Regulatory documentation for identification painting of pipelines

Each industry has a number of regulatory documents that govern the issues of identification painting of pipelines, however, all these documents either refer to or repeat the requirements of the main standard for identifying pipelines in the Russian Federation - GOST 14202.

Such unification of the marking makes it possible to unambiguously determine the contents of the pipeline at any facility - from a small modular boiler house to a nuclear power plant and an oil refinery.

Exceptions to which the requirements of GOST 14202 do not apply are pipelines with medical gases, ship and aviation pipelines.

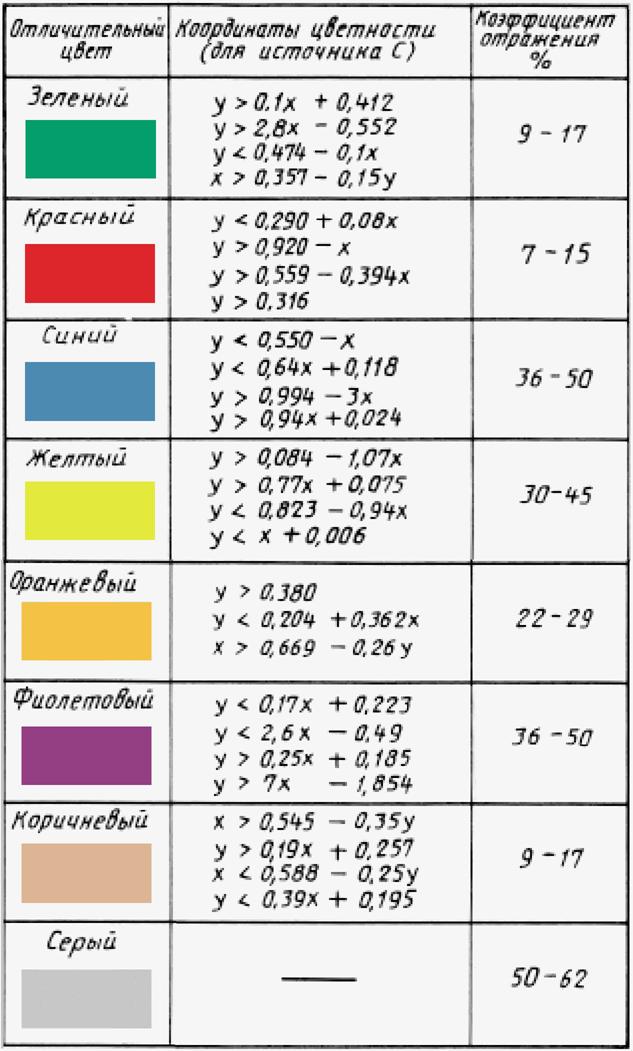

Color marking of pipelines in accordance with GOST 14202-69

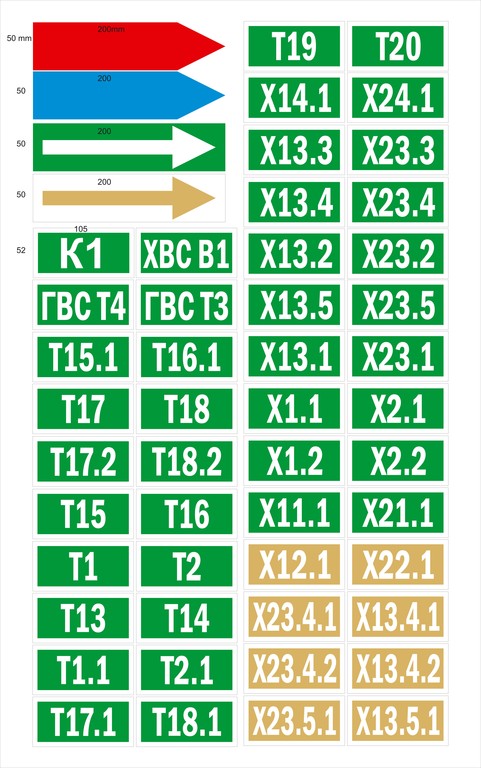

To identify pipelines by the type of medium transported through them, in accordance with GOST 14202-69, color marking of pipelines is used. Pipelines are painted as a whole, including fittings, fittings and fittings. The pressure taps and impulse lines leading to the instrumentation sensors are also colored.

For more accurate identification of the purpose of the pipeline, digital marking is additionally applied to it. Marking is applied to the so-called marking plates, which, in addition, may contain additional information about the direction of the medium flow, its temperature, pressure, etc.

| Numerical designation | Name of the transported substance |

| 1 | Water |

| 1.1 | drinking |

| 1.2 | technical |

| 1.3 | hot (water supply) |

| 1.4 | hot (heating) |

| 1.5 | nutritious |

| 1.6 | reserve |

| 1.7 | reserve |

| 1.8 | condensate |

| 1.9 | other types of water |

| 1.0 | waste, waste |

| 2 | Steam |

| 2.1 | low pressure (up to 2 kgf/cm2) |

| 2.2 | saturated |

| 2.3 | overheated |

| 2.4 | heating |

| 2.5 | wet (juice) |

| 2.6 | selective |

| 2.7 | reserve |

| 2.8 | vacuum |

| 2.9 | other types of steam |

| 2.0 | spent |

| 3 | Air |

| 3.1 | atmospheric |

| 3.2 | conditioned |

| 3.3 | circulation |

| 3.4 | hot |

| 3.5 | compressed |

| 3.6 | pneumatic transport |

| 3.7 | oxygen |

| 3.8 | vacuum |

| 3.9 | other types of air |

| 3.0 | spent |

| 4 | combustible gases |

| 4.1 | luminous |

| 4.2 | generator |

| 4.3 | acetylene |

| 4.4 | ammonia |

| 4.5 | hydrogen and gases containing it |

| 4.6 | hydrocarbons and their derivatives |

| 4.7 | carbon monoxide and gases containing it |

| 4.8 | reserve |

| 4.9 | other types of combustible gases |

| 4.0 | waste combustible gases |

| 5 | Non-flammable gases |

| 5.1 | nitrogen and gases containing it |

| 5.2 | reserve |

| 5.3 | chlorine and gases containing it |

| 5.4 | carbon dioxide and gases containing it |

| 5.5 | inert gases |

| 5.6 | sulfur dioxide and gases containing it |

| 5.7 | reserve |

| 5.8 | reserve |

| 5.9 | other types of non-flammable gases |

| 5.0 | waste non-combustible gases |

| 6 | acids |

| 6.1 | sulfuric |

| 6.2 | hydrochloric |

| 6.3 | nitric |

| 6.4 | reserve |

| 6.5 | inorganic acids and their solutions |

| 6.6 | organic acids and their solutions |

| 6.7 | acid salt solutions |

| 6.8 | reserve |

| 6.9 | other acid reaction liquids |

| 6.0 | waste acids and acidic effluents (at pH 8.5) |

| 8 | Flammable liquids |

| 8.1 | category A liquids (th.p28 °С |

| 8.3 | category B fluids (tv.p>120 °C) |

| 8.4 | lubricating oils |

| 8.5 | other organic flammable liquids |

| 8.6 | explosive liquids |

| 8.7 | reserve |

| 8.8 | reserve |

| 8.9 | other flammable liquids |

| 8.0 | combustible drains |

| 9 | Non-flammable liquids |

| 9.1 | liquid food products |

| 9.2 | aqueous solutions (neutral) |

| 9.3 | other solutions (neutral) |

| 9.4 | aqueous suspensions |

| 9.5 | other suspensions |

| 9.6 | emulsions |

| 9.7 | reserve |

| 9.8 | reserve |

| 9.9 | other non-flammable liquids |

| 9.0 | non-combustible drains (neutral) |

| Other substances | |

| 0.1 | powder materials |

| 0.2 | bulk materials granular |

| 0.3 | mixtures of solid materials with air |

| 0.4 | gels |

| 0.5 | water pulps |

| 0.6 | pulps of other liquids |

| 0.7 | reserve |

| 0.8 | reserve |

| 0.9 | reserve |

| 0.0 | waste hard materials |

The serial number of the pipeline can also be applied to the pipeline in accordance with the piping scheme. It is necessary to distinguish between the serial number of the pipeline and the identifier of the medium type.

You can find more information in the FAQ section.

View other articles including about marking.

Painting pipes from and to or how to paint pipes correctly

Painting pipes from and to or how to paint pipes correctly

Modern dwellings, among other things, consist of various engineering structures and communications, including: gas pipeline, sewerage, water and heat supply, telephone and Internet networks. Some of their components, such as pipes, may need to be protected from corrosion. For this, it is best to paint them. In addition to the practical purpose, the paint will give the pipes a nice appearance. The only condition for this operation is the ability to get to the pipes.

Perhaps, for residents of many houses and apartments, such a problem is not relevant. Currently, water pipes are designed from metal-plastic and polypropylene. Nevertheless, there are still quite a few iron pipes in operation, primarily located in dachas. It was from them that water pipes were installed for watering the crops in the plots. Irrigation pipes should be repainted every spring. How to do this is described below.

Preparation for painting iron pipes

Before you start painting water pipes, you need to determine what they are made of. Also for the choice of paint their temperature matters. In addition to paint and brushes, it will be impossible to do without sandpaper, gloves, rags, cuvettes and soil. If the pipes are covered with old paint, it must be removed. After their surface is cleaned of it, it will need to be sanded. Thus, rust is removed. After that, the surface of the pipes is degreased. Then all the garbage is removed, and fresh air is let into the room. Only after all this, coloring begins. To prevent the paint from dripping onto the floor, the brush must be held over some kind of vessel.

Where to start coloring?

A pipe to which there is free access is painted much easier than one that is difficult to approach. This applies to risers and radiators. Paint should start from the top and work your way down.

It is important not to leave unpainted areas on the surface. The second layer should be painted when the previous layer is dry.

Plastic pipes are prepared for painting differently. After washing with warm water, they are allowed to dry. Oil or water-based paints are best suited for them. What color of the wall, this should be the pipe.

How to paint black pipes?

Communication pipes made of ferrous metals - steel and cast iron - are most susceptible to corrosion. In order to protect them from possible destruction and extend their service life, they should be painted. And before that, conduct a thorough preparation: wipe off the dust and clean the rust.

It is important that the paint lays on a dry surface. Cast iron and steel pipes are best painted with enamel, which includes a rust converter, a primer with anti-corrosion functions and the enamel itself, which has high wear protection

It is necessary to paint over the surface of the pipe well, using two layers.

How to paint a sewer pipe?

Recently, plastics have been used in the manufacture of sewer networks. And this material does not need the protective functions of the paint. So you can only paint the metal line to give the protruding pipe a decent look.

As you know, paints exist for any surface, and even for plastics. To purchase the desired paint and varnish product, you need to find out what the pipe is made of (it should be written on it), and what kind of paint, according to the specialist, is recommended for it. Be safe by reading the label on the paint can.

If the pipe is metal, but still not so simple. Rather, it will be easy to paint it, but it is problematic to prepare for painting. This is due to the fact that part of the sewer networks is within sight, and part is securely hidden. In this case, a building hair dryer can help. With it, the cleaned surfaces that are in the public domain will be dried. The paint should be chosen so that it can withstand high temperature and humidity (relevant for bathrooms).

How to calculate pipe color?

It is quite difficult to immediately figure out how much paint you need to buy for pipes. After all, its consumption is calculated in square meters on a flat surface. The following knowledge can help in calculating the amount of paint:

- A lot of paint is wasted when you have to paint in hard-to-reach places. Because small strokes obviously consume more paint. The first layer takes more paint than subsequent ones. A smooth surface absorbs paint less than an uneven one.

- You also need to remember that a hot pipe dries faster than a cold one. The same thing happens when painting it with spray paint.

You can get all the information by phone

Paint for heating pipes

In this section, we will tell you what a good galvanizing paint should be, which not only gives an attractive appearance and fits into the interior of the room, but also protects it from corrosion and rust.

In order for the pipeline in which hot and cold water passes to have a positive end result, the paint must be:

- With high temperature resistance more than 110 degrees;

- Stable, not washed off;

- Non toxic;

- Resistant to aggressive environment.

Manufacturers offer a range of manufactured products that amazes with the quantity when choosing:

- Acrylic enamel. They are produced using an organic solvent as a basis, therefore, painting galvanized metal with such a paint does not have a specific smell after drying. As for the final result, everyone is satisfied - the presence of a glossy sheen and a service life of up to 10 years.

- Alkyd enamel. Such products in work are accompanied by an unpleasant odor, which, after drying and turning on the heating, is felt very strongly. But such painting of pipes is not erased and withstands high temperatures. The manufacturer offers a wide range of colors to suit every consumer.

- Water-dispersion. This paint is suitable for painting galvanized iron. The products are widespread and are in great demand, because while working, unpleasant odors are not felt, and the products dry out instantly.

If you decide to paint the heating pipes, we do not recommend that you paint with an oil base. Such products at high temperatures will immediately change color, become dull, and besides, they do not last long on the plumbing system.

Manufacturers of paints for galvanized profile pipes

Paint for galvanized pipes is presented in stores from different manufacturers - domestic and foreign, which offer a huge number of types and colors. As for the pricing policy, it depends on the number of liters in the bank, the manufacturer and quality. Among the assortment of goods, preference is given to German paints, Dutch, Swiss and others.

Dutch paints are durable, after drying you will see a glossy surface with a smooth texture and be satisfied with the result. German products are of high quality, resistant and do not change color at high temperatures. If we talk about Swiss, then this paint is used as a primer, and when painting. It is worth noting the ratio of not high price and excellent quality.

Pipe coloring online calculator

Online calculator for calculating the color of the surface of the pipeline by the outer diameter - we will independently calculate how much paint is needed to completely cover the line of pipes with a round, rectangular or square section.

With our calculator you can make an online calculation of the surface area of the pipe for painting based on the volume of paint, determine the estimated amount of paint for the area to be painted, calculate the total area of all sections and the estimated amount of paint for the entire pipeline section.

Pipe Color Calculator

Any pipelines need some protection - this is an axiom. One of the ways to perform such a technological operation is to paint the surface - both external and internal.As for the main and other external networks, this is done to protect the outer surface of metal products from corrosion, since corrosion-resistant materials are not used for them due to their high cost.

Concerning the inner surface of steel products, the protective coating is applied on them not only as a corrosion protection, but also to give an improved surface quality to reduce flow resistance. Various varnishes or cement-sand mixtures are used for coating. A pipeline color calculator is needed to accurately determine the amount of paintwork or other protective coating.

Of course, such an operation is not cheap. But today it is time to replace metal products with plastic products that do not need to be protected. They are used even for high pressure pipelines.

How to calculate coverage requirement online

However, the application of protection is still relevant, especially for the protection of internal water supply networks.

All manufacturers of paint and varnish products regulate the consumption rate of their materials relative to a square meter of surface. These data are the basis for calculating the need for paint per linear meter of the product. With them, it is easy to calculate the total need to cover the entire pipeline. Any round pipe when unfolded is a rectangle. For our case, its length is one meter, and the width is determined by the circumference of the outer diameter. The calculation formula for this case is simple and clear:

S = ПD*L, where

S is the surface area of the pipe section,

D - outer diameter of the product

L is the length of the sweep; according to the conditions of the problem, it is equal to one meter.

It remains to use the rate of paint consumption per square meter of pipe in order to obtain standard data on consumption per linear meter.

For example: for a standard product with a cross section of 42x2.5 mm, the area of the nozzle will be:

0.42 * 0.42 * 3.14 * 1 = 0.55 (square meters).

With a consumption of, for example, 0.15 kilograms, to paint such a segment, you will need paint in the amount of: 0.55 * 0.15 \u003d 0.083 (kg). Obviously, the calculation of the color of pipelines with a school-style calculator is quite within the power of even a person with a secondary education. And if you have even small computer user skills, you can use the Excel program and create a table for any pipe size by entering a single formula. It remains to select the paint and enter the standard indicator for the consumption rate in the required field.

The Internet is full of various construction calculators, you can use them without downloading, online, choosing in advance the paint to paint the pipeline. The online tube color calculator will give you the desired result without a hitch. It remains to purchase paint in the right amount and work without a doubt.

When purchasing a coating for metal, one must also take into account that as a result of long-term storage, it can thicken, which will cause an increase in its specific consumption. In addition, the application of paint with a brush and a spray gun also affects the amount of consumption. Therefore, when purchasing a coating, it is advisable to purchase it in quantity 10-12% more than the calculated quantity.

If galvanized products are used for plumbing, a protective coating is still necessary. Installation of steel pipe-rolling materials cannot be performed without the use of welding, in place of which the protective layer of zinc burns out. To avoid corrosion at the site of the weld, you need to paint it with a special paint. It consists of 95% zinc powder, the rest is binders. Such a coating reliably and permanently protects the welding site. I wish you success!

GOST 14202-69

- Information

- GOST text

- Download GOST

Categories GOST 14202-69 for OKS:

- 23. Hydraulics and pneumatics

- 23.40.

Pipelines and their components

Document status: current Purpose GOST 14202-69: This standard applies to identification coloring, warning signs and marking plates of pipelines (including fittings, fittings, fittings and insulation) at designed, newly built, reconstructed and existing industrial enterprises inside buildings, at outdoor installations and communications located on overpasses and in underground channels in order to quickly determine the contents of pipelines and facilitate the management of production processes, as well as ensuring labor safety. The standard does not apply to the identification coloring of pipelines and ducts with electrical wiring. Amendments and changes to GOST 14202-69 the standard has no amendments

Versions of GOST 14202-69 available for download:

Date added in file version: Downloads: Size: Download link: 12/12/2011 02:57 5979 0.62 Mb download GOST 14202-69 ')8. /var/www/gosexpert2/data/www/gosexpert2.ru/engine/system/filters/filterChain.

php:55, In: contentFilter->run(object 'filterChain')7. /var/www/gostexpert2/data/www/gostexpert2.ru/engine/system/filters/authFilter.php:44, In: filterChain->next()6. /var/www/gosexpert2/data/www/gosexpert2.ru/engine/system/filters/filterChain.

php:55, In: authFilter->run(object 'filterChain')5. /var/www/gosexpert2/data/www/gosexpert2.ru/engine/system/filters/configFilter.php:23, In: filterChain->next()4. /var/www/gosexpert2/data/www/gosexpert2.ru/engine/system/filters/filterChain.

php:55, In: configFilter->run(object 'filterChain')3. /var/www/gostexpert2/data/www/gostexpert2.ru/engine/system/filters/filterChain.php:64, In: filterChain->next()2. /var/www/gosexpert2/data/www/gosexpert2.ru/engine/system/core/Core.

Important

php:38, In: filterChain->process()1. /var/www/gosexpert2/data/www/gosexpert2.ru/index.php:25, In: Core->run()

SAPI: apache2handler, Software: Apache/2.2.22 (Debian), PHP: 5.4.4-14+deb7u8 on Linux,

Categories GOST 14202-69 for OKS:

- 23. Hydraulics and pneumatics

- 23.40. Pipelines and their components

Causes of chimney wear

There are a large number of reasons leading to the wear of the chimney.

For instance:

- corrosion arising from the impact on the masonry and other materials of the chimney of combustion products, flue gases;

- wind, humidity, precipitation, excessive heat;

- design flaws, the construction of the pipe itself;

- unskilled intervention in the chimney system;

- when using the structure for other purposes, for example, when connecting artificial ventilation, the risk of destruction of the chimney increases;

- switching from one type of fuel to another;

- technologies, including "wet cleaning", aimed at protecting nature;

- strong air blowing from the boiler.

Metal chimney painting technology

Pipe painting is not an easy process. The specialist of our company should first of all come and evaluate the scope of work. The fact is that very often it turns out that the chimney requires minor repairs. If you start painting without fixing the problems, then the work will be done in vain. When it comes to metal chimneys, they are usually made of steel, which is resistant to corrosion, so preparatory work does not take much time.

First, the pipe must be cleaned of dirt. Over time, a thick layer of dust, sand, and other contaminants settles on the outside of the pipe. From the inside, the chimney is also recommended to be regularly cleaned of soot and soot, which can clog it. Our specialists can do this both manually and with the help of mechanized equipment.

Secondly, before painting a metal chimney, it is imperative to remove the previous layer of paint. Exfoliated pieces are cleaned with scrapers, spatulas, brushes, and often you can limit yourself to only these tools, since usually up to 30 percent of the surface is cleaned. Manually, individual sections of the pipe can be put in order, however, in some cases, complete removal of the old coating is required. In this case, the specialist will select the appropriate technology that allows you to dissolve the paintwork material on the entire surface of the pipe.

Do not forget that the quality of staining directly depends on how well the previous layer is removed. Otherwise, soon you will again have to resort to the services of industrial climbers again.

Thirdly, the painting itself is done. It is produced in two ways: with the use of a primer and without.In the first case, a primer is applied to the pipe, and then one layer of special paint. In the second case, the paint is applied in two layers. When applying coatings, a pneumatic sprayer is used, which allows you to accurately, evenly and without smudges apply the optimal layer of paint.

Separately, we should talk about the paintwork materials that our specialists use when painting metal chimneys. The paint must be heat and frost resistant. In particular, organosilicon enamel has proved to be excellent - it is a strong and durable coating that protects the metal from damage, exposure to ultraviolet radiation and dirt.

The specialists of our company will select paintwork materials suitable for your case. We use high-quality, certified materials, because this is a guarantee of excellent work!

Need to paint a metal chimney?

Painting metal chimneys is our job. Professional climbers will perform painting with high quality and on time. If you need to paint a metal chimney, call us and our specialist will answer all your questions, and an expert on site will make an estimate based on your wishes!

Best Answers

Stas Shabanov:

what's in the ground-bituminous mastic, above the ground-primer, Kuzbass varnish

Basilisk the Beautiful:

There is galvanization.

svetlana throat:

there is paint for metal, it painted window pipes very well and does not peel off metal and wood

Nastya Sereda:

Or "Spetsnaz" enamel on rust. That's what it's called, and there are three commandos on the package.

Lion Heart:

Paint only by TIKKURILLA and spray with BODI car varnish on top

Sergei Prokhorov:

Alkyd enamel

Josef Schweik:

The main thing is not how to paint, but how to paint. Pipes (if they are new) must first be degreased (with a rag moistened with paint thinner) and primed. After the primer has completely dried, the pipes can be painted (preferably in two layers) with an exterior paint intended for painting metal surfaces. Apply the second coat of paint only after the first has completely dried. If you just paint the pipes (without degreasing and priming) with even the most expensive paint, then such a coating will not last long.

Truculentus:

Primer GF-021 and enamel PF-115.

Victor Bemsky:

In stores you will find paint for ships. There is no deficiency in it. Or something from the Finnish range of Tikkurila. Their paint, depending on what it is for, really works. You can also pick it up with an accent to keep the color on the street or indoors, 12 years guaranteed.

TYULEPASHA:

Colored primer.

Types of paint for heating pipes

When deciding what paint to paint heating pipes with, you should pay attention to the following types of such compositions, which today are most popular among consumers:

- acrylic enamels. The basis of such paint is organic type solvents, which explains the not very pleasant smell during its drying. However, such a sample will provide a perfectly smooth and glossy surface and will last a very long time;

- alkyd type enamels. These compounds also emit an unpleasant odor, which can periodically appear in the future with an actively operating heating system. However, such paint will be very resistant to any mechanical damage and will not change its structure under the influence of high temperature. Do not forget that on the modern market there is a wide choice of shades of such enamel, so it will not be difficult to choose the option suitable for a particular interior, it will be enough just to study the photos of the samples provided by the manufacturer;

- water-based paints. Painting heating pipes with this composition is the most common option among consumers.This composition does not exude an unpleasant odor, in addition, such paint for hot heating pipes dries very quickly.

It is also impossible not to mention such an option as oil paint, which, however, is rarely used today for painting pipes.