room;

- uniform distribution of heat throughout the heated space;

- thermal reflection coefficient up to 95%;

- waterproof material that expands the range of use of insulating foil (walls, ceiling, floor);

- ease of installation allows you to do the installation work yourself;

- the thermal conductivity of penofol is 0.037-0.051 (for various types).

Penofol insulation has technical characteristics that are ideal for thermal, hydraulic and steam insulation. Penofol is good for use both for insulating an apartment, a private house, and for storage facilities, hangars, and workshops.

The properties of self-adhesive polyethylene foam can be used for shielding rooms with high humidity: baths, showers, changing rooms in swimming pools, saunas. Those. this material is in great demand during construction work on the insulation of various objects, where constant humidity or steam will be present.

In addition, polyethylene foam perfectly absorbs sound waves and mechanical vibration. These properties are used in the construction of operator cabins (for example, boiler rooms or steelmaking). The advantage of using penofol in this case is just perfect: it eliminates sound, absorbs vibration, creates a thermal shield.

Foil self-adhesive penofol is often used to insulate boiler equipment, shield various cables, and insulate pipes. Such insulation will be useful when laying networks below ground level, where there is high humidity, and the insulating material does not absorb moisture.

Advantages and disadvantages

The use of penofol has its advantages:

- The small thickness of the material allows you to create reliable thermal insulation of the room.

- Installation of building materials does not require special skills and special tools. Working with such material is much easier than with other types of heaters.

- The material is environmentally friendly, which makes it possible to use it for food storage.

- Fire safety. This building material belongs to the class of fire-resistant materials.

- Convenience during transportation. The thickness of the product allows you to roll the insulation into a roll, which allows you to transport it in the luggage compartment of the car.

- Excellent soundproofing. Mounting penofol over the frame of building structures provides good isolation of extraneous sounds.

Penofol has not only positive qualities. There are also disadvantages of using this building material:

- The heater is soft. Because of this, this product is not suitable for finishing plastered walls. With light pressure, the material bends.

- To fix the insulation, special adhesives will be required. It is not recommended to nail it to the surface, because in this way the penofol loses its heat-insulating qualities.

Foil insulation for walls and floors

Insulation with foil relatively recently appeared on the construction market, but is rapidly gaining popularity for various reasons. Next, we will consider the types of this material, the advantages in comparison with traditional heaters and how to use it correctly.

What is rolled foil insulation

This is a combined material for the insulation of walls, floors and ceilings, consisting of several layers:

- Insulation made from conventional materials.

- foil layer.

The material is rolled, therefore it has a relatively small sheet thickness. What is heat retention?

- A thin working layer delays the penetration of cold air from outside,

- The foil reflects the heated air into the room.

Varieties

Roll heaters are classified according to the main material:

- Polyethylene foam with foil that can be attached on one or both sides.

- Folgoizol is created on the basis of bitumen / rubber, mineral fillers and an antiseptic.

- Mineral wool rolls with one-sided foil surface.

- Basalt lamellar heaters,

- Expanded polystyrene boards with one aluminum surface.

Each of the presented materials is intended for use in certain conditions.

Application

Penefol (closed-cell polyethylene foam) is versatile in use.They isolate walls, floors in residential premises.

Foil insulation for pipes and roofs - foilizol. It is also used in the construction of industrial facilities.

Rolls of mineral wool with an aluminum layer are used in the same way as conventional insulation mats: for insulating walls, floors and other structures. The difference between foil mineral wool and ordinary wool is built-in waterproofing, aluminum does not let moisture into the fibers, preventing the material from getting wet.

An ideal foil insulation for a bath based on basalt: it has a low heat transfer coefficient, is not afraid of humidity and large temperature changes. As you know, stone wool is a hard material. To roll it into a roll, basalt is sawn into lamellas, and they are laid on an aluminum base. This insulation is used to isolate various social and industrial facilities.

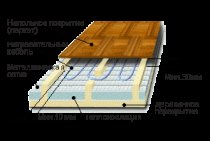

Foiled polystyrene foam is used for floor insulation.

All materials with an aluminum foil interlayer have a higher technical performance than their traditional form. The cost of foil insulation is an order of magnitude higher than the cost of conventional material, this is the main drawback of the "advanced" sample.

The first and most important question is which side to put the foil insulation on?

The first rule of laying: the reflective side should be directed towards the room. This will provide natural heat reflection.

The structure of insulation and finishing should be thought out: between the insulation and the subsequent finishing, in the case of walls, there must be an air gap. When using a mineral wool base, it is necessary to isolate the material from water penetration; for this, a membrane is attached to the base, which allows steam to pass out.

How to fix the foil insulation to the wall: an insulator is rolled out over the fixed membrane and fixed with guide rails, the thickness of which should exceed the thickness of the main insulation. The layers are connected with staples along the edges of the rails. The subsequent finishing of panels or lining is carried out along the guides, which provide an air gap with their thickness.

Some craftsmen recommend protecting the foil with vapor barrier films to prevent moisture from entering the body of the mineral wool layer through possible holes in the metal.

For wooden and concrete floors, the algorithm of actions remains identical:

- The base is cleaned of old coatings, garbage is carefully swept away.

- Prime the subfloor with a primer for concrete or wood.

- After the primer dries, measure the required amount of rolled insulation and roll it out. It is optimal to use an adhesive-based material. The strips are overlapped by 10 cm, the joints are glued with aluminum tape.

- Lay top coat on top.

If the room has an electric or water "warm" floor, the rolls are rolled out with the reflective side up, a reinforcing mesh is laid on top, then heating elements and a cement screed is produced, followed by cladding.

Foil insulation for walls and floors Consider the types of foil insulation, the advantages in comparison with traditional heaters and how to use it correctly.

Features of foil insulation, some disadvantages and scope. How to properly mount penofol on glue. The choice between penofol and basalt wool.

Where is Penofol used?

Based on the foregoing, it can be understood that Penofol insulation technical characteristics are simply universal. And therefore it can be used both for thermal insulation of light summer houses in holiday villages, and for insulation of high-rise buildings. Offices, industrial premises, kindergartens, hospitals, saunas with baths can be insulated with this material. They also insulate warehouses with hangars, both warm and unheated.Stalls and modules for trade, temporary huts and refrigeration rooms can also be insulated with Penofol. They also wrap pipes (water, ventilation and heating), insulate wagons, vans and cars, shield heating batteries.

Penofol, which has a foil coating on both sides, will not only help keep you warm on frosty days. Laid under the roof, he will not allow the scorching summer heat to get into the house. So, for example, laying Penofol with double-sided foiling, having type "B" and a thickness of 5 millimeters, leaving two layers of air, 2 centimeters each. The result will not keep you waiting: the thermal resistance of the structure will increase by 1.2 square meters-degrees Celsius per watt.

Get to know Penofol

This insulation consists of several layers. In the middle there is a self-extinguishing foam type polyethylene, and on the edges there is a high-quality aluminum foil. Its thickness is from 12 to 30 microns, and the proportion of pure matter in it is 99.4 percent. The result is a material of small thickness and weight, which does not contain any harmful additives and is absolutely safe.

Being practically unable to absorb thermal radiation, Penofol works on the principle of its reflection. In this it differs from the vast majority of heat insulators, the layers of which trap the heat coming out of the room. It should be noted that the word PENOFOL does not mean at all the type of insulation, but the name of the brand.

To understand how heat is reflected by Penofol, let's recall how the Dewar flask works. This device, usually called the Dewar vessel, was invented by a Scotsman - a scientist in the field of physics and chemistry, James Dewar. At the beginning of the twentieth century, he conducted a series of experiments in the laboratory to test how heat would behave if it was isolated by the walls of a vessel. The same principle applies to all thermoses.

So, Dewar found that any substance known to people has a certain value of resistance to heat transfer "R". And no matter how important this indicator is, not a single material can stop the transfer of heat. It is only possible to slow down this process. In this case, the substance absorbs heat waves, accumulating energy in itself. As soon as it is saturated with this energy, the reverse process will begin - the release of heat.

But there are a number of materials that are not characterized by the absorption of thermal energy - they reflect it. These are, for example, precious metals such as platinum, silver and gold. And this ability has pure aluminum, well polished. Rays of thermal energy that reach the surface of such a material are almost completely reflected (98-99 percent). There is only one “but” - these substances conduct heat well. Therefore, it is necessary to supplement them with some thermal barriers, for example, foamed polyethylene. It is able to absorb heat. Thus, the technical characteristics of Penofol combine both reflection and absorption of thermal rays.

Studies have been conducted for more than 40 years, and as a result, it was found that both the loss of heat in rooms and its accumulation are directly related to infrared radiation. But everything can be balanced by using reflective type thermal insulation materials, which are easy to install and are very effective and inexpensive reflectors of infrared radiation.

People are gradually starting to get used to heat-insulating materials of a reflective type. They are profitable and convenient, so experts predict that gradually such heaters will take a leading position. With their use, equipment wears out less, and the time and money spent on heating and air conditioning equipment are significantly reduced. Working with reflected thermal energy is much easier than with absorbed.

Since the heat rays are reflected, in winter the heat loss for heating the floor, ceiling and walls will be much less. And when using double-sided reflective insulators in the summer, in the heat, there will also be no negative consequences of absorbing thermal energy from the outside.

Penofol parameters

What is Penofol

Now a lot of materials are produced under the brand name PENOFOL. Perhaps it is worth listing those that are most in demand. Among them, one can single out the classic Penofol, covered with aluminum foil on only one side. Such Penofol has type "A".

Penofol in which foiling is made on both sides has type "B". Penofol of both these types is quite dense, and also resistant to physical exertion.

Penofol type C belongs to the category of self-adhesive materials. In it, a polished aluminum coating is applied to a layer of foamed polyethylene on one side, and on the other, a layer of moisture-resistant glue and a film that prevents the adhesion of materials. This type of insulation is used where ordinary Penofol is not suitable or is too expensive, because no additional devices are needed for its fastening.

And there is Penofol, which has perforation. It can also be one-sided or two-sided and is produced not so long ago, but is used for thermal insulation of facades from the outside. Perforation allows moisture to escape from the material to the outside. In other words, walls insulated with such material can “breathe”.

About Penofol thickness

The thicker the insulation, the more expensive it is. And the price and technical characteristics of foil Penofol are also affected by the number of layers of aluminum foil: there can be one or two. As for the thickness, its standard dimensions are: 10, 8, 5, 4 and 3 millimeters. It can be understood that a centimeter-thick material with a double layer of foil will be the most expensive. By the way, it not only keeps heat best of all, but also protects well from noise.

According to the optimal ratio of price and quality, Penofol 0.5 cm thick came out on top. If maximum thermal insulation is required, as well as protection from noise and moisture, then it is better to opt for a centimeter layer of Penofol. As for the remaining parameters of the insulation, they also depend on the thickness of its layer, as well as on its type.

About Penofol heat conduction

Since this insulation is combined, combining the reflection of heat and its absorption, it is difficult to compare it with traditional heat insulators. Penofol insulation helps to reduce convection due to the polyethylene foam layer, and the foil layer on the outside can reflect up to 97% of heat rays. As a result, the isolation is complex.

And yet, let's try to compare, if not the thermal conductivity, but the heat transfer resistance of Penofol and other heaters. If we take this material with a thickness of 4 to 5 millimeters, covered on both sides with aluminum foil, we get a resistance to heat transfer from 1.2 to 1.23 square meters-degrees Celsius per watt. To achieve the same result, the mineral wool layer should be no less than 8 or 8.5 centimeters. Data are calculated according to SNIP II-3-79.

About water absorption

Penofol almost does not absorb moisture, and it does not matter what humidity the air has in the street and in the room. It does not depend on the change of season and temperature change.

This distinguishes this insulation from most modern heat insulators.

About the vapor permeability of Penofol

A film for vapor barrier when using Penofol does not need to be laid. After all, its vapor permeability coefficient does not even reach 0.001 milligrams per meter-hour-Pascal. We can say that this insulation is an excellent barrier to evaporation.

Sound resistance

Speaking about the sound absorption of Penofol, we can name the following number: 32 decibels. It is this sound absorption that class “A” material has. It is mounted not inside the frame of the building structure, but on top of it, with no seams. Therefore, it allows you to protect yourself from various noises: both acoustic and structural. This versatility is a definite plus.

Fire protection

This material according to the norms refers to substances that are difficult to burn and do not support combustion. The Research Institute of Construction Physics issued Penofol with a certificate of conformity confirming that the material is not flammable. When fired, polyethylene releases water and carbon dioxide. True, if there is not enough oxygen, carbon monoxide may also appear.

Service life and safety

One of the cleanest materials in terms of ecology is polyethylene foam. Therefore, it is he who underlies Penofol. By the way, in terms of durability (200 years), this substance can be given the highest score. Along the way, you will be able to protect yourself from the harmful effects of electromagnetic radiation. They can be reduced by two or even ten times.

Advantages and disadvantages of the material

The main advantages of the material:

- Affordable price. The cost of Penofol is much lower than analogues from other manufacturers. At the same time, the low price does not affect the quality of the material.

- Durability. Penofol is based on only high-quality and natural raw materials, so the life of the insulation is from 10 to 15 years.

- Choice. A variety of product types allows the buyer to choose the material with the qualities he needs and the best price.

- Light weight, which directly affects the installation and transportation - only one person is required to lay the insulation. Reloading also does not take much time, as the insulation is delivered to the buyer in the form of convenient rolls.

Ease and speed of installation

Ease and speed of installation

Insulation, in addition to positive qualities, also has disadvantages. The main one is careful handling during installation. Penofol is attached to the surface with construction glue; it is forbidden to use self-tapping screws and dowels that can damage the structure of the sheet. Accordingly, additional costs for glue are necessary.

Secondly, the material does not have sufficient rigidity, so a layer of plaster or putty cannot be applied on top of it. Penofol has a soft structure, just press a little on the surface of the sheet, and it will bend, but will restore its shape after a short period of time.

Penofol belongs to the category of universal materials, the use of which is allowed in rooms with sharp temperature changes or no heating at all. The heater has several varieties with certain technical characteristics. The packaging with the material provides a convenient and easy-to-understand instruction for use.

The insulation is durable and environmentally friendly, resistant to burning. It has the main operational qualities: high sound insulation, low thermal conductivity, increased density and light weight.