A bit of history

The Junkers company was founded in 1895 for the industrial production of gas appliances for individual consumers. The production was located in the city of Düssau. The name of the company comes from the name of the German industrial engineer Hugo Junkers, a famous 19th century inventor in the field of thermal engineering, who has almost two hundred invention patents.

By 1904, the company had mastered the production of gas water heaters and other equipment. The use of advanced technologies made it possible to develop a gas supply control system depending on the hot water consumption.

In 1932, due to the global crisis, the management of Junkers sold its concern to the Bosch company, which continued the development of the concern and its production. New factories were opened, quality control of manufactured products was improved, development of new technologies was continued, for example, the idea of piezo ignition of a flame for columns was embodied. After 10 years, heating boilers for surface mounting were launched into production. And in 1985, mass production of gas boilers with an environmentally friendly clean combustion system began. The company produces household gas appliances in which the combustion chamber is closed and there is no need to connect a chimney.

Today, Bosch Thermotechnik is one of the largest manufacturers of gas heating appliances in Europe.

The product range of the Junkers brand includes gas floor and wall-mounted boilers, solid fuel boilers, water heaters.

Additional elements and spare parts for units of this brand are inexpensive, and surpass competitors in quality. The company sets a 25-year warranty period for its products.

Consider several series of products of this brand.

Safety Instructions

The regulator is to be used only in connection-

tion with the listed Junkers gas heating

units. The respective circuit diagram must

be observed.

The regulator must under no circum-

stances be connected to the 230 V

mains.

Before installing the regulator, the volt-

age supply (230 V, 50 Hz) to the heating

unit must be interrupted.

The regulator is not suitable for installa-

tion in damp rooms.

2

Application

TR 200 is a room temperature regulator with a

digital time switch (weekly programme; three

heating and one reduction starting times per

day) for controlling the Junkers gas heating

units with continuous control listed below.

heating unit

Mains

connections

illustration.

ZE/ZWE .. K…

illustration.

ZE/ZWE .. — 1 K…

illustration.

ZE/ZWE .. - 2 K…

ZE/ZWE .. — 1A…

illustration.

illustration.

ZE/ZWE .. - 2A…

illustration.

ZR/ZWR/ZSR…-3

illustration.

ZR/ZWR/ZSR…-4

heating equipment

with

Bosch Heatronic

illustration.

TR 200 is in accordance with the regulations

and is recommended for floor-areas up to ap-

2

prox. 80 m

.

Room temperature regulators like TR 200 are

not suitable for buildings with underfloor heating

systems. In those buildings we recommend

the use of a regulator controlled by atmos-

pheric conditions.

2.1

Scope of delivery

TR 200 includes the room temperature control

lator with inserted brief operating instructions

(illustration

).

2

Malfunc-

remote control

indicator

active

no

9

no

9

no

9

no

10

no

10

no

10

no

10

yes

11

2.2

Accessory

An external room temperature sensor RF 1 in

in addition to TR 200 is available as an accessory.

For example, the use of this temperature

sensor is of advantage when the mounting lo-

cation of the regulator is not suitable for meas-

urement of temperature (see chapter 4).

Furthermore, a remote control switch (e.g. a

telephone commander) can be connected by

customers (see chapter 6.8).

The remote control switch must be equipped

with a potential-free contact which is suitable for

5VDC.

3

technical data

Dimensions

Rated voltage

Rated current

Regulating range

Regulator

output

Permissible ambient

temperature

operating reserve

protection class

4

Mounting

Before mounting the regulator, the volt-

age supply (230 V, 50 Hz) to the heating

unit must be interrupted.

4.1

Selecting the mounting location

It is important for the regulation quality of

TR 200 to select a suitable mounting location.

The installation room must be suitable for the

temperature regulation of the complete heat-

ing system. The radiators installed in those

rooms must not be equipped with thermostatic

valves. Instead, hand valves with pre-adjust-

ment should be installed so that the heating

output of the radiators in the installation room

of TR 200 can be set to the lowest possible

value.

see illustration

3

24 V DC

0.03 A

5 to 30 °C

constant, 2.8 to

21.5VDC

0 to +40 °C

approx. 2 hrs.

IP20

5

Basic error codes

45

Error 45 may flicker alternately with 90. This is an indicator of insufficient traction. In turbocharged models, it is necessary to check the operation of the fan and the differential pressure switch. In atmospheric boilers, the draft in the chimney and the serviceability of the draft control sensor are checked.

60

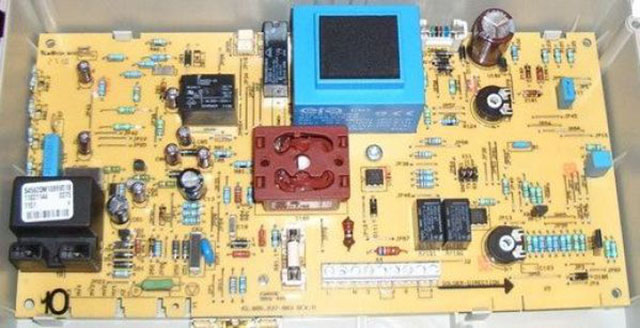

Error 60 appears when the control board malfunctions. One of the reasons may be the burning of the resistor next to the ignition transformer. If you are not well versed in the electronic part, it is advisable to contact the service department.

75

Error 75 indicates a malfunction in the electronic board. Most likely the problem is in the circuits tied to the ignition and combustion control. You may need to completely replace the control board.

90

Error 90 flashes once every four seconds when there is low pressure in the network. The electronic control board may be faulty. If you have problems with electricity throughout the room, buying a voltage stabilizer will help.

A4

Error A4 is displayed when the flue gas outlet is detected on the flow fuse. Check for any obstructions in flue gas evacuation.

aa

Error aa appears when the flow temperature in the heating system is exceeded and the water flow is insufficient for the set power level. It is necessary to check the presence of lime deposits on the plate heat exchanger and in the combustion chamber, to inspect whether the pump is working. Also, the cause of the breakdown may be a malfunction of the NTC sensor.

e2

Error e2 indicates that the supply temperature sensor is damaged. It is necessary to inspect the sensor and its wires.

e9

Error e9 is output if the flow temperature limiter is activated. Look at the pressure in the system, the operation of the temperature sensor, the pump and the control board. Blowing out the system may also help.

ea

Error ea means that the flame in the burner is not recognized. Check the flow of gas into the column and its pressure, the serviceability of the gas flow control switch. The cause of the breakdown may be a clogged heat exchanger, a clogged drain of the condensate siphon. The flame may not ignite due to lack of draft - inspect and, if necessary, clean the chimney, ensure the flow of air into the room.

с4

Error c4 means that the differential pressure switch cannot open at rest. Inspect the switch, the cable it connects to and the condition of the flexible connecting pipes.

с6

Error c6 is displayed if the fan stops working. It is necessary to check the operability of the fan and the integrity of the connecting wires and plug. If necessary, replace damaged parts.

When Repair Is Needed

The German unit has many advantages over analogues of competitors' gas equipment. However, malfunctions in the operation of the Junkers gas boiler, as in any other heating unit, are possible. For example, a common malfunction is a malfunction of the control module. The boards in such devices are very fastidious. They are difficult to repair, and often there is a need to buy a new one, and this costs a lot of money.

To eliminate such problems, it is necessary to install a boiler voltage stabilizer that isolates the coupling

for gas and grounding.

In addition, as evidenced by reviews of the Junkers gas boiler, starting problems are not uncommon. In this case, the electric ignition is activated, the flame burns for an average of 4 seconds and goes out, and so on in a circle. The ignition of the flame indicates its instability. The boiler body heats up strongly, the liquid temperature does not rise above 45 °C. This problem can be eliminated by completely cleaning the combustion chamber and burner device. After all, as a rule, the operation of the boiler is getting better.

The device and principle of operation of Junkers boilers

Classic gas boilers

The Junkers company produced several series of gas boilers with a classic device: Ceraclass, Ceraclass Comfort, Ceraclass Exellens and Junkers Euroline. Among them there are models with one and two circuits, as well as with closed and open combustion chambers. The devices can operate both on natural gas from a centralized gas pipeline, and on liquefied gas from cylinders.

They are compact and wall mounted. At the bottom of the column body there is a Heatronic control panel with knobs for adjusting the temperature of the coolant and hot water, setting buttons, a pressure gauge and a multifunctional display. In Ceraclass Comfort models, the electronic part is closed from above by a cover.

Devices with closed combustion chambers are additionally equipped with fans in the upper part for the forced removal of combustion products and air into the furnace. In the center of the boiler is a burner with an ignition electrode and ionization flame control.

Above it is a heat exchanger made of copper or stainless steel. On the right, a little lower, there is a circulation pump that ensures the movement of the coolant through the radiator system. In double-circuit devices, a second plate heat exchanger is installed, which provides heating of water for domestic needs.

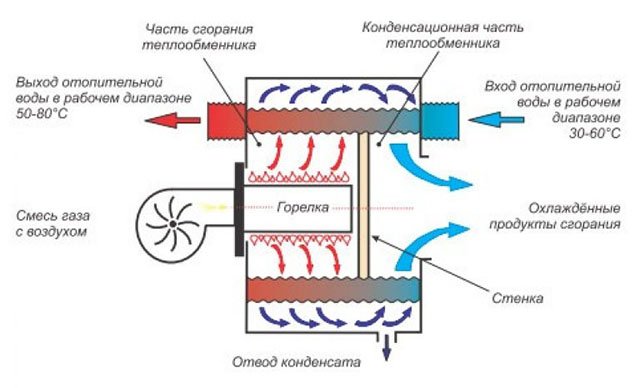

Condensing gas boilers

Condensing boilers are represented by the Ceraput Smart, Comfort, ACU and Modul series. There are both floor and wall configurations. They are more economical than classical ones due to the use of heat from the condensation of the vapor of combustion products.

Additional elements of such devices are condensate collectors located in the lower left part of the case. A coaxial chimney exits from above, through the central part of which the cooled combustion products exit to the street, and through the outer part oxygen into the furnace.

All Junkers boilers are equipped with the necessary protection devices. Modern models can be connected to the Smart Home system and controlled remotely. Consider which Junkers gas boiler shows error codes and what to do to correct these faults.

General Information

… and hints on saving energy:

When the regulator settings are changed

regulator reacts with a time lag. Every 20 sec

onds the processor compares all desired and

actual values and carries out all necessary

corrections with the necessary speed.

The room in which the room temperature reg-

ulator is mounted (control room) determines

the temperature for all other rooms.

I.e. the room temperature in the control room

acts as a control input for the entire heating

network.

For this reason all thermostat regulated radiation-

tors located in the control room must be

opened completely at all times. Otherwise the

thermostat valves would reduce the heat sup-

ply although the regulator constantly requires

more heat (see also chapter 4.1).

If in the adjoining rooms a lower temperature

is wanted or if the radiator should be turned off

completely, the (thermostatic) radiator valves

must be set accordingly.

Since the room where the room temperature

regulator is mounted acts as a control room,

any external heating sources (e.g. insolation,

tiled stove, etc.) can result in insufficient

heating of the remaining rooms (the radiators

stay cold). In order to avoid this room

temperature sensor RF 1 can be used

according to the notes in chapter 2.2,

chapter 5.1 and chapter 6.7.

When the room temperature is reduced during

the day or during the night a lot of energy can

be saved.

If the room temperature is reduced by 1 K (°C)

this can save up to 5% of energy.

It is not recommended to let the temperature

of daily heated rooms drop below +15°C.

When the room is heated up again the com-

fortability is diminished by the walls which

are cooled down. So if one wants a real com

fortable room temperature regulator must

be turned up and so a lot more energy is used

up than is in case of an even heat supply.

If the building has good thermal insulation it is

possible that the set economic temperature is

not reached. But even in this case energy is

saved since the heating system is not activated-

ed.

In this case the starting time for economical

operating mode can be set earlier.

Do not let windows stand ajar for airing the

rooms since this would constantly withdraw

heat from the room without improving the air in

the room considerably. Do avoid continuous

airing!

It is better to air the room briefly but properly

(open the windows completely).

Set the temperature regulator to a lower value

during airing.

15

Advantages of the Junkers geyser

Almost all Junkers wr 10 gas water heaters and Junkers wr 275 gas water heaters are adapted for countries such as Russia. These heating devices have their own advantages, such as:

- They are adapted to a gas pressure of 13 Mbar for Russia. Compared to Europe, the pressure in the gas pipeline there reaches 20 Mbar. If your Junkers column is not adapted to gas pressure, then it may be less productive. And this moment is important.

- In multi-storey houses, the Junkers gas water heater can work stably at a pressure of 0.1 ATM. And this is a very good indicator.

- The device of the Junkers gas column is made in such a way that such heating devices can heat from 11-20 liters of water per minute. It should also be noted that in these columns, water can itself be mixed in the mixer.

- The Junkers geyser has flame modulation, which allows it to automatically change power depending on the water supplied.

- It has a high-quality German assembly and a 2-year warranty for the device, as well as a long service life, unless of course you follow all the safety and use rules.

- The low price of Junkers geysers, unlike its counterparts.

Junkers column scoreboard

Boilers of condensing type

They include the Junkers brands Cerapur Smart, Cerapur Comfort, Cerapur ACU, Cerasmart Modul - condensing gas boilers of various capacities, wall or floor-mounted.

The boilers of this series are equipped with three-stage pumps, the ability to control the heating of hot water and the intensity of heating, an indicator of malfunctions and malfunctions of the automatic control system. The device with the ZW23 index contains a stainless steel heat exchanger, which allows for high performance when heating water. Properly designed body design makes it possible to harmoniously place the boiler in the kitchen. The device is equipped with an electronically controlled burner ignition and a troubleshooting system. Additional connection of the temperature sensor in the room is possible. Boilers with the ZW index perform the functions of heating and hot water supply, and ZS - only heating.

Junkers Eurostar

Boilers of this model are wall-mounted, with a two-stage pump, heating intensity and water heating temperature regulators. There must be an auto-electronic control program and digital fault diagnosis. The "Comfort" mode minimizes the water heating time.The boiler can operate in two modes of hot water supply - economical or comfortable. Devices with the index ZWE - heating and hot water, ZSE - heating.

EuroMaxx

Will repairs be required?

The main malfunction of Bosch Junkers boilers is the failure of the control module. The boards in these devices are very capricious. Repairing them is quite difficult and often you have to purchase a new one, which is extremely expensive.

In addition, there may be problems with starting, when, after the electric ignition is triggered, the flame burns for 3-5 seconds, then goes out and so on several times. If the flame ignites, then it is not stable as usual. The boiler body is heated strongly, and the water temperature does not rise above 45 C. Such a malfunction can be eliminated by high-quality cleaning of the combustion chamber and burner. After that, the malfunction usually disappears and the boiler works normally.

Floor standing gas appliances Junkers

Junkers floor-mounted gas boilers are purchased for residential buildings and industrial premises. The performance of the units reaches 56 kW, which is enough for high-quality heating of an area up to 500-600 m². It is possible to connect two floor heating boilers to one network (cascade). Installed if desired.

A distinctive feature of the outdoor devices of the German manufacturer in the heat exchanger, made of refractory cast iron. This increases the heat transfer coefficient and extends the operating period.

In equipment with installation on the floor, according to the manufacturer, it can be used for boilers. This significantly increases the heat output during heating, and also protects the heating system from defrosting.

Atmospheric wall equipment

- Comfort

- the device of the boiler allows you to reduce the number of possible malfunctions and increase the service life. A self-diagnosis program has been installed, information about problems in operation and malfunctions is displayed on the LCD display. The basic Comfort package contains all the equipment necessary for operation: a circulation pump, gas burner control, sensors and devices that protect against overheating. - Excellence

- the modification includes both wall-mounted single-circuit gas heating boilers of the Junkers brand, and double-circuit analogues. They have high performance. Can be connected to the smart home system. It is possible to connect several heating systems at the same time.

Floor type boilers

It is allowed to connect two Junkers outdoor gas heating cats to one network (cascade). If necessary, you can install an indirect heating boiler.

The advantage of Junkers models of floor-standing heating boilers is that their heat exchanger is made of refractory cast iron. This made it possible to increase the heat transfer coefficient, as well as the service life.

In floor-standing units, according to the manufacturer, antifreeze used for boilers can be used. This increases the heat transfer during heating several times, and also prevents the heating system from defrosting.

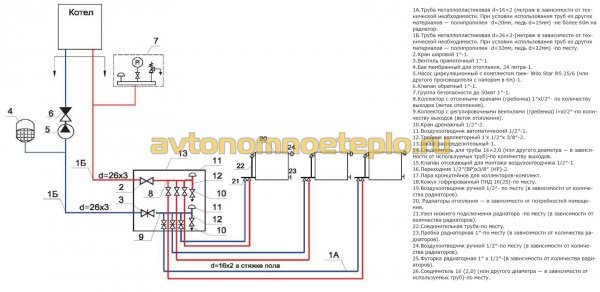

Tying and commissioning

Required installation of water treatment. The internal design of the heat exchanger is sensitive to the effects of an aggressive environment, therefore, before entering the heating system supply into the boiler, coarse and fine filters are installed.

Maintenance of the boiler is quite simple, thanks to the front removable panel, which provides access to important components. The heat exchanger is cleaned at the beginning and end of the heating season.Fault diagnosis is carried out automatically, the results are displayed.

Advantages and disadvantages of choosing a Junkers boiler

Another common problem occurs as a result of poor boiler maintenance. The principle of operation of the equipment is based on the use of sensors that prevent overheating of the coolant. So, automation works in the presence of a large amount of soot in the furnace. In this case, the water heating temperature does not rise above 45 ° C.

Otherwise, Junkers boilers work as befits German equipment - with accuracy, performance and reliability. Junkers is a good solution for those who value quality first and foremost and are willing to pay for it.

The requirements for heating gas appliances are high, since devices of this kind are purchased for long-term operation. Junkers brand products have always met the most stringent requirements in this area and rightfully enjoy great success.

Junkers gas individual boilers are distinguished by the traditional German quality of components, a rich model range, wide capabilities and inspire unconditional confidence in hundreds of thousands of customers around the world.

Junkers Ceraclass

The line of wall-mounted boilers is represented by models with Junkers Ceraclass ZS, ZW indices of various performance and design features.

They are designed for heating installation in apartments or houses of not very large area, up to 150 square meters.

Boilers ZS have one circuit and are intended only for space heating. An external boiler-type storage device can be connected to such a boiler.

The ZW boiler, which has 2 circuits, in addition to the heating function, will provide your home with hot water.

The boilers are equipped with a burner of both open and closed type, all models are equipped with electric auto-ignition, a three-stage pump, sensors for the presence or absence of draft, and are protected from overheating. It is possible to connect temperature sensors indoors, which will automatically maintain the desired temperature in all rooms. The automatic electronic control system is equipped with a liquid crystal display showing the temperature of the heating circuit and the current operating mode.

Bosch Junkers Ceraclass heater instructions: