Welding technologies for galvanized products

Technologists offer several ways to solve the problem of welding galvanized pipes:

- preliminary removal of the protective coating with its subsequent restoration;

- decrease in welding temperature;

- reduction of welding time;

- preventing evaporation of zinc by using flux.

Cleaning of the work area is carried out either mechanically or chemically. In the first case, use a grinder with a metal brush or an abrasive wheel. Here it is difficult to control the locality of the removal of protection. Chemical removal of galvanizing is carried out by treating the joint with a solution of hydrochloric acid. It is applied carefully, in small portions, without damaging the base metal.

Normative service life of steel pipes according to GOST

One of the important characteristics of the product is, among other things, the period of operation. Any material wears out over time, but this time can be very different and depends on the load, on additional factors and, of course, on the quality of the product itself. The standard service life of steel water pipes largely determines their purpose.

Types of pipeline

Several types of metal products are used in heating and water supply systems:

- black steel pipes - steel of a different grade is used in the manufacture, but does not have corrosion resistance. Such rolled metal needs additional protection - painting, for example;

- galvanized steel pipes - products are covered with a layer of zinc. The latter forms a galvanic couple with iron and is destroyed by an electrochemical reaction, protecting the steel from corrosion. It is obvious that the service life according to SNiP and GOST for such a model is much longer;

- stainless steel - alloys with the addition of nickel and chromium. Depending on the value of the alloying addition, steel can be resistant to corrosion under normal conditions, is characterized by increased resistance, which allows it to be used in sea water, for example, and also not oxidize under the influence of not only moisture, but also high temperature. The product does not need protection, however, its cost is noticeably higher;

- copper - rarely, but used in domestic conditions. They are distinguished not only by resistance to corrosion, but also by disinfecting properties.

Each option from the list can be used for water supply, gas pipelines, heating, and not only water, but also steam. However, their service life will be different.

Alas, this option is not particularly durable. Even with the most careful painting and care, they rust over time. The fact is that after the construction of communications, individual fragments are inaccessible, and it is impossible to renew the paint, for example.

In addition, black steel loses its smoothness rather quickly. And this leads to the fact that the water and gas or heating pipe “overgrows” rather quickly: first, very small debris and salt deposits are held on the uneven surface, and then increasingly large particles of rust, fibers, and lime deposits. The rate at which deposits build up is directly proportional to the hardness of the water.

The standard operating time is as follows:

- the service life of steel water pipes - a riser or an eyeliner, is 15 years;

- a heating system assembled from gas steel pipes is usable for 10 years;

- heated towel rails in the bathroom can "work" for 15 years;

- according to GOST, the standard service life of a gas pipeline made of steel pipes is 30 years.

In fact, various destructive factors significantly reduce the operating time. So, for example, a pipeline with cold water wears out much faster than with hot water, as it rusts faster: condensation appears in the warm season.Yes, and the pipeline overgrows faster, since there are special additives in hot water that prevent this.

Galvanized steel

Such material is much more resistant to corrosion, which significantly extends the standard time. The most significant destructive factor here is only a welded joint, if, for some unknown reason, the installation is carried out by welding. In the photo - water and gas steel pipes.

In fact, this installation method is prohibited: zinc burns out completely during welding, respectively, the seams remain completely defenseless against rust.

Products made of galvanized steel overgrow much more slowly. Firstly, the smoothness of the wall is much higher, and secondly, the actual "garbage" - particles of rust, scale, sand is much less. But if the taps in the water supply system do not open completely, and a sufficiently dense flow of water is not created, scale and sand can accumulate.

The service life of the product according to GOST is as follows:

- risers and connections in cold water supply systems have been in operation for 30 years;

- the service life of steel heating pipes in a house with a closed system is 20 years;

- an open heating system will last 30 years.

It is allowed to construct a gas pipeline from galvanized pipes. But there is still a nuance: unlike plumbing systems, the gas pipeline must be one-piece, which involves welding. And the compound destroys the zinc at the junction. On the other hand, gas pipelines, as well as water pipelines, are coated with polymer paint, which prevents corrosion.

In fact, galvanized steel pipes for both plumbing and heating serve for 50–70 years.

Varieties of pipes and their scope

The classification of profile pipes with a protective zinc coating can be made according to the following criteria:

- manufacturing method;

- section shape;

- overall dimensions;

- wall thickness.

Manufacturing methods and their advantages

Depending on the manufacturing method, profiled galvanized pipes are manufactured:

welded. Pipes made by welding are distinguished by a reduced wall thickness, but at the same time, a lower margin of safety. They are mainly used for the manufacture of decorative partitions, benches, small greenhouses;

Profile pipes made by welding

seamless. They are distinguished by higher strength, since there is no weak point - a weld. The field of application starts from the construction of building frames and ends with the manufacture of small items.

Sturdy profile pipes with a protective coating

In turn, seamless pipes are divided into the following subgroups:

- cold-formed. The profile pipes made by this method are distinguished by the accuracy of the declared dimensions, the ability to withstand hydraulic shocks, negative temperatures, temperature changes, as well as the possibility of self-bending;

- hot-formed. They are distinguished by strength, including to earth vibrations, resistance to mechanical damage, water hammer, pressure drops, and so on, as well as increased wall thickness. This method of production does not allow you to clearly observe the dimensions of the products, so they may differ by 3-5 mm from those declared upwards.

Scope of cold-formed pipes:

- production of furniture frames;

- construction of lamps;

- construction of various pipelines;

- organization of work of boiler installations;

- mechanical engineering;

- oil and gas industry.

Garden furniture from profile pipes

Hot formed pipes are used:

- in construction. Of these, you can build the frame of a building, gazebos, garages and other premises;

- during the construction of heating mains and domestic heating;

- in the gas, chemical and oil industries.

The frame of a residential building from shaped hot-formed pipes

Variety by wall thickness

Various manufacturing methods allow you to get:

- thick-walled profile pipes;

- thin wall pipes.

The greater the thickness of the pipe wall, the greater the load the product can withstand.

Due to this pattern, the scope of pipes with different wall thicknesses is also determined:

- thin-walled are widely used in the construction of arbors, fences, furniture, a roof is being built, a frame for a greenhouse, and so on, that is, where there are no significant loads;

- thick-walled ones can be used to build a garage, a house, and so on, that is, those structures that will be heavily loaded.

Section types

For the construction of various structures, profile pipes of different sections are produced:

- rectangular;

- oval;

- square;

- round.

From pipes with corners (square, rectangular), fences, frames, gates and so on are made. Oval and round pipes are mainly used in mechanical engineering, as well as in the laying of pipelines.

Assortment of pipes of different sections

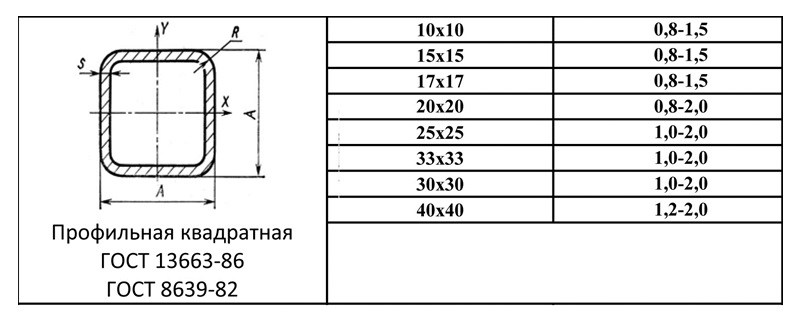

Pipe dimensions are determined according to the following GOSTs:

- square pipes (GOST 8639-62) are produced with an outer diameter from 10 mm to 180 mm, while the thickness of the pipe wall can vary from 0.8 mm to 14 mm. The most popular sizes used in private construction are 20x20 pipes (for additional elements) and 40x40 pipes (for the manufacture of the main load-bearing structural elements). The length can be measured (set by the manufacturer) or unmeasured, determined by the consumer's order;

The shape and most popular sizes of square pipes

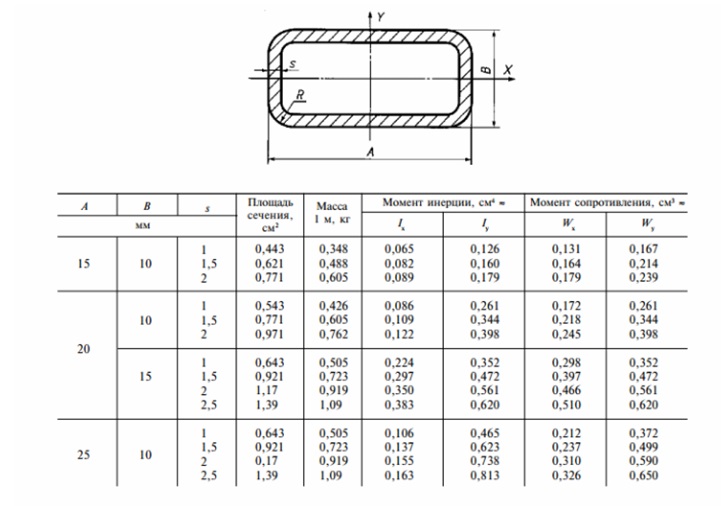

- rectangular pipes (GOST 8645-68) are also available in standard sizes, fixed or random lengths;

Sample shape and assortment of rectangular pipes

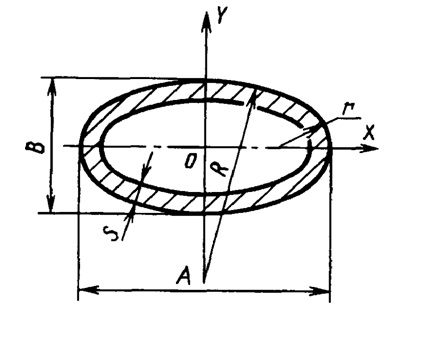

- oval pipes are also produced in accordance with GOST under the number 8642-68. Diameters can vary from 3x6 mm to 90x32 mm, while the wall thickness of the oval pipe can be 0.5 - 2.5 mm.

The shape and dimensions of oval pipes

You can watch the video on the production and use of profile pipes.

All the main parameters of profile pipes with a protective coating are indicated on the marking, which is applied directly to the product (if it is of large diameter) or is available in the accompanying documentation. From the marking, you can find out the dimensions and shape, the details of the document in accordance with which the pipe is made and the method of manufacture, which is quite enough for an independent choice.

Disadvantages of steel pipes

Unfortunately, despite all the advantages, steel pipes are characterized by many disadvantages. Firstly, they have significant weight and large dimensions, which makes their operation difficult. Secondly, the gas welding used to connect them significantly increases the cost of installation.

The main disadvantage of steel pipes lies in their corrosion instability and susceptibility to various damages. These pipes quickly overgrow with rust and various deposits, which causes the release of harmful substances into the water and the deterioration of the functioning of the locking elements. Due to rusting, the inner diameter of the pipes decreases, which impedes the circulation of the coolant, which is the rationale for why the pipes are buzzing. The best method of protecting steel pipes is galvanized. But, after this process, the use of antifreeze becomes impossible.

It is believed that the connection of galvanized pipes cannot be carried out by welding. This is due to the burning of the zinc coating on the seams. For their connection, couplings, tees and drives are used, which is an additional cost. Due to the low throughput property, steel pipes are inferior to pipes of similar parameters made of copper and plastic. When transporting cold water, steel pipes are characterized by negative thermal conductivity due to their sweating and rusting, which can destroy the building structures adjacent to them.

Types of galvanized pipe products

Pipes with a protective zinc layer are used for pipelines for various purposes:

| View | Application | Dimensions |

| Water and gas pipeline | for indoor lines | length - 4-12 m |

| Pipe for electric welding | agricultural engineering and construction | diameter - 110- 480 mm |

| Profile with square or rectangular section | industrial and domestic construction | section size - 10 -150 mm |

| Seamless pipe made of carbon or alloy steel | mechanical engineering | wide size range |

The diameter of pipe products with a galvanized surface is from 17 to 150 mm. The value of the nominal diameter is 10-155 mm.

By weight they distinguish:

| Pipe type | Size (thickness) of the wall in mm |

| light galvanized | 2 — 4 |

| galvanized ordinary | 2.2 — 4.4 |

| reinforced galvanized | 4.5 — 5.0 |

Advantages of profile pipes with zinc coating

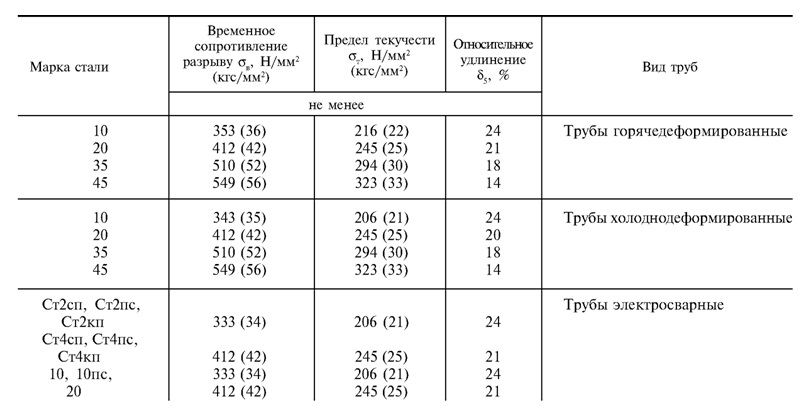

Profile pipes are manufactured in full compliance with GOST 13663-86. For production, high-alloy steel is used mainly of the following grades:

- St2sp;

- St2kp;

- St2ps;

- St4sp;

- St4kp;

- St4ps and so on.

The properties of pipes of different types are presented in the following table:

Mechanical properties of pipes depending on steel

The properties of pipes determine the advantages of this type of product, which include:

- enhanced mechanical strength, which allows you to expand the area of \u200b\u200buse of pipes to enormous sizes;

- corrosion resistance. The main disadvantage of steel pipes is their susceptibility to rust. This drawback was minimized by using zinc as a protective layer. The profile galvanized pipe is not exposed to rust even under the most adverse conditions;

- light weight;

- ease of installation. Various methods can be used to connect pipes: welding, coupling connection, connection with fittings, and so on.

Due to the additional zinc coating, the service life of profile pipes is increased by 10 to 15 years compared to conventional steel pipes.

Normative service life of steel pipes according to GOST

One of the important characteristics of the product is, among other things, the period of operation. Any material wears out over time, but this time can be very different and depends on the load, on additional factors and, of course, on the quality of the product itself. The standard service life of steel water pipes largely determines their purpose.

Types of pipeline

Several types of metal products are used in heating and water supply systems:

- black steel pipes - steel of a different grade is used in the manufacture, but does not have corrosion resistance. Such rolled metal needs additional protection - painting, for example;

- galvanized steel pipes - products are covered with a layer of zinc. The latter forms a galvanic couple with iron and is destroyed by an electrochemical reaction, protecting the steel from corrosion. It is obvious that the service life according to SNiP and GOST for such a model is much longer;

- stainless steel - alloys with the addition of nickel and chromium. Depending on the value of the alloying addition, steel can be resistant to corrosion under normal conditions, is characterized by increased resistance, which allows it to be used in sea water, for example, and also not oxidize under the influence of not only moisture, but also high temperature. The product does not need protection, however, its cost is noticeably higher;

- copper - rarely, but used in domestic conditions. They are distinguished not only by resistance to corrosion, but also by disinfecting properties.

Each option from the list can be used for water supply, gas pipelines, heating, and not only water, but also steam. However, their service life will be different.

Alas, this option is not particularly durable. Even with the most careful painting and care, they rust over time.The fact is that after the construction of communications, individual fragments are inaccessible, and it is impossible to renew the paint, for example.

In addition, black steel loses its smoothness rather quickly. And this leads to the fact that the water and gas or heating pipe “overgrows” rather quickly: first, very small debris and salt deposits are held on the uneven surface, and then increasingly large particles of rust, fibers, and lime deposits. The rate at which deposits build up is directly proportional to the hardness of the water.

Constant contact with moisture - in the bathroom, for example, in the toilet, leads to faster destruction of the material, which is reflected in the norms of SNiP. Here, the weak link is often the seams: the first fistulas appear precisely on the welds and on the thread, where the wall thickness decreases.

The standard operating time is as follows:

- the service life of steel water pipes - a riser or an eyeliner, is 15 years;

- a heating system assembled from gas steel pipes is usable for 10 years;

- heated towel rails in the bathroom can "work" for 15 years;

- according to GOST, the standard service life of a gas pipeline made of steel pipes is 30 years.

In fact, various destructive factors significantly reduce the operating time. So, for example, a pipeline with cold water wears out much faster than with hot water, as it rusts faster: condensation appears in the warm season. Yes, and the pipeline overgrows faster, since there are special additives in hot water that prevent this.

Connection Methods

The most common ways to connect steel pipes are threading and welding. But modern technologies do not stand still, but are constantly being improved. Today it is already possible to join steel pipes without welding or threading. However, there is one limitation here: pipeline elements whose diameter does not exceed 60 cm can be hermetically joined in this way.

Pipes of small diameter can be connected without welding, using special fittings

Most often, a special coupling is used to connect steel pipes without welding. Its design includes:

- frame;

- four washers and two nuts;

- two rubber pads.

For connection, it is necessary to pass the ends of the pipes through the gaskets, washers and nuts and dock them inside the body. From tightening the nuts, the gaskets are compressed, providing tightness. If its level is insufficient, an additional spacer ring should be added.

The success of this operation depends on the correct selection of the coupling diameter. And if everything is clear with respect to a too small value of this parameter - the pipes simply will not squeeze into its body, then a coupling with a too large cross section will not create a tight connection.

The flange method is another alternative type of threadless connection of steel pipes. At the same time, it must be understood that the thread is absent on the surface of the pipes and is available only on the fittings.

The connection of pipes with flanges is considered one of the most reliable, but subject to its correct implementation

This method of docking involves taking into account the following points:

- twisting nuts is not allowed. That is, it is necessary to tighten them not in a circle, but diametrically against each other;

- the gasket must be made of asbestos cardboard;

- bolts should not protrude from the nuts by more than half;

- the outer diameter of the gasket should not touch the bolts, and the size of the inner one should be slightly larger than the pipe section;

- in order not to reduce the tightness and the period of trouble-free operation of the pipeline, several gaskets should not be used for one flange.

If the technical characteristics correspond to the expected operating conditions, the flange connection will be the most reliable.

In conclusion, it should be noted that the installation of the heating system can only be entrusted to an experienced master. So you exclude the possibility of domestic problems for you and your neighbors.

Classification of steel pipes

For the manufacture of pipes intended for water heating, mild carbon steel is preferred. Its use is explained by the significant strength and plastic properties of raw materials. Due to this, steel pipes are processed by bending, cutting, welding, riveting and other manipulations.

Steel pipes are distinguished by significant thermal conductivity, which is important when the movement of heated water. An important factor influencing the laying of pipes in concrete is the correspondence of their temperature coefficient of linear expansion to the coefficient of concrete expansion

For water heating systems, preference is given to:

- "Seam" water and gas black welded pipes, obtained by bending a sheet of steel with subsequent seam welding, and electric-welded galvanized pipes with a straight seam. Such pipes are a low-budget option with a limited service life of up to 4 years. At the junction of steel layers, the formation of a welded seam occurs, which is processed from the outside, which prevents the appearance of bumps and notches on the surface of the pipe. From the inside, the welding seam cannot be processed, its quality control is difficult. Due to a small shell flaw, the metal thins in this place. This leads to a leak with subsequent forced dismantling of steel pipes.

- Seamless seamless pipes, which are more reliable in operation, used in places that are inaccessible for repairs. They are made by pressing, forging and rolling. However, the cost of such products is an order of magnitude higher than the suture version.

Manufacturers produce pipes with a diameter of 8 to 150 millimeters. The thickness of steel pipes can be light, ordinary and reinforced. The most common and worthwhile option is steel pipes with a thickness of 2.7 millimeters and a diameter of 25 millimeters. Such parameters provide protection of pipes from rupture.