The principle of operation of the IR heater

Infrared heaters differ in principle from other devices, they do not heat the air, but the surrounding objects, that is, they operate on the principle of sunlight.

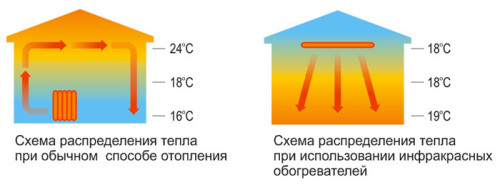

The scheme of heat distribution in the greenhouse.

When taking pictures with thermal cameras of the situation in the room using infrared devices, one can observe the following picture: the maximum temperature is observed near the equipment and at the floor surface, that is, heating is felt immediately after switching on. And with a conventional heater, warm air rises, that is, it takes a very long time to wait for the temperature to rise below, and this significantly increases energy consumption. That is, we can conclude that infrared heaters are much more economical, it is recommended to choose them when electricity consumption is a critical value, comfort is a priority.

Lamp and film heaters with minimal power consumption

To install an efficient and simple IR heater, ceiling lamp and film structures are often used, which are very easy to install, their power consumption is quite economical.

Scheme of the lamp IR heater for greenhouses.

Lamp infrared devices use halogen lamps with a tungsten filament in a flask filled with a mixture of argon and nitrogen as a radiation source. The power of such lamps is 150-250 W, which is quite enough to heat an ordinary living space. Lamps for such devices are available in various:

- conventional infrared mirrors, which are similar to conventional lamps for lighting, but emit more IR rays;

- mirror red infrared lamps with a dark red glass bulb, they give little light, but more heat, and the power consumption is much less.

Film infrared heaters are attractive because they do not have a body, that is, they are a film with carbon paste with a thickness of one micron. Such a film has summed up copper contacts. You can choose such a heater if you need to heat the device to a maximum of 110 degrees, and the average heating temperature is 30-45 degrees Celsius. The electricity consumption of a film heater is not very large; it is often used for mounting not only on ceilings, but also for floor heating.

Gas panels and longwave infrared

Gas infrared heaters are mainly used for local heating of small outdoor areas. This allows you to create comfortable conditions on the verandas, in open cafes, terraces. Often, gas appliances are made in the form of elegant modern lanterns that serve as a design decoration.

Types of IR radiation.

The device itself is a gas cylinder hidden under the base of the umbrella. The consumption of the cylinder is very economical, it lasts for 22-25 hours of continuous operation, so they are often taken to picnics, put on playgrounds, sports grounds, in parks. There is enough power to feel comfortable even at sub-zero temperatures.

Gas ceiling heaters are used when a mobile source of heat is needed in an area from 9 to 60 sq.m, bottled liquefied gas serves as fuel.

Most often, long-wave devices are used to heat a house, in which a special aluminum alloy plate with a special coating acts as a radiation source. Such a plate is heated by a heating element up to 300 degrees Celsius, between it and the body there is a heat-insulating material that provides heating of the body itself to only 50 degrees, that is, the heat is directed exactly where it is needed.

Household infrared devices of this type are produced in the form of rectangular cases, they are mounted on the ceiling with special brackets, the angle of inclination of the device can be easily adjusted. Long-wave devices are very convenient for heating not only in residential premises, they can also be successfully used for offices, shops, kindergartens.

Varieties of heating systems for polycarbonate greenhouses

The simplest solution to the issue related to the organization of additional heating in the greenhouse can be the installation of a conventional stove in the room. In this case, the stove is erected in the middle of the room, the chimney is brought out, and firewood, coal, and peat are used as fuel. In order for the plants to feel comfortable, they equip the simplest ventilation system. It would seem that this method is quite simple and affordable to implement, however, the main drawback of stove heating is that it is impossible to achieve a uniform distribution of heat over the entire area of the greenhouse. Therefore, plants that are closer to the furnace receive an excess of heat, and their more distant counterparts receive a lack.

Some summer residents are trying to equip the greenhouse with electric heating. To do this, they mount various heating elements, convectors, fan heaters around the perimeter of the greenhouse. Also, cable heating systems for greenhouses are very popular, which ensure uniform distribution of heat throughout the entire volume of the room, during installation and subsequent maintenance require a minimum investment of money. Electric heating systems of the greenhouse can be connected to an automatic regulator that will adequately respond to changes in air temperature outside the room, maintaining a predetermined temperature in the greenhouse. Those wishing to equip their greenhouse with electric heating should not forget that you have to pay for electricity. The cost of paying for electricity for heating air in a greenhouse directly depends on the type of heating element chosen, so electric heating is not always justified from an economic point of view.

The most acceptable way to heat a greenhouse is the use of infrared heaters. Infrared heaters do not heat the air in the room, they only heat the plants. Moreover, infrared heaters do not emit light, consume a small amount of electrical energy, which justifies their use even in small greenhouses.

Installation of ceiling heaters

The small infrared ceiling heater for domestic use can be easily installed by hand. This can be done by a professional electrician or an ordinary person, the main thing is to follow all the steps exactly. It is necessary to start with the correct placement of the equipment, it is impossible to place the device less than 30 cm to the furnishings and structures of the room. Now you need to decide what is included in the kit of a conventional ceiling heater:

- the infrared device itself (it can be any design, including glass panels);

- device suspension elements;

- heating electric heater;

- heat-emitting plate;

- fasteners, clamping plate;

- screws, bolts, etc.

Schematic diagram of an IR lamp for a greenhouse.

Often, all the necessary fasteners are already included with heaters for installation on ceilings, these can be cables, chains, and so on. In this case, it turns out to ideally determine the height of the heater, if necessary, adjust it.

Installation steps include:

- first you need to choose the installation site, mark it with a simple pencil;

- then the infrared heater is pulled out of the package, placed on a horizontal flat surface with the plate down;

- a ring screw is screwed on the ceiling, chain links for fasteners are suspended, their reliability is checked;

- the heater is suspended on a chain to a selected height between the brackets (all screws must enter the prepared grooves, after which they are tightly wrapped);

- the heat-emitting plate is wiped with alcohol just before connection;

- the ends of the cable are connected to the heater and the fixed network in strict accordance with the diagram given by the manufacturer;

- a device with a thermostat should be located approximately 1.5 m from the floor level, the device itself should not be in the field of action of the heater rays, in a draft or near other heat sources.

There are other mounting options, for example, using terminals for glass heaters. These appliances are a decorative tempered glass panel that is attached to the ceiling with a terminal block and self-tapping screws.

There are gas heaters, the installation principle of which is also different, so when buying, always pay attention to how exactly the device will be attached, whether you have the conditions for its installation

Infrared heaters today are used not only for heating a private house, but also for shops, cafes, industrial workshops, even for open spaces. Not all heaters are capable of this. At the moment, this is the most promising type of heaters with a variety of advantages.

When installing, you can observe the shortest length from the device itself to structures and furnishings, that is, IR heaters are absolutely safe. Manufacturers today offer us various models, including gas appliances for ceiling mounting, industrial and household, outdoor. The devices themselves can be made of a special film, glass, have various heating elements. Installing household IR devices is also very simple, usually it is enough to install ceiling mounts, the device itself is fixed using special brackets, terminal blocks, or suspended on chains and cables.

Rules for heating greenhouses with infrared devices

Such equipment is very easy to install and connect, so you can handle this work yourself. But at the same time it is necessary to follow the recommendations of experts. For example, by installing heaters near windows and doors, heat losses can be reduced. When organizing heating, you need to focus on the power of the devices.

Easy-to-use devices that have special attachments to the ceiling. Such heaters can, for example, be hung over the table where the seedlings are located. But it is difficult to say at what height the device should be - you will have to find out from your own experience. Once the heater is set at a certain height, it must not be moved until the plants begin to grow. As the crops rise, the greenhouse infrared heater will need to be hung higher. If it is not possible to attach the device to the ceiling, you can fix it on a rigid base.

As for the number of heaters, for every 1.5-3 meters of area there should be one device. The distance between them depends on greenhouse dimensions and the height at which the devices are located. The higher the device is located, the larger the area it heats. Therefore, if possible, heaters should be installed higher, then a smaller number of them will be required. However, we must not forget that the higher the device is, the less heat the plants receive. Still, it is better not to save, but to proceed from how much more comfortable it will be for crops.

You can also use devices with a power of 250 watts. In this case, more appliances will be required to achieve the optimum temperature. The distance between them should be 1.5 meters.The height of their placement above the plants will also need to be determined from your own experience. The position of the heaters should remain the same until the seedlings begin to grow. Gradually, as the plants grow, the devices are raised to a greater height. Heaters of such power are small in size and weight, they are simply hung on wires. The height of the devices is very easy to adjust - just pull or release the wire.

There are some recommendations that will make infrared heating for greenhouses as efficient and economical as possible. For example, they can be arranged in a checkerboard pattern - then the room will be evenly heated over the entire area, and energy consumption will be less. In this case, the number of unheated areas will be minimal. However, this advice can only be used if you need to evenly heat the entire greenhouse. If it is necessary to create different temperatures in different parts of the room, you should not follow this recommendation. In this case, you need to install heaters in those places where you want to achieve a higher temperature regime.

Heating a greenhouse with an infrared heater, see the video:

Advantages of infrared heaters

An infrared heater is a piece of equipment that emits rays similar to the sun. Objects and surfaces absorb them, and they, in turn, give off heat to the air. Exactly the same thermal effect gives and sunlight.

Thanks to this, infrared heaters have the following advantages:

- low power with high efficiency, which saves on electricity;

- practicality in operation;

- do not create drafts;

- distribute heat evenly throughout the room.

Using convective heating devices, you can notice that the heated air rises, and the cold remains at the bottom. Such devices are ineffective in terms of heating greenhouses, since the plants are just below, and they will not have enough heat. Infrared heaters for greenhouses are good just because they evenly distribute heated air, thereby creating optimal conditions for plant growth.

Also, IR devices are able to get rid of drafts, which are undesirable for many vegetables and greens. To do this, you just need to place the device in the area where there is poor thermal insulation - during operation, it will eliminate heat losses without creating air movement. Infrared batteries have a high efficiency.

These devices are highly practical. Their advantage over other heating devices is the ability to divide the room into zones, setting a special temperature regime in each. With high efficiency, infrared heaters are economical: if installed and used correctly, energy consumption can be reduced by up to 40%.

These devices allow you to warm the soil to a depth of 5-7 centimeters, and this stimulates the root system of plants, creates the required conditions for successful development. Other heating devices cannot purposefully heat the soil. IR rays warm the ground up to 28 degrees - the optimum temperature for plant growth. At the same time, the air temperature in the room itself is about 21 degrees.

Also, infrared devices are safe to use, so they can be left turned on unattended, setting the desired temperature level.

How to do infrared heating in a greenhouse based on polycarbonate with your own hands

In order to equip a polycarbonate greenhouse located in a summer cottage or suburban area with infrared heaters, it is not at all necessary to attract expensively paid specialists. All work can be done independently.The only condition: if you do not have the skills to work with electrical equipment, do not know the basics of electrical safety, it is better to involve a professional in work related to connecting sources of infrared radiation to the network.

- 2-4 ceiling heaters should be installed in the upper part;

- in the lower part, for effective heating of the soil, it is necessary to install film-type heaters.

In order to achieve the maximum effect from the work of ceiling heaters, in the middle of the building, under the location of the infrared devices, a concrete path should be equipped. It will accumulate the heat generated at the top and evenly distribute it throughout the entire volume of the room. Film heaters buried in the ground will warm the soil from below.

To install film heaters, it is necessary to remove the top layer of soil to a depth of 40-50 cm. Sand should be poured into the bottom of the resulting trench in an even layer. Further, any heat-insulating material with a low moisture absorption coefficient is laid on a sand pillow. Expanded polystyrene can be used for this purpose. The purpose of this insulating layer is to retain heat and prevent its penetration into the ground. Further, after the polycarbonate or other similar insulation is laid, it must be covered with another layer of sand 5 cm thick. The sand must be poured with water, and then carefully compacted.

Then, a film infrared heater is laid on a layer of compacted sand. Before laying the heater, do not forget to connect the power wires to it and lead them out of the trench. After laying the film infrared heater, its surface is covered with another layer of sand, which is poured with water and rammed to remove air bubbles. If the air bubbles are not removed, they will act as an unwanted resistance to the passage of heat. Then, a perforated sheet of asbestos cement or a metal mesh is laid on a layer of sand, which will protect the heating element from possible mechanical damage that may occur during digging up the soil inside the greenhouse. Further, the remaining space of the trench is filled with ordinary fertile soil.

How to choose an IR heater for a greenhouse

Of course, it should be borne in mind that positive feedback from IR heaters was received from people who were able to choose the right device for their greenhouse and install it properly. The maximum positive effect of the operation of the device depends on the exact calculation of heating systems, connection and location.

So, to explain everything simply and quickly, consider the calculation using the example of a standard greenhouse with dimensions of 6x3 m. For such an area, only two heaters with a power of 1.2 kW to 1.5 kW are enough

But it is important to consider not only the power, but also the size of the devices themselves. For example, a device about 1.8 m long with a beam scattering angle of 100-120 degrees is able to heat an area with dimensions of 2.5x3 m

Even the most rough calculations will make it clear that two heaters are more than enough for the greenhouse taken as an example. Of course, larger areas will require more heaters or more powerful models.

For wide greenhouses, there is another option - to install heaters not in the center, but on both sides. To do this, you will need about 4 devices, and their power should be correspondingly reduced by 2 times. So you can be absolutely sure that every square centimeter of space is exposed to the warm effects of the rays.

Types of heaters

There are several types of IR for greenhouses. Varieties have been described above in terms of the nature and length of the radiation, but now the difference lies in the method of installation.

Types of devices by type of installation:

- ceiling - the optimal location a meter from the surface of the earth.Best suited for greenhouses with high levels of humidity, creating an additional greenhouse effect;

- ground - placed directly on the ground;

- wall;

- infrared films - can be installed on the ground vertically or horizontally. Vertical installation is carried out between the beds, when the film goes around the entire perimeter. When installed horizontally, the film is dug into the ground to a depth of about 50 cm under the beds. This method is more suitable for a stationary greenhouse, when you do not need to regularly dig up the beds.

general information

When growing horticultural crops in a greenhouse, special attention must be paid to the microclimate. Regardless of the time of year and the ambient temperature inside the building, there must be comfortable conditions under which the growth, development and yield of plants will be most productive.

And no matter what type of heaters will be used, it must perform its basic functions in the best possible way.

Some gardeners equip heating systems with their own hands, building small solid fuel stoves. However, such inventions are not known for their safety and need constant monitoring and fuel addition. In addition, they heat only the air, which is why the efficiency indicators are seriously reduced. Often, pipes with water are brought to the structures, which are located around the perimeter of the greenhouse. Unfortunately, this approach does not improve heating efficiency, but only requires large investments.

The next type is electric air heaters. They are easy to install and also support full automation, making them comfortable to use. Unlike the previous type, such systems do not heat the air, but they do not boast a high level of efficiency.

Among the advantages of fan heaters for a greenhouse powered by electricity, instant heating of the internal space is distinguished, although this leads to one unpleasant phenomenon - excessive drying of the air. In turn, dry air negatively affects green spaces and reduces yields.

The most unsuitable option for a heater is a gas appliance. During the operation of such a system, any air humidity drops to a minimum, which entails disastrous consequences for the crops grown.

Also, when arranging electric heaters for greenhouses, soil heating cables are considered. They are able to warm the root system of plants, but are expensive and require expensive maintenance.

In this video you will learn more about infrared heaters;

Ways to improve the efficiency of the heating system

As you know, infrared heaters do not heat the air, but objects, including the ground of the greenhouse. At the same time, they are able to warm the soil only by 7-10 cm, and as plants such as cucumbers grow, less heat gets to the soil. Therefore, in order to increase the efficiency of the heating system, experienced vegetable growers recommend providing for heating the soil. The following options are possible:

- supply of warm air from any source through pipes;

- traditional cable "warm floor";

- laying a layer of foam between the foundation and the ground;

- laying under the ground IR film PLEN.

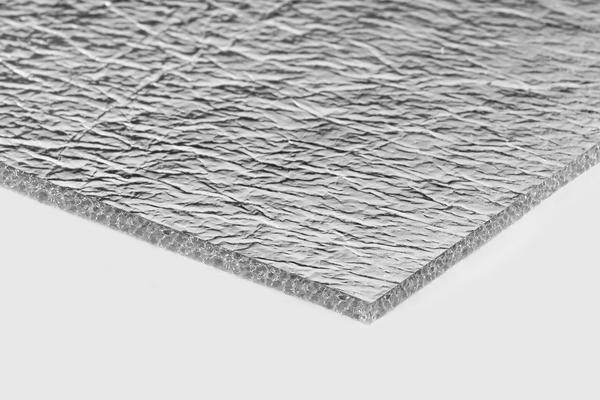

Penotherm is an effective and inexpensive material for thermal insulation of greenhouse soil

Penotherm is widely used as a heater for saunas and baths. It is also the most budgetary way of thermal insulation of the soil of the greenhouse. A material with a thickness of 0.5 cm is used, which is laid directly on concrete with an overlap on the walls of the greenhouse to a height of 10-15 cm. A layer of soil up to 50 cm thick is poured over the insulation. Such a “pie” tolerates frosts well 30-40 ° C.

Infrared film can be laid under the ground to a depth of 30-50 cm in stationary greenhouses or used for temporary heating, covering plants from above only on very cold days. The film under the ground can be mounted both horizontally on a concrete or crushed stone base, and vertically along the perimeter or between the beds. Film heaters are also convenient when growing seedlings in boxes on racks or on the floor.

Infrared film can be used for “bottom” heating of the greenhouse soil or cover plants with it from above during very cold periods

When placing IR units in a greenhouse, it is also useful to take into account the recommendations of experienced users.

The potential of infrared heaters with a power of 500 W or more is fully manifested when they are placed in the coldest zones of the greenhouse along walls and windows. Moreover, the distance from the device to the plant should not be less than 1 meter. Powerful heaters with ceiling fastening are effective. They are placed above tables with seedlings, above tall plants in the ground, but the optimal placement height in each case must be determined empirically independently.

Usually, 1 heater is installed for every 1.5-3 meters of the greenhouse length. The higher the ceiling of the greenhouse, the larger the area covered by one device. True, the higher the unit is located, the less heat the plants receive.

To some growers, the scheme of infrared heating of the greenhouse with 10-12 heaters with a power of 250 W seems more flexible. It allows you to concentrate more devices in one zone, leaving another cooler. In this case, the distance between the heaters should not exceed 1.5 meters, and the height of their placement above the plants is also determined empirically: first lowered lower, and raised as they grow.

To increase the efficiency of the infrared heating system and at the same time reduce energy costs, heaters are placed above the plants in a checkerboard pattern, thus reducing the number of "dead" zones.

An example of the organization of infrared heating of a greenhouse based on 3 units with a power of 1000 W on the video:

Users point out the only drawback of infrared heating of greenhouses - the cost. But plants with rapid growth and high yields fully compensate for these costs.

Variety of IR heaters

Today you can choose a variety of infrared heaters, which are divided into:

- Low temperature ceiling infrared (long wave) models. The heating of such devices ranges from 100 to 600 degrees, they are used for residential premises, where the ceiling height is no more than 3 m. The power consumption of such devices is very economical, and the atmosphere in the room is comfortable and pleasant. The air does not dry out during use.

- Medium-temperature infrared (medium-wave) is better to choose when it is necessary to heat a room with a ceiling height of 3 to 6 m. The heating temperature is from 600 to 1000 degrees, such equipment is great for large residential and non-residential premises, restaurants, cafes.

- High temperature infrared (shortwave). Such devices are heated to a temperature of 1000 degrees, they are used for installation in production workshops, warehouses, in stores where the ceiling height is from 6 to 8 m.