What threatens the occurrence of air congestion

The presence of air in the lines will not allow to provide the radiators with the required amount of coolant, which means that the heaters will not give out the required heat and the room temperature will be lower than desired. The noise inherent in overcoming an air obstacle in the system will not cause irritation during the daytime, but at night it will not let you sleep. In places where traffic jams form, the internal environment becomes aggressive, which contributes to the active formation of rust.

The worst thing is overheating. The presence of air in the heat exchanger or heat "supply" pipeline will prevent the movement of the coolant, and an increase in temperature can damage the coil or pump.

The ability to bleed air from a boiler or individual sections will allow owners of private houses with autonomous heating to get rid of traffic jams on their own, preventing harmful consequences, without resorting to the help of customer services.

The air in the heating system is one of its main enemies. Therefore, automatic air vents must be provided in the heating system. Since not all heating systems work on the same principle, the process of air circulation in the circuit also differs. Before you bleed air from the heating system, you should figure out how to do it, or you don’t have to do anything and it will come out by itself, for example, as in an open system.

Service menu of the boiler

For all manipulations with switching modes, only 4 buttons are involved - Plus, Minus, Ok / Menu, ESC.

It is important to understand that not all menu items of the boiler will be available to you, some of them will become available only when additional devices are connected to the boiler, such as external sensors or a solar collector. And most of the menu items are available only by the service code, I'll tell you about it below, but for now, "let's practice on cats"

And most of the menu items are available only by the service code, I'll tell you about it below, but for now, "let's practice on cats"

Our kitties will be values that are open to free access. But first, read how to work with the menu.

What are the types of wall-mounted boilers Ariston

All Ariston boilers are divided into 3 series. They have different technical indicators and functions, namely:

- Clas - this series refers to more bulky and powerful devices for heating residential premises. They are equipped exclusively with special regulators that automatically regulate the gas supply. This is necessary to save fuel, which is very convenient in terms of utility costs and frequent business trips for the home owner.

- Genus. These are the most innovative and multifunctional models of Ariston gas units. They have more features than other boilers from this manufacturer. Along with the equipment itself, the buyer will receive additional accessories such as a fan required for smooth speed control, as well as heat exchangers, primary and secondary. All devices from the Genus line are distinguished by the presence of a large liquid crystal display. It will display all the characteristics that correspond to the operation of the boiler at the moment.

- Egis. The units from this series are small in size and attractive in appearance, which have earned them great popularity among owners of small apartments. The device will fit well into any interior. An important feature of these boilers is that, for their size, they have a fairly high level of efficiency and low fuel consumption, which is controlled by an intelligent control system.

Causes of rising pressure. Ways to solve the problem

To understand that there is too much pressure in the system, you can use the pressure gauges. Normal readings are 1-2.5 bar.If the pressure gauge needle reaches 3 bar, sound the alarm. If the increase is constant, it is urgent to find the cause and reduce the pressure.

Also pay attention to the safety valve: to relieve pressure, it will constantly emit water

Expansion tank issue

This tank can be located separately from the boiler or be part of the structure. Its function is to take excess water when heated. Hot liquid expands, it becomes 4% larger. This excess is sent to the expansion tank.

The size of the tank is affected by the power of the boiler. For gas equipment, its volume is 10% of the total amount of coolant. For solid fuel - 20%.

Membrane rupture. If the part is damaged, the coolant is not restrained by anything, therefore it completely fills the compensation tank. Then the pressure starts to drop. If you decide to open a tap to add water to the system, the pressure will rise above normal. The connections will leak.

The tank or diaphragm needs to be replaced to reduce the pressure.

The pressure is below or above normal. A machine pump will help to achieve normal values \u200b\u200b(nominal value) in a gas boiler.

- Drain all water from the system.

- Close the valves.

- Pump the circuit until you are sure there is no water.

- How to release air? Through the nipple on the other side of the supply.

- Download again until the indicators reach the norm indicated in the instructions "Ariston", "Beretta", "Navien" and other brands.

The location of the tank after the pump provokes water hammer. It's about how the pump works. When it starts, the pressure rises sharply, and then also drops. To avoid such problems, in a closed heating system, install a tank on the return pipe. The next to hit is the pump in front of the boiler.

Why pressure rises in closed systems

Air accumulates in a double-circuit boiler. Why does this happen:

- Wrong filling with water. The fence is from above, too fast.

- After repair work, excess air was not released.

- Mayevsky cranes for air release are broken.

The pump impeller is worn out. Adjust or replace part.

To relieve or reduce pressure, fill fluid correctly. The fence is carried out from below, slowly, while Mayevsky's taps are open to bleed excess air.

Open System Issues

Problems are the same as described above.

It is important to properly fill water and bleed air. If after that the pressure has not returned to normal, it is necessary to drain the system

Secondary heat exchanger

The unit is used to heat domestic hot water. Its design consists of two insulated tubes. Cold water flows through one, hot water flows through the other. If the walls are damaged, a fistula appears, the liquids mix and enter the heating part. Then there is an increase in pressure.

If you do not want to repair and solder the heat exchanger, you can replace it. To do this, buy a repair kit and get to work:

- Shut off supply valves.

- Drain the water.

- Open the case, find the radiator.

The assembly is secured with two bolts. Unscrew them.

- Remove the defective part.

- Install new gaskets at the mounting points and connect the heat exchanger.

Other reasons

There are other reasons for such problems:

- Armature closed. During the intake, the pressure rises, protective sensors block the equipment. Inspect the taps and valves, unscrew them until they stop. Make sure the valves are working.

- Clogged mesh filter. It is clogged with debris, rust, dirt. Remove and clean the part. If you don't feel like cleaning regularly, install a magnetic or flush filter.

- The feed faucet is out of order. Perhaps its gaskets have worn out, then you can get by with a replacement. Otherwise, you will have to change the valve.

- Automation problems. Faulty thermostat or controller. The reason is wear, factory marriage, incorrect connection. Diagnostics and repairs are underway.

Check whether the boiler protection parts are in good condition: pressure gauge, valve, air vent. Clean radiators and other components from dust, soot, scale. Prevention helps prevent serious damage to gas equipment.

Stopping the boiler for a long time

When the boiler is stopped for a long period (more than 10 days), measures are taken to protect the boiler from corrosion resulting from the action of moisture and oxygen. For this purpose, various methods of protection are used, the choice of which is determined by local conditions. The following are most often used: the dry method, in which the boiler is freed from water and the air is kept constantly dry with the help of desiccants (calcium chloride - 1 kg / m3 of internal volume, lime - 2 kg / m3, etc.); wet method - the entire volume of the boiler is filled with an alkaline solution (when filled with feed water containing 2 kg / m3 of caustic patr, 5 kg / m3 of trisodium phosphate or 10 kg / m3 of soda ash in solution); method of excess pressure, which consists in the fact that the stopped boiler is constantly maintained at a pressure above atmospheric pressure (due to the supply of steam from other boilers or periodic heating by burning fuel). This prevents air from entering the boiler.

Specifications

Almost all gas boilers from the Ariston brand have a capacity of 15 to 30 kW. Thus, each client will be able to choose the necessary indicators for the size of his apartment or house. It is also worth noting other distinctive characteristics of such gas equipment:

with maximum efficiency, boilers have a high level of efficiency;

all wall-mounted boilers have Russian instructions and designations on the equipment itself, so citizens do not have problems with controlling the unit;

most models from this manufacturer are able to perfectly cope with water in the system and low pressure;

special attention to this equipment should be given to those people in whose houses power surges often occur. Ariston boilers can easily cope with such jumps in the network;

all models are very easy to operate

To start using the boiler, you do not need to study the instructions for a long time, all the features of operation are intuitive and accessible even for those who install such a unit for the first time.

In some cases, the boiler cannot simultaneously heat water and provide sufficient space heating, this applies to budget models. In this case, a person needs to think about installing an additional boiler.

Heating and production boiler house GUP FAPK Yakutia. Graduation projectMaterials Heating and production boiler house GUP FAPK Yakutia. Graduation projectPage 21

11.8. Periodic blowdown of the boiler.

Periodic purging of the boiler is carried out after a certain period of time and serves to remove sludge and dirt from the lower points: drum, collectors.

It is carried out for a short time, but with a large ejection of boiler water, which, during its movement, captures the sludge located in the drum or collectors, and takes it to the so-called expander (bubbler), designed to cool the boiler water. Cooling is carried out by mixing it with cold tap water to a temperature of 60-70 ° C, at which it can be released into the sewer.

Periodic purge is carried out at least once per shift. If the quality of feed water is poor, on the recommendation of a water treatment laboratory assistant, a second purge is performed. The duration and sequence of this operation is indicated in the production instructions for each boiler. The personnel of the boiler room, as well as all those involved in the repair of neighboring boilers, are warned about the purge. If the purge valve is located near the front of the boiler, the purge can be performed by one operator, and if it is located on the sides and back of the boiler, then it is performed by two operators.Periodic purge is performed in the following sequence:

1. Check the serviceability of the purge lines by touch. Before the first valve, the pipe must be hot, and after the second valve - cold. The fittings are checked for ease of rotation of the valve flywheels.

2. Check the serviceability of the feed pumps and the availability of a sufficient supply of feed water.

3. Purge water-indicating devices.

4. Feed the boiler to the upper working level or 3/4 according to the water gauge.

5. Reduce combustion in the firebox.

6

On the line, which, according to the instructions, should be purged first, carefully open the second purge valve in the direction of the purge from the boiler, and then slightly loosen the purge valve closest to the boiler in order to warm the purge line. After warming up, carefully open it.

The second operator at this time must observe the water level in the boiler and the steam pressure in the drum. If water hammer, pipe vibration or other problems appear in the purge lines, the purge must be stopped.

7. When the water level drops to the lower operating level (at the signal of the second operator), the purge valve (first) closest to the boiler is gradually closed, and then the second.

8. The rest of the lines are blown in the same way, observing the water level.

9. After the end of the boiler blowdown, you need to make sure that the blowdown valve is securely closed and start the boiler in normal operation.

10. Make an entry in the shift log indicating the start and end times of the purge.

11. After 30 minutes. you need to check how tightly the purge valve is closed. If the fittings will leak water, then you should inform the head of the boiler room and continue to monitor the water level in the boiler.

11.9. Normal shutdown of boilers.

The shutdown of boilers can be normal - by written order of the person responsible for the boiler room, and emergency, which is carried out without an order, followed by a message from the administration.

Normal stop sequence:

– reduce the load of the boiler, if possible, in several stages (100%, 75%, 50%, 30%), achieving gradual cooling of the boiler and furnace;

- turn off the gas burners - close the "working" valve (valve) and the "control" valve (valve), open the purge "candle" between them;

- close the valve on the gas pipeline in front of the boiler and open the purge "candle" of the gas manifold of the boiler;

- disconnect the boiler from the general boiler steam collector;

if the pressure in the boiler rises above the permissible level, bleed it through the safety valve into the atmosphere;

- as necessary, maintain the water level in the boiler between the highest and lowest;

- after 10-15 minutes. turn off the fan and smoke exhauster, further cooling of the firebox is carried out in a natural way. Repeated artificial ventilation of the firebox is allowed only after 6-8 hours;

- make an entry in the shift log about stopping the boiler, indicating the time.

Cooling of the boiler must be carried out slowly due to natural cooling: keep doors, hatches and manholes closed.

Rapid cooling may lead to a leak in the boiler. Descent of water from the boiler must be performed only after the pressure drops to zero, the temperature drops to 70-80 ° C and the laying of the brickwork cools down. The descent should be done slowly and with the safety valve raised.

Pages:21

https://tomsk.rf-54.ru/catalog/velosipedy/vzroslye/gorodskie/

How to enter the closed sections of the menu by access code

So, if you understand how to work in the menu, then it's time to move on to more serious things. The vast majority of all settings are closed from accidental interference by an access code. Therefore, in order to proceed with the boiler settings, we perform the following steps.

Press "OK" several times until the indicator shows the value 222 - Then hold "Plus" until the value becomes 234 - then again "OK" - Everything is ready!

Now we have one number 2 constantly lit and another 2 blinks - Which, as you understand, means the following - Menu 2 is on and you can select a submenu, and then a parameter. By setting the desired three-digit code and clicking "OK" we will see the value of the parameter that can be changed.

Use the ESC key to go back and select other menu items and submenus.

Brand operations

Boilers of different brands have their own characteristics, which are reflected in their documents. Below are examples of some models of well-known companies and measures for the necessary devastation of water.

First: Bosch boiler, Gaz 6000 W modification.

The valve for pumping the system is unscrewed. Cold water enters the heating circuit. The pressure gauge should show no more than 2 atm. A plug is unscrewed on the radiator, a fitting and a rubber hose leading to the sewer are placed there. The air is then bled off the radiators. In this model, this will be done by an automatic device (air vent).

Second: Vaillant apparatus, model atmoTEC pro.

When installing it, a special drain valve should be installed. It can be located at the boiler or in the lower piping area. In the first case, only the boiler is drained, in the second - the heating system.

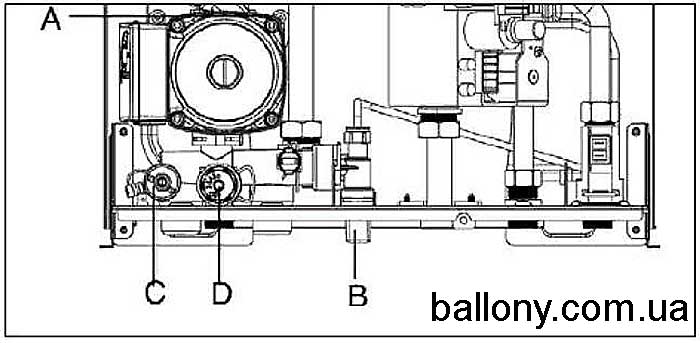

Third: Beretta unit, CIAO 24 CSI device. To drain the liquid from it, you should be guided by this scheme:

Process:

- The device turns off.

- The fluid drain valve (letter C) is loosened.

- Water is drained from the very bottom of the heating system.

If there is a threat of freezing equipment, the DHW circuit is emptied in the following algorithm:

- The main faucet is closed on the water supply.

- Open all valves with water (both hot and cold).

- Analogue of item 3 from the previous process.

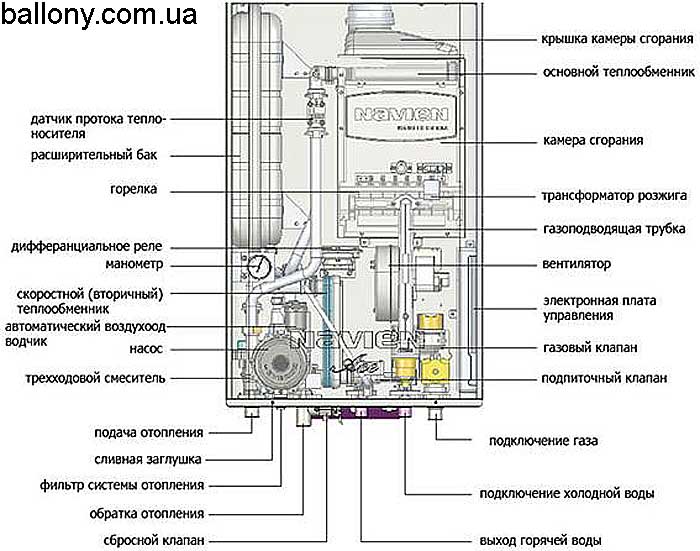

Fourth: Navien, model - Deluxe. Look at the diagram of the device.

And then proceed like this:

- Switch off the boiler, close the gas cock.

- Block two valves of the heating network and one with cold water.

- Open the faucet that you usually use in your home and drain the hot water.

- Close the DHW valve.

- Open the cap at the bottom of the case and drain the water into the container.

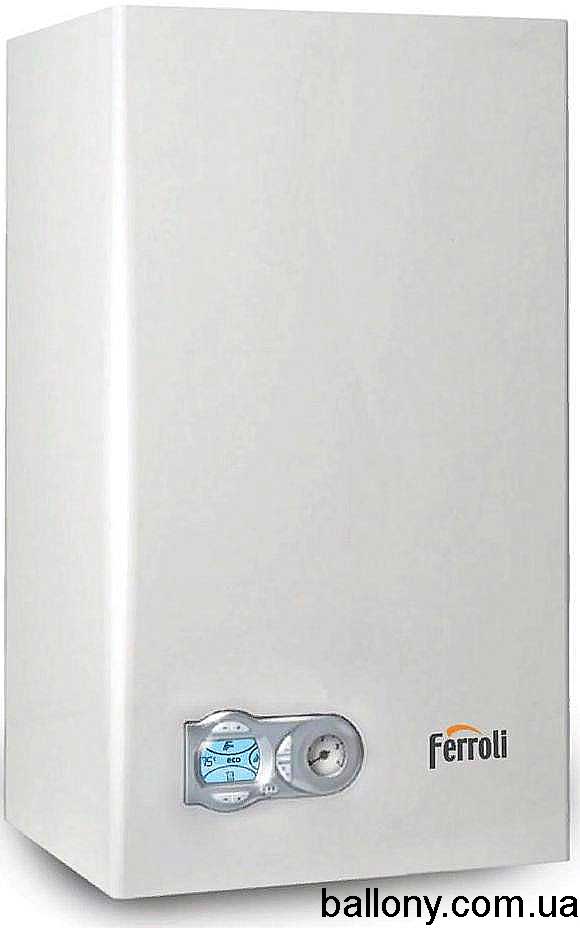

Fifth: Ferroli boiler modification Divatech D F24.

All actions come down to opening the drain tap and turning the place from which water flows. There is no special handle here. The drain in the model is white, the filler is black.

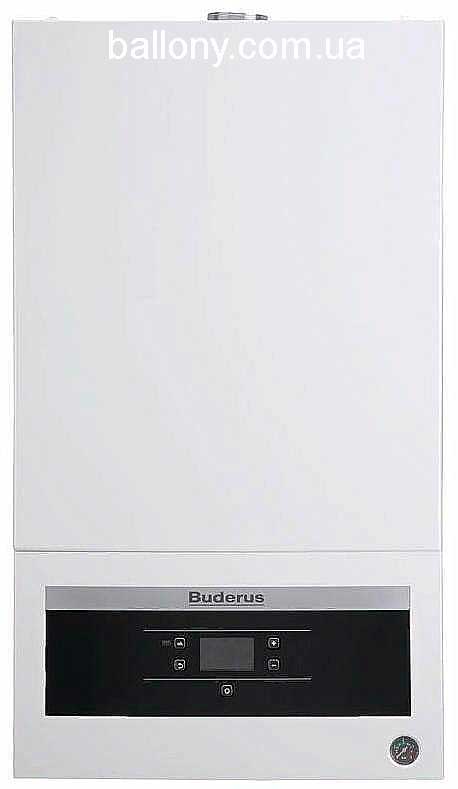

Sixth: Buderus, Logamax U072.

There is a non-return valve on the inlet section of cold water. The liquid is removed through the drain line from the valve to the sewer. At the same time, a water seal is arranged, and the jet breaks into a receiving funnel. So the pump of the device is protected from the ingress of debris.

Seventh: Neva Lux model 8618.

Actions:

- The device is powered off.

- The gas valve is blocked.

- The air vent opens slightly.

- The drain valve opens. The water is directed to the container.

The second way is to use the relief valve located at the bottom of the boiler.

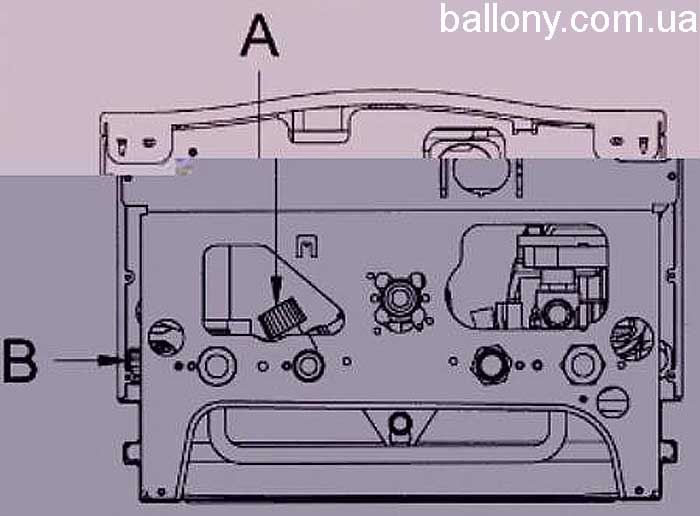

Eighth: Baksi, modification of Main Four 24. This scheme helps in the procedure:

Shut off the system, open the drain cock (letter B). Water will leave through a special nozzle on it.

Ninth: Ariston, model Class 24.

For work you need: adjustable wrench, hose, screwdriver, hexagon 4 mm. Procedure steps:

- The device is de-energized.

- The faucet supplying cold water is closed.

- The hot water valve is unscrewed. This equalizes the pressure inside the boiler.

- Air is let into the boiler: a valve opens on the pipe that lets in hot water.

- A hose of the required diameter is connected to the device, a drain valve opens, the tank is completely emptied.

An example of the procedure is shown in this video:

Operating instructions for gas boilers Ariston

Before purchasing an Ariston gas boiler, you need to understand that if the buyer does not understand its installation, it is better to contact experienced specialists and entrust all the work to them. After all, even with the most detailed instructions, it is not a fact that the case will end successfully.In this case, there is every chance of damaging the equipment, after which you will have to call repairmen, and this will result in additional costs.

It is very important to keep children away from the equipment. To do this, after, it is necessary to have a conversation with them and explain in an accessible language that nothing can be twisted and put on the unit, only an adult should do this

If the family leaves, for example, on vacation, after the boiler is turned off, it is also necessary to shut off all pipes for the supply of gas and water. Only after that the equipment is disconnected from the network.

If a display is provided on any model, all indicators that it displays must be strictly controlled. It can display malfunctions or deviations from normal operation that occurred during the heating process.

One of the most important points in the instructions for gas equipment is safety. Before connecting the boiler, you need to familiarize yourself with it first.

Filling up the gas tank

To understand the so-called bottling, one must initially understand what liquefied hydrocarbon gas used to gasify private facilities consists of. Actually, there are only two main components - propane and butane. In this case, propane is considered the main substance as a lighter gas. In winter, its content in the mixture should not be less than 75%. This is due to the fact that butane does not change from a liquid to a gaseous state even at a temperature of -1 ° C, while propane continues to work even at -40 ° C.

If the gas holder is not located deep enough, as a result of which the internal temperature of the vessel is negative, only one component, propane, evaporates, and liquid butane remains inside the vessel. In this case, you have to either pump out the butane accumulated in the tank, or wait for the temperature to rise so that it begins to evaporate on its own.

Freezing of the gas tank due to shallow occurrence leads to the shutdown of the gas boiler

And this is what the frozen upper part of the gas tank looks like:

Frozen gas tank

First start-up and adjustment of the boiler

When the installation and connection work is over, you can proceed to setting up and testing the equipment.

Performing the first run

The initial action that accompanies the first launch of an Ariston brand gas boiler is water. In this case, it is necessary to set the air valves of the radiators to the working (open) state.

The same actions aimed at bleeding air from the system apply to the boiler circulation pump. As the circuit is filled with water, air is removed from the system, the water pressure on the pressure gauge reaches 1 - 1.5 atmospheres, the valve on the feed line is closed.

—

CAUTION 3

ROOM из нагоÑнÑÑ ÐºÐ°Ð½Ð°Ð² в кÑвеÑÑ Ð·Ð°Ð¿ÑеÑен. ENGLISH PLAY ROCK ONLINE ROSTAGE RUMP Ð Ð Ðμñðð¸ðð'''ððñðð¾ñññððððððððñºññ¶ðμμð½ð ²²ð'Ððð ° ððððððð ¾¾¾ººººñññ

a

ROOM Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ÐμÐ Ð Ð Ð Ð μ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ² ² ÑÑÐµÐ¼Ñ Ð¾Ð±Ð¾ÑоÑного водоÑнабжениÑ.

a

ROOM Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð μm Ð Ð Ð ²ÐðÐ Ð Ð Ð ² Ð ²ÐðÐðÐ Ð ² Ð ²ÐÐðÐð Ð ² Ð δÐ ·

a

ROOM, Ñ Ð Ð Ð Ð Ð 'Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð μ · Ð ²Ð Ð Ð Ð Ð ²Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ² в ´Ð° из коÑоÑÑÑÐ¼Ð¾Ð¶ÐµÑ Ð¿Ð¾ÑÑÑпаÑÑÑÑÑÑи пÑÑ´´Ñ, заѿÑеÐ

a

ROOM иР· оÑÑÐ ° новР»Ðμнного коÑл Ð ° Ñ ÐμÑÑÐμÑÑвÐμнной ÑиÑкÑÐ »ÑÑиÐμй ÑÐ ° Ð · ÑÐμÑÐ ° ÐμÑÑÑ Ð¿Ð¾Ñл Ðμ ÑнижÐμÐ½Ð¸Ñ Ð'Ð ° вР»ÐμÐ½Ð¸Ñ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ² Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ñ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð μl R¡.

a

|

и½ðððð ° Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ²ñññ²¾¾¹ñ²²². | ÐоÑмР° ÑивнÑÐμ Ð · нР° ÑÐμÐ½Ð¸Ñ Ð²ÐμÑоÑÑноÑÑи пÑÐμвÑÑÐμÐ½Ð¸Ñ ÑÐ ° ÑÑÐμÑнÑÑ ÑÐ ° ÑÑоÐ'ов пÑи опÑÐμÐ'ÐμÐ »Ðμнии ÑÐμÑÐμÐ½Ð¸Ñ Ð²Ð¾Ð'ооÑвоÐ'нÑÑ ÑÑÑÑойÑÑв , %. a |

ROOM Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð μñ Ð Ð ², дÑÑгиÑбаÑÑейнов запÑеÑаеÑÑÑ. Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ²Ð Ð Ð Ð Ð Ð ²Ððð𾺾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾¾ Ññðððñññμμ½ð ññðððμРРРРРРРи Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð

a

ROOM Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ÐμÐ Ð Ð Ð Ð μ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ² ² ÑÑÐµÐ¼Ñ Ð¾Ð±Ð¾ÑоÑного водоÑнабжениÑ.

a

ROOM Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð μm Ð Ð Ð ²ÐðÐ Ð Ð Ð ² Ð ²ÐðÐðÐ Ð ² Ð ²ÐÐðÐð Ð ² Ð δÐ ·

a

ROOM Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð δ Ð Ð Ð Ð Ð Ð ²Ð Ð Ð Ð Ð Ð Ð δÐ Ð Ð Ð Ð Ð δ R°. Ð ²Ð Ð Ð ÐμÐ Ð Ð ÐμÐ Ð ÐμÐ Ð Ð ÐμÐ ÐμÐ Ð Ð Ðμ Ð Ð Ð Ðμ Ð Ð Ðμ Resume. Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ² Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ¿ Ñнойи

a

ROOM иР· коÑÐ »Ð¾Ð² нР° вÑÐμÐ¼Ñ Ð¸Ñ ÑÐμмонÑÐ ° оÑÑÑÐμÑÑвл ÑÑÑ ÑÐμÑÐμÐ · ÑпÑÑкнÑÑ Ð »Ð¸Ð½Ð¸Ñ 19 Ñ Ð¿ÑоÑоÐ'нÑми кÑÐ ° нР° ми 18 нР° нÐμй.

a

ROOM Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð μ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ðμ Ð Ð Ð Ð Ð Ð Ð Ðμ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ðμ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ñññññððððÐμμñññððððвñññññððððð коÑле до 60 - 70 С.

a

ROOM Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ° Ð Ð Ð В Ð¾Ð · Ð δÐ Ð Ð Ð Ð Ð Ð Ð ° Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð μññññºººðð ° ° °ññññºððð °ðð ° ° ° °

a

ROOM иР· оÑÑÐ ° новР»Ðμнного коÑл Ð ° Ñ ÐμÑÑÐμÑÑвÐμнной ÑиÑкÑÐ »ÑÑиÐμй ÑÐ ° Ð · ÑÐμÑÐ ° ÐμÑÑÑ Ð¿Ð¾Ñл Ðμ ÑнижÐμÐ½Ð¸Ñ Ð'Ð ° вР»ÐμÐ½Ð¸Ñ Ð Ð Ð Ð Ð μl RUR 80 ÐÐ · оÑÑÐ ° новР»Ðμнного пÑÑмоÑоÑного коÑл Ð ° ÑÐ ° Ð · ÑÐμÑÐ ° ÐμÑÑÑ ÑпÑÑкР° ÑÑ Ð²Ð¾Ð'Ñ Ð¿Ñи Ð'Ð ° вР»Ðμнии вÑÑÐμ Ð ° ÑмоÑÑÐμÑного; Ð ²Ðñññ½½ððооонРРРРРРРРРРРРРÐμÐ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð μ Ð · Ð μ Ð ² Ð · Ð · Ð ² в ÑимоÑÑи Ð¾Ñ ÑиÑÑÐµÐ¼Ñ Ð´Ñенажей и ÑаÑÑиÑиÑелей.

a

ROOM Ð · Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð μ Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ðμ

a

Types of equipment and the principle of its operation

How to remove air from a closed-type heating system with a simple tank? It can only perform the function of an air vent in open circuits. Since it is not possible to ventilate a closed circuit heating system using a tank. They are installed only sealed tanks. The open reservoir is at the peak of the contour, where the oxygen bubbles tend to go.The problem is that water is enriched with it in the same tank, therefore, there is a high level of air in the coolant, which is there until the liquid is heated;

It is installed at the highest point or in a place where oxygen accumulates. The threaded part of the heating air vent comes in two diameters: ½ or ¾ inch. In shape, they can be even or bent at a right angle, the letter "g". The air outlet is located either in the end part or on the side of the housing. Works offline. Air is released from the heating system when the pressure in the system rises to a critical level. Consists of valve and float. The principle of operation is that when oxygen rises, the float drops and opens the valve. As soon as an ejection occurs, the float rises, returned to its original position, and closes the valve;

air separator for heating.

Placed on the pitch. Unlike an automatic air vent, it does not remove the oxygen that has itself separated from the coolant and rises up. The air separator in the heating system independently separates and disposes of oxygen particles. It is designed in such a way that the flow is mixed, bumping into obstacles. Barriers can be:

Air separator for heating

Since they are installed in the area behind the boiler, where the temperature is highest, their work becomes more efficient. Oxygen is more readily separated from hot water. Automatic venting of the heating system is carried out continuously. Works autonomously without human intervention;

Mayevsky crane.

Removing air from the heating system requires human intervention. The valve is located at the end of the heating radiator. This is that white "kreverka" on the battery, in which a bolt is screwed in the middle. There is a hole in the plastic, as small as a needle, since this is more than enough to bleed air from the heating radiator. In order to do this, you need to prepare a vessel for water, a half-liter jar will do, unscrew the tap a little and, after the hissing stops and a trickle of water flows, close it. That's all, the cork is removed.

What are the advantages of Ariston gas boilers

Recently, the popularity of the Ariston brand has increased significantly due to high-quality gas boilers, and this is not in vain. operates silently and consumes as little fuel as possible. This will allow the owners of the unit to save on utility bills and, at the same time, provide comfort and warmth to the house.

The client will receive a high-quality device that provides round-the-clock water supply and heating of the house, even with a large area of up to 500 square meters. Also, do not forget about the durability of the service of each boiler. The terms indicated in the guarantee are much more modest than they actually turn out to be. In terms of dimensions, the equipment is much more compact than other brands, which means that it can be installed absolutely anywhere, even in a small apartment with limited space.

Emergency stop of the boiler

boiler emergency pressure manometer

An emergency stop of the boiler unit can be in the following cases: when the steam pressure in the boiler rises above the permissible level (despite the decrease in fuel supply, blast and draft and increased water supply); in case of water leakage and overflow of the boiler with water; failure of both safety valves; due to a malfunction of the pressure gauge and all water-indicating devices; failure of all feed pumps and interruption of water supply to the boiler; the presence of significant damage to the elements of the boiler (pipe rupture, cracks, bulges, leaks, etc.); detection of abnormalities in the operation of the boiler (shocks, knocks, noise, vibration); destruction of masonry, red-hot frame, boiler plating; in the event of a fire threatening the boiler

In the event of an emergency shutdown, the boiler is immediately disconnected from the main steam line, the fuel and air supply is stopped, and draft is sharply reduced; burning fuel in layered furnaces is immediately removed or carefully filled with water

The functionality of the heating system of a private house depends on the operability of the heating equipment and the correct gas supply to it. In this article, we will look at external reasons for stopping the gas boiler

when a serviceable device is not able to provide the required temperature in the room due to the low pressure of propane-butane or its complete absence at the inlet to the boiler room.

This situation can be caused by a problem with shut-off and control valves, a gas pipeline or a gas tank, and is most typical for the cold season. Below we will discuss each case in detail.

Ariston boiler menu structure

At first it may seem complicated, but as you figure it out, everything will be simple and clear, so:

Each parameter is identified by a three-digit numeric code. For example 228 (this is just a parameter code that depends on the version of the boiler)

The first digit of the three-digit code means a separate menu group, the boiler has six separate menu groups, each is responsible for its own settings section. Here they are.

2 - Boiler settings

3 - Solar collector and storage boiler

4 - Zone 1 parameters

5 - Zone 2 parameters

7 - Testing and maintenance

8 - Technical parameters.

The second digit of the three-digit code indicates the submenu, and the third is the parameter itself to which access is granted.

For example, code 228 already known to us stands for: 2 - Boiler settings (this is Menu), 2 - Basic boiler settings (Submenu), 8 - Boiler version (Parameter).

Thus, by dialing the three-digit code 228, we get access to the set value of this parameter, which, according to the table, can vary from 0 to 5 and depends on the version of the boiler.

I will provide tables with menu codes and a description of what is regulated by a specific code a little lower, but for now let's figure out how to enter the boiler service menu.