general information

Installation of an electric underfloor heating is carried out in one of the following ways:

- on the base immediately under the coating;

- on the screed, followed by laying under the screed and top coat.

The latter option is usually used when installing cable underfloor heating in residential premises. When there is a well-heated apartment below or there is no desire to reduce the distance to the ceiling, you can think about laying a film infrared system. It is not recommended to lay this material under the tile, as well as to “brick” it into a screed. It is also possible to install a warm floor from mats consisting of carbon rods, but this is an expensive and not yet the most popular solution, which we will talk about sometime next time.

How to prepare the surface of the features of base insulation for underfloor heating

The old screed will need to be completely dismantled. In the case of installation of a warm floor, it is necessary at the initial stage to align the floor base horizontally if there are differences of more than 1 cm.

Next, a waterproofing layer must be laid on the cleaned base. A damper tape must be fixed around the entire perimeter, which will make it possible to compensate for the thermal expansion of the floor surface in case of heating.

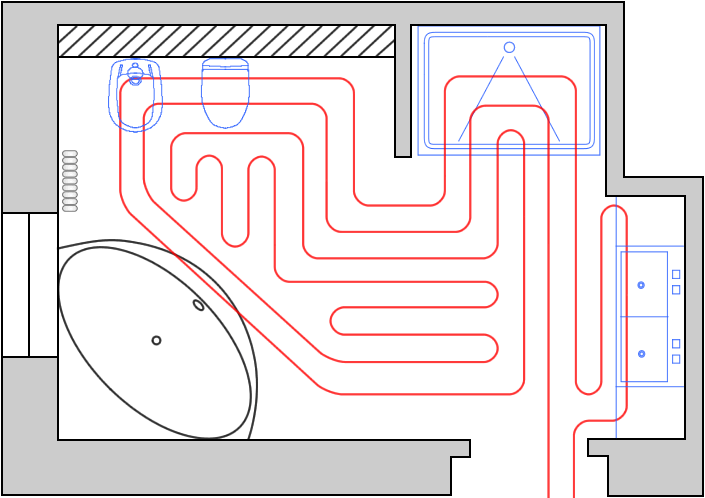

Project of a warm water floor in the bathroom.

So that the heat could not go down, it is necessary to insulate the base of the floor. Depending on the location of the room and the type of floor surface, as well as on the target orientation of the heating system, you need to choose the appropriate method of insulation:

- If a warm floor is an addition to the main heating system, then it is necessary to lay polyethylene foam as a substrate for warm floors, which has a reflective foil coating.

- If you plan to install a warm floor in an apartment, below which a heated room is located, you must use sheet or extruded polystyrene foam, which has a thickness of 2-5 cm.

- For apartments, below which basements or other unheated premises are located, it will be necessary to lay thick insulation materials. In this case, expanded clay or expanded polystyrene sheets 5-10 cm thick are well suited.

You can also use a specialized insulating material for underfloor heating, which on one side are equipped with special channels for installing pipes for underfloor heating systems.

On top of the insulation material, it is necessary to lay a reinforcing mesh, which will be needed in order to fix the screed layer.

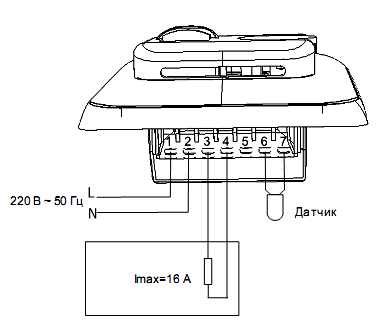

Placement of the thermostat.

First of all, you need to remember that the method of installation depends on how evenly the heat will be distributed in the room. The water that flows through the pipes will gradually cool down. That is why it is necessary to start the installation of pipes from the walls, moving towards the center or exit. In this case, everything will depend on which installation scheme is selected.

There are the following schemes for installing underfloor heating:

- snake. The pipe is laid first along the perimeter of the outer walls, after which a wavy line is laid from one of the walls to the beginning of the room.

- Snail. Pipes run along the perimeter of the room, narrowing towards the central part with each new circle. In order to have room for a return stroke, it is recommended to install pipes through one row.

- Combined option, which includes the two previous options. For example, half of the room is laid with a snake, and the other half with a snail.

The diagrams can be clearly seen in Fig. one.

Installation

If you have underfloor heating to install yourself, you may need to purchase additional electrical devices. The kit should include:

- regulator (thermostat) with temperature sensor;

- connecting cables and clamps;

- RCD protective system;

- ground wire.

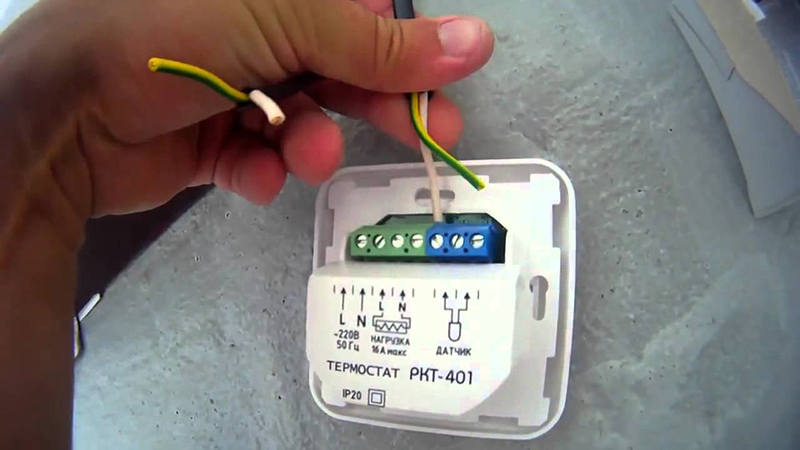

Before laying a warm electric floor with your own hands, you should figure out if the resistance matches. The permissible run-up with passport data cannot exceed 10%. The regulator is mounted on the wall. The height of 1-1.5 m is considered optimal, but this is already as convenient for anyone. The main thing is not to get too close to the floor. At the designated point, a hole is made for the junction box and a strobe for the temperature sensor wire.

Installation of the underfloor heating cable is carried out using special tapes. If there is a reinforcing mesh, you can attach the wire to it. For this, screeds are used.

It is important not to overtighten to avoid damaging the contacts. Do not forget to follow the step of laying the underfloor heating cable, indicated in the diagram.

Otherwise, the equipment parameters will not be as expected. At the same time, the probability of its accelerated failure is high.

When it comes to how to mount an infrared warm floor, the film is also laid out according to the chosen scheme. Strips are contraindicated to overlap. You can fix the unfolded film with adhesive tape or through special ears on the material. It depends on the design decision of the manufacturer. The process will not be difficult even for a non-professional - elementary accuracy is enough.

Having completed the laying of the underfloor heating cable, proceed to its connection to the regulator. In the case of the film, you have to additionally work on fixing the wires. How to do this and how to connect to the regulator is described in detail in the manufacturer's recommendations. If there is no step-by-step instruction for an electric underfloor heating with your own hands, we recommend that you contact the master or search for this document on the Internet. Many companies post electronic versions. Connecting on your own in this situation is too risky.

The temperature sensor must be hidden in the corrugation

When installing an electric underfloor heating with their own hands, many people forget about this important requirement. The result is a quick failure of the device and failure of the entire system.

When the thermostat receives false information, it also regulates it. Another disadvantage is that to remove the sensor, you will need to unscrew the coating. With corrugation, the extraction process will not cause the slightest hassle.

The final scheme for laying a warm electric floor must be fixed. You can take a picture of the location of elements and fasteners or just sketch

This precaution comes in handy when there is a problem with the system or the need for some kind of repair operation on the flooring. Before installing the underfloor heating finally, it is recommended to measure the resistance again

If the discrepancies with the previous testing are insignificant, you should start checking the equipment.

After making sure that it was possible to set up the warm electric floor correctly, all equipment is de-energized, and the thermostat is disconnected from the mains. The final part of the process begins - laying the finish coat. In the case of a film, there is no need for a screed. The only thing is that some kind of moisture-proof material can be used on top. In other situations, a screed of the required thickness is poured. How to install a warm floor for a specific coating should also be described in the instructions of the system supplier.

When it comes to a wet room - a bathroom or a sauna - you need a screed

In the presence of a reinforcing mesh, it is vital to properly ground the latter. You will also need to install an RCD

Work in these areas should definitely be entrusted to a professional. You can turn on the system only after the screed / adhesive solution has not just set, but has dried completely. This may take several weeks. Haste in this matter is unacceptable. Otherwise, damage to the cable or film is almost guaranteed.

We talked about what an electric underfloor heating is and how to install it, only in general terms. If you need more specific information on these issues, you can get it on our website in Moscow. Professional consultants are always ready to help with the solution of your problem.

Water heated floor as the main heating system

To determine the ability of a warm floor to heat the entire house without the use of heating batteries, it is necessary to carry out an appropriate calculation, which will determine the possibility of installing a warm floor as the main heating

When performing the calculation, it is important to consider:

- Room parameters;

- Required air temperature;

- Heat loss.

An approximate calculation of heat loss can be done by yourself or entrusted to a qualified specialist.

An approximate calculation of heat loss can be done by yourself or entrusted to a qualified specialist.

Layered installation scheme:

- Draft coating;

- Thermal insulation;

- Reinforcing mesh and plastic clamps;

- Pipeline;

- Concrete screed;

- Clear flooring.

- Preparatory work. Leveling the surface of the subfloor and cleaning it from dust;

- Laying a heat-insulating layer of foam or polystyrene;

- Laying multifoil as a heat reflector;

- Reinforcing mesh flooring, to which pipes are knitted, a special substrate is also used, in which pipes are conveniently laid;

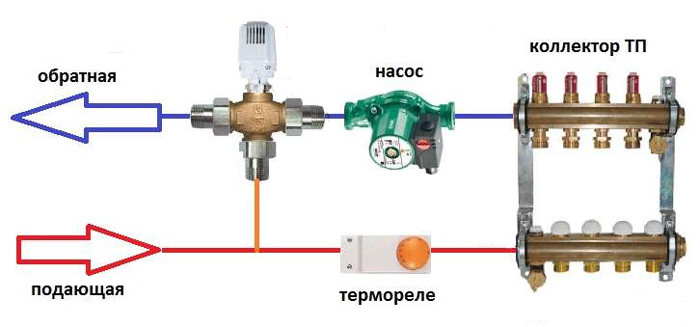

- Installing a collector that distributes the coolant through the pipes and also regulates the temperature;

- Laying pipes throughout the floor area. The laying pattern can be "snail" or "snake";

- Pressurization and pouring of concrete screed. At this stage, the pipes must be filled with water;

- After the screed has completely dried, you can start the system, first weakly, then gradually to the maximum value;

- Finishing flooring.

Conditions for installing underfloor heating as the main heating system

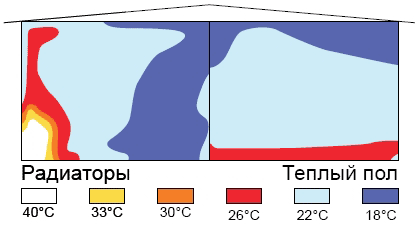

In order to operate only a warm floor without additional use of heating batteries, the power of the equipment must be enough to maintain the temperature regime in the room within 20–24 ° C

It is important to take into account not only heat loss through the walls, but also through window and door openings, if it is a private house or cottage, it is also necessary to take into account heat loss through the roof. When choosing the type of underfloor heating, it is necessary to correlate the pros and cons of various systems

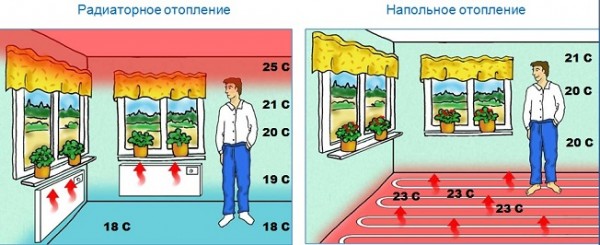

The electric floor heats the room unevenly, because it fits only in places where there will be no furniture and heavy household appliances, this also applies to IR film. The disadvantages of these systems become invisible when using a combined type of heating.

Considering that cold penetrates through the walls and heat is lost, it is advisable to distribute the pipes with the coolant in such a way as to provide greater heating of the area closer to the wall.

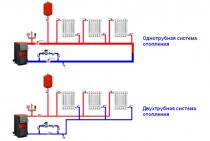

It is technically possible to make heating with water floors in an apartment, but permission is required for this. In order not to break the law, other types of floors are used instead: infrared or electric. Considering that a central heating system operates in an apartment building, a combined option is possible.

The heating system of new buildings is equipped with risers designed for arranging a water floor; there will be no installation problems here.

Benefits of underfloor heating without radiators:

- A significant part of the heat from radiators goes into the walls instead of heating the air;

- It is possible to lower the temperature in the system at its own discretion;

- A comfortable temperature is maintained for a long time after the system is turned off;

- The presence of radiators in the interior violates the design of the room.

Disadvantages of underfloor heating without the use of radiators:

- Complicated installation requiring repair work;

- High cost of equipment;

- In the case of electric floors, the cable used requires high energy costs;

- The need to raise the height of the floor by 6 - 10 cm.

Planning

It all starts with creating a schema. It is necessary to determine the areas where heavy household appliances and furniture will be located. Radiators and other heating elements must also be located at a certain distance from the heated surface. As a result, we get a figure of a certain configuration, within which the cable floor heating will be laid. For each room, it is better to form a separate circuit with its own regulator.

Next, you should calculate the required amount of materials. If you are installing a cable system, the manufacturer must provide ready-made heat loss tables for specific rooms. Based on these data, you will be able to determine the optimal laying step for electric underfloor heating and the total length of the system. With film, everything is much easier. It is enough to cut the required number of strips of suitable length. It is forbidden to connect the wire from the floor directly to the outlet. If you are not well versed in electricity, the procedure for connecting to the general power supply system should be done exclusively by a specialist.

How to calculate the required number of pipes

Figure 2. Scheme of the collector.

The calculation of the length of the pipes and the step of their installation for each room should be done individually. The calculation can be performed using special computer programs. To perform the calculation, you can also contact design organizations for help.

It is quite difficult to independently calculate the power for each of the circuits, because you will need to take into account a large number of parameters and various nuances. If errors are made in the calculation process, not the most pleasant consequences may occur in the operation of the heating system. There are the following problems: insufficient circulation of the coolant, alternation of warm and cold areas, uneven heating of the floor surface and the appearance of heat leaks.

To make a calculation, you will need to take into account the following parameters:

- Dimensions of the room in which it is planned to install a water heated floor.

- The material from which the walls of the room were made.

- Type of thermal insulation.

- Type of floor covering.

- The diameter of the pipes of the water floor heating system and their material.

- Boiler power.

Based on these data, it is possible to calculate the required pipe length for the room and determine the installation step of the structure.

To insulate a loggia or balcony, it is necessary to lay a separate circuit that is not combined with adjacent rooms. If you do not install a separate circuit, then a large amount of heat will be spent on heating the loggia, while the room will be cold. It is necessary to insulate the loggia in the same way as the room located above the basement.

Foundation preparation

Before you start laying an electric underfloor heating, you need to prepare the right base for it. The easiest way is to pour a new screed, but if the old surface looks fairly even, you can do without it. If the height differences fixed by the level do not exceed 3 mm, all that remains is to repair all cracks and other noticeable defects. Installation of a warm floor requires mandatory waterproofing. A layer of material is placed over the entire surface with a slight approach to the wall (10-15 cm). A damper tape is attached around the perimeter, the task of which is to compensate for thermal expansion during the heating process.

On this, the laying of a warm floor with insulating materials does not end. So that the heated air is not wasted in vain, going down and delighting the basement or neighbors with this, a layer of insulation is required. The choice of material is determined by the characteristics of the room and the heating system. If the latter is an addition to the main one, then penofol can be used.We are talking about foamed polyethylene with a metallized surface.

When installing underfloor heating in an apartment building above the ground floor, a few sheets of extruded polystyrene foam should suffice. The thickness of the material will be 20-50 mm, depending on the other operating conditions of the system. For a loggia or balcony, a more powerful insulation will be required. It can be ten-centimeter polystyrene foam or mineral wool. If you are installing an electric underfloor heating with your own hands for these "outdoor" premises, take care of the proper insulation of the entire room. At a minimum, a good double-glazed window must be present for sure. Insulation is usually covered with reinforcing mesh, but often this is not necessary.

Finishing Infrared Floor Heating System

The main advantage of this type of panel heating is that the connection does not require a wet screed. Therefore, any finish coating is allowed. The exception is parquet and glued parquet board. So, you can take the floor with you if you have the opportunity and desire to move.

Decoration takes place only after a test run of the system and successful installation. Most often, do-it-yourself infrared warm floor is installed under the laminate. The high popularity of this solution is due to the fact that the coating is easy to install and just as easy to remove.

Installation under a tile is carried out in bathrooms, bathrooms, kitchens. Ceramics has a high heat transfer, which has a positive effect on the coefficient of performance (COP) of the device.