What is the correct way to clean the burners

First of all, you need to take care of safety. Close the gas supply and ventilate the room. It is possible to clean the burners using improvised methods, or with special preparations. Choose the method at your own discretion. Water or vinegar. If there is little dirt, then you can simply wipe the stove and burners with a simple soft cloth, which will be soaked in a solution of simple soda. Make sure the stove is no longer hot. Remove each burner and remove each element. If necessary, wipe the divider.

Boil water in an ordinary kettle and pour it into a saucepan. In a simple case, it is possible to use hot water from a conventional faucet. Then add vinegar or soda. Put everything into the finished solution for a while, then put on gloves and start cleaning the items. Use for an ordinary sponge that will not harm the surface of the burners. Rinse all items properly in water and leave to dry. After all this, simply assemble the burner back. When cleaning, use only ecological methods.

Stages of cleansing

Before cleaning the burner, you will have to perform a few simple steps to prepare for the hygiene procedure:

- Provide intensive ventilation in the room. When working with gas equipment, unforeseen situations may arise, so a constant supply of fresh air is a must.

- Close the valve to shut off the gas supply. You need to rotate the device strictly in the direction of the arrow shown on it.

- Remove all unnecessary items from the hob surface, such as grids, flame spreaders, sponges or cloths.

After preparation, you need to clean the gas burners from carbon deposits and grease in any suitable way, and install the grate in place.

Folk remedies in the fight against pollution time-tested

The modern chemical industry offers a lot of products that will easily and quickly clean your stove from any contaminants. But lately, housewives have been skeptical about such substances. There are several reasons for this: such products can be expensive, they are unsafe, therefore they require special storage (which becomes more relevant if there are children in the house), and it is recommended to use them with rubber gloves.

The stove can be perfectly cleaned with the help of folk remedies

For women, it is important that such products, even with protection, negatively affect the skin of the hands, which means that creams should be used. This adds cost to the already high cost of cleaning gels and powders.

In addition, we all faced such a situation: it is urgent to clean the stove, and the industrial tool is over. And running to the store is not an option. This is where the well-known and used tools will come to our aid, which are probably always at hand:

- laundry soap solution;

- lemon acid;

- vinegar;

- ammonia alcohol;

- baking soda;

- ammonia-anise drops.

Almost all of these tools will easily help you cope not only with pollution on the gas stove, but also clean almost all household appliances to a shine - a refrigerator, a boiler, an electric kettle, a washing machine, a juicer.

They can handle any dirt, and most importantly, their advantage is the possibility of safe use even with children.

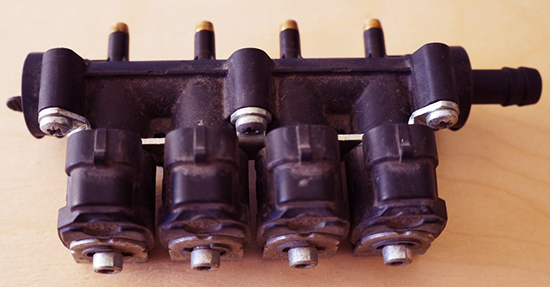

General information

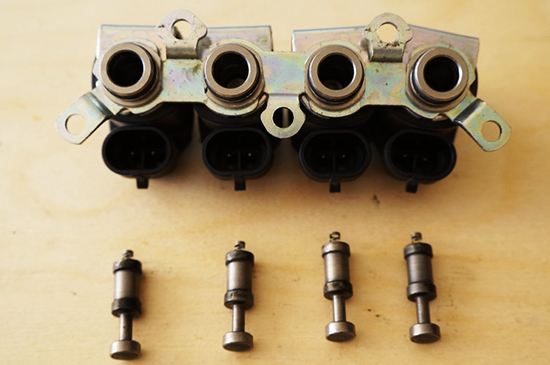

Gas injectors are special HBO units that are responsible for the dosage of fuel, in fact, being high-speed valves. Thanks to their proper operation, the necessary ratio of the gas-air mixture in the internal combustion engine is ensured. Such mechanisms began to be used in the 4th generation of HBO.

One of the most popular are stock models from Valtek (Valtek), Rail (Rail), Digitronic (Digitronik), OMVL (OMVL), Lovato (Lovato). Their undoubted plus is that they are easy to repair, which consists in flushing, replacing the repair kit and adjusting, unlike non-separable injectors like BRC (BRS), Barracuda (Barracuda) and the like.

Washing grates and handles

Lattices are made of cast iron or metal with an enameled layer on top. Cast iron cannot be washed with clean water to remove soot, they must be calcined over a fire. But this process is labor intensive.

The latter can be washed using a dishwasher, if any. Well, no, soak in a soapy solution, and then clean with a sponge with soda sprinkled on top.

Handles - although a small detail, they suffer from pollution during cooking no less. But washing them is often problematic. This applies to those cases when they are not removed. Wash on the spot. Use cotton buds or a worn-out toothbrush for convenience.

But it is easier to take care of removable ones: soak in soapy water, and then wipe. If stains remain, use baking soda. By the same principle, you can clean the burners.

How to clean the gas column heat exchanger

Our next task is to remove all contaminants in the radiator. To do this, we take the following measures:

Disconnect the heat exchanger

If the surface of the nuts is covered with scale, then it should be treated with any scale remover and left for 20 minutes.

To wash the body of the equipment, place it in a container with soapy water and gently wipe it with a soft sponge.

Using a hose, pour the descaling liquid into the pipeline and leave it for at least 10 hours. If you clean your equipment every few months, just wait 15 minutes

After that, rinse the pipes thoroughly with water and return the parts to their place.

As you can see, there is nothing complicated in cleaning the gas column. The main thing is to strictly follow the instructions and do not forget about safety precautions.

Owners of geysers are one of the few people for whom flushing and cleaning the heater is an urgent need.

Gas column cleaning is a mandatory process that should never be ignored.

Why do this, what do speakers most often clean from and how to do it yourself at home? Now you will know.

Features and types of blockages

Before you figure out how to clean a gas column, you need to understand what we actually clean it from?

To do this, you need to make a short digression into the mechanism of operation of gas water heaters, as a class of heating equipment.

The geyser is working due to the heating of the liquid passing through it by the gas.

It consists of several sections and large parts, which, in turn, are divided into even smaller ones.

You can mount it anywhere where there is access to the water supply. Pipes with cold water are connected to the inlet of the heater, then it is started, and a liquid heated to a certain temperature is formed at the outlet.

How does this happen? Very simple. Once in the column, the water is distributed through many small pipes and a heating chamber. A gas burner or igniter operates in the chamber - the main heating element in this type of equipment.

The liquid, passing through a system of pipes with a small diameter, heats up faster, then again reduces into a single stream and tends to the outlet, or to the storage tank (which happens more often), and from there to the water supply.

The problem here lies in the fact that we work with tap water filled with mineral additives, and most often without pre-filtration. Also, a gas-powered igniter makes its share of the inconvenience.

The heat exchanger tubes have a small diameter. As a rule, up to 10 mm.From a technical point of view, this decision is fully justified. The smaller the tube, the easier it is to heat it, which means to raise the temperature of the carrier in it.

On the other hand, when heated, water, especially poorly purified, constantly forms scale or various kinds of sediment. Scale can be observed even when boiling tap liquid in a kettle. Moreover, a sufficiently large amount is formed at the bottom of it.

Now imagine how much scale and sediment can form after long-term operation of the geyser. A mechanism through which hundreds and thousands of liters of untreated tap water pass.

It is obvious that washing the column regularly is necessary under such conditions. The igniter is clogged in the same way. Only, unlike the heat exchanger tubes, the igniter does not suffer from scale, but from burning.

Fortunately, cleaning a geyser is not so expensive, and besides, you can do it yourself.

1.1

What if you don't clean it?

We will try to warn you against possible desires to leave the column as it is. You can't do that.

If you do not clean the device in time, serious problems will begin. At first you will not notice them, but over time they will increase in magnitude, which can lead to dangerous situations.

A gas burner igniter is more difficult to control than the electronics in boilers, so it cannot accommodate a drop in outlet temperature. And it will definitely be, since scale on the walls of the heat exchanger reduces the heating efficiency. The efficiency of the installation is seriously reduced.

Even the throughput of the column suffers from the same scale over time. The larger it is, the smaller the diameter of the tubes.

Have you ever seen a clogged pipe with a centimeter layer of mineral deposits, which actually clogs 50% of its plane. Approximately the same thing happens in the tubes of the heat exchanger, if they are not cleaned in time.

Another problem area is the igniter. The cinder formed on it over time can completely clog the gas supply pipe, which is already fraught with problematic passage.

It is already impossible to put up with this, because gas is a substance with which jokes are bad.

Handle cleaning

Many device owners admit that it is very difficult to clean the handles of a gas stove, but at the same time a large amount of dirt always accumulates on them. Dirt usually accumulates in the most inaccessible places, so we should talk about cleaning handles in more detail.

Removable handles can be washed in the same way as a grate: put in a container filled with a solution of laundry soap and left for 30-40 minutes. After soaking, it will be much easier to remove the softened dirt. For the same purposes, it is quite possible to use vinegar essence, a couple of tablespoons of which dissolve in a liter jar of water. It is necessary to use such a cleanser with gloves so as not to damage the skin of the hands. The pens are boiled in the essence solution for 5-7 minutes, then the water is drained. Let the handles dry naturally and screw them back on.

Unfortunately, not all models of household stoves are equipped with removable handles, in which case other auxiliary items and tools are suitable, for example:

- toothpicks and cotton swabs;

- hard toothbrush;

- food or soda ash;

- ammonia.

Each area to be cleaned must be treated with a damp sponge coated with soda, usually even old dirt is removed the first time, but if we are talking about hard-to-reach places, you will have to use cotton swabs dipped in a solution of ammonia.

The second cleaning method

The unit must be cleaned every 6 months, but at least once a year. If there is an agreement on gas supplies, then the company's specialists must carry out maintenance of gas boilers in a timely manner. If you want to clean the column on your own, then you must follow the following instructions:

- 1

Initially, you need to turn off the gas, the faucet is usually located under the device. Then you need to loosen the bolts that secure the casing, then unscrew them and clean everything with a needle with 4 edges. Today it is possible to buy a special brush for cleaning boilers, which is more convenient to use than a needle. The next step is to wash the burner sections in a degreaser. If the wick is clogged, it must also be cleaned with a needle or a metal scraper. At the last stage, it is necessary to assemble all the details of the column in the reverse order and, before starting the gas, fill the unit with water. - 2

To clean the burners in the gas pipe, you can use a stiff brush. The pipe must be cleaned with wire and washed with water and solvent. The upper area of the burner is cleaned with fine sandpaper. - 3

Units that are cleaned in a timely manner will work much longer. The fire will be glare-free and uniform. If it is noticeable that the column is smoking, the fire is uneven, weak or, conversely, strong, then it must be cleaned. An uncleaned unit is dangerous.

Symptoms and possible causes of malfunctions

Symptoms of a malfunction of one or more injectors may include:

- high fuel consumption;

- deterioration of the dynamic characteristics of the machine;

- unstable operation of the engine, troit of the internal combustion engine (one or a pair of nozzles does not work);

- dips when pressing the gas pedal;

- failures in the operation of various sensors, the appearance of “Check engine” errors (for example, a MAC sensor);

- knocking in the nozzles (they work loudly “click”);

- gas leaks through injectors (pour / poison);

- the car stops idling, the injectors do not turn on.

The reasons for this may be:

- wear of the damper rubber rings on the valve stems (because of this, nozzles knock);

- development of a seat (saddle) of the valve or its locking gum;

- wear of the rod (it is also called a piston, anchor) or sleeves (it is also a core, cylinder, flask);

- anchor jamming in the cylinder;

- weakening of the elasticity of the piston return spring;

- failure of the electromagnetic coil (solenoid);

- violation of the integrity of the wiring.

All of the above reasons may appear naturally or due to poor-quality parts, untimely maintenance of gas equipment, violation of the rules for installing injectors. So, for example, without replacing HBO filters in time, gas condensate (oily liquid, water, dirt) can get into the nozzles, which can cause them to wedged or accelerated wear.

Also, the horizontal position during installation affects the uneven wear (ellipse) of the sleeve body and stem. Yes, and the banal non-compliance with the rules for installing wires (twisting instead of soldering, tangling, improper fastening) can cause problems over time. One way or another, but nozzles of this type rarely live up to 70 thousand km. mileage without repair (repair kit change). It all depends on the conditions of their use.

Why is it necessary to properly care for burners

For starters, dirty burners when heated can be a good sign of bad spirits, which can ruin your appetite.

That is why it is very important to regularly remove all leftover food from such a stove. You also need to thoroughly clean the detergent every time if you want to avoid a chemical smell during the cooking process.

Further, dirty dividers or nozzles can easily be the basis for poor ignition of all burners. During the entire cooking process, a lot of water can accumulate in them or parts of the food can become clogged. A cleaning agent in the form of a powder can easily become the basis of dirt. In a good way, clean the burners at least once every few days, and also wipe them if necessary.

How to remove fat

To wash the device as efficiently as possible and remove all contaminants, you will need preliminary preparation.With the help of hot water poured onto the surface of the stove, and baking soda, old dirt can be softened.

. Soda must be evenly scattered over the wet surface of the device and then left for about 30-40 minutes. This simple method allows you to clean both the stove and the oven, the insides of which can also be scrubbed with soapy water. After some time, you can start cleaning, soda with water must be removed from the surface with a soft sponge.

Metal washcloths should not be used, as they can seriously damage the surface, in addition to a sponge, it is best to use toothbrush

or cotton swabs for the most inaccessible areas, such as pens. For those who want to learn how to clean a gas stove grate, the homemade soap solution mentioned above is the best option. Vinegar essence, as well as lemon juice and acid, are also excellent aids, they can be used separately or together. A solution of ammonia and vinegar will help remove dried and burnt areas on the tile surface.

Geyser pollution

Easy-to-use gas appliance, allows you to heat any amount of water. To heat water, the column uses natural gas, which is burned in it. Thus, we get two directions of pollution at once. On the one hand, burning gas inside the device promises us soot and soot, on the other hand, poor-quality water carries salt with it, which creates scale and limescale.

Inside the geyser there is a heat exchanger (radiator), which is subjected to the greatest tests. Water is supplied through it for heating and it is he who is overgrown with the largest growths of slag. In order for the device to function properly, it is necessary to monitor, care for, and remove scale from the gas column.

According to experts, if the water is heated to less than 80 degrees C, then much less scale is formed. You can take note of this temperature, and try to set it on your device.

Typical insides of a geyser

It is very easy to determine that it is time to clean the column; several factors signal this at once:

- If the geyser works intermittently, turns itself off and on, while gas and water are supplied constantly, then there are some problems in its operation.

- If the heat sensors are triggered, it is safe to talk about scale. It is the reflection of heat from scale that causes the equipment to overheat. With a heavy crust of limescale, the appliance simply cannot cool down.

- At the same temperature as before, the hot water became colder. This is again the tricks of scale, which do not allow the gas column sensors to accurately set the rate of water heating to a certain temperature.

- The water pressure from the hot tap decreases, as a result of which the geyser does not always turn on.

To remedy the situation, drastic measures must be taken. We can easily clean the part of the device that comes into contact with water, remove scale build-up from the water heater. To fix problems in other elements of the column, you need to contact the gas service and call a wizard who will help you clean the gas equipment.

Repairing such devices and cleaning them is a very responsible and serious task, which you can partly do yourself, but be extremely vigilant and careful, even when cleaning the plumbing system.

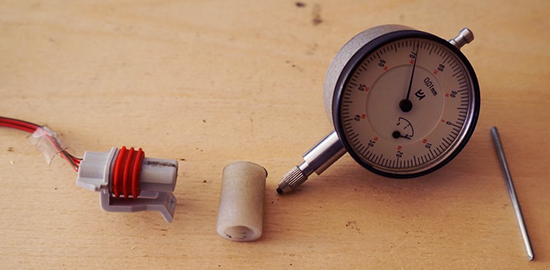

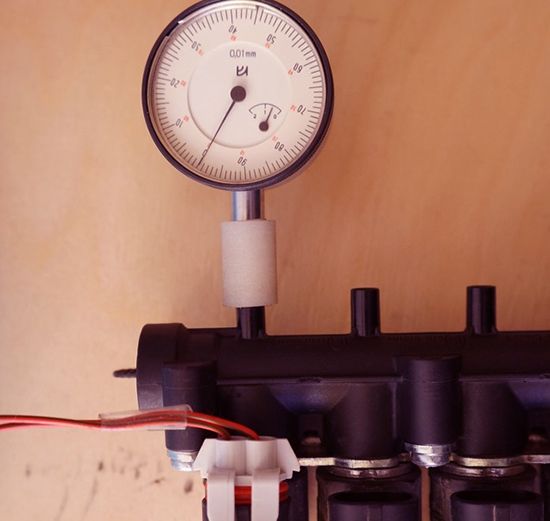

The second stage is the adjustment of the stroke of the nozzle rod

1. We unscrew the jets from the ramp.

2. We take out the appropriate power plug.

3. Instead of a jet, we install a special adapter into which a micrometer will be installed.

4. Next, install the micrometer, look at the arrow, if it starts to move, then the anchor has come into contact with the micrometer rod.

5. Install the plug into the gas nozzle coil.

6. Knock down the readings of the micrometer to zero.

7.Apply 12V power to the coil for 1 second or less.

8. We write down the value that the device shows.

| Nozzle | Nozzle stroke (in mm) |

| 1 | 0,37 |

| 2 | 0,47 |

| 3 | 0,45 |

| 4 | 0,51 |

9. Now we actually begin to regulate the gas nozzles. To do this, it is necessary to turn the hexagon bolt, which is the adjustment screw for the armature travel.

Twisting (clockwise) - we reduce the stroke of the nozzle armature.

Unscrewing (counterclockwise) - we increase the stroke of the nozzle armature.

10. We again supply power to the gas nozzle coil and make control measurements. By the same principle, it is necessary to check all the nozzles. The maximum allowable stroke of the Valtek injector armature must not exceed 0.7 mm.

Rules for the care of the oven

How to clean the oven in a gas stove? Strong chemicals will not work, replace them with others:

It is possible to return the nurse to the original brilliance and purity, the main thing is to know the methods and suitable means. And do not leave stains for a long time, it is better to carry out the cleaning procedure more often.

The stove is the most difficult appliance to maintain in the kitchen, especially if it is gas. Indeed, unlike the electric one, it has a heavy cast iron grate, burners that periodically clog, and handles that get dirty very quickly with grease. Stationary gas stoves also have an oven and a drying cabinet, a back shield or a cover. In this article, you will learn how to clean your gas stove at home from grates to knobs, as well as how to make cheap and super-efficient DIY cleaning solutions.

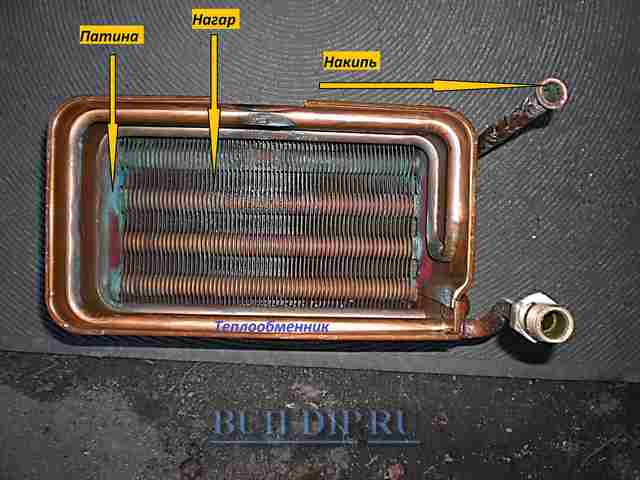

Signs of contamination of the heat exchanger

In order to exclude premature failure of the water heater with the listed signs, it is advisable to call specialists in the near future to diagnose and fix the problem. Since the heat exchanger is contaminated from the outside with soot, and from the inside with scale and patina (copper corrosion), we will consider the signs for each individual case.

The following indicators indirectly indicate the appearance of scale in the heat exchanger

geyser and water heating system:

- The consumption of water from a hot water tap is much lower than from a cold one. To identify the true cause of the decrease in pressure, the condition of the valves is checked, since its failure can lead to a similar situation.

- The device is set to maximum power, but the water does not reach the set temperature. Such symptoms are possible with a decrease in pressure in the gas line. Therefore, before dismantling and cleaning the heat exchanger, the pressure of the supplied gas should be examined. In the absence of a low pressure manometer, you can navigate according to the readings of the gas stove burner. The presence of an ordinary flame will indicate normal pressure in the system.

- Water heater burners start to turn on and off frequently. But, such a malfunction can also occur when the gas valve or control module is unstable.

- Noise appears inside the double-circuit boiler. It should be borne in mind that noise in the heat exchanger also occurs due to boiling water, or breakdown and clogging of the pump turbine. Boiling of the coolant is possible due to poor contact of the temperature sensors with the pipeline.

The listed signs indirectly indicate the formation of scale in the column heat exchanger, therefore, first of all, you need to check the nodes that affect the occurrence of the above signs.

External contamination of the heat exchanger is determined by opening the device case. The radiator is considered contaminated if it is covered with black deposits by more than 30%.

Instructions for cleaning the water intake unit

Before you start cleaning the column from scale, you should take care of the tools that will be useful to you during the work. So, you will need the following:

- wrench;

- crosshead screwdriver;

- flat screwdriver;

- rubber hose;

- paronite gaskets (set);

- funnel;

- high-quality anti-scale agent.

After a visual inspection of the water intake unit, you will find a mesh (filter) and a membrane designed for automatic gas supply inside. Get her out. Then remove the "coil". The work instructions are as follows:

Carefully unscrew and open the case;

Treat the filter by washing it under water;

Inspect the membrane - if it has stretched during operation, it is better if you replace it.

By the way, it is worth buying a new silicone membrane, which is more reliable and durable. In the end, when assembling the case, be sure to ensure that the membrane is evenly tensioned inside the device so that after the start of operation you do not have to disassemble and assemble the column again.

To start, a little introduction.

Everyone knows that we have “badyazhat” not only gasoline and diesel fuel. A long time ago, gas filling stations learned to “inflate” our brother, and not with gas, but with air, mixing various muck into gas fuel, which adversely affects the state of gas equipment and the entire engine as a whole.

So once it was noticed that the engine was unstable on gas, while switching to gas, the engine stalled, and there was simply no idling. Among other things, the dynamics worsened, traction disappeared, gas consumption increased and dips appeared during acceleration. Moreover, the above-described "glitches" were manifested, as a rule, "on the cold". Some time after the engine warmed up to the optimum temperature, all these "sores" practically disappeared.

The problem did not allow to live and drive any car. After rummaging through the Internet, I found similar cases, as well as reviews of those who "defeated" this problem. Suspicion fell on the filter (how to change filters and drain condensate is written here and here), as well as gas nozzles. The filters were replaced, by the way, during the replacement, a large amount of resin was found in the filter elements, which alerted and made me think. If there are so many “kaki” in the filters, then what is in the gas nozzles? The decision was made - it is necessary to clean the gas nozzles, as well as their further calibration. What came of it - read on.

Surface cleaning

Starting the process of washing the plate, it is important to figure out what material its surface is made of. It could be:

- enamel white and dark;

- stainless steel;

- ceramics.

As for the latter, be careful with it. Spilled soup is better to clean up immediately, then it is much more difficult to do it.

Under no circumstances should the ceramic coating be scraped off, otherwise damage will result. When cleaning, use special preparations that are easy to purchase at any household department and store.

But enamel and stainless steel are easier to clean, even if the stains are old. A popular way is to use all the same cleaning products

Important: just do not use abrasives, save them in case of emergency

Well dissolves grease and dirty stains dishwashing detergent. You can clean the stove with a solution of soda, diluting it with water to a state of slurry.

Choose a method and get started. If the stain is fresh, it is easy to remove it the first time. The old ones will have to be dealt with. To begin with, they should be poured with the prepared cleaning solution, let stand for at least 15 minutes, and only then rinsed with a sponge or rag

Important: Clean with thick rubber gloves. Take care of your skin health

After washing off the cleaning agent, wipe the stove with a dry cloth, giving it the necessary shine.

Cleaning gas injectors step by step photo report

1. The first step is to turn off the gas supply, for this we twist one or two valves on the gas cylinder.

2. We start the car and let it work in order to relieve pressure in the gas lines and work out the remaining gas.

3. We dismantle the gas rail with nozzles. For each, this process will occur in its own way, it all depends on the brand of injectors and the type of engine.

4.Next, using a screwdriver, unscrew the screws and take out the gas nozzles.

5. Remove the rods from the nozzle body. The photo shows the cause of all my troubles - resinous deposits, they even did not allow the nozzles to fully function. When the engine is cold and the nozzles are not warmed up, the viscous resin interfered with the normal stroke of the gas nozzle rod.

6. Using cotton swabs and alcohol (a solvent is also possible), we wipe the rods, as well as what is inside the cases.

7. Assembly is carried out in reverse order.

How to properly clean nozzles

If, when a spark is applied, the burner does not ignite very strongly, then it is necessary to check the entire condition of the nozzle. Maybe the whole cause of the problem is simple dirt. To do this, to remove it completely, you must perform some actions:

- Remove the entire grate from there.

- Pull out the burner. From the inside, you should notice a small hole, this will be the jet.

- Start cleaning the nozzle itself, using a needle or a simple paper clip. You can use a pin.

- Reassemble the burner and install the grate.

- If after the whole process the problem does not go away, then call a specialist who can see the gas supply. You should not fix these problems yourself.

We remove pollution

To work with a geyser, you will need a number of tools, stock them up right away so that you don’t run around, don’t look. It is necessary to find an adjustable wrench, a Bako wrench, several Phillips and flat screwdrivers, powdered antiscale, a funnel, paranitic gaskets, and an inch rubber hose.

It is not necessary to immediately disconnect the column from water and gas, we will need gas in the process of work. First of all, we disassemble the column, remove the handles and switches, and then the protective iron casing. Carefully inspect the supply pipes, we do not need gas pipes, we will work with water pipes. Having determined the water, we block the water supply to the column.

Antinakipin in liquid form

To flush the heat exchanger, we need to perform the following manipulations with the column:

- open the hot water tap near the column to drain the water from the heat exchanger;

- we specify in the passport for the column how much water can be drained from the heat exchanger during flushing, usually about 1 liter;

- we twist the water supply pipe to the heat exchanger and move it to the side;

- by removing the nut from the heat exchanger, you will open the way for water to the outside, drain the required amount of water and close the tap;

- then we need to pour antiscale into the device, for this we put the prepared hose on the heat exchanger, bring it up, just above the column, place a funnel into it and carefully pour the composition;

- it is necessary to fill the solution in a thin stream so that a premature reaction inside the heat exchanger does not push it back, besides, the solution contains hydrochloric acid, which causes burns;

- pouring the solution into the heat exchanger, leave the product to work for a couple of hours, while the solution will warm up on a burning igniter, from which its operation time will be reduced;

- then open the tap and slowly supply water to the column, the pressure in the tap should be good, and you should see a large amount of slag and traces of scale, which means the work was successful, otherwise repeat the flushing.

Removal from the heat exchanger column

If it’s easier for you to disassemble the column, remove the heat exchanger (radiator) from it, rinse it and reassemble it, you can do the following:

- to begin with, the water and gas supply is turned off 10-15 minutes before the start of work;

- after which the radiator is taken out, it is disconnected from all supply and discharge pipes, if the connections are acidified, use cleaning compounds, such as VDshki or Sillit;

- the radiator itself can be washed with soapy water, a lot of dirt always appears on its body;

- pour liquid antiscale inside, for which we use a hose and a funnel, leave the radiator to infuse for 10-12 hours;

- after the time has elapsed, it remains only to rinse the radiator from the cleaning agent, for which ordinary tap water is used;

- now the radiator can be placed back into the gas column, twisted and started the device, while the performance of the device should improve.

By flushing the heat exchanger, you will greatly facilitate the work of the device, but do not relax too much if you have hard water, scale will soon appear in it again. But by that time you will already have an idea how to clean your geyser from traces of scale.