Why you should brick the oven in the steam room

Despite the fact that modern products look beautiful and representative, in the interior of the steam room against the background of natural wood, they will look inorganic. And this is not the only reason to overlay the stove in the bath with bricks.

The following factors speak in favor of the event:

- The outer surface of the metal is very hot. This leads to overheating of the room and the creation of an uncomfortable environment in it.

- Fire hazard. If you overdo it with fuel, the heat from the boiler becomes so strong that it can start to smolder first, and then burn the finish of the steam room.

- Potential for burns if accidentally touched. In the case of brick, this risk is eliminated, since this material absorbs heat, evenly distributing it throughout the volume.

- Iron heats up quickly and also cools down quickly. Because of this, it is difficult to control the temperature in the room.

- Corrosion protection. Sooner or later, the protective coating comes off the iron and the boiler begins to rust. This is not aesthetically pleasing and is fraught with thinning of the walls of the furnace body in the future.

- Organic interior. Brick against wood looks much better than metal.

Do-it-yourself brick chimney for a solid fuel boiler

In itself, the construction of the pipe is not difficult, especially for those who already had experience with similar material.

However, during construction, it is important to take into account some features that will allow you to create a reliable and durable structure. It will effectively cope with the effects of condensate and precipitation.

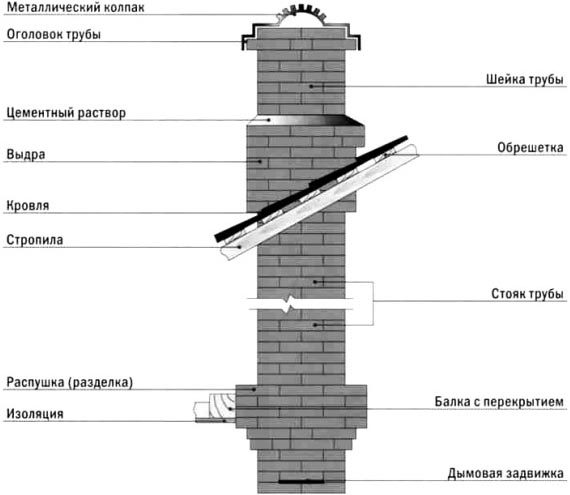

Brick chimney diagram: main components

Important: A brick chimney for a boiler can only be installed during the construction of a house, since such a pipe will have a considerable weight and will require a solid foundation at its core. The height of the foundation should be at least 30 cm, and the width should be selected based on the width of the structure itself: the foundation should exceed it by 15-50 cm on each side

The height of the foundation should be at least 30 cm, and the width should be selected based on the width of the structure itself: the foundation should exceed it by 15-50 cm on each side.

If the boiler chimney becomes part of an external wall, the foundation must also come out and be the lower level of the wall foundation.

- For laying out, it is necessary to use refractory bricks M75 or M50. To fix them, a cement mortar or a mixture of cement and lime is suitable. A high-quality chimney can be obtained by performing masonry with dressing: ensuring that the seams of the previous row are overlapped by the next.

- When erecting, it is necessary to process the inner surface and rid it of roughness.

- It is better to finish the upper part of the chimney for the boiler with a head protruding 10 cm beyond the brick base.

Under the head, you can add ventilation holes that will prevent air from blowing in. They must be placed on two opposite walls or on each side.

Compliance with these principles will allow you to create a chimney for a solid fuel boiler on your own, whether it is a straight pipe through the roof or going into the wall. Each design method has its own advantages:

- A chimney passing through an attic or roof will give off heat to all rooms through which it passes, therefore it is suitable for two or more storey buildings. In addition, it is easy to build.

- A chimney passing through a wall is compact and safer than a conventional chimney.

↓ Be sure to read the recommended material on the topic ↓

Blows the boiler through the chimney: what to do and how to prevent

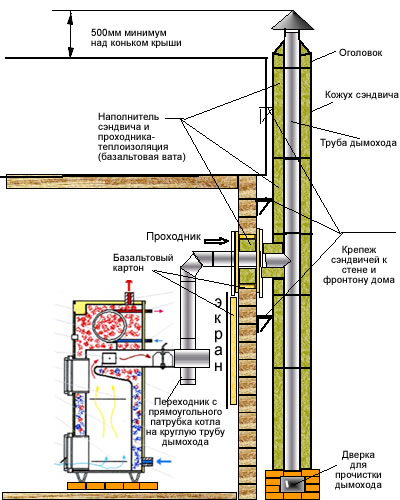

Scheme of installation of a metal smoke exhaust pipe

Tip: A metal pipe can be added to the inside of a brick chimney for a boiler, which will protect the walls from soot.

Video: tips for choosing and calculating a chimney for a solid fuel boiler

Thus, brick chimneys for boilers are the most optimal if the complexity, cost and reliability of construction are compared. Therefore, having studied all the necessary information, you can purchase materials and start building a chimney with your own hands.

Browse other related topics

Do-it-yourself chimney deflector: drawings and diagrams

Do-it-yourself ceramic chimney installation, tips and tricks

Advantages and disadvantages of asbestos pipes in the furnace business

steel chimney

Steel chimney: collapsible design

You have a choice of a chimney made of plain or stainless steel. As you understand, the latter is becoming increasingly popular, since the service life of a chimney made of ordinary steel is no more than 3-5 years.

high thermal stability - they can withstand temperatures from 500ºС to 700ºС.

resistance to condensation - and this, in turn, ensures the reliability and durability of the system itself

316, 316L, 321 - stainless steel grade, which is suitable as a material for the chimney of a solid fuel boiler.

Affordable price is another important plus that attracts attention.

the possibility of adjusting the design of the chimney - unlike glass or brick, you can easily add the necessary details to this device, for example, a damper, if you forgot about it in the original version .. Read more about the construction of a steel chimney in our article

Read more about the construction of a steel chimney in our article.

Masonry cladding

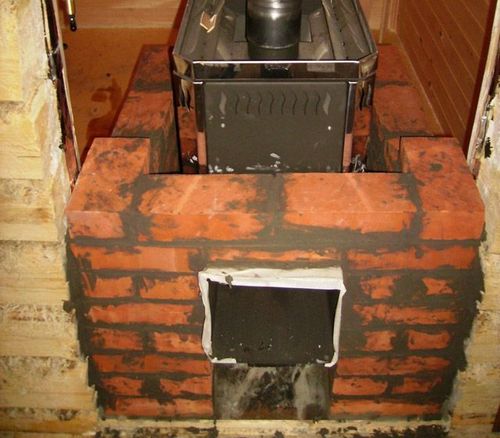

Before overlaying a heating boiler with bricks, it must be remembered that the stove with a brick "shirt" should be located at a distance of at least 20 centimeters from the wall.

If it is made of wood or other flammable materials, the gap should be increased to 50 centimeters. It is possible to ensure the fire safety of walls made of wood materials with the help of finishing from metal or asbestos-cement sheets.

Furnace lining is carried out subject to certain rules:

- Masonry must be done in half a brick and not thicker, otherwise it will not warm up. When the first row is made, the indents are measured from the outer side of the unit body to the inner side of the cladding. At the same time, the minimum allowable distance is 5 centimeters, and the recommended one is 10 centimeters.

- Laying is done in a checkerboard pattern. Bricks are pre-soaked, shake off moisture from them, and only then a solution of clay is applied over the entire surface. If the brick is not moistened, it will absorb all the liquid from the solution and the mixture will lose its binding qualities. A brick is applied to an adjacent product with a smeared part and tapped with a wooden mallet.

- In order to increase the rigidity of the fence, a reinforcing mesh is used, it is laid on top of each row of masonry. In the place where the corners pass, the mesh must be pulled together with soft steel wire. It is necessary that the mesh does not protrude beyond the edges of the masonry, but fits snugly against it.

- The seams should immediately be rubbed with clay mortar.

- To ensure unhindered movement of air around the furnace body, several holes are left in the masonry. The easiest way to make them is to fix the brick across. On each side of the cladding, 4 holes must be equipped - 2 at the top and 2 at the bottom.

- The lower holes are for cold air in, and the upper holes are for hot air to exit. Thanks to this, overheating of the boiler will be prevented and the free flow of heat into the room will be ensured.

- Masonry is carried out to the top of the metal unit. For the last row, you can take bricks decorated with a textured decorative surface.

- After the masonry is completed, the walls are allowed to dry.The final solution hardens in a few days.

- Then the surface must be cleaned of excess clay mixture. The bricks should have only an even color. This job is best done with a drill with a brush attachment or the old method using sandpaper. Put on a respirator before cleaning.

- If, after completion of work, dark spots are visible on the surface of the cladding, they should be walked over with a stiff brush dipped in soapy water. Then it is washed off and the masonry is allowed to dry.

This should be done carefully, without overloading the unit, so that the solution acquires maximum strength with a non-critical and gradual increase in temperature.

If the lining was exposed to an iron stove in the bath, then after the first visit to the steam room, the changes that have occurred will be noticeable, since the heat will become softer and smoother, it will last longer in the room.

By the way, a brick "shirt", erected around a metal unit, when heated, gives off excess moisture to the surrounding space, and when cooled, absorbs excess vapors available in the steam room. Thanks to this, the indoor climate will be comfortable and beneficial for the human body.

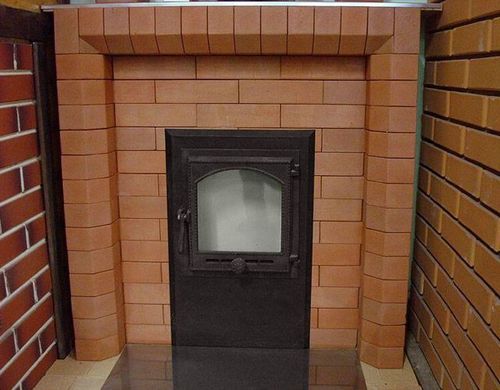

Methods for lining the furnace in the bath

The hearth during the combustion process is heated to a high temperature, which is accompanied by its thermal expansion. All this must be taken into account when choosing a facing material and the method of its application. At the same time, it is necessary to plan the finishing of not only the walls, but also the pipes.

The oven can be lined with the following materials:

- Ordinary red brick made of baked clay. It is better to choose solid blocks that conduct well and keep heat longer.

- Monolithic ceramic brick. Excellent material, characterized by medium thermal conductivity, strength and resistance to sudden changes in temperature.

- Chamotte refractory stone. It is used for laying a firebox, it absorbs heat well, and therefore, it is not suitable for exterior decoration.

There are such options for wrapping the hearth, regardless of its location:

- Solid cladding. This is the easiest way to finish the boiler. It is similar to laying tiles on the floor and walls of rooms. Only here there are some nuances. The first is the correct choice of lining. It is necessary to take tiles that are resistant to high temperatures and have the same coefficient of thermal expansion as metal. Another condition is the preparation of a solution with the desired composition. A mixture of clay, sand and cement works best. Seams must be sealed with a special waterproof grout.

- Thermal shield. This design is a blank brick wall, laid out at a distance of 2-3 cm from the outer surface of the boiler. The advantages of this design is that the heat is transferred to the stone, which ensures good heating of the room, while preventing the likelihood of fire and burns. In addition, the absence of contact between metal and brick eliminates the appearance of cracks during uneven thermal expansion of materials.

- Facing-convector with products. Such structures are used for lining high power hearths, which are developed by pyrolysis plants or long-burning boilers. A vertical wall of half a brick is laid out 4-5 cm from the stove. Air vents are left in the lower and upper parts, through which air circulates under the influence of changes in altitude and air temperature. Such a system works efficiently, evenly distributing heat throughout the volume of the steam room.

Why brick cladding is needed

Without a stove in a private household or a bath, it is impossible to create coziness and comfort. Units made of metal have undeniable advantages, including:

- compactness;

- mobility;

- good heating of the room;

- Easy installation and you can do it yourself.

But due to the fact that the metal is characterized by a high heat capacity and the body of it quickly heats up and cools down quickly, many property owners prefer brick structures, despite their massiveness.

It will take only half an hour to heat a metal unit, but in order to constantly maintain heat in the house, the fuel in it must constantly burn. True, much depends on the design features of the device. For example, a long-burning furnace can effectively function during the day on just one fuel tab.

To significantly extend the heating time, it is necessary to figure out how to brick a metal stove in the house. Due to this, the time for generating thermal energy increases several times. Brick tends to heat up for a long time and cool down slowly. Therefore, even when all the firewood has already burned out in the combustion chamber, the heated walls of the structure will continue to give off heat for several more hours.

During operation of a metal furnace, its body becomes very hot and careless contact with it will be enough to cause a serious burn. If the unit is protected with brickwork, then it will help protect the residents of the house from such wounds.

Of course, its surface will not be cold, but it will not heat up enough to damage the skin.

Expert answers

1:

And how many on the street? The house most likely should not warm up but should dry out and then it will start to keep warm.

Vyachesl@v:

7 to 10 days

ALAN:

If foam concrete is laid on a cement-sand mortar (as is usually practiced), then the house will warm up only in summer (naturally). If laid on glue (as it should be), then warming up takes 8-10 hours. What does bricked up mean? Is there a fan heater? The thickness of the foam blocks? In general, forumhouse will help you.

Vladimir Rudakov:

Battery temperature? - if hot - add registers, if cold: air in the system? - check, remove the boiler power enough? (MDK 4-05.2004 - “METHODOLOGY FOR DETERMINING THE NEED FOR FUEL, ELECTRIC ENERGY AND WATER IN THE PRODUCTION AND TRANSMISSION OF THERMAL ENERGY AND HEAT CARRIERS IN PUBLIC HEAT SUPPLY SYSTEMS” - google, download, study, count (the calculation is really simple, all the necessary coefficients are in the tables) - calculate how much heat is needed, how much gas is needed for this heat, and how much you really burn - it will be seen:

Andrey Subbotin:

WHAT IS THE NUMBER OF RADIATOR SECTIONS? IF THE CALCULATION BY SECTIONS IS MADE PERFECTLY THE HOUSE SHOULD WARM UP IN 1-2 DAYS, WHAT IS THE HUMIDITY IN THE HOUSE? IT'S POSSIBLE THE WALLS ARE DAMP. ADD T FEED MAKE 75 degrees.- DON'T FEAR. I HAVE A SIMILAR HOUSE AND THE SAME SITUATION - EVERYTHING HAS ALREADY WARMED UP.

Andrey:

You were deceived, the house warms up and freezes completely in 72 hours. Who did the thermal calculations for you? They suggested to you, the word "any way", and as a specialist I can give many options in which a battery of 8 sections will be completely insufficient for heating a room of 9 square meters. m. Baxi moon 3 comfort is available in eight modifications of different power and can produce from 9.3 kW to 31 kW, depending on the settings made. The boiler was set up for you to work with the existing ones; chimney, gas pressure and quality, heating system. It threshes loudly, your boiler is capable of supplying up to 85 degrees to the heating system, it can supply 65 degrees to the hot water supply, either look wrong or the settings are wrong.

irinka:

the boiler was launched in December, though after severe frosts, during a thaw. the first 2 weeks was all in frost. moisture probably came out .... threshed with us at 80. I gained normal humidity and temperature for a month and a half. but the temperatures were in the 30s.

Blumenbacher:

with a plus on the street of 9 kilowatts of a boiler for a house with such walls (foam block and lined with red brick) "it should be enough for anyone."But a house is more than just walls. heat is lost both through windows-doors, and through ceilings and through the floor and through ventilation. look for where the heat leaves, otherwise it will be very tight in the cold

Cat smile:

It won't be the case. The box will be red-hot, the firebrands of burned-out firewood will remain in it, there will be no traction in this nook, everything will deform over time due to temperature and there will be smoke, it will probably burn out ... - I have firewood to order at the same price, you can order the length, not an option ? Or sawing yourself, or fuel briquettes ...

Valery:

I also have short ones along the firebox, I lay the long ones across the upper burner across.