Requirements for premises

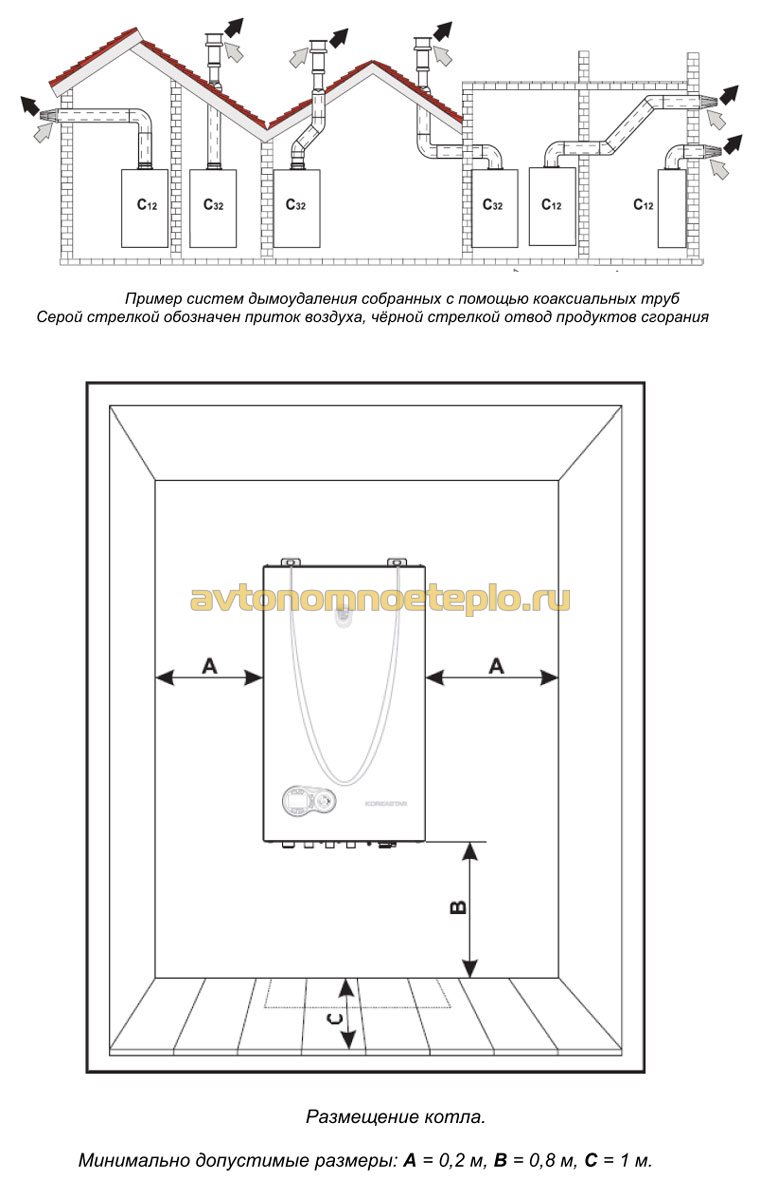

The room in which the gas equipment is to be installed should be equipped with forced ventilation. Moreover, door and window openings cannot be classified as such if they do not have devices that ensure the constant movement of the air flow - fans, holes in the door leaf, etc. When the heater is put into operation, it is forbidden to carry out construction work in the room that can change the design of the ventilation, thereby affecting the volumes of incoming oxygen.

In the boiler room it is prohibited:

- Store flammable substances and materials.

- Store chemically active substances - chlorine, ammonia, acids, etc.

- Place heaters and air conditioners near the boiler.

- Install equipment near stairs, in wall openings, near windows and emergency exits.

Power setting

After starting the device, you need to press and hold for 5 seconds. buttons to adjust the temperature to enter the setting mode. Adjust the gas pressure by decreasing and increasing the pressure using the DHW adjustment buttons. While the setting is in progress, a number will appear on the screen. This display designation is the value of the minimum power in percent: 44–54. When the pressure gauge shows the required pressure value, press the RESET button, the parameters will be saved.

When setting the operating power, set the gas pressure with the buttons that regulate the temperature of the heating water. The display will show the power value as a percentage: 0–99. Having set the required value, press RESET, save the parameters, exit the settings mode.

Operation features

Boilers "KoreaStar", being productive and reliable, have advantages and disadvantages typical for any equipment with a closed firebox:

- Noise. The reason is the operation of the fans. With their help, air is injected and removed from the coaxial chimney. A distinctive feature of all forced draft burners is their noisy operation. It is advisable to install such heaters away from living rooms.

- The water in the hot water supply is heated separately from the coolant. The three-way solenoid valve increases the heating rate, ensures a uniform supply of water at any pressure in the water pipes.

- When the coolant cools down to +5 °C, the boiler starts automatically, preventing the heating system from defrosting.

- Energy dependence. The instructions for use of KoreaStar heaters say that they are able to function with voltage surges up to 15% of the nominal value. But in practice, there are problems, the controller board fails. Installing an uninterruptible power supply will help prevent breakdowns.

- Before connecting the device, you need to obtain permission, order project documentation from the gas service.

Error codes and malfunctions

In case of any malfunction in the operation of the boiler, the user must first look at the instructions. Most errors are listed by the manufacturer. It's just not always clear how to fix them. We recommend restarting the equipment immediately:

- Press the restart key;

- Wait for the boiler to restart;

- Make sure the characters have disappeared from the screen.

If nothing has changed, start looking for a breakdown. The table below shows solutions for different problems.

| Fault codes | What do they mean | How to fix it yourself |

| A01 | The system does not report the presence of a flame. |

|

| A02 | A flame was reported, although there was no ignition. |

|

| A03 | Overheating technology. Boiler operation is blocked. The temperature is over 90 degrees. |

The thermostat has tripped. First of all check it for serviceability. Drain excess air from the system using Mayevsky taps. Run diagnostics:

|

| A08/F10 | The heating circuit temperature sensor is out of order. | Checking the sensor, its connections and contacts. In the event of a short circuit (short circuit) or open circuit, a new element is installed. |

| F05 | Incorrect operation of the gas removal system. | View:

|

| F11 | Hot water NTC temperature sensor failed. | I got error F11, what to do:

If ignition does not occur when DHW is turned on, inspect the three-way valve that switches heating between circuits. |

| F37 | Low pressure in the circuit (less than 80 kPa). | Make sure the pressure sensor, its wiring is in good condition. Inspect all connections and assemblies for leaks. Any damage is sealed. Turn on water supply to the system. |

| F41 | The movement of the coolant is disturbed. The heat exchanger is overheating. | How to fix the situation:

|

| F50 | The electronic board is not working. | Checking grounding, boards for breakdown. It is better to entrust repair and replacement of the control module to a specialist. |

Unfortunately, not all malfunctions of Koreastar heating equipment are displayed as a code on the display. Users complain that the devices are sensitive to voltage drops, which is why the control board often suffers. And this is despite the manufacturer's assurances of stable operation at any jumps. Therefore, when choosing Koreastar, it is worth additionally connecting a stabilizer.

Experts recommend annual preventive maintenance of breakdowns. Clean the unit from dirt, scale, conduct a technical inspection.

Design features

- Devices for 10–20 kW are equipped with a copper heat exchanger of 24 kW, so when the DHW circuit is turned on, they are not afraid of extreme loads. Their water capacity is 13.6 l/min.

- Thanks to the double protection of the heat exchanger, it does not overheat, and the service life is extended.

- Combustion chamber in two versions - closed (PREMIUM E) and open (PREMIUM A).

- Economical fuel consumption.

- Equipped with an LCD screen. Self-diagnosis.

- Modulated fire intensity.

- Equipped with WILO pump (German production), anti-blocking system.

- Freeze protection system.

- Connecting the remote control, room thermostat.

Advantages of Korean equipment

- Does not respond to pressure drops in the gas line.

- High value of efficiency, efficient fuel combustion.

- A wide range of models, there are wall and floor models, with one and two circuits.

- Stylish design. Compactness.

- Equipped with built-in fuses that guarantee the safety of the equipment in case of emergency.

- They are converted to liquefied gas, jets are included in the kit.

- They can provide the house with hot water.

- Ability to select the operating mode. Temperature setting.

Question 1 Solutions

The boiler is equipped with a self-diagnosis system and fault signals appear on the display. Errors marked with the symbol A cause the boiler to block. In this case, the user must manually reset the boiler by pressing the "RESET" button. Errors marked with the symbol F cause a temporary shutdown of the boiler with automatic switching on after the value that caused the error returns to normal values.

Accordingly, the errors A01.

Coreastar Boiler Error Codes - Troubleshooting Instructions

Did the Koreastar boiler show errors on the display? This means that the self-diagnosis system "detected" a malfunction. All modern heating equipment is equipped with automation - sensors that control the operation of each unit. Sometimes the user does not even need to contact the service center. It is enough to determine the meaning of the code and find the problem.

Specifics of application and operation

Judging by the feedback from consumers, Koreastar boilers are productive and reliable equipment that have their own specific disadvantages that are inherent in all equipment with closed combustion chambers.

The range of Koreastar gas wall-mounted boilers has the following characteristics:

- High noise during operation - is a consequence of the operation of the burner fans. The intake of air and the output of combustion products is carried out using a coaxial chimney, in a forced way. All pressurized burners are noisy, so the stations must be installed away from living quarters.

- DHW heating - hot water heating is performed independently of the heating system. The presence of a three-way solenoid valve significantly increases the heating rate. A uniform supply of hot water is provided, regardless of the pressure in the water supply system.

- Safety group - when the coolant cools down to a temperature of + 5 ° C, the boiler automatically starts, preventing the heating system from defrosting.

- Connection to the power supply - although the manufacturer indicates the ability of the equipment to work, despite voltage drops in the network up to 15% of the rated power, practice shows that this is not always the case. The controller board can fail with any electrical surge. The installation and installation of a UPS can provide protection.

Tips and tricks for choosing

Coreastar boilers can operate with a gas drop of up to 4 mbar, they are resistant to voltage drops. Models are characterized by stable heating of hot water and are intended for domestic use.

Koreastar products should be chosen for rooms with a maximum heated area of up to 320 m² and the need to provide domestic hot water.

Gas boilers Koreastar Buran

There is only one unit in this series. The Korea Star Buran gas boiler is installed on the floor, it is single-circuit, does not depend on electricity and can work with open and closed heating circuits. Such units are called AOGV and are themselves simple heaters. At the same time, they are very reliable and have earned a good reputation.

Floor model warranty 5 years.

Characteristics of Korea Star Buran:

- open type combustion chamber;

- Italian-made mechanical automation (SIT);

- 15 power options from 7.5 to 100 kW.

The Buran model differs from the Koreastar Senator series in the heat exchanger material, which is made of steel. While in the Senator boiler, the heat exchanger is made of high quality cast iron. Buran can only run on natural gas. The gas pressure must be at least 6 mbar, and the coolant pressure must not exceed 0.4 mbar.

The maximum temperature is 90 degrees. During ignition, due to the fact that the temperature of the coolant is below 30 degrees, condensation may occur.This leads to corrosion, so it is not necessary to allow such a decrease in the temperature of the water in the circuit. Before the heating season, the device must be checked for serviceability, if necessary, clean the heat exchanger and chimney.

- Content:

- Features and technical data of boilers

- Specifics of application and operation

- Tips and tricks for choosing

The consumer is offered two basic wall-mounted Koreastar models - classic and bithermic type.

Installation

Before installing the machine, make sure it is powered by natural gas. If the use of liquefied gas is supposed to be used, it is necessary to readjust the heater - this should be done by a specialist. Power supply with 220 V/50 Hz parameters must be supplied to the place of installation of volatile models. Deviation of parameters from the norm leads to a decrease in productivity, a reduction in service life.

It is forbidden to connect other electrical appliances to the boiler power supply. It is also forbidden to use extension cords and adapters when connecting. Failure to comply with safety regulations may result in a fire.