Polyfoam and expanded clay

Styrofoam in its appearance resembles a foamed plastic material having a cellular structure. Usually it is produced in the size of a meter by a meter and is used not only as an internal, but also an external insulation. Its thickness can vary from twenty to one hundred centimeters.

It depends on the type of finish needed. Can be used as a base for ceiling putty. Another of its features is the ability to use it to level surfaces.

Styrofoam is not only convenient to use, it also has a number of advantages, such as:

- It has established itself as a universal remedy. Rather low cost. Based on this factor, this makes it more accessible to the population. Durable in use. Provides a very high level of reliability of the protection of the premises. It has good thermal insulation.

The main component of expanded clay is clay, from which it is subsequently made. It looks like balls, it is easy for them to insulate the room. The principle of working with it is to backfill in the attic, so it is relevant only in private homes.

When insulating the roof of a house with expanded clay, you can use such useful instructions to help you install it correctly. These tips include specific actions such as:

- The work process should begin directly with the laying of waterproofing. The choice of means for it is quite large, and all of them are ideal for the implementation of this process. It is necessary to prematurely overlay the rafters and the chimney. For a better vapor barrier effect, lay a layer of clay on it. Expanded clay is laid out in layers of at least 15 cm. Thus, thermal insulation is significantly increased .

Expanded clay has a number of advantages, such as:

- It is one of the materials that does not decompose over time. Various insects and small rodents can start in others. Expanded clay completely eliminates this possibility. It is considered fire-resistant and fireproof. It has good sound insulation. Water-resistant. It has frost resistance, which is very important in winter. . It can also be used for foundations and walls.

Ceiling plate insulation how to fix the insulation on the ceiling

How to insulate the ceiling in a private house

The issue of warming a typical apartment is quite relevant, and everyone solves it in their own way. Some change the glazing, others prefer the insulation of walls or floors. But experts are sure that an integrated approach is important in this matter, in which the main thing is not to forget about the insulation of the ceiling from the inside of the apartment. It is easy to do this even with your own hands. There is a simple instruction that tells you how to carry out such work.

Why is ceiling insulation necessary?

Not everyone understands why it is necessary to insulate the ceiling, for example, in an apartment building. In fact, it is through it that a significant part of the heat generated by the batteries escapes. And this is due to the laws of physics.

Warm air, heating up, rushes up and seeps through existing microcracks. The ceiling plate can give off heat only when it warms up well, but it is unlikely that it will be possible to do this with the help of central heating.

Step-by-step instruction

The insulation of the ceiling from the inside occurs in exactly the same way as the insulation of the walls. First you need to fix the insulation. Then build a frame from a metal profile and install it in the same way as for a plasterboard false ceiling.

In advance, you need to think about how to fix the insulation on the ceiling - with what help to keep the mineral wool.It is her experts who recommend choosing as a heat insulator. Synthetics such as foam will not help in this case, because it is a vapor-tight material that can make it impossible for the room to “breathe”.

Note! As a result of the wrong choice of insulation, the level of humidity increases significantly, which can provoke the appearance of mold. Then even forced ventilation will not save

There are two ways to fix mineral wool on the ceiling:

Insulation of the ceiling from the inside

- Glue it to the ceiling and press it with a hanging frame. As an adhesive, you can use ordinary putty, which is applied to the ceiling with a thin layer. The heater is simply pressed against it. If cotton wool is sold in rolls, you won’t have to keep it for a long time. This method of fastening is applicable only if the height of the suspended structure does not exceed 10 centimeters. If you sew it with drywall, it will be strong and reliable.

- But what if a stretch ceiling is chosen as a finish? Here it is necessary to act somewhat differently. The insulation will have to be glued and supported by a frame, as described above. But then a special vapor barrier film must be stretched over the frame. It will prevent the insulation from falling off, which will begin to crumble over time. The most important thing is not to confuse which side and where to attach such a film.

Warming and spot lighting

Many do not know how to insulate the ceiling slab from the inside without giving up spotlights. The fact is that by filling the formed niche in the suspended structure with insulation, we deprive it of the ability to be well ventilated. This means that any lamp, working, will produce heat, which will have nowhere to go. As a result, the light sources will overheat and fail.

Warming and spot lighting

And this is not the only trouble. Nearby wires will melt from high temperatures. It is not difficult to predict the consequences - this is a short circuit and a fire.

How to solve this problem? Removing part of the insulation around the lamp is not an option. Experts suggest completely abandoning spot lighting in such a situation, preferring a central chandelier and wall sconces.

If you want to please yourself with the described light project, then you can use multi-level ceilings for this. This compromise will keep you safe.

The first level in such structures will protect the layer of mineral wool, and the second will make it possible to install spotlights. It is possible to use multi-level suspended structures only in rooms with sufficient height.

In conclusion

Insulating the ceiling from the inside is not so difficult

It is only important to take into account the features of the technology and comply with all safety rules. In this case, the process can be performed independently

To do this, it is necessary to strengthen the mineral insulation on the ceiling with putty. Then mount the frame from the guide profiles, and then sheathe it with plasterboard plates or stretch the stretch ceiling film, having previously fixed the vapor barrier layer.

Stages of external thermal insulation

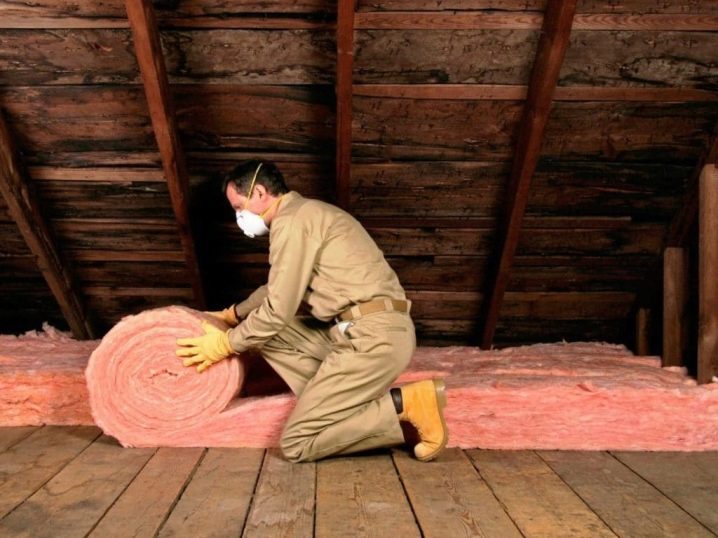

For external insulation, the presence of an attic non-residential premises is mandatory. The process of laying mineral wool is simpler than during interior work, and takes less time, because the mineral wool is fixed not to the ceiling, but to the floor.

We observe the following procedure:

We cover the entire area of the attic floor with a layer of glassine, laying the sheets overlapping (10-15 cm is enough). We glue the joints or strengthen with adhesive tape.

The effectiveness of the vapor barrier layer will increase several times if it is reinforced with sheets of 5 cm polystyrene foam. We make sure that there are no gaps between the plates. If the rolls are covered with foil on one side, the insulation process ends there.

Sheets must be positioned so that the foil is on top. We fix the material with rails, it is not recommended to directly pierce the thermal insulation with nails. On top of a simple mineral wool (without foil), we stretch a dense film (you can use a greenhouse), fix it with rails. We glue all joints and joints with double-sided or ordinary tape.

External insulation with mineral wool - laying slabs on the attic floor

The floor is laid on top of any available material: chipboard, plywood, boards. Sometimes the roof also requires additional insulation. Thermal insulation is carried out according to the same principle as the option for apartments, but with one caveat - instead of a powerful frame, a fairly light crate of their counter-rails.

Types and materials

Various shops and building materials markets offer a large selection of insulation. Against this background, several varieties stand out.

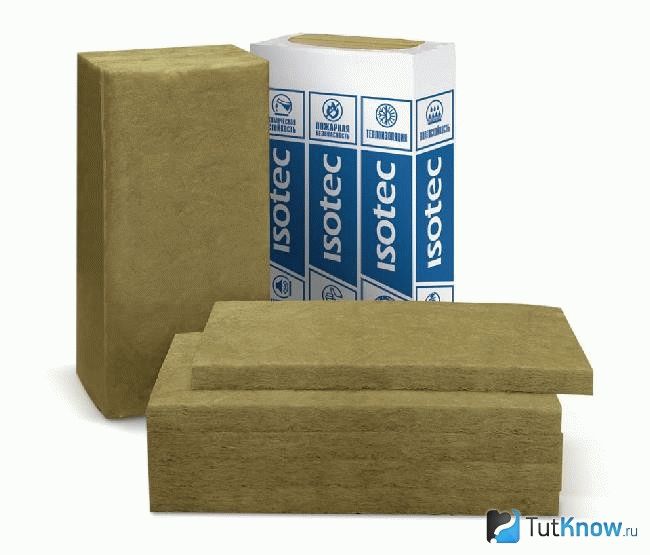

Mineral wool

Mineral wool is a common textile fiber obtained by various methods. Fiber made from volcanic materials is called stony. Slag wool is created on the basis of blast-furnace slag. Glass wool is a raw material created on the basis of glass melt. As for the thickness of the insulation, the indicator ranges from 2 to 20 cm.

Polyethylene foam

Polyethylene foam in the form of a foil-based roll is a new generation of insulation. The thickness of such material is from 3 to 20 mm. Polyethylene foam is the most effective material used for ceiling insulation. The small thickness makes it easy to install it in a private house and apartment.

Styrofoam

Styrofoam is a material made from plastic mass in the form of cells. It is produced in the form of squares measuring 1 x 1 m. The thickness of the sheet is from 2 to 10 cm. The density of the material varies between 15-25 kg / m2 (foam 25 kg / m2 is often used to insulate the ceiling). Styrofoam is often used to insulate suspended frames, walls and other coverings of a private house. It has good reviews.

Styrofoam

Extruded polystyrene foam is formed by the production of special polymers: the finished insulation is created by extruding the material through a special mold measuring 120 × 60 cm. The thickness of the finished sheet ranges from 10 to 200 mm. For insulation of ceiling structures, a material with a density of 25-45 kg / cm2 is more often used. In simple terms, this is foam plastic made using a different technology. Its main difference is the higher strength of the material.

You can insulate the ceiling with loose expanded clay. This material is often used for insulation of attic floors. In addition to the basic materials, insulation can be carried out with isolon, penofol, penoplex

It is important to fix the insulation material correctly. Materials suitable for insulation on the top floor, veranda, basement, attic

Brief overview of manufacturers

Now it is easy to purchase products for any construction purpose, and mineral wool on the ceiling is no exception. Most likely, in the supermarket you will be offered several options that differ little from each other.

Brands known for the excellent quality of the goods and being leaders in the market of thermal insulation products:

- Knauf (Knauf - an international company); Isover (Isover - international group of companies "Saint-Gobain"); Technonikol (Russian corporation); Ursa (Ursa - a subsidiary of the Spanish group Uralita); Rockwool (an international group of companies with a center in Denmark).

Stone wool, produced on the basis of basalt rocks, and glass wool, which is produced after processing quartz sand and glass production waste, are also suitable for ceiling insulation.

Scheme of one of the options for warming the attic floor

How to fix insulation to the ceiling

Ceiling insulation is a topical moment in repair for many. Insulated ceiling will not only save you from the cold in a house or apartment.But, it will also save on heating, since with proper insulation, heat loss in the premises will be significantly reduced. However, not everyone knows how to properly fix the insulation to the ceiling, and a violation of the technology will reduce the efficiency of insulation work.

The choice of insulation

There are several popular materials that can be used to insulate floors. Depending on the method of work, one or another type can be used, but, as a rule, you have to choose from the following materials:

- Mineral wool. To date, this is the most popular type of all such materials. It is fireproof, has excellent heat saving characteristics and improves the sound insulation of rooms. When deformed, it may lose its properties, therefore, it fits tightly, but without pressure. It can accumulate water in itself, which leads to loss of properties.

- Basalt slab. One of the varieties of porous insulation, but with increased resistance to fire and moisture protection. In addition, basalt slabs are less prone to deformation.

- Styrofoam. A well-known material with good thermal insulation properties. It can be combustible, and also does not tolerate ultraviolet light, from which it can be destroyed. It is very cheap and therefore very popular. Easy to mount with glue.

- Liquid heaters in the form of a solution. A modern type of insulation with unique characteristics. Thermal insulation is achieved by a huge number of small ceramic balls placed in a liquid binder substance. It is applied like paint, after which it dries and forms a non-combustible moisture-resistant film.

It makes no sense to consider the last two options for thermal insulation in detail - liquid solutions are simply applied with a roller, like paint, and the foam is simply glued to a special glue. Therefore, we will further consider how to attach such insulation to a wooden or concrete ceiling as mineral wool or a basalt slab.

concrete base

When working with concrete floors, you will need not only a heater and a minimum amount of tools, but also skills in working with a perforator, as well as the perforator itself. With porous heaters, work is carried out in the following order:

- The floor is processed with a primer and the wiring for the fixtures is laid.

- A certain number of holes are drilled in the ceiling, arranged in such a way that the dowels inserted into them can hold the insulation.

A frame is assembled along the pre-applied marking lines, on which the outer coating will be held after finishing. He will also create a small niche in which cotton wool is laid.

Cotton wool or basalt slabs are laid. It is necessary to fasten both types of material with the help of special plastic dowels, for which holes have already been drilled in the floor slab. If necessary, we additionally fix the insulation with a strong cord.

The entire plane is covered with a special vapor barrier film, which will protect the material from moisture.

The ceiling is being finished.

wooden ceilings

It is easier to work with wood than with concrete, and therefore, a hammer drill is not needed here. If the overlap is made along the logs, then the space between them is simply filled with mineral wool, basalt slabs or foam. The latter can be fixed with mounting foam, which is necessary to seal all joints and seams. If the ceiling is a flat surface, then you have to do the following:

- The frame is assembled first. It can be assembled from wooden bars or a metal profile. Boring between the frame parts should be selected in such a way that the sheet of insulating material fits tightly into the resulting niche, but without deformation.

- The entire space is filled with the selected type of heat insulator and covered with a vapor barrier film.

- The final surface of the new ceiling is being finalized.

Bottom insulation

This view implies the process itself from the bottom of the ceiling itself. Materials made in rolls or beams are ideal for it.

This method is considered more difficult and labor-intensive. The process itself includes the following stages of work:

- It is necessary to make fastening with the help of filing. If it was not possible to implement it, you can build up the beams, on which the installation will be carried out in the future. If it is done using foam, then the process itself is greatly simplified. It can be simply glued to the ceiling. But after that, to increase reliability, it should be additionally fixed with dowels designed for these types of work. After the installation process, the ceiling itself, if its condition requires it, can be decorated by painting or using putty.

It is possible to carry out fastening, thus, with your own hands. The main criterion is the presence of either a suspended frame or specially made mounts.

With a low ceiling height, it is better to opt for foil-wrapped polyethylene foam. The profiles on which they will subsequently be attached can be made of metal or wood. After the implementation of insulation, at will, the ceiling can be decorated in various ways, the main of which are painting or installing a stretch ceiling.

To date, there is a huge selection of insulation materials that can keep not only heat in your home, but also provide good sound insulation, which is quite important in multi-storey panel or brick houses.

- Date: 05-02-2015Views: 160Comments: Rating: 15

Warmth and comfort in the house are one of the first tasks that must be solved for a comfortable life and maintaining health. In the modern world, where the daily rise in the price of energy resources is by no means new, the issue of warming a dwelling is acute.

Scheme of insulation and soundproofing of a wooden ceiling.

To ensure the safety of heat from below, they use "warm floors", in order to avoid leaving it through walls and windows - plastic structures.

But it is extremely important to pay attention to heat loss through the ceiling. This is due to the fact that more than 30% of all heat is concentrated at the top of the room. If proper thermal insulation is not observed, this will inevitably lead to settling condensate, an increase in the amount of moisture and, as a result, the formation of mold.

If adequate thermal insulation is not observed, this will inevitably lead to condensate settling, an increase in the amount of moisture and, as a result, the formation of mold.

How to avoid this, you ask? Is it possible to insulate the ceiling with your own hands?

Of course. In addition, it is quite simple to do, while not spending a large amount of effort and material investments. It is only necessary to properly disassemble the question, how to fix the insulation to the ceiling?

Before disassembling the issue of fixing the insulation to the ceiling, you should pay attention to such an important aspect as the types of insulation. What is the material with which you will insulate your ceiling? After all, only having decided on this issue, you can purchase it and fix it

Best Answers

Solntseva star:

Shoot the crate according to the size of the insulation plates to the plate with dowels, lay the required thickness of the insulation layer and sew up with plasterboard or stretch ceiling

Vitalik Panov:

foam is lighter and better

Alexander L.:

fastened with special fasteners, commonly called "fungi"

Airat Sattarov:

I sewed a rail with a thickness under the thickness of mineral wool (50 mm) at distances 2 cm less than the width of the plate. Rockwell entered tightly and held on due to this, while I pinned him with fungi (4 per sheet) - I drilled the slab right through the insulation. Next to the rail - plastic panels (I'm talking about my loggia)

Victor Victor:

“How to fix the insulation on the ceiling in the apartment? "- It will be correct from the side of the roof, otherwise the dew point will move into the insulation and in winter it will get wet. To protect against heat, I would make a false ceiling made of drywall, for example, along profiles, without insulation.

Polyethylene foam and polyplex

In addition to mineral wool, insulation can be fixed to the ceiling using other materials, such as:

Foil polyethylene foam. In appearance, it is polyethylene foamed in a special way and subsequently glued to aluminum foil. You can meet a similar look in rolls. Their width is standard and reaches one meter, and the thickness can vary from one to twenty centimeters.

It can be used alone or in combination with mineral wool to improve the thermal barrier. Also, this combination makes it possible to protect against various carcinogens that may appear due to the use of cotton wool.

Polyplex is the result of the extrusion of expanded polystyrene. It can be purchased in the form of sheets measuring 60 * 120 centimeters. The thickness can be different: from one to twenty centimeters. Among the advantages, an increased density can be distinguished, due to which it has found its application not only in the form of a heater, but also as a rough base for puttying.

From the above, we can conclude that both varieties have their advantages and their installation can be done independently. Polyethylene foam is fastened by gluing it with special glue or using dowels, widely used in construction. The polyplex is attached with dowels or holders that look like the letter P.

Bottom insulation

This view implies the process itself from the bottom of the ceiling itself. Materials made in rolls or beams are ideal for it.

This method is considered more difficult and labor-intensive. The process itself includes the following stages of work:

- It is necessary to make fastening with a binder.

- If it was not possible to implement it, it is possible to increase the beams, on which the installation will be carried out in the future.

- If it is made using foam, then the process itself is greatly simplified. It can be simply glued to the ceiling. But after that, to increase reliability, it should be additionally fixed with dowels designed for these types of work.

- After the installation process, the ceiling itself, if its condition requires it, can be decorated by painting or using putty.

It is possible to carry out fastening, thus, with your own hands. The main criterion is the presence of either a suspended frame or specially made mounts.

With a low ceiling height, it is better to opt for foil-wrapped polyethylene foam. The profiles on which they will subsequently be attached can be made of metal or wood. After the implementation of insulation, if desired, the ceiling can be decorated in various ways, the main of which are painting or installing a stretch ceiling.

To date, there is a huge selection of insulation materials that can keep not only heat in your home, but also provide good sound insulation, which is quite important in multi-storey panel or brick houses.

In winter, the heat loss of the ceiling structure is about 15%. Since the house is warm and it is cold outside, condensation forms in the room, creating a favorable atmosphere for the growth of bacteria and fungus. Therefore, it is necessary to think about the effective insulation of the ceiling in the interior of the house.

What materials are suitable

In private houses, when insulating ceilings, various components are used that retain heat inside. These include both well-established and familiar to all, and completely new technologies. The following are most commonly used:

- sawdust;

- polystyrene (polystyrene);

- expanded clay;

- ecowool;

- mineral wool.

Of course, sawdust as a material has long been outdated, but is still used and often. The only and main advantage is the price. But their use is potentially dangerous and threatens to cause a fire. In addition, sawdust shrinks and requires systematically pouring them.

Styrofoam or polystyrene has the lowest heat transfer. In addition, insects and microorganisms are not bred in it. The cost is acceptable. If the choice fell in favor of this particular remedy, then it is necessary to ensure good ventilation and systematically carry out full ventilation, since it does not allow oxygen to pass through. However, according to the requirements of fire hazard, it does not pass.

But expanded clay is more suitable for insulation from the outside. Lightweight and porous building material made of clay resistant to high temperatures. Mice and rats will never get in it. It has a good level of sound and heat insulation, is not affected by water. It is distinguished by sufficient weight, as a result of which a screed is often made on top of it.

Another relatively new product is ecowool, created on the basis of cellulose, it contains antibacterial substances. It has good elasticity, steam conductivity and elasticity. In the event of a fire, it begins to smolder, that is, it is fireproof.

Mineral wool is an environmentally friendly product. It is widely used for thermal insulation, as it retains heat and excess noise well, and also helps to remove steam. Vatu can be divided into several subspecies:

- Stone;

- Lacquer;

- glass wool;

- Kemamic.

This material must not be tamped under any circumstances. When you lay the insulation, you need to control it to prevent the formation of cracks. Before work, be sure to wear safety glasses, a respirator, gloves and clothing, preferably made of very dense fabric.

Expert answers

Sergei:

In general, heaters are laid from the cold side. If you do not have such an opportunity, then increase the thickness of the insulation and install a vapor barrier from the bottom of the insulation with gluing the seams (universal type - isospan D), and only then finish the ceiling. No moisture or steam should get into the insulation layer.

Stas Shabanov:

I would like to look at the installation diagram of the insulation, it is not advisable to fix it from the inside. Sometimes even a vapor barrier is a problem. Or ventilate or redo more often.

Mikhail Godunov:

100% styrofoam insulated?

Andrey:

There must be waterproofing on the ceiling under the insulation. Insulates from internal moisture. There should be nothing on the heater to ventilate.

Alexei:

on the beam - moisture insulation (their sea), then - plates of dense foam (it is called and looks differently, but you need one that has grooves for joining and is not cut with a knife, up to 4-5 cm thick, plaster mesh on it (better galvanized), align with sand concrete (m300) and tile adhesive - tiles - that's it! (mesh and slabs can be fixed with facade dowels directly into the timber (those with a large plastic cap and in the middle of the plastic body metal nail - there will be no heat transfer through them. everything I made your repair in 3 minutes (wrote), you should also do it faster! )))

Dim-Dim:

if you poop in winter, then if summer is not

Valentina M.:

It is necessary to insulate from the outside so that the so-called. bridge of cold in the walls. Look at what heaters are sold in your area, what is their coefficient of thermal conductivity and resistance to moisture, then calculate the consumption and price of the issue. Don't try to save at any cost, heating the atmosphere and changing rotten logs will cost more. If possible, and you live in cold regions, insulate inside as well.

INTERCEPTOR:

What is the thickness of the beam? If 150x150, then a ventilated facade can be made from the outside - that is, there must be a gap between the beam and the finishing material of the facade so that the beam is ventilated. Nail parchment paper to the beam.Inside is a slab insulation, URSA or ROCKVOL, whatever you want, but always with a pressed plate. Then you can shoot a polyethylene film and on top of it a finishing material - PVC-MDF panels, etc.

Lukin Sergey:

It is better to insulate the outside, there are a lot of materials and siding and aquapanels, and a heater between the siding or aquapanel. from the inside you can use gypsum fiber (you can glue tiles on it; it is moisture resistant.

User deleted:

The ceiling can be insulated with glass wool, and attic insulation made from dried seaweed is also very fashionable now, it is environmentally friendly, does not rot. Styrofoam is extremely efficient, durable, but there are environmental problems. Read more hereYou can also read articles How to keep warm in the house? How to insulate the floor?

Eugene Bebikh:

It is necessary to insulate effectively both walls and floors. Outside is by definition.

Zhenya Barannik:

can be insulated both from the outside and inside, the foam material is of different thicknesses. then plastered and sheathed with plastic from the inside. from the outside, too, foam and then plaster for facades (bark beetle). It will be warm and cute.

Proper ceiling insulation to avoid common mistakes.

- The first and important point is the choice of heat-insulating materials - heaters, when preference should be given to those that are suitable for the temperature difference in your region and the level of humidity, i.e. to climatic conditions.

- The second point is to find out the ability of the heat-insulating material to absorb and give off heat, i.e. how quickly a concrete ceiling insulated with this material can cool or heat up.

- The third point is to know the ability of the insulation to absorb vapor formations from the surrounding air (a feature of bathrooms and kitchens).

Do-it-yourself ceiling insulation - What else you need to consider when choosing a heater.

1. The best option is when the insulation has low thermal conductivity, light and thin. But such a heater is expensive.

2. But you should not save on such characteristics of the insulation as moisture resistance and fire safety.

3. In this age of environmental trouble, try to choose an environmentally friendly material.

4. Insulation must be durable and elastic.

Ceiling insulation with stone wool

- Cream for joints from arthritis and arthrosis - Artrade

- Abdominal Bioliposector for weight loss in the abdomen and thighs

- How to increase breasts by 2 sizes with Upsize cream at home

Insulating the ceiling with stone wool is an inexpensive way to prevent heat from escaping through the ceiling by installing it from inside or outside the room. The quality of work depends on well-performed operations, so in the article we will consider the rules for placing and attaching the insulator to the surface in various situations. Using our recommendations, you can avoid unnecessary financial costs and common mistakes during insulation.

Features of thermal insulation of ceilings with stone wool

Stone wool is a fibrous insulator made from basalt. To improve the characteristics, various substances are introduced into its composition, including hydrophobic ones. The material is quite loose, saturated with an inert substance that does not transmit heat.

To avoid skin irritation, wear tight clothing with long sleeves and gloves. Wear goggles and a respirator to protect your eyes and respiratory organs. Change after work.

It is often said that cotton wool is very dangerous, but this statement is not true. Modern technologies completely isolate the coating from the living space, and it will not bring trouble to anyone.

Advantages and disadvantages of stone wool ceiling insulation

The fibrous material has unique characteristics, due to which it is considered the best among products of a similar purpose.

- Very low thermal conductivity, which creates a comfortable environment in the room.

Users should be aware of the problems that sometimes arise during the operation of a room insulated with wool:

Unscrupulous sellers can sell low-grade goods with a high percentage of toxic elements.

Stone wool installation technology on the ceiling

Before insulating the ceiling with stone wool, inspect it for defects and eliminate deficiencies. The insulator is not afraid of irregularities less than 3 mm, more serious defects will have to be removed.

- Clean the ceiling from the decorative coating and plaster.

Choice of stone wool

The components of the warming "pie" must be of high quality. In order not to doubt the purchased product, control the following points:

Conditions for storing stone wool for the ceiling. The ideal option is to store the product in a dry room.

For thermal insulation, purchase products with the following technical characteristics:

- Density. Not less than 80 g/m 3 . The higher the value, the greater the mechanical load the coating can withstand. The value is relevant for insulation from the attic.

- Read about Virgin Star Vaginal Tightening Cream Gel

- How to lose weight by 20 kg – real reviews of Guarchibao

Installation of basalt wool from the inside of the room

The technology for insulating the ceiling with stone wool depends on the method of fixing the material. From the side of the room, the insulator is attached in several ways:

- Laying in the frame. It is used if it is planned to make a false ceiling under it. The frame is assembled from wooden bars 40 × 40 mm or metal profiles, which are used to fasten drywall. The choice of material for the crate depends mainly on the financial viability of the owner of the house, but metal products last longer. If you plan to use lumber, treat it with antiseptics, despite the fact that the structure is indoors. It won't hurt to re-insure yourself.

The procedure for using the crate is as follows:

Fasten the frame to the ceiling, placing the slats parallel to the window. The distance between them should be 1-2 cm less than the width of the insulation. The insulator is soft, after laying it will occupy all the space and close the crate. Connect the frame elements with each other with corners, and the structure itself with dowels.

If the boards are to be glued, do the following:

- Make sure the surface is ready for application.

Tips for working with dowels:

Do not drive the hardware too deep; drowning the cap by more than 1 cm is not allowed.

Laying stone wool on the ceiling outside

Laying stone wool outside is easy, no ladder is needed and no need to stand with your hands up. Apply this method in the case when the premises have already been overhauled.

- Before insulating the ceiling with basalt wool, clean the attic of debris. If there is a subfloor, dismantle it.

How to insulate the ceiling with stone wool - look at the video:

Stone wool is made from natural, environmentally friendly material. If you have done the insulation correctly, you will enjoy the warmth and comfort of your home for many years.