Normative base of sandwich panels

Indicators based on which it is possible to judge the technical properties of sandwich panels are:

- density;

- thermal conductivity;

- water resistance and more.

All these indicators are characterized in the previously mentioned GOST 15588-86, but only for two types of insulation: polystyrene foam and polyurethane foam. But, the most common are just panels on mineral wool insulation, there is no standard for them. Moreover, even existing norms fall far short of European standards. Thus, according to Russian standards, the thickness of the steel sheet contained in sandwich panels should be at least 0.7 mm, while in Western products the thickness of such a sheet is 0.55 mm.

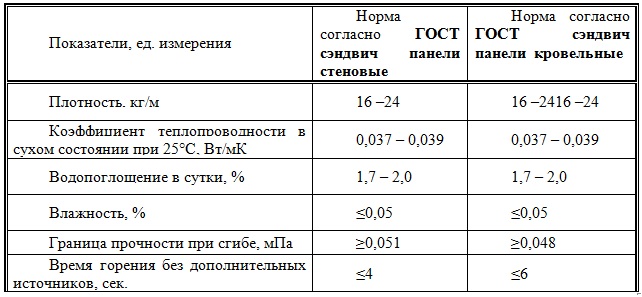

Materials that meet special requirements, that is, those used in hazardous facilities, must meet certain standards and characteristics. So, GOST indicates that panels on polyurethane foam must comply with the standards given below:

The procedure for installing the window slope

In any case, you need to remove excess insulation. In the case of a modern installation, this will be foam. It is cut with a knife flush with the frame. It is not necessary to remove more, so as not to violate the insulating properties of the seam:

- A starting profile is mounted along the perimeter of the window frame. It's almost like a P, but one leg is longer. It is recommended to put it inside.

- Under the other side of the slope, on the outer edge of the perimeter of the window opening, a wooden crate is installed.

- Put, in fact, the slope itself is made of plastic. Under it, it is usually recommended to lay a sheet of foam cut out in shape, or spray it from a polyurethane bottle.

- The slope is inserted at one end into the starting profile, and at the other end it is screwed onto the crate of a wooden glazing bead.

- The outer edge is finished with an F-profile corner.

Everything! Window trim has been completed. If necessary, with special compounds (for example, Feyco), it is painted in the desired color, or it is cleaned (a series of Cosmofen products) from contamination. In fact, all this is easier than a steamed turnip, especially for someone who has ever dismantled a finished window frame.

Guide to finishing window slopes according to the rules

If the technology for installing the plastic window itself is carefully regulated by the standard, albeit in a flimsy and arbitrary form, then the installation of slopes was left without attention. Therefore, we make seams in accordance with the GOST 30971 documentation, and then we are faced with the problem of interior finishing of the entire structure. Yes, many sites link to government documents, but when it comes to numbers, everyone shrugged helplessly. And it seems that there are so examples by which window slopes can be finished, but there are a lot of omissions here. That is why real masters do not use all types of knots. And only those who showed themselves from the best side.

Installation of windows according to GOST

Well, firstly, what is GOST. In short, this is a state standard or a certain norm that enterprises must comply with.

Currently, GOST for the installation of PVC windows has been canceled and is advisory in nature. But self-respecting companies did not recognize this cancellation and continue to work in accordance with GOST.

By the way, there are several GOSTs for PVC windows. For those interested, the list can be viewed here. But in my opinion, this “GOST R 52749-2007” is the most correct and useful one.

Installation of windows according to GOST will cost customers about 1.5 - 2 times more expensive than the so-called conventional installation. Therefore, many managers do not even offer GOST, and do not explain its benefits, fearing that customers will not buy anything at all.

What is the basic principle of this expensive installation of windows according to GOST?

And the principle is simple and it is also used in the construction of frame housing construction (the insulation must remain dry, but if the insulation still absorbs moisture, it must be able to go outside).

It's all about mounting foam - the main window insulation. And this foam is hygroscopic, that is, it absorbs moisture well. And if this moisture is not removed, then the mounting foam loses its energy-saving properties.

What does GOST offer us for window installation? And he offers a system for removing moisture from the installation room foam and protection against this moisture, both from the room and from the street.

The moisture removal system is either:

- PSUL is a vapor-permeable self-expanding universal tape. It also protects the foam from external factors (rain and snow).

- Mastic, for example the most popular STIZ - A. It has a high vapor permeability.

From internal evaporation from the room, the foam is protected by a vapor barrier foil tape.

What are the disadvantages or, more precisely, what should be taken into account when choosing this type of window installation?

The most important thing here is:

- The quality of PSUL (To be honest, I have not yet met a PSUL that would not crumble after a while. You can simply pierce it with your finger without much effort. That is, I assume that the resistance to ultraviolet in low-quality PSUL is low. Here is my recommendation for the manufacturer , which you can trust - illbruk (you can buy a complete set of materials for installation in accordance with GOST from them).

- The layer of applying mastic should not exceed 3 mm. If the foam is covered with a thick layer on the street side of the window, the steam will not be able to get out of it.

- In the old fund, it is impossible to work according to GOST, without additional financial costs and time losses. The vapor barrier tape should be the maximum width, which is still not enough. Because the quarter is deep. And it is either reduced with the help of masonry (and this is expensive and long), or the tape is calculated in double or even triple size and glued together (most often).

Installation of windows not according to GOST

And what is it all about - the usual installation (not according to GOST). And why, this option seems to be wrong, but most of the windows in our country are installed in this way?

This method is considered incorrect for one reason:

if the mounting foam does not ensure the removal of moisture, this is fraught with the formation of mold

But why is this mold and fungus only special cases, and not universal? Let's finally figure it out.

How is window installation done? In the same way, polyurethane foam is used as the main insulation. Instead of PSUL, the outer seam is sealed with facade plaster. A vapor barrier tape is not used at all.

For some reason, everyone talks about the physical properties of PSUL and vapor barrier tape, but no one says that:

- facade plaster has good vapor permeability

- and PVC sandwich - panels that serve as window slopes - are vapor-tight

By the way, the fungus is most often found on slopes made of drywall and on plaster slopes. Because these materials have good vapor permeability, that is, steam from the interior penetrates into the mounting foam, destroying it.

And you should not seal the outer seam with conventional sealants. Thus, the exit of steam from the foam to the outside is blocked. You can read about the main mistakes of installers here.

It begs a conclusion. There is an alternative to installing windows according to GOST - this is a regular installation using 3 layers of insulation:

- Vapor-permeable facade plaster

- Mounting foam

- Internal slopes of their PVC sandwich panels

The essence of voluntary certification

As mentioned above, some companies that monitor the image of their products undergo voluntary certification in order to obtain a certificate of conformity for it. The process of passing certification testifies not only to ambitious intentions, but also to the quality of products. From the date of obtaining such a certificate, all relevant products must be produced in the same way with an approved quality system.

Also, to comply with these rules, there is a kind of control department, the work of which is the supervisory function

Thanks to this approach, there are almost no deviations from the developed certified system, and if any quality inconsistencies are found, then, depending on the reason for the deviation, their importance, the product or material is sent for processing.

The functions of the control department do not end there, its competence also includes - to control the quality indicators of all purchased raw materials that are used for the manufacture of certified products. The described activities are carried out within the company. In addition, without fail, the company is sent for verification once (or twice) a year to the regulatory authority that previously issued the quality certificate.

If during the passage of such a check any inconsistencies of the technological process that are prescribed in the previously issued certificate are found, they are brought to the attention of the company's management, the control department of the manufacturer's company, and also directly to the contractor. After that, the manufacturer is given a certain time to eliminate the defect, and at the end of this period, the company is re-tested. In case of successful completion, the manufacturer receives a conclusion on the conformity of products with the requirements of GOST.

Many enterprises operate under the scheme of such voluntary certification. Companies engaged in the production of sandwich panels can do the same. Firstly, this is a huge advantage over competitors. A manufacturer who has a quality certificate for his products is always a level higher than an ordinary non-certified product. And, secondly, it is the presence of such a certificate for products that plays a decisive role in the selection of companies for public procurement.

Appointment of sandwich panels

With the help of sandwich panels, namely SIP boards, consisting of OSB sheets with insulation inside, it is possible to significantly simplify the process of building low-rise buildings and minimize the cycle time. With the use of sandwiches, the construction of any object becomes a production game in the designer - large house structures are assembled from small parts.

The standard sizes of sandwich panels have a variation that allows the use of products in any construction. So, the length of one slab can be up to 14 meters, the width of the structure is within 1.0-1.025 meters, the thickness of the slab is 0.05-0.25 meters. The most popular panel dimensions are shown in the table below:

| Product name | A type | Length (m) | Panel mounting width (m) | Panel thickness (m) |

| Wall panel | Mineral wool insulation | 1,2-1,4 | 1,025 (1,0) | 0,05; 0,06; 0,08; 0,10; 0,12; 0,15; 0,20; 0,25 |

| Expanded polystyrene insulation |

Sandwich panel for gost slopes

Sandwich panels are multilayer frameless building structures. The word "sandwich" (from the English. sandwich - to layer) means the "layered" structure of the building structure.

Properties and applications of PVC sandwich panels

The panels are assembled into wall blocks with the help of a profiled locking joint located in the body of the panel. Sandwich - panels belong to a number of light building envelopes.

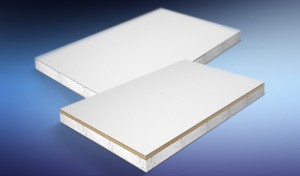

PVC - sandwich panel is a three-layer structure: two rigid PVC sheets between which there is a heater (polystyrene foam (pressed or foamed (PSV), extruded - ST, XPS), or in rare cases - polyurethane foam - FPU).

Picture 1PVC sandwich panel

PVC sandwich panels filled with polyurethane foam have the best heat-saving characteristics. Polyurethane foam is the most environmentally friendly material. Approved for residential use. Has the minimum hygroscopicity and the greatest service life.

Expanded polystyrene filler is an environmentally friendly material, has low thermal conductivity and low weight (which is very important if the sandwich panels are load-bearing). Non-hygroscopic, does not support the combustion process without a source of fire, is a self-extinguishing material

Expanded polystyrene is characterized by high strength, chemical resistance, durability, high thermal insulation properties.

Depending on the climatic conditions and the purpose of the object under construction (reconstruction), one or another type of insulation material is used.

Various materials can be used as the outer layer of a plastic sandwich panel:

• Rigid PVC sheet • Foam PVC sheet • Laminated plastic (HPL)

Rigid PVC sheet is the most common material used in plastic sandwich panels for slopes. For the production of sandwich panels with rigid PVC, white sheet material is most often used, the thickness of which varies from 0.8 - 2 mm, the surface of the sheet can be either glossy or matte. The density of such material is 1.4 g/cm3.

Foamed PVC sheets got their name because of the porous internal structure, which is specially obtained during the extrusion production of sheets. Foaming of the plastic occurs at the outlet of the extrusion head, while the thickness of the sheet produces a fine-meshed structure containing a large percentage of the smallest closed air bubbles. Therefore, in addition to the above properties, PVC sheets have low density (0.6g/cm3), and good thermal insulation. Foamed PVC sheets, like rigid PVC sheets, have good moisture resistance. At negative temperatures, the impact strength of foamed plastics decreases.

The term HPL means the method of production of the material: a “pack” of papers is assembled (kraft paper for the inner layers, decorative for the surface, overlay for surface protection) is impregnated with phenol-formaldehyde and amino-formaldehyde resins and pressed in a floor press under a pressure of 90 to 110 kg/cm2. During pressing, technological equipment is used, which determines the surface texture. In this capacity, special interleaving metal sheets and matrices are used, the surface of which is a relief image imitating the pores of a tree, the surface of a stone, etc. These reliefs are transferred to the surface of the plastic sheet, which makes it possible to obtain various types of surface: gloss, "satin", wood pores, "asphalt", etc. HPL is produced only in sheets. The thickness of laminated sheet for the production of sandwich panels is most often 2 mm. Of all the plastics described above for cladding insulation in a sandwich panel, HPL is the most durable and reliable material, and sandwich panels with HPL can be used in such operating conditions that involve the greatest stress on the material.

Any of the above cladding plastics can be coated with a renolite film, which will make it more suitable for decoration. Most often, HPL sandwich panels are used for decoration purposes. For slopes and windows, a simple rigid matte or glossy white PVC sheet is most often used. The most commonly used panels with foamed PVC.

Table 1 Physical properties of heaters

On October 1, 2014, the first GOST was adopted for metal three-layer sandwich panels, the production of which was previously regulated exclusively by the specifications of each individual manufacturer

Build-Insulation.ru. Copyrighted

Subsection: Sandwich panels

Technologies

PUR panels - technical specifications

PUR sandwich panels are a versatile building material with excellent thermal insulation and other characteristics.

PIR sandwich panels - advantages and disadvantages

PIR sandwich panels are lightweight three-layer panels insulated with fire-resistant PIR foam, an ideal thermal insulation material.

PIR sandwich panels: characteristics

Sandwich panels PIR - lightweight three-layer panels with thermal insulation from fire-resistant polyisocyanurate foam PIR

Sandwich panels: expert reviews

Sandwich panels all over the world and in Russia have long deserved the highest reviews of specialists due to their unique characteristics.

Rules for calculating sandwich panels

To correctly select the required thickness of insulation for sandwich panels, it is necessary to perform a heat engineering calculation. The calculation will also be needed to accurately determine the number of panels for construction in order to minimize the amount of waste.

Metal sandwich panels: characteristics

Plastic sandwich panels are used for finishing slopes, filling doorways, building office partitions and insulating facades.

The main nodes of the sandwich panels

The most common sandwich panel fasteners are developed by each sandwich panel manufacturer as a technical solution.

Thickness of sandwich panels

The thermal efficiency of the building, its strength and reliability depend on the correct selection of the thickness of the sandwich panels. It is necessary to select the thickness of the panel depending on the core material, climate zone, type of construction, etc. factors

Three-layer wall sandwich panel: main characteristics

Wall three-layer sandwich panels have different technical characteristics, which depend on the material and thickness of the insulation, base and cladding

Self-tapping screws for sandwich panels - which ones to choose?

A self-tapping screw for fastening sandwich panels is as important as cement mortar for a brick house. How to choose the right self-tapping screw?

news

The evolution of one manufacturer of SIP panels from Naberezhnye Chelny

Recently, Maitek Isolux from Naberezhnye Chelny presented a new project…

Ruukki and ISOVER launch a joint product - Life sandwich panels

Ruukki announced the start of production of innovative sandwich panels…

In 2016, Teplant expects a 15% increase in market share

According to information provided by Teplant, in 2016 one of the leading…

Another line for the production of AKP was launched at Aluminstroy

The press service of the domestic company Aluminstroy announces the launch of another…

The production of "sandwiches" of a new type plans to launch "Tata Steel"

The press service of the metallurgical concern Tata Steel announced its intention to…

When insulating an old house, Belgian builders used innovative hemp material

While renovating one of the old residential buildings located in the Belgian countryside…

Production of unique "sandwiches" mastered in Altai

At the Altai plant of sandwich panels, forced to compete with those with…

A unique enterprise for the production of mineral wool and "sandwiches" will be built in Chechnya

In Chechnya, construction is starting to be unique not only for the republic, but also for ...

Italians launched the production of "sandwiches" in Russia

According to the data provided by the press service of the Manni Group holding (Italy),…

A new product from Knauf has appeared on the Russian market

This year, Knauf introduced a new product for the Russian market - a suspended…

VRK1 will build a prefabricated building in St. Petersburg

The cost and deadlines are ideal for an existing business. Already…

TechnoStyle has been supplied with European Cannon equipment

As part of the program of technological re-equipment and expansion of production,…

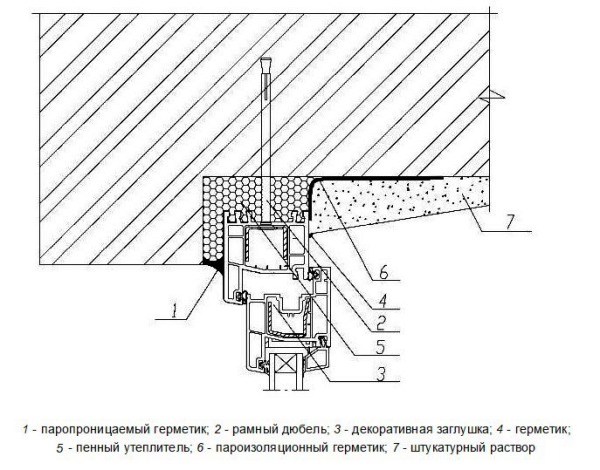

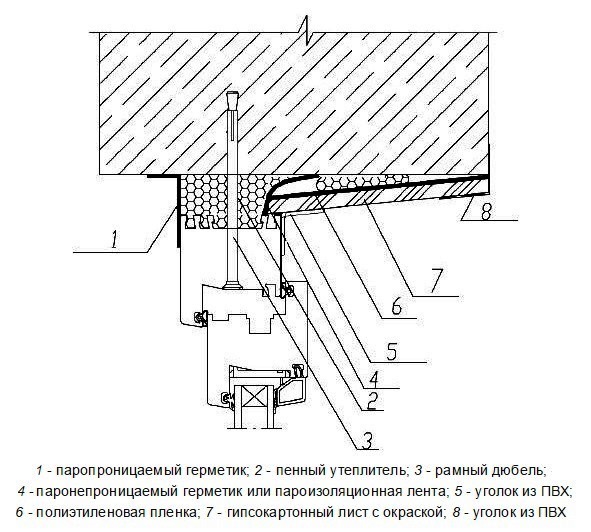

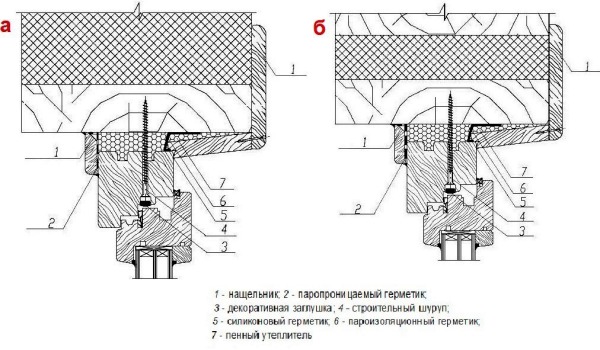

How to finish window slopes in accordance with GOST 30971

As such, there are no slopes in GOST, but there are types of nodes, which partially include these elements. There are some types of solutions in the recommended Appendix B. We remind you that slopes are decorative elements that cover the inside of the window opening from above and from the sides. GOST recommends making it from plaster or moisture-resistant drywall. There is also an option with insulation, which can be covered with ... anything?

Let's see how bad this or that finish option can be in order to find the right one among them.

- For example, in Figure B.2a of the standard, an embodiment of the junction of a window frame to a quarter with a slope of plaster is shown. We see that the insulation layer is surrounded on both sides by a vapor barrier material. From the inside it is a self-adhesive film, and from the outside - any plastic composition that meets the requirements. The frame is fastened to the anchor by through-drilling the profile. We see that after that it is proposed to simply apply plaster at an oblique angle, and we can calm down on this. What is the trouble here? There are even several of them. First, the coefficients of thermal expansion of plastic and concrete are not the same. For plastic, the value is much, much (5-6 times) higher. Therefore, a crack is guaranteed to form on the border of the formed seam near the frame after some time. And no matter how much you close it, it will not give an effect. In addition, any plaster is not very durable or resistant to abrasion. As a result, in places of collision with an open sash, pieces will soon begin to break off, and anyone who accidentally leans on will scrub his clothes for a long time. But that's not all. Anyone who has tried to equalize a wall with putty or other mortar knows how difficult it is to do it purely technically, even with free access. This means that the slope of the plaster is guaranteed to come out wavy. And it will be noticeable from the outside. And it is very difficult to maintain exactly right angles. Therefore, the slope will probably also be slightly curved. Well, since most people put the window sill also made of plastic, like the frame (and not made of artificial or natural stone), cracks will soon form over the compensation gaps at the ends. No matter how you put silicone, it is almost never taken on plaster.

Warming in this case is carried out by any available method. By the way, PVC fabric can be decorated beautifully from all sides: from the window, window sill, wall. Another thing is that it is not always possible to do it yourself, and sometimes you have to place an order. The downside is the relative vulnerability of such a technical solution to sharp objects. Well, and, of course, you can lose the warranty, because the installation is not in accordance with GOST.

Importance of norms in production

State All-Union Standards (GOST) ... Quite common in the USSR. At one time, everyone adhered to them, but unfortunately, this does not apply to the present. There are a lot of new materials on the market right now. In the production of which often do not adhere to any rules and regulations. These circumstances could not but affect the quality of products.

Construction is no exception. Today, almost all manufactured building materials do not pass the previously mandatory certification. Only often large firms, for which the image is primarily provided to the buyer, are only certified goods of suitable quality.