Installation question

How to install an additional expansion tank? First you need to calculate its volume. The most commonly used option is 10 liters. Often its installation occurs with a reserve. And it turns out a volume of 12 liters.

Before installation, it turns upside down. The stub is removed. The nipple for the machine pump becomes open.

This pump is put to it, air is expelled.

Air is then pumped back into the tank. Its parameter is 1.8-2 kPa. This pressure must be in the expansion tank of the boiler. The indicator in the network is inferior to these values by 0.2 - 0.5 kPa.

After these steps, you can install the tank. Only here another dilemma arises - where is the expansion tank installed in the heating system? The answer lies in the instructions for the RB: the most suitable place for installation is where the pressure is lowest.

- The boiler is switched off.

- The valves supplying water to the heating equipment are blocked.

- Water is removed from the batteries. For better draining of the liquid, Mayevsky's taps are opened.

The following is an example with a network of polypropylene pipes. Here, to connect the RB, a unit for soldering pipes, couplings, fittings and corners is required. It is optimal to use the "American" here.

Before its connection, a sealant is wound on its thread: flax and a special paste, for example Unipack.

The first part of such a fitting is screwed with a gas wrench.

You need to make sure that there is no water in the network. Then you can mount the pipes.

RB is put in the "return". This is the path that liquid follows into the apparatus from the batteries.

The soldering unit starts up. The required temperature is fixed on it.

The pipe is cut in the intended soldering area. Special scissors are used.

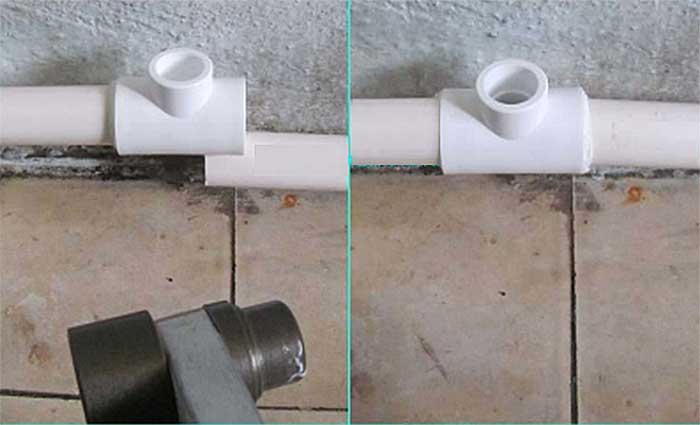

When the unit warms up, the tee is soldered.

A pipe is soldered to it, then a shut-off valve. This will make it possible to repair the RB without draining the water.

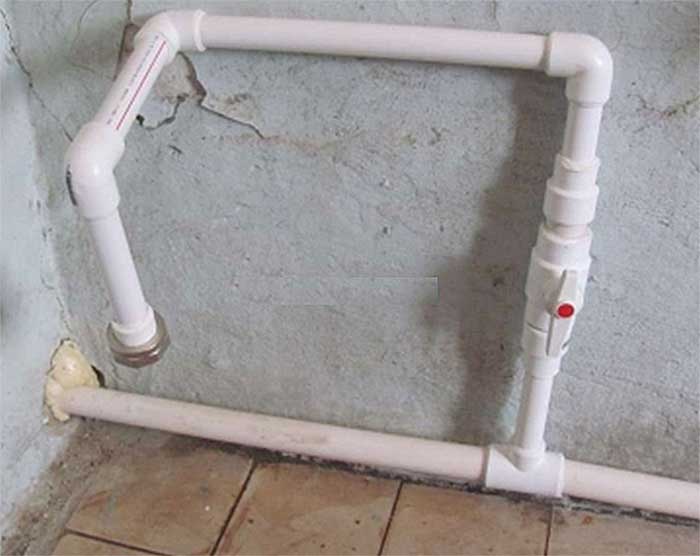

After that, the corners are used. With their help, pipes are soldered so that the final coupling is easily connected to the tank.

All components are best soldered on a self-leveling floor. And then the formed structure joins the network.

After these steps, RB is connected. An American is screwed on it. The tank is placed in the lower corner, against the wall. This makes it easy to access.

While there is no water in the network, you can clean or change the filters.

Next, the water supply valves open. Radiators are filled to the level of 1.2-1.3 kPa.

Pipes are freed from air. Mayevsky valves are screwed on. The boiler starts up.

It does not hurt to check how the RB functions. It is filled with air up to 1.6 atm. The equipment turns on. The data in the network is brought up to 1.5 atm. Through the nipple, air is removed from the RB. As an indicator, it will turn out to be less than 1.5 atm, water from the network will penetrate into the tank. This will be reflected in the thermometer: its arrow will fall. This is a sign that all operations were carried out correctly, and there are no errors in connecting the RB.

Expansion tank malfunctions

Checking the pressure of the expansion tank is included in the list of annual maintenance procedures and if it is followed, there will be no problems, but if neglected, it can bring unpleasant surprises to the owner:

the pressure in the air chamber gradually decreases and with each feeding of the boiler, the tank is more and more filled with water and gradually ceases to fulfill its function. In this case, the membrane is so pressed against the wall of the air part of the tank that it can be damaged by the valve spool and the tank will have to be replaced.

the pressure of the heating circuit is at the permissible limit, the expansion tank has not been serviced - there is no pressure in it. When the heating system cools down, the volume of liquid decreases, the pressure drop is not compensated by anything - the boiler stops due to an accident.Such a situation may arise, for example, when the boiler is running for a long time in the DHW mode or when there is a power outage.

the owner of the boiler often has to feed the boiler for no apparent reason, for example, while hot water is being used - the pressure on the pressure gauge drops and the boiler stops by mistake - the owner feeds. Since the thermal expansion is not compensated by anything, with further heating of the coolant, the excess pressure is released through the safety valve. Some users dismiss the reset and simply do not notice this situation. Frequent feeding of the boiler with untreated water is detrimental to the heat exchanger!

Meaning

Do I need an expansion tank for a double-circuit boiler? In principle, the boiler can work without this add-on. But when the template capacity of such a boiler does not allow to normalize the volume of water that occurs during heating, an expansion tank (RB) is required.

Water expands when heated. Its excess volumes need to be compensated. For this, a stationary RB is intended. When the volume of water develops in the pipes, pressure develops. And part of the water ends up in Belarus.

When the temperature drops, water leaves the RB, fills the radiators. So its performance in batteries is stable.

If you need to heat a large area, a standard RB for 6-8 liters will not be enough. So excess water will fill the entire Republic of Belarus. In the pipes themselves, the development of pressure will be indicated. In such scenarios, an emergency release occurs at the boiler until the pressure in the radiator blocks normalizes.

When the temperature drops, the water cools down and leaves the tank. With such an emergency situation, the device can no longer work on the machine.

It is required to feed the heating network with water in a timely manner. Otherwise, at low external temperature indicators, the network will unfreeze and collapse.

Selection Guide

If a natural circulation circuit is planned or already installed in the house, then an open-type expansion tank is just for you. It’s not worth it to be smart with a vacuum tank, remember that water in such a system moves only due to the difference in specific gravity and the device may not play its role. You can buy an open vessel, or you can make it yourself, the main thing is to correctly calculate the volume of the expansion tank, which we will discuss below.

With vacuum membrane vessels, the situation is a little more complicated. There is one caveat: once in a store among many similar products, do not confuse a heating tank with a hydraulic accumulator for water supply. Outwardly, they are very similar, even the color can be the same, so the selection of a tank on this basis is excluded. The tanks differ according to the inscription on the nameplate; for heating, the operating temperature is up to 120 ºС and the pressure is up to 3 Bar. On the accumulator, respectively, up to 70 ºС and pressure up to 10 bar.

When making a choice, it is also worth paying attention to the possibility of replacing the “pear” in case it fails. The size of the apparatus is selected according to the results of the calculation of the tank of a closed type

The need to install an additional tank

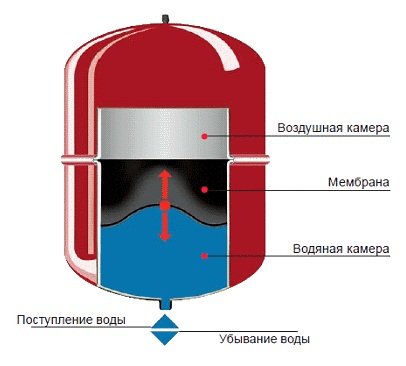

Expansion tank device. Click on the photo to enlarge.

If the house is heated with a double-circuit gas boiler, then the built-in expansion tank should compensate for the excess water. When the liquid is heated in the heating system, the pressure rises. The inlet valve of the expansion tank opens and part of the liquid enters the tank. With a decrease in temperature, the volume of water decreases, excess liquid in the tank fills pipes and batteries. So the required water level is maintained in the heating system.

Double-circuit gas boilers are most often equipped with expansion tanks with a volume of 6-8 liters. Such capacity can successfully work in small houses. If it is necessary to heat a large area, and many radiators are used in the heating system, then a large volume of capacity is required.The expansion tank built into the gas boiler is not able to accommodate the entire volume of excess water. Therefore, for the smooth operation of the heating system, additional capacity is required.

If we neglect the additional capacity, then after the standard tank is completely filled, an emergency discharge of water from the boiler will occur. The liquid will be removed from the heating system until the pressure in the batteries stabilizes.

After the temperature drops, water from the tank will begin to flow into the heating circuit. But after an emergency discharge, the pressure in the system will drop so much that the boiler will not automatically be able to start working. Delay in replenishing the heating system with water can result in its defrosting or destruction.

Installing an additional tank will avoid emergency discharge. After filling the tank installed on the gas boiler, water will begin to fill the auxiliary tank. And when the water temperature drops, the liquid will go into the radiators, maintaining a constant volume in the circuit.

It is better to install an additional tank of a larger volume than the calculated value. In most cases, a 10-12 liter expansion tank will cope with excess fluid.

Manufacturers and prices

It should be borne in mind that it is important not only to buy an expansion tank for closed-type heating, it also requires its correct installation. Having the necessary skills, subject to the instructions, it is possible to install it yourself

If the master still has any doubts about his knowledge, then it is best to turn to professionals to ensure the stable operation of the heating network and eliminate possible malfunctions.

- How to pour water into an open and closed heating system?

- Popular Russian-made outdoor gas boiler

- How to correctly bleed air from a heating radiator?

- Expansion tank for closed heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes in case of malfunction

Recommended reading

Heating collector: equipment design and installation features Why do we need a heat accumulator for heating? Heating appliances: their types and design features How is the thermostat for heating arranged and how does it work?

2016–2017 — Leading heating portal.All rights reserved and protected by law

Copying site materials is prohibited. Any copyright infringement entails legal liability. Contacts

We determine the malfunction of the boiler and prepare for repair

First of all, make sure that your boiler's expansion tank is defective. To do this is quite simple. When filling it with water, the pressure in the system changes greatly. From the minimum pressure, when the boiler is not working, up to 3 Bar, when heated. Often, this triggers the safety valve. To be completely sure, you need to disconnect the tank from the system, drain the water from it and check the pressure in it.

If the pressure is less than 1 bar, then first pump up to the desired pressure, and after a while check again. Try to bleed air through the nipple. If water comes out from there, then the tank must be replaced. If not, then you need to check the nipple, maybe it's in it.

To replace the expander, we need a Phillips screwdriver with a length of at least 200 mm. A shorter screwdriver will not work, as access to one screw is very difficult. It's also a good idea to have pliers on hand. And if you want to make repairs very quickly, then take care of the repair kit of gaskets for the filter and drain plug in advance. There is a very high chance that they will leak when removed.

Expansion tank calculation

In the technical literature and on the Internet, you can find many methods by which the expansion tank is calculated for a heating system with natural and forced circulation of the coolant. But for the most part, they contain a lot of complex formulas linked to the boiler power and other parameters. You will not be mistaken if you use an easier way to determine the volume of the tank.

The method is based on the assertion that the amount of water in the system at maximum heating will increase by no more than 5%. That is, first calculate the volume of water as follows:

- the amount of coolant in the boiler tank - according to the passport;

- the volume of water in the pipelines - using the circle area formula, find the cross-sectional area of \u200b\u200beach pipe and multiply it by the length;

- capacity of radiators - also according to the passport for the product.

Having summed up the results, you select and calculate the expansion tank with a margin, taking not 5, but 10% of the resulting amount. This will be its capacity.

Baksi boiler pressure drops when hot water is turned on

Sometimes, users encounter a problem when the pressure drops when hot water is turned on in the baxi boiler. This problem may just be due to insufficient pressure in the expansion tank. The fact is that when the boiler switches to the hot water preparation mode, the circulation pump pumps liquid in a small circle, i.e. only inside the boiler itself - through a secondary plate heat exchanger. At the same time, the heating circuit does not actually heat up and the coolant begins to cool down, the volume decreases and in the absence of compensating pressure in the expansion tank, the pressure of the heating system may drop and the boiler will have an error e10.

In such a situation, one can still consider the option of a breakdown of the heat exchanger itself (a gap between the plates) and the ingress of water from the heating circuit into the DHW system, but this is easy to check. To check, you need to turn off the cold water supply to the boiler and open any parsing valve. If under such conditions water comes out of the tap, it is obvious that this is a coolant from the heating circuit and the heat exchanger needs to be replaced.

Remember, timely maintenance of the gas boiler will help to avoid such situations and increase the life of the unit.

We also recommend watching a video of one of the users, which clearly shows how to pump up pressure in the expansion tank:

Hello dear readers. What is the importance of an additional expansion tank for a double-circuit gas boiler? How to mount it in the heating network.

The movement of the coolant in the heating system

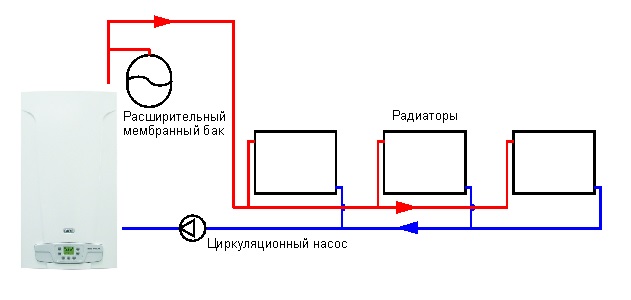

When organizing heating systems, various options can be used, but recently closed-type systems have become more popular, in which the movement of the coolant occurs due to the operation of the circulation pump. The gas burner heats the water (or antifreeze) in the primary heat exchanger, and the pump pumps it through the radiator system, transferring the heat to the rooms.

At the same time, for the normal circulation of the coolant, it is required that the system be completely filled with water, and since the liquid tends to expand when heated, it is necessary to somehow compensate for the increase in volume. Expansion tanks are provided for this in heating systems.

The diagram shows a system in which the boiler acts as a heater only. In household wall-mounted boilers ECOFOUR, an expansion tank and a circulation pump are already built in, which is why such boilers are convenient to use in small apartments.

Finally

Thanks to the RB, the boiler and the heating network last longer. No risk of accidents

It is important to mount it correctly

Good evening, the question is the installation of a bath, namely a double-circuit wall-mounted gas boiler 24 kW Volf. I convince people that we need an additional expansion tank for the heating system of liters, so for 12-14, in addition to the built-in 8l, we have 1 supply and return from the boiler to the collector group for 6 outlets for the warm floor, the total square footage of the warm floor is 70 square meters and hot water and cold water tell me I'm right. Evgeniy

The required volume of the expansion tank is determined by calculation:

VL - full capacity of the heating system (volume of heat carrier in the boiler, heaters, pipes, storage water heater coil and heat accumulator), l;

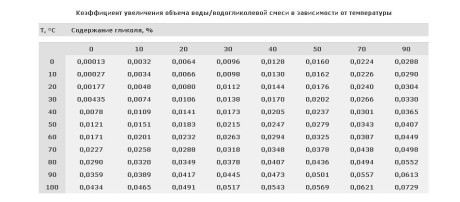

Е – liquid expansion coefficient, %;

D is the efficiency of the membrane expansion tank.

In turn, D = (PV - PS) / (PV + 1)

PV - maximum working pressure (for a private house of an average area, 2.5 bar is enough);

PS - charging pressure of the expansion membrane tank, m (0.5 bar = 5 meters, we use the static pressure value, it is determined by the difference between the upper mark of the heating system and the tank installation level).

Since we do not know the characteristics of your heating system, nor the diameter of the underfloor heating pipes and their pitch, it is not possible to accurately calculate the required volume of the expansion tank.

The length of each heating circuit can be set according to the markings on the inlet and outlet pipes connected to the combs. During production, they are marked in meters. By subtracting the smaller value from the larger value, you can find out the length of the loop. Knowing the total length of all pipes and their diameter, you can calculate the volume of liquid in them. The amount of coolant that the boiler can hold is indicated in its technical passport. If there is a heat accumulator, a water heater, the data should also be taken from the instructions for the equipment. You don’t mention heating batteries, but if there are any, you also need to calculate the volume of liquid both in the heating devices and in the supply pipes. Add up the resulting numbers, this will be the total capacity of the system. Knowing it, you can calculate the volume of the expansion tank yourself.

Whether an additional expansion tank is needed and what its volume should be can be estimated very, very roughly, based on the power of the boiler. In the absence of an additional heat accumulator, in the circulating heating system, on average, there is:

- for convector wiring - 7 liters per 1 kW of boiler power;

- for radiator - 10.5 l / kW;

- for warm floors - 17 l / kW.

In our case, based on your description, the approximate volume of the system is 17 l / kW x 24 kW = 408 liters.

For an approximate calculation, we conditionally accept the values of the following indicators: PV = 2.5 bar; PS = 0.5 bar (height from the top point to the tank 5 m); E = 0.029 (water, 70 ºС).

We count according to the formulas:

D \u003d (2.5 - 0.5) / (2.5 + 1) \u003d 0.285

V = (408 x 0.029) / 0.285 = 41.5 liters

We get: an additional expansion tank should have a volume of 41.5 - 8 = 33.5 liters. When choosing between a smaller and larger option, it is better to take a larger one - 40 liters, and not 30 liters.

You, Eugene, are, of course, right: an additional expansion membrane tank is required in this case. The estimate, carried out "by eye", eloquently speaks of this. However, the volume of the expansion tank, as well as other system parameters, require a fairly accurate calculation, otherwise the heating may work unstably and not economically enough.

Describe your question in as much detail as possible and our expert will answer it

good afternoon, I have a gas wall-mounted boiler, it has its own expander inside, is it possible to put an additional expansion tank