Preparing the stove and charcoal firebox

Before starting kindling with coal, it is necessary to inspect the stove for serviceability and carry out some preparatory procedures

This is especially important for cottages, where the owners are not often present, and the stove has been idle for a long time:

- It is necessary to carefully inspect the stove for cracks in the masonry. If they are, then smoke, carbon monoxide can enter the house. As the temperature rises, cracks can become larger and further damage the masonry. Cracks must be sealed with a mixture of clay and sand.

- It is worth inspecting the pipe (attic and roof) for whitewash.

- It is not recommended to leave combustible and flammable objects closer than 1.5 meters from the hot walls of the furnace. And also stack dried firewood close to the stove.

- It is necessary to clean the pipe with constant use 2-3 times a month.

- The oven must be cleaned before lighting. Slag and ash are poured with water and raked out with a poker, removing from a specially designated place. Outside, the stove must be cleaned of dust with a dry cloth, otherwise there will be an unpleasant smell in the room.

- Do not use pieces of bitumen, construction and agricultural waste, plastic for kindling.

- It is not recommended to open the blower and the stove door at the same time.

- So that the stove does not overheat, it is heated a couple of times a day with a duration of no more than two hours.

- Coal is used dry, medium size. It is cleaned of dust, dried.

In no case should you use kerosene, gasoline and similar flammable liquids for kindling.

Do not leave the stove unattended during the heating period. Especially if there are children or animals in the room.

Now, as for charcoal kindling:

- The first thing to do is to clean the stove from soot and ash, prepare the coal.

- A layer of crumpled newspapers or paper is laid at the bottom of the combustion chamber, and a layer of small wood chips is placed on top.

- Small dried logs, for example, birch, are placed on the chips. For better combustion, firewood is laid in a "well" or "hut" and leave space between them for good air circulation.

- You can set fire to newspapers with ordinary matches, as well as with a special spray can.

- The oven door is closed. The blower is opened. It regulates the strength of the flame. Accordingly, the more air enters, the more intense the fire in the stove.

- When the logs burn out, a layer of hot coals appears. A layer of fine (about 15 cm) coal is poured into the stove.

- If the furnace door opens, then the blower should be closed.

- After a good ignition, coal must be added up to 60 cm (large fraction).

The coals at the time of ignition must be stirred a little to improve air circulation and prevent the mass from baking.

The laying of coal is done through the furnace door or through the shifted burners of a metal stove (this option is considered more convenient and safe).

https://youtube.com/watch?v=7HkjdAuxcCo

It is not difficult to buy coal or anthracite in Russia - you can buy it either in one small bag or in large quantities at once by placing an order for delivery directly to the place of storage.

Heating with coal in bags is very popular among residents. And this is due to the fact that it is very convenient to purchase packaged fuel. It is easy to transport, store, it does not get dirty and crumble as much as loose coal.

If you have a stove at home, or you are going to fold it, or buy it, then for sure you will face the question of how to heat it.

Coal is a rock. Origin - plant world. This rock is combustible, that is, fuel. The main structural element is carbon.

The most economical type of fuel after gas is coal. It has the advantage over wood in that less heat is needed to achieve the same amount of heat.It also weighs less than wood, is more efficient for heating, and is easier to transport.

As children, we lived in a private house and stoked the stove with coal in winter. At that time, we did not know what coal was, however, it was possible to determine by eye that coal can be different.

Sometimes coal simply did not want to flare up and it took a lot of firewood to kindle it. Such coal gave little heat, and a lot of slag remained after combustion. In addition, it differed in color.

Sometimes my father managed to buy a car of beautiful black coal, which shone in the sun with its facets. This coal burned beautifully, almost did not smoke, easily flared up and burned out, leaving behind only a handful of ash, with a small amount of solid slag.

After the stove was lit, we liked to sit right here in the kitchen, read fiction, watching mom cook dinner.

The nuances of buying coal

The retail trade offers many types of charcoal for barbecue directly from the manufacturer: birch, coconut, oak, aspen or special briquettes.

Any of the grades of coal has its own specific application and has separate characteristic features.

Any of the grades of coal has its own specific application and has separate characteristic features.

Birch - the cheapest and safest option. High-quality coals from this wood provide uniform heat, do not emit unpleasant odors during smoldering, burn for a long time and are great for any culinary devices: barbecues, barbecues, grills, and so on. They do not contain phosphorus, sulfur and other harmful substances. Experts advise using birch charcoal.

Coconut charcoal is a good imported novelty, but quite expensive compared to birch counterpart. It is made from coconut shell and has several advantages:

- Increased heat dissipation.

- No harmful chemicals.

- It burns without smoke and has no odors.

- Sufficiently long combustion time.

- Its consumption is five times less than when using any other varieties.

Briquettes are a good option for barbecue, however, they are also more expensive than the usual birch charcoal. It is produced by briquetting small pieces of wood.

Main advantages:

- High heat transfer and calorie content.

- Impressive burn time.

- Minimum amount of residual ash.

- Economical consumption of briquettes, which exceeds the consumption of wood (for similar purposes) several times.

Oak - although a worthy combustion product for cooking, it is not quite suitable for home barbecues. It is difficult to ignite and will require some skill to achieve its maximum effectiveness. The main purpose of this representative of the coal family is the use in professional barbecue, bars and restaurants.

Charcoal - this name on the package clearly indicates that there are softwood coals inside, which are absolutely not acceptable for barbecue. Resins always remain in them, which, when burned, will certainly spoil the taste of kebabs.

Stone - absolutely can not be used in barbecues, even if the packaging says that it has undergone special processing. When it burns, a whole bunch of harmful substances and specific odors are released, which will definitely pass into the upcoming barbecue.

Sometimes aspen or pine trees are given out for birch trees. Exposing the deception is easy enough - only birch has a brilliant anthracite color. Aspen and pine have no shine. They are just black.

When buying coal, first of all, it is necessary to take care of the question: "How much does the proposed product cost?" It should be remembered that even the cheapest birch coal cannot cost less than 100 rubles per 3 kg package. Lower prices are simply not possible.

The packaging of the goods will also help you choose the best option.It should contain min = 8 positions required by law: the correct name of the product, the contact details of the manufacturer, certification information, the purpose of the product, and so on.

Unfortunately, it is rather problematic to buy excellent coal for a brazier. There are a lot of fakes in this segment of production and trade. And even Moscow cannot guarantee that the coal bought in its outlets will be a quality product.

Therefore, it is much more practical and profitable for an ordinary layman to prepare good charcoal with his own hands.

Dimensional drawings

A few drawings to help you navigate the dimensions of the building. Adjust as necessary to suit your site or needs.

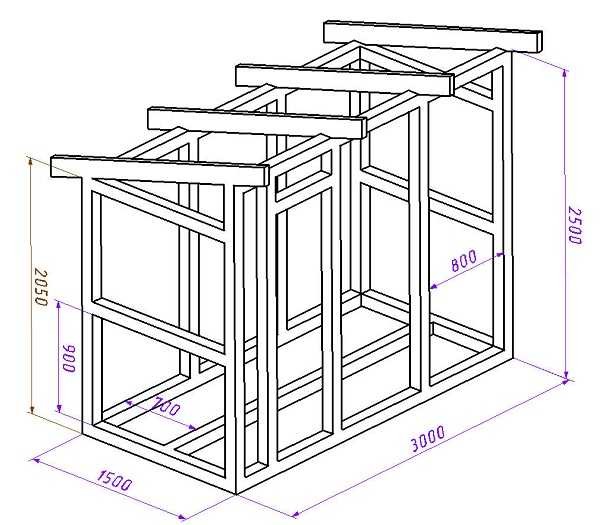

Single Pitch Roof Shed - Rack Layout Drawing

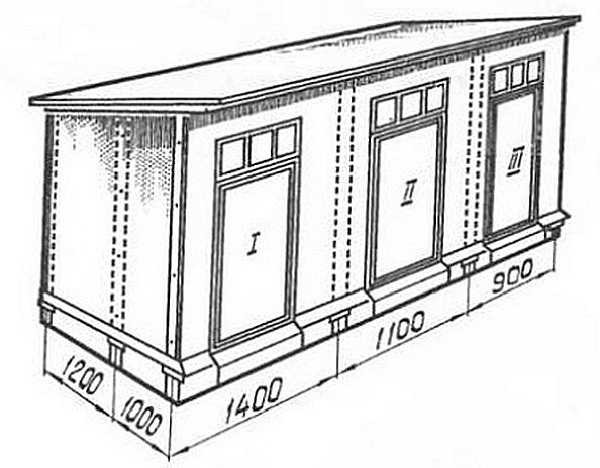

A barn with three compartments under a pitched roof. The dotted line indicates the installation locations of the racks (and supports under them)

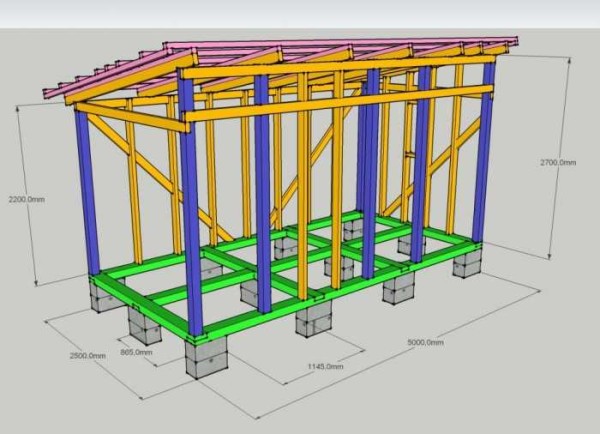

Barn design showing all required elements

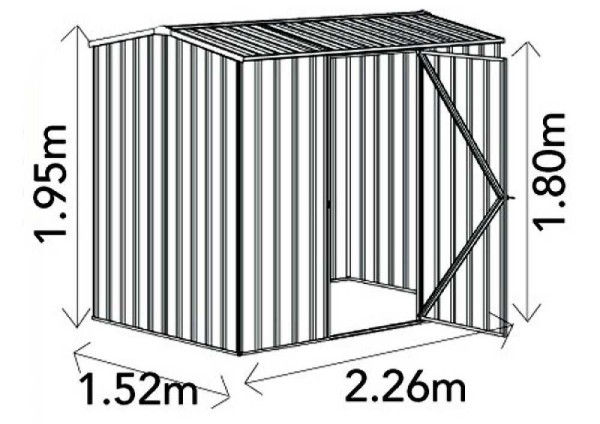

Gable roof on a shed made of metal profiles

Before proceeding with the design work, you should understand the features of the improvement itself, the rules for its planning. And also find out about some of the main elements. Only then can you start somewhere.

Properties of coal

The qualitative characteristics of coal are important in order to determine whether it can be used for a solid fuel boiler:

The first parameter that speaks about quality is the specific heat of combustion. It displays the amount of heat released when a unit of fuel is burned. According to the standard, the measurement is made in Kcal / kg. Brown coals show the least heat transfer (maximum 4500 Kcal/kg). The hottest are coking coals (almost 8700 Kcal/kg) and anthracites (8600 Kcal/kg)

Experts do not advise the use of coking fuel in the operation of household units, as it is designed for elevated temperatures, and anthracite must be used with caution.

The second is the amount of ash residue. And this is the main indicator of quality coal, depending on the amount of non-combustible impurities in the fuel.

There are few impurities - there is little ash, and more heat is given off. Ash content is indicated as a percentage. The lower the value, the higher quality the coal. High-grade grades are characterized by an ash content of up to 25%, low-grade grades - 40% and more. The frequency of cleaning the stove directly depends on this parameter. It is logical that the more waste remains after burning coal, the more often the owner will have to clean it. In addition, some of the slag settles on the pipes, which will also need to be cleaned.

The third is moisture content, which can be surface and internal. In the first case, moisture disappears during drying in air, in the second - only during combustion. Thus, the higher the percentage of moisture content in coal, the less heat will be obtained for heating. Instant drying takes a huge amount of energy. Sometimes you can estimate the humidity by eye. Freezing of fuel, when small fractions stick together or cake, indicates a high water content.

Which is better, coal or gas

It is generally accepted that the most profitable option for heating is main gas.

However, having learned the cost of summing up and connecting, many residents are looking for ways of alternative heating. It is better to compare these types of fuel according to three criteria:

- Energy. When burning 1 m 3 (0.62 kg) of natural gas, you will receive 9.45 kWh of heat without taking into account the efficiency of the boiler. A kilogram of anthracite will give 7.16 kWh.

- Economic. Tariffs for the population for the supply of gas are taken into account, as well as the cost of transporting coal and the efficiency of boilers.

- The convenience of use. In all cases, the arrangement of the chimney and ventilation will be required. Space is needed to store coal fuel, and it will have to be bookmarked manually, while gas is supplied through the pipeline.

Reference.If the house is already connected to the gas main, then you can not look for a more profitable way of heating. In the absence of a connection, the best option is coal-fired boilers operating in automatic mode.

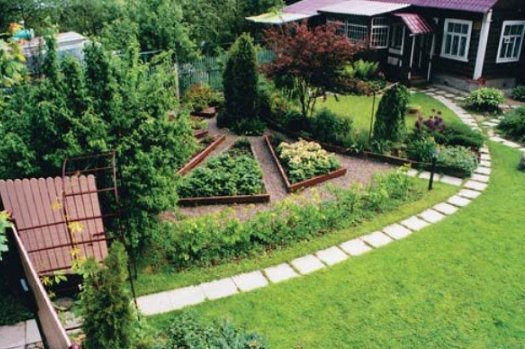

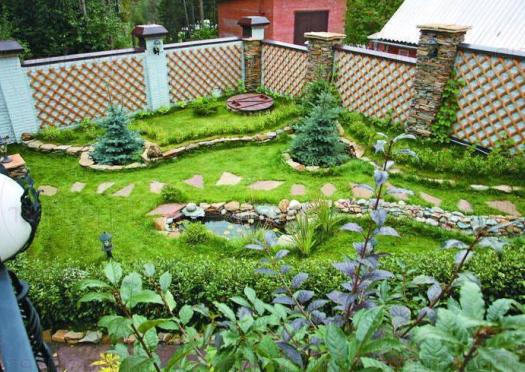

Fundamentals of design and landscaping of the yard

1. Accounting for the characteristics of the territory. With the help of modern technologies, the professionalism of the workers, it is possible to make the entire site smooth, which will require a lot of physical and financial investments. But is it worth breaking all this?

Indeed, on the site of a hill, you can break a beautiful and modern alpine hill, and in the hollow - a transparent reservoir. But if the differences are simply huge, then you can use the services of a vertical planning specialist who will make the desired picture for you and make it a reality.

2. Harmony with the building and various small structures. The design of the courtyard of a private house should adapt to the structure itself, which plays a dominant role. With the help of landscaping, you can hide outbuildings and make a beautiful approach to the main element on the territory. Opening the view of the facade of the house should be smooth and organic.

3. Functionality - this means planning the territory by zones. It all depends on the preferences of the owners, their type of activity, the presence of children.

For example, the following zones should be present: front (entrance), household (orchard), zone for quiet rest, sports, active recreation, children's zone (if there are children), and others. The breakdown is made in advance, carried out by the road-path network system.

4. Visibility of the territory. It is necessary to think in advance how the yard looks from all windows and balconies. After all, even while at home, you can admire the open views.

It is not at all interesting if the owners watch the place for drying clothes from the bedroom, or the car peacefully standing in the parking lot. It is more pleasant to look at a beautiful landscape design, a pond or a sculpture.

5. Lighting will help diversify and make a beautiful yard. You can play with light throughout.

Thinking through this process is very important. For example, illuminated paths with small lamps, or the use of special flashlights built into the tiled paving.

6. Gardening and landscape design. A lot depends on these processes - this is leisure, and a person's internal perception of the environment, and the aesthetics of the courtyard. Also, such processes are the final stage of design and improvement.

Expert answers

Grey:

The highest quality brand of coal is anthracite. It contains about 90-94% carbon and is velvety to iron black in color with a glassy or metallic sheen. Anthracite coal is characterized by high hardness, it burns perfectly only with strong air draft, practically without flame, odor and smoke. According to the size of the pieces obtained, the grades of coal are divided into: P - slab (more than 100 mm); K - large (50-100 mm); O - walnut (26-50 mm); M - small (13-25 mm); C - seed (6-13 mm); Ш - shtyb (less than 6 mm); P - ordinary - unlimited in size. Accordingly, belonging to the brand of coal and the size of the pieces are indicated by letter combinations - AO, AS and others.

◄Non-GMO►:

if the traction is good, then any.

Alex Mishin:

In those days, when young scientists were sent to harvest crops 150 km from home in the fall, they brought luxurious coal, shiny on chips, they said - anthracite. When burned, it turned into pieces of brick (!) of the same size and shape as coal was - that is, in fact it was not coal, but shale - clay or sandstone soaked with bitumen! Be mentally prepared for such surprises! And what kind of coal is needed for your stove - read in its description (unless, of course, this is a stove built by a stove-maker). Please note that a stove designed for burning wood may not be able to withstand work on coal - it will burn out.

Ginger cat:

Anthracite (from lat. anthracites, from other Greek.ἄνθραξ "coal; carbuncle") - the most ancient of fossil coals, coal of the highest degree of coalification.

It is characterized by high density and gloss. Contains 95% carbon. It is used as a solid high-calorie fuel (calorific value 6800-8350 kcal/kg).

Anthracite is the oldest fossil coal. According to its characteristics and properties, anthracite is most similar to coal. Their difference lies in the fact that anthracite contains more carbon (more than 90%). In color, it can be both velvet and iron black, and always with a steel sheen.

Anthracite burns only with a strong draft of air with almost no flame or no flame at all, no smell and no smoke. At the same time, he does not bake.

Anthracite is harder than coal and brown coal. Just like them, it is a product of the slow decay of plants. Anthracite deposits can be found next to coal deposits.

Coal is a fossilized plant remains, and in anthracite these remains are maximally transformed, so they are almost impossible to identify. It was formed from the Devonian to the Triassic. Among fossil coals, its share is about 3% of the total volume.

Explored world reserves of anthracite - 28.2 billion tons, including in Russia - 6.7 billion tons. The main coal-bearing basins: Pennsylvania (USA), Alberta (Canada), Vitbank (South Africa); in Ukraine, the eastern part of the Donets Basin. In Russia - Kuznetsk, Tunguska, Taimyr basins, Gorlovsky basin.

Anthracite is used in power engineering, ferrous and non-ferrous metallurgy, as well as for the production of adsorbents, electrodes, electrocorundum, microphone powder.

MELOMAN Klondike SuperCity:

it's anthracite

dmi78:

Kuzbass? (Anthracite)

Observer:

Anthracite… Up to 60 percent resin content…

Irina Rukina:

Anthracite, I know from personal experience that they used to heat stoves

Alexander Muraviev:

Ekibostuk

Brown coal

Brown coal is the youngest hard rock, which was formed about 50 million years ago from peat or lignite. At its core, it is "immature" coal.

This mineral got its name because of the color - shades vary from brown-red to black. Brown coal is considered to be a fuel with a low degree of coalification (metamorphism). It contains from 50% carbon, but also a lot of volatile substances, mineral impurities and moisture, so it burns much easier and gives more smoke and a burning smell.

Depending on the humidity, brown coal is divided into grades 1B (moisture more than 40%), 2B (30-40%) and 3B (up to 30%). The yield of volatile substances in brown coals is up to 50%.

With prolonged contact with air, brown coal tends to lose structure and crack. Among all types of coal, it is considered the most low-quality fuel, since it emits much less heat: the calorific value is only 4000 - 5500 kcal / kg.

Brown coal occurs at shallow depths (up to 1 km), so it is much easier and cheaper to mine. However, in Russia, as a fuel, it is used much less frequently than coal. Due to the low cost, brown coal is still preferred by some small and private boiler houses and thermal power plants.

In Russia, the largest deposits of brown coal are located in the Kansk-Achinsk basin (Krasnoyarsk Territory). In general, the site has reserves of almost 640 billion tons (about 140 billion tons are suitable for open pit mining).

It is rich in brown coal reserves and the only coal deposit in Altai is Soltonskoye. Its predicted reserves are 250 million tons.

About 2 trillion tons of brown coal is hidden in the Lena coal basin, located on the territory of Yakutia and the Krasnoyarsk Territory. In addition, this type of mineral often occurs together with coal - for example, it is also obtained at the deposits of the Minusinsk and Kuznetsk coal basins.

Coal storage rules

The shelf life of coal depends on the grade, deposit and environmental conditions.Anthracites and semi-anthracites are most likely to retain all the properties of the fuel during storage. With sizes from 70 cm to 100 mm, this coal is stored without loss of quality for up to 36 months, and with sizes from 100 mm - about a year. If you order coal with delivery, then plan the volumes that you use in order to avoid quality loss.

It is best to place coal in a covered room (barn, dry basement), where the sun's rays do not penetrate. Coal oxidation begins at a temperature of 20-25 °C. At 40 °C, weathering begins, which can be seen from the reduction in the size of the pieces. It is also necessary to periodically check the condition of the coal, since, for example, brown and stone porous ones are capable of spontaneous combustion. The ignition temperature for brown is - 40-60 ° C, fatty - 60-70 ° C, lean and anthracite - from 70 ° C.

Watering piled fuel is not recommended, since when wet it passes oxygen better and oxidizes faster. In order to prevent fire, it is best to cover the coal with a tarp.

How to calculate the expense

When calculating fuel consumption, many factors are taken into account: quality, brand, duration of coal burning, average temperature in the street, area, material and degree of insulation of the house. With the help of calculations, an average value is obtained, since it is difficult to take into account all the criteria, as well as the onset of thaws and frosts.

Before starting the calculation, the total area of \u200b\u200bthe house is calculated. According to the standard formula, the boiler power is calculated: 1 kW per 10 m 2. For example, for an average country house of 160 m 2, 16 kW equipment will be required. The efficiency of modern boilers is from 50 to 90%, for example, we take the average value of 70%. We consider the duration of the period during which heating is needed (on average 6 months).

Fuel consumption is calculated as follows:

- To operate a boiler with a capacity of 16 kW with an efficiency of 70%, 11.2 kW / h will be required. To generate 1 kW, you need 0.25 kg of coal with average characteristics. 11.2 * 0.25 \u003d 2.8 kg per hour.

- We calculate the daily amount of fuel: 2.8 * 24 \u003d 67.2 kg.

- We determine the consumption of coal for a month: 67.2 * 30 \u003d 2016 kg.

- To calculate the amount of coal for the winter, we multiply the resulting number by the number of cold months: 2016*6 = 12096 kg.

- To calculate the cost of heating for the winter, we multiply the obtained value by the price of coal per 1 kg.

Reference. To get data on consumption, preferred brand and duration of work on one tab, see the technical documentation for the boiler. Instructions are always included with purchase.

Coal consumption for home heating

The first calculation method - in fact. We use the simplest "folk" capacity of weight and volume - a bucket. Usually coal is measured in tons, but it is unlikely that your boiler room will have scales to accurately weigh out the required dose for loading.

Approximately 18 kilograms of coal is placed in one bucket.

For heating a house with an area of 200 square meters, approximately:

- September-October - 1 bucket per day;

- November-February - 10 buckets;

- March-April - 2 buckets.

Considering rounded that there are 30 days in a month, we calculate the total number of buckets:

- September-October - 1x60=60;

- November-February - 10x60 = 600;

- March-April - 2x60 = 120.

- Total 60+600+120=780 buckets.

We translate the result into kilograms 780x18 \u003d 14,040 kilograms.

That is, during the heating season for heating a house of 200 square meters, a coal-fired boiler for heating a private house can burn a little more than 14 tons of coal.

The second calculation method is near-scientific. Combustion of 200 grams of coal releases approximately 1 kW of heat. To comfortably survive the heating season, approximately 50,000 kW of heat is required. We multiply 50,000 by 0.2 - we get 10,000 kilograms or 10 tons.

How to calculate the amount of coal for the winter

The amount of coal needed to heat a house depends on many parameters:

- from the heated area and from the material from which the house is built;

- on how it is insulated and what windows are, how tightly the doors are fitted;

- on the type of heating and type of boiler, type of coal;

- on the severity of winters in your area and their average duration, etc.

All these "little things" are very important. So most of the coal will be needed for heating a brick house - 30-35% more than for a wooden similar area or a house made of aerated concrete blocks.For heating a well-insulated cinder-block house (wall thickness 45 cm) with an area of 90 m 2, the owners spend 2.5-3.5 tons of coal (1 ton of anthracite "walnut" and two "seeds"). Heating stove. For others, a house of the same area, but without insulation, takes about 6-7 tons.

How much coal do you need for the winter? It depends on the area of the house, what it is built from, how it is insulated, on the type of boiler, and on many other factors.

Owners of 2-3 room apartments in the same region buy 1.5-2 tons to feed solid fuel boilers. In another region, for heating a wooden house 80 m 2 from a bar, 5 tons of coal and firewood are bought, but their winters are harsh - up to -40 ° C for a month and a half and the rest of the time -20 ° C.

To determine how long tons of coal will last for you, it is recommended to buy several bags of the selected brand (and in the place where you plan to buy) and see how much it is required per day to maintain a comfortable temperature. Take into account the "outboard" temperature and compare it with the average during the winter. Draw conclusions from the results. If you are drowning for the first year, try to take it with some margin. If it remains, it doesn’t matter, it does not lose its properties (unless you bought brown coal), but if it’s not enough, it’s already unpleasant.

TOP 5 pellet boilers

If you still do not know which solid fuel boiler is best to purchase for heating your home, we strongly advise you to take a closer look at pellet heaters. Installing such a unit will allow you not to look into the boiler room at all for several days. There can be only two difficulties here:

you need to have enough space for storing pellets;

similar fuel material is not available in every region.

If you do not foresee difficulties with the acquisition and storage of pellets, such a boiler will definitely allow you to appear in the furnace as little as possible.

Zota Pellet 25

One of the most popular and expensive devices is the ZotaPellet boiler. This ultra-modern unit is equipped with a liquid crystal display and is able to control as many as five pumps simultaneously. Literally everything can be connected here - from a warm floor to a centralized heating system. A power of 25 kW is enough for high-quality heating of a house with an area of at least 250 m2.

Pros:

- Efficiency over 90%;

- electric ignition;

- high energy efficiency;

- reliable automation;

- high-quality thermal insulation;

- multifunctionality.

Minuses:

a considerable cost, about 3300 USD. e.

Biomaster BM-15

And here is another high-quality pellet boiler. This model is good for heating a large area house. Depending on the configuration, it can have a hopper for 200 or 400 liters. Equipped with an automatic ash removal system.

Advantages:

- absolutely undemanding to the quality of the pellets used;

- good efficiency;

- profitability;

- ease of installation and comfort of use.

Flaws:

- cost from $2,800;

- has a lot of weight;

- requires a foundation.

Teplodar Kupper OK 30

And this unit is generally “omnivorous”. Teplodar Cooper, although it has much fewer "bells and whistles", is absolutely not picky about the quality and type of fuel. Compact dimensions allow you to comfortably place fuel equipment on an area of about 5 square meters. meters.

Pros:

- Efficiency over 89%;

- high-quality thermal insulation;

- compact dimensions;

- variety of fuel;

- automatic fuel supply;

- automatic adjustment of t˚C mode;

- ease of operation;

- low price, from $600.

Minuses:

difficult to install on your own, requires the involvement of a specialist.

Pelletron

There are only 2 modifications of the boilers of this company: for 40 and 20 kW, which allows you to perfectly heat rooms up to 700 or 400 m2, respectively. The cost of pellet boilers "Pelletron" can reach 1,500 conventional units, depending on the capacity.

Advantages:

- Efficiency up to 92%;

- compact dimensions;

- light weight;

- equipped with a smoke exhaust system, which eliminates the need for chimney equipment;

- has automatic protection against fire or overheating.

Flaws:

- has excessive requirements for the quality and size of pellets;

- if installed and used incorrectly, fire can be transferred to the bunker.

Kiturami KRP 20-A

An interesting model of a pellet boiler is capable of providing not only space heating, but also additional provision of a home with hot water.

Pros:

- autodosing of fuel;

- the presence of a thermostat;

- the possibility of heating water;

- ease and accessibility of cleaning the ash pan;

- ease of installation;

- capacious fuel bunker;

- auto protection against freezing or overheating.

Minuses:

price, about 3,500 US dollars.

Video about the construction of wooden sheds

The barn turned out beautiful, but not cheap. But decent in size, strong and in appearance does not differ from the house - it fits into the composition. Everything is shown / painted in detail, there is one violation: the waterproofing under the metal tile is laid vertically. Even with good gluing of the strips, sooner or later the water will make a path for itself. The rest is all right.

In this case, the do-it-yourself barn was built on the cheapest, probably, foundation: concrete was poured into the old tires. On these "pillars" the frame stands. Naturally, you need to put them on a flat, reliable surface and they themselves must be on the same level. In terms of strength, the tacon base will not yield to the best concrete blocks, and maybe even surpass them. The tires protruding from under the structure can be closed by making a step and subsequently placing flowers on it or using it for other needs. Even more practical.

Another video with a step-by-step illustration of the construction of a frame barn from a bar.

Boiler selection

This question will directly depend on: how exactly do you plan to use the boiler, in what conditions? In the event that your house is gasified, then the best option would be to use a gas boiler, but in the absence of gasification, you should not despair: there is also equipment that runs on solid or liquid fuels, as well as electric boilers for heating.

gas boiler device

Heating a private house with a gas boiler is carried out if there are any gas communications near your house, then for reasons of economy it is worth installing a gas boiler. Blue fuel is a cheap pleasure, which is enough to stimulate many!

Despite the fact that a gas boiler is a fairly everyday thing, the variety of its shapes and designs will not disappoint you. Many parameters can be combined in one boiler: the ideal color and size for you, as well as the design option. In addition to the heating function, the gas boiler is capable of heating water for personal needs.

Gas boilers, of course, run on natural gas and, most often, are fully automated, the only thing that is required of you: electricity.

This type of boilers can be of different forms: floor, wall, double-circuit or single-circuit:

- floor boilers are preferably installed in separate rooms that have a chimney and good ventilation, since this type of equipment needs an assistant to work effectively - a water pump.

- wall-mounted boilers already have a built-in water pump and combustion chamber. Using this type of boiler is not only profitable from a financial point of view, but also allows you to minimize the time spent on it.

When heating a house with a solid fuel boiler, any solid materials are suitable as fuel for this boiler: coal, briquettes, firewood, etc. Their main and very significant drawback: the need for frequent fueling (approximately every 3-4 hours).

But, in spite of everything, solid fuel boilers have an undeniable advantage: they are in no way dependent on electricity, which gives them many advantages!

solid fuel boiler device

Heating with electric boiler. Installing this type of heating is the easiest in almost any home. They will not require from you any ventilation ducts or chimneys. They are quite compact and easy to install. Equally important is the fact that they are environmentally friendly and do not create any noise during operation. The only downside is that you will have to run wiring that can withstand high voltages.

electric heating boiler

Diesel boiler for home heating. It is no secret that storing fuel near the house is very dangerous, and the cost of diesel fuel is quite high. That is why it is by no means possible to call this option preferable. This type of heating should only be selected if solid fuel and gas are not available.

Heating by a coal boiler of a private house. If you are concerned about the constant rise in prices for diesel fuel and electricity, then a coal-fired boiler is the best option, because such a service will cost you 4 times cheaper. Its main, and perhaps the only drawback: the need for constant refueling

Before installation, you should definitely pay special attention to its power and decide on the piping scheme from it, because the carrier circulation system is an important component of the quality operation of a coal-fired boiler

Combined boilers for heating a house are able to operate on diesel fuel, gas or electricity alternately, which can significantly save finances, because only the burner is subject to replacement during the fuel change.

In the event that you have hired a professional whose function is to bring heat into your home, then it is best to leave the choice of the boiler to him, as only this will allow you to achieve the best combination of price and quality, as well as avoid further problems when installing equipment.

Coal heating pros and cons

Coal-fired heating systems do an excellent job with increased heating demands in severe frosts. One of its main advantages is the ability to retain heat for a long time. In addition, coal stove heating has other advantages:

- independence from the availability of main energy resources (electricity, gas);

- availability: coal, like the boilers themselves, is domestic and inexpensive;

- efficiency: average efficiency for different types of equipment - 70%;

- autonomy: if you purchase the appropriate model, you will not depend on electricity and gas;

- simplicity of design ensures long-term uninterrupted operation of the device;

- automation: many models themselves solve the issues of fuel supply and thermoregulation.

Despite the perfection of technology, coal devices are not without drawbacks:

- In order for combustion to bring maximum efficiency, special conditions will have to be observed: requirements for the brand, quality, and moisture content of the combusted raw materials.

- The need to allocate a utility room for storing fuel and installing the unit.

- Cyclicity of the process - different download frequency (depending on the type of device). Coal will have to be loaded into any boiler.

- The need for maintenance: removal of soot, soot, ash, cleaning.

Many devices require the installation of accessories such as pumps and forced ventilation units. Despite the automation of many systems, coal-fired generators need constant monitoring.